Patents

Literature

595results about How to "Not easy to wrinkle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

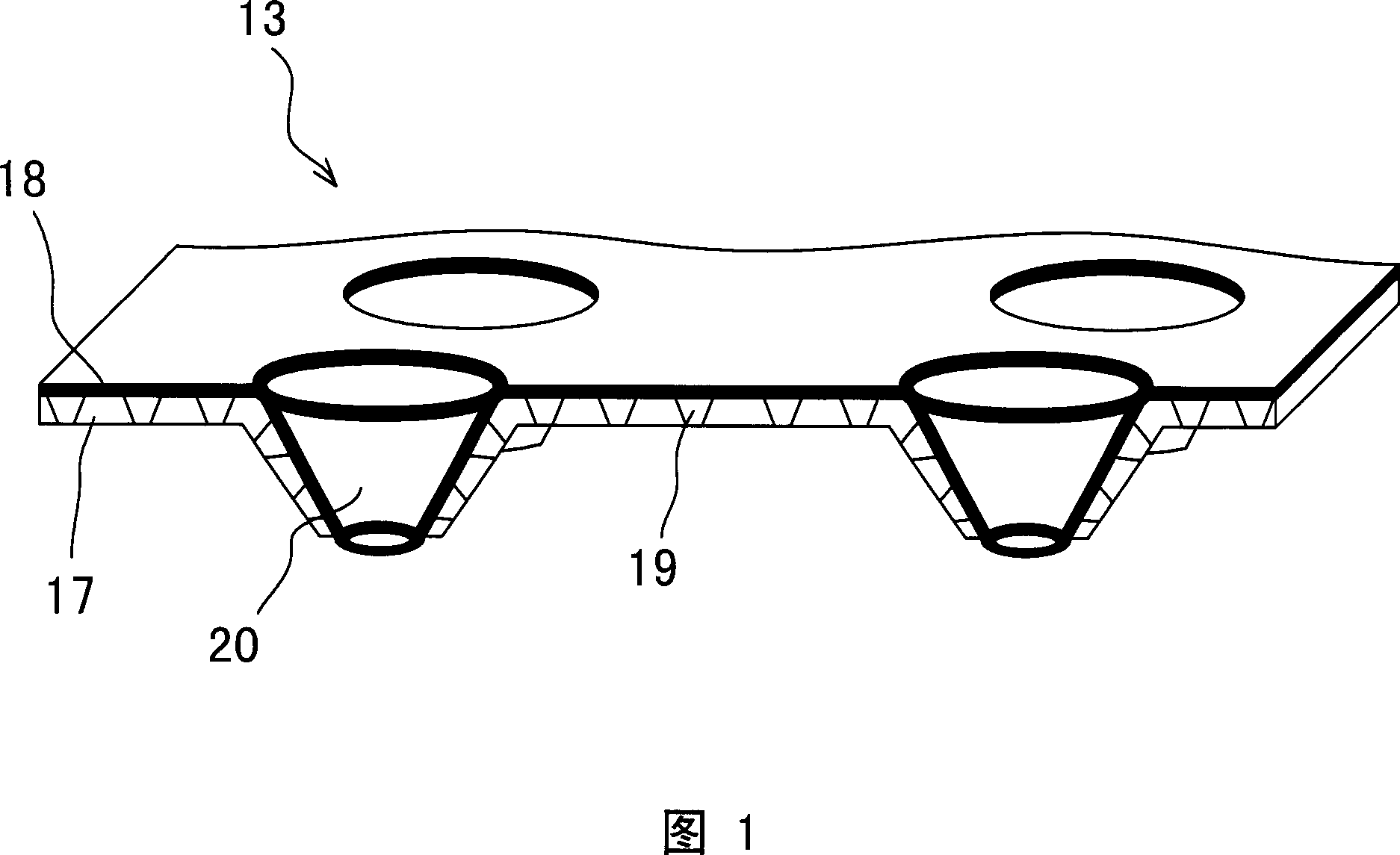

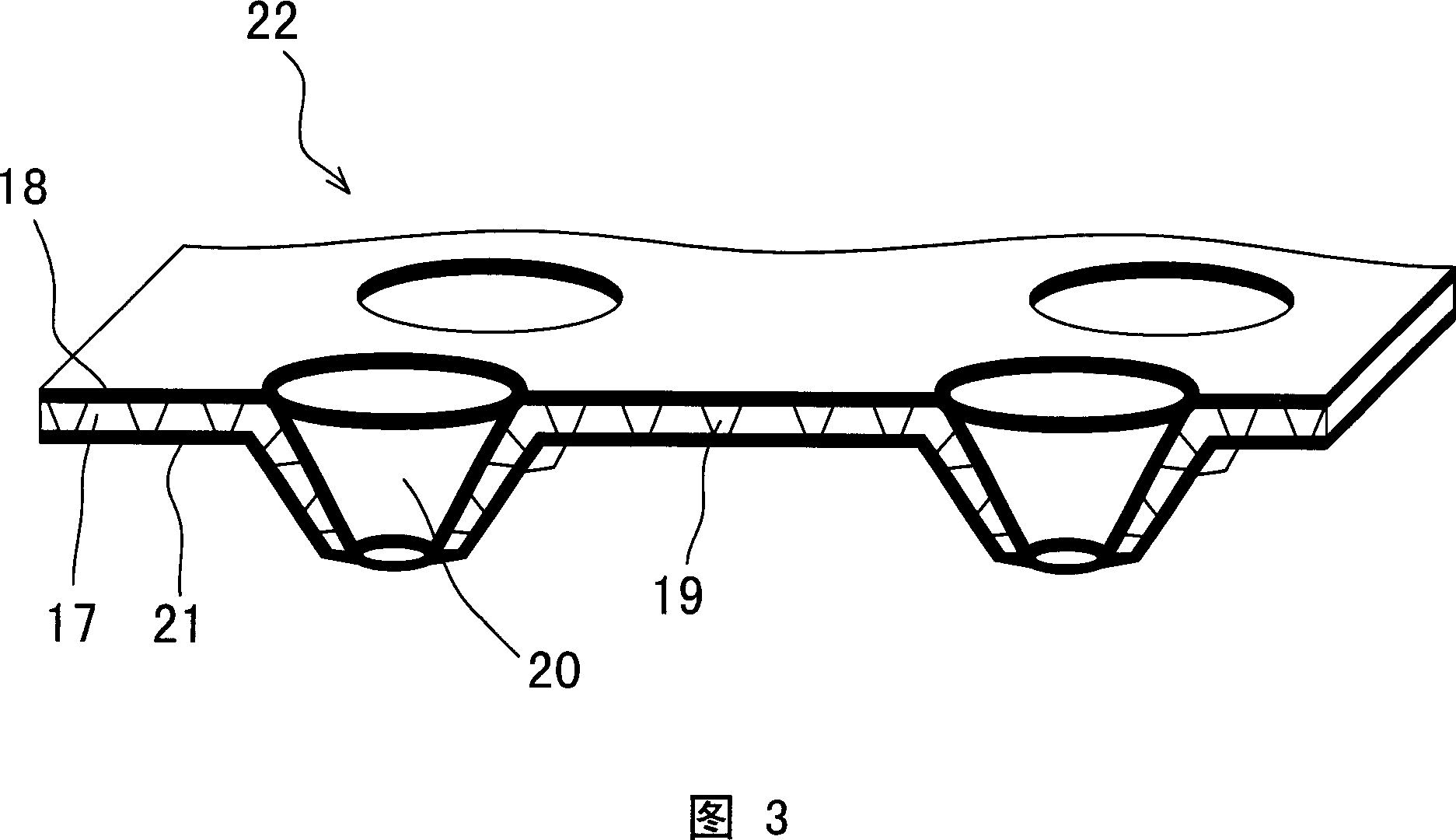

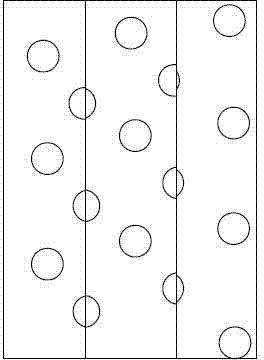

Composite punching film and its producing method

InactiveCN1943530AImprove breathabilityHigh porositySynthetic resin layered productsLaminationPunchingVolumetric Mass Density

A compound punching film and preparation thereof, said punching film consisting of a layer of plastic film and one or two side compound non-woven fabrics. On plastic film is of evenly spread tiny mesh, density thereof is 170-500 mesh / C sqm ,perforating rate is 10-35%. Said whole compound film is perforated of evenly big mesh , aperture thereof greater than that of tiny mesh two times, the shape of big mesh is of funnel, thereof protruding to one side and on the surface of awl is of tiny mesh. Said invention combines PE film technique and punching one, making compound of a layer of non-woven fabric and cast film with the help of high melting temp. of cast film, also making use of mesh cage through vacuum suction nozzle punching tiny mesh, thereafter punching big mesh by pressure roller machine, thus to prepare new compound punching film with good permeability, softness and strong third dimension.

Owner:蔡子辛 +1

Preparation method of hollow fabric with radial elastic shrinkage

ActiveCN102776649AHigh tensile strengthHigh temperature resistantWoven fabricsEngineeringWear resistance

The invention discloses a preparation method of a hollow fabric with radial elastic shrinkage and relates to the preparation method of the hollow fabric. The object of the invention is to solve the problem that elastic hollow fabric available in the market does not meet the requirement of thin diameter and longitudinal elasticity and very large radial elasticity when being used in a specific task, has poor strength of bearing accidental drawing and poor wearability, as well as poor dimensional stability, and especially poor radial elasticity. The method comprises the preparation work of warp yarns, which includes selecting fine denier 75-200D aramid fiber fibers, 100-300D PBO (p-phenylene-2,6- benzobisoxazazole fiber) fibers or aramid fibers and PBO combined filament yarns as warp yarns; preparation work of weft yarns; directly winding of the weft yarns to form a pirn with a size same as that of a shuttle of a shuttle loom; and a determining and weaving process of metric portie. The hollow fabric prepared by the preparation method provided by the invention has excellent radial elastic recovery, and also the characteristics of superstrong resistance to longitudinal stretching force and wear resistance and corrosion resistance. The method is used for preparing elastic hollow fabrics.

Owner:HARBIN INST OF TECH

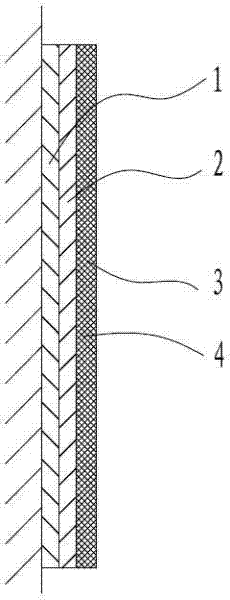

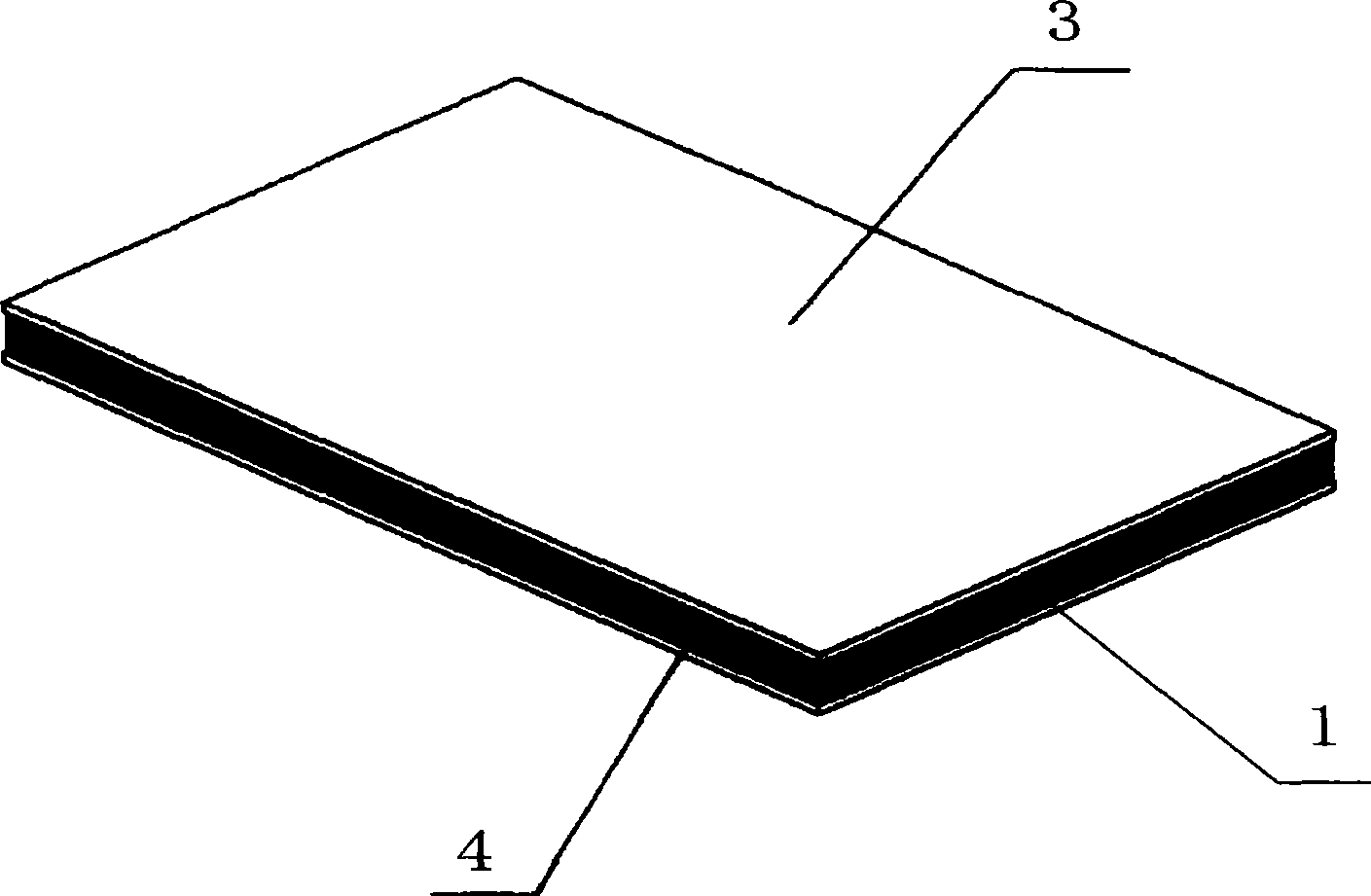

Seamless embroidery wall fabric and production method thereof

ActiveCN102644363AEvenly bondedNo limitationsCovering/liningsPaper/cardboard layered productsPolymer sciencePaper based

The invention belongs to the technical field of facing decoration materials and particularly relates to a seamless embroidery wall fabric which has a simple sticking method, strong artistry and low possibility of crinkling after being pasted with a wall surface. The seamless embroidery wall fabric comprises embroidery traycloth with embroidery patterns, wherein a wall paper base paper layer is bonded on the back side of the embroidery traycloth by an EVA (Ethylene Vinyl Acetate Copolymer) adhesive film layer. The invention also discloses a production method of the seamless embroidery wall fabric. According to the production method, the produced seamless embroidery wall fabric is full of exquisite embroidery patterns, width wall fabric products can be obtained and the defects that the wall fabric produced by a traditional method is not high in artistry, easy to crinkle and can be only produced into narrow products are overcome.

Owner:ZHEJIANG LIANXIANG EMBROIDERY CO LTD

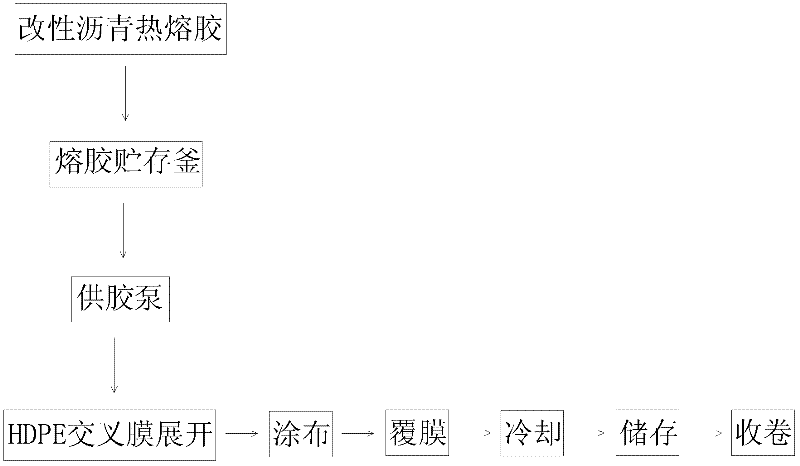

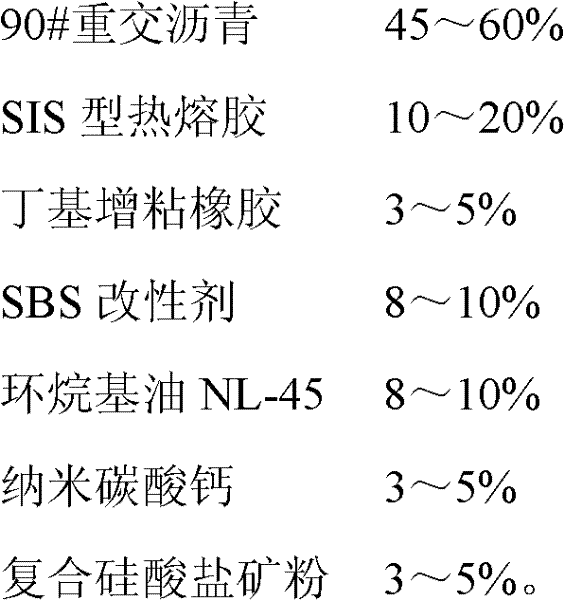

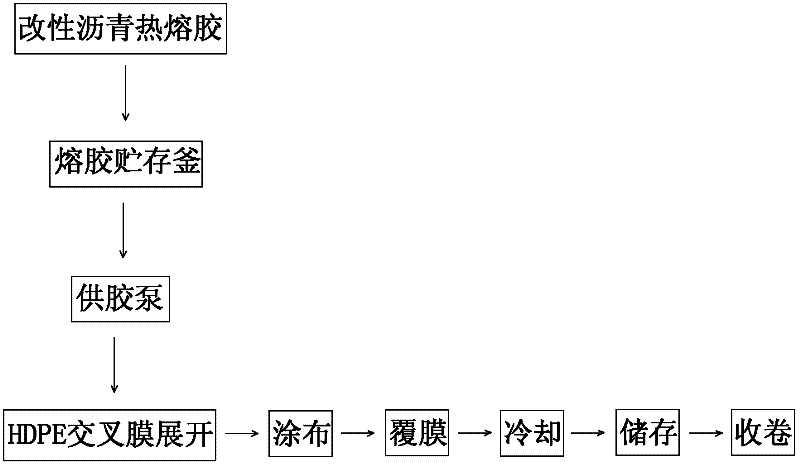

Reaction-type high-strength laminated film waterproof roll

InactiveCN102604553ASolve the problem of poor UV and weather resistanceNot easy to ageNon-macromolecular adhesive additivesUnderground chambersCross-linkAging resistance

The invention discloses a reaction-type high-strength laminated film waterproof roll which comprises a layer of high-strength cross laminated film (HDPE, high-density polyethylene) with thickness of 0.10-0.14mm and a layer of modified asphalt super glue which can react with cast-in-place concrete and is solidified together with the cast-in-place concrete. The waterproof roll can be chemically cross-linked and physically blended with concrete; under the effect of a coagent, a bonding layer can be continuously and permanently bonded with a base layer processing agent or the concrete poured on the bonding layer so as to completely prevent water from permeating into a clearance between the waterproof roll and the structure and form a skin-type net-shaped integer together with the base surface. Since the high-strength cross laminated film of special material HDPE has good tensile strength, breaking elongation rate and anti-puncture capability, the self-adhered waterproof roll of the high-strength cross film has the advantages of relatively good tensile strength, breaking elongation rate, anti-puncture capability and aging resistance.

Owner:KESHUN WATERPROOF TECH CO LTD

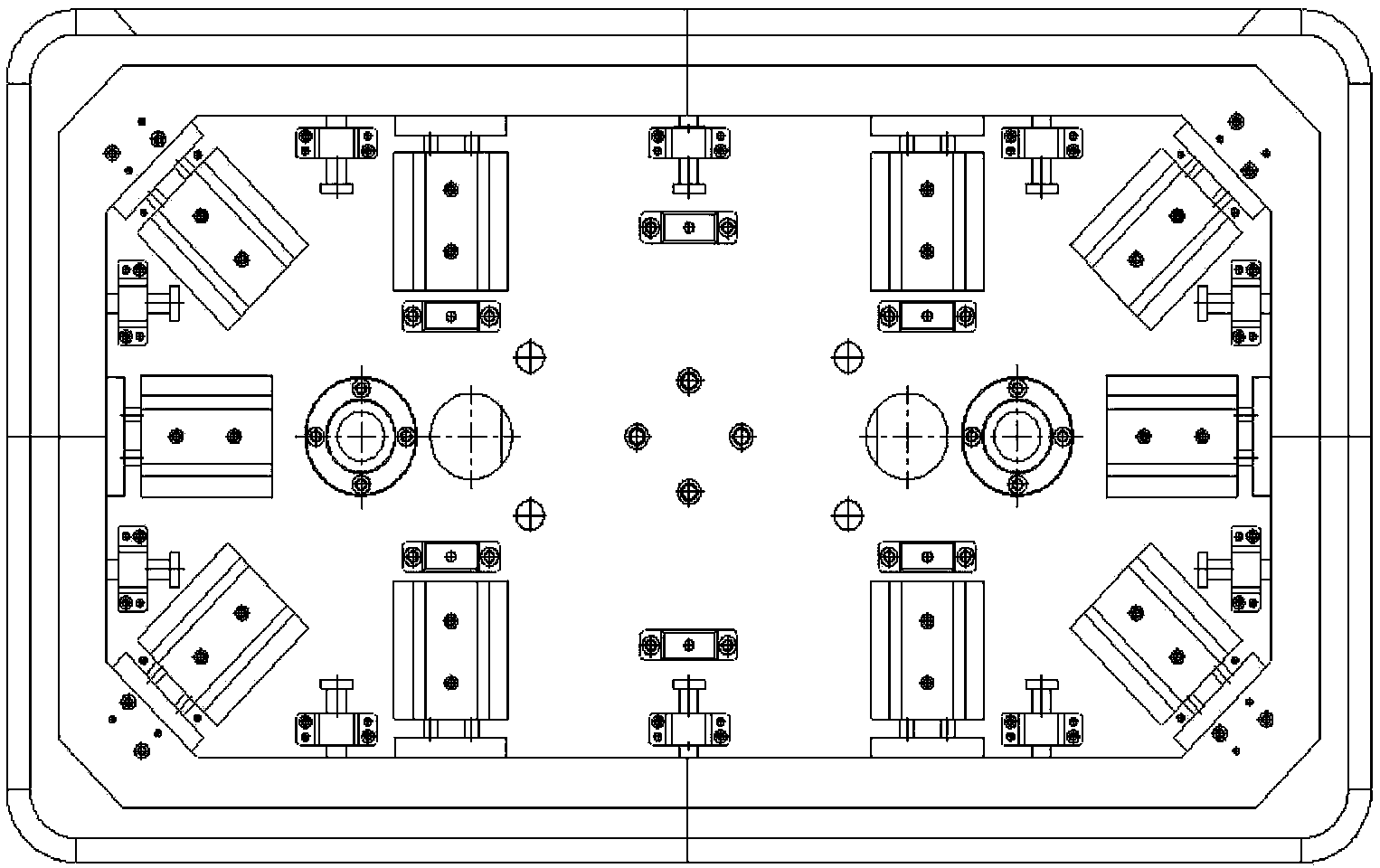

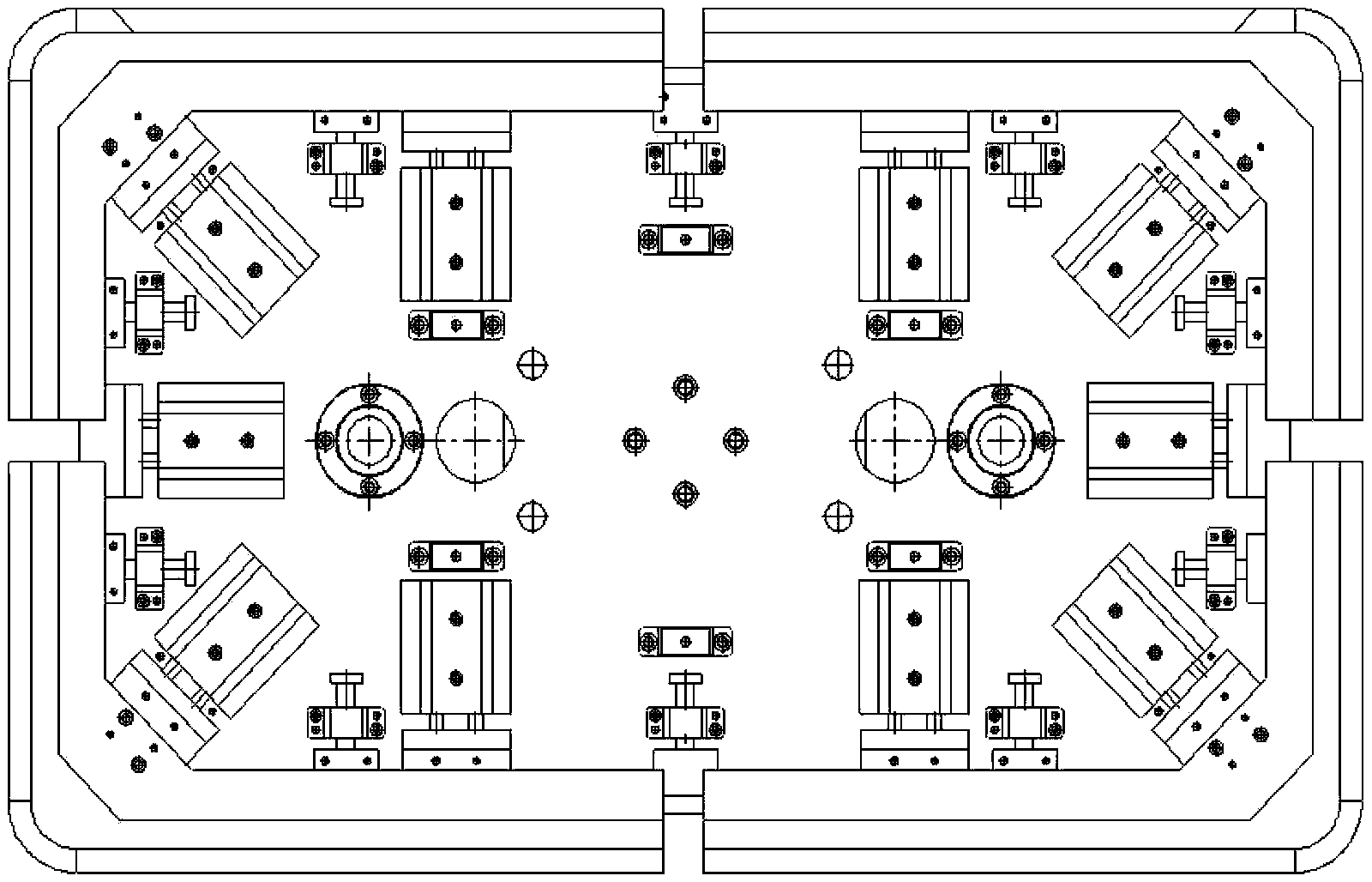

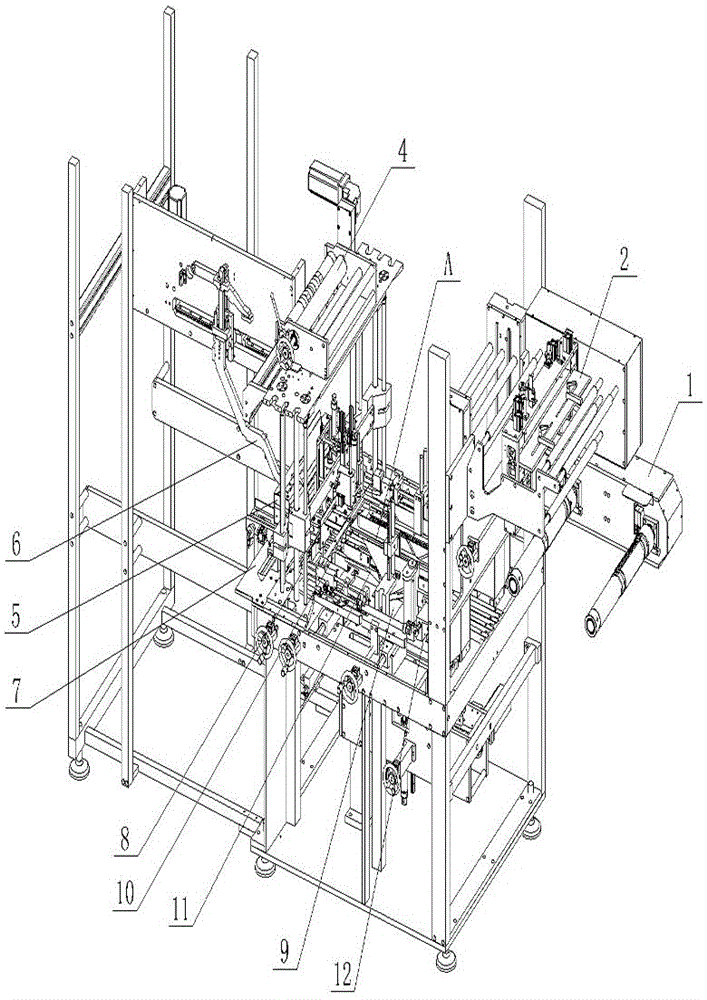

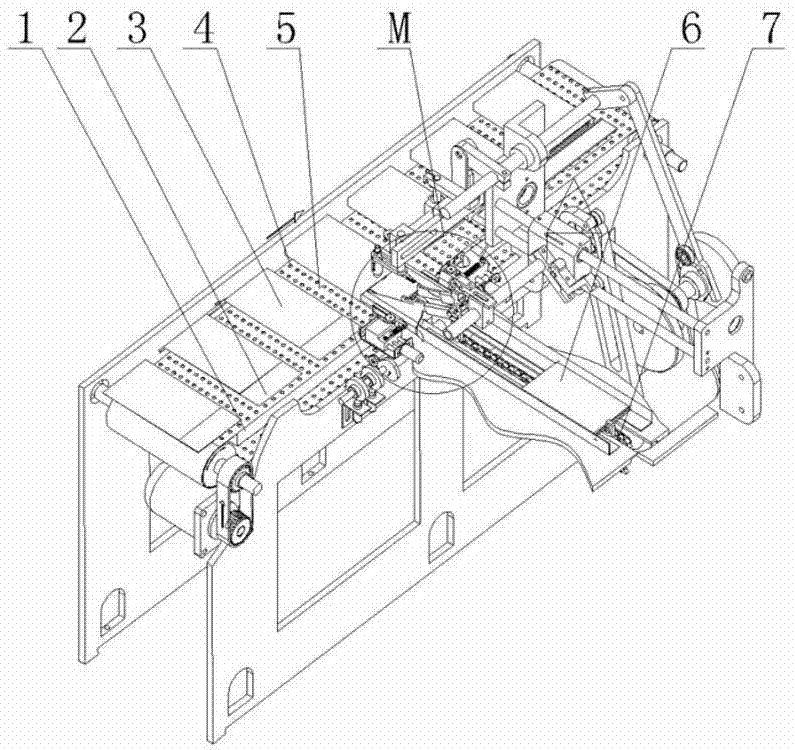

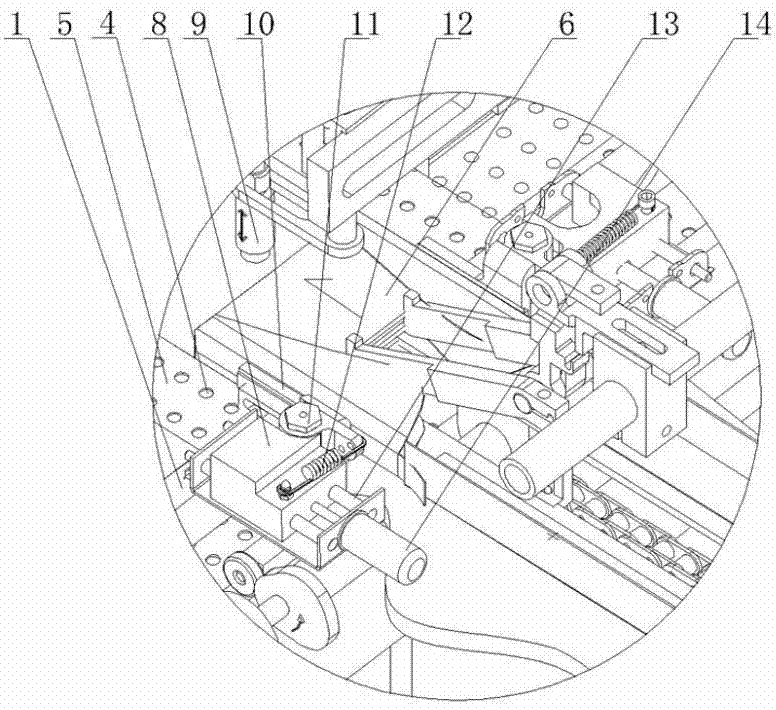

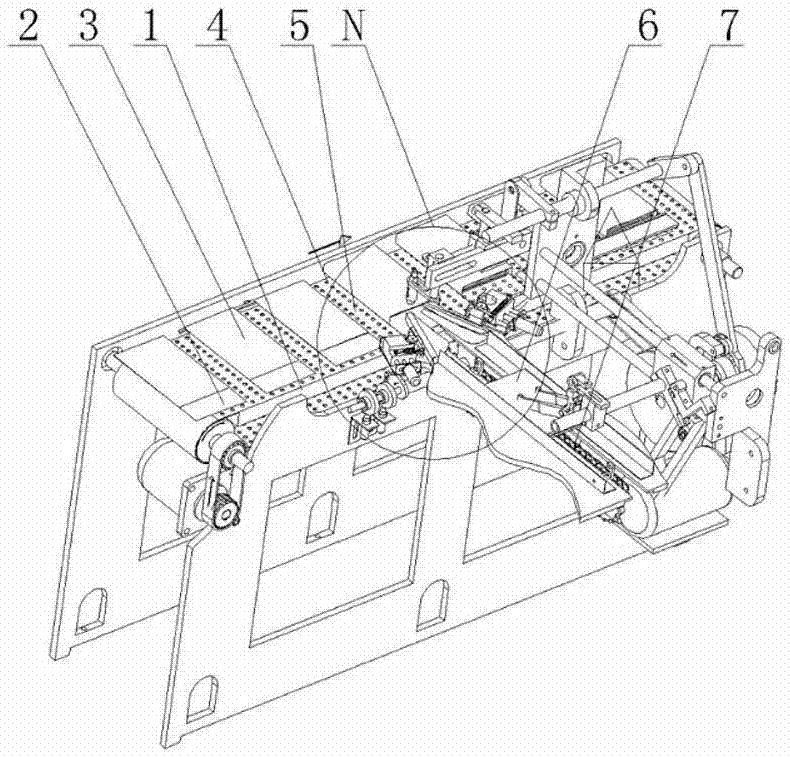

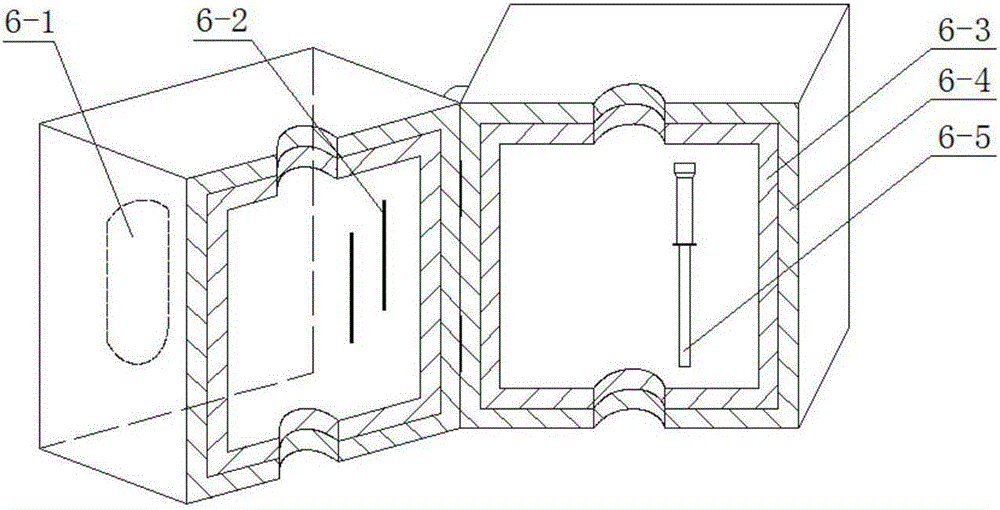

Turning device and edge covering equipment

ActiveCN104162976AGuaranteed aestheticsSolve wrinkleLaminationLamination apparatusMechanical engineeringSunroof

The invention relates to a turning device and edge covering equipment. The turning device is used for outwards turning a decorative fabric glued on the inner surface of the skylight opening part of a vehicle interior ceiling and gluing the decorative fabric to the outer surface of the skylight opening part. The turning device comprises a frame mechanism and a control mechanism, wherein the size of the frame mechanism corresponds to that of the skylight opening part; the control mechanism controls the frame mechanism to operate; the frame mechanism comprises four corner turning blocks and four edge turning blocks, the corner turning blocks are matched with shapes of corners of the skylight opening part, the edge turning blocks are matched with shapes of edges of skylight opening part, and the corner turning blocks and the edge turning blocks are contacted through inclined surfaces. During turning, the corner turning blocks and the edge turning blocks can turn the fabrics at the corners and the fabrics on the edges respectively, so that the problem of wrinkling after the fabrics at the corners are turned is solved, and the integral attractiveness of a finished product of the interior ceiling can be kept.

Owner:CENMOY AUTOMATION TECH SHANGHAI CO LTD

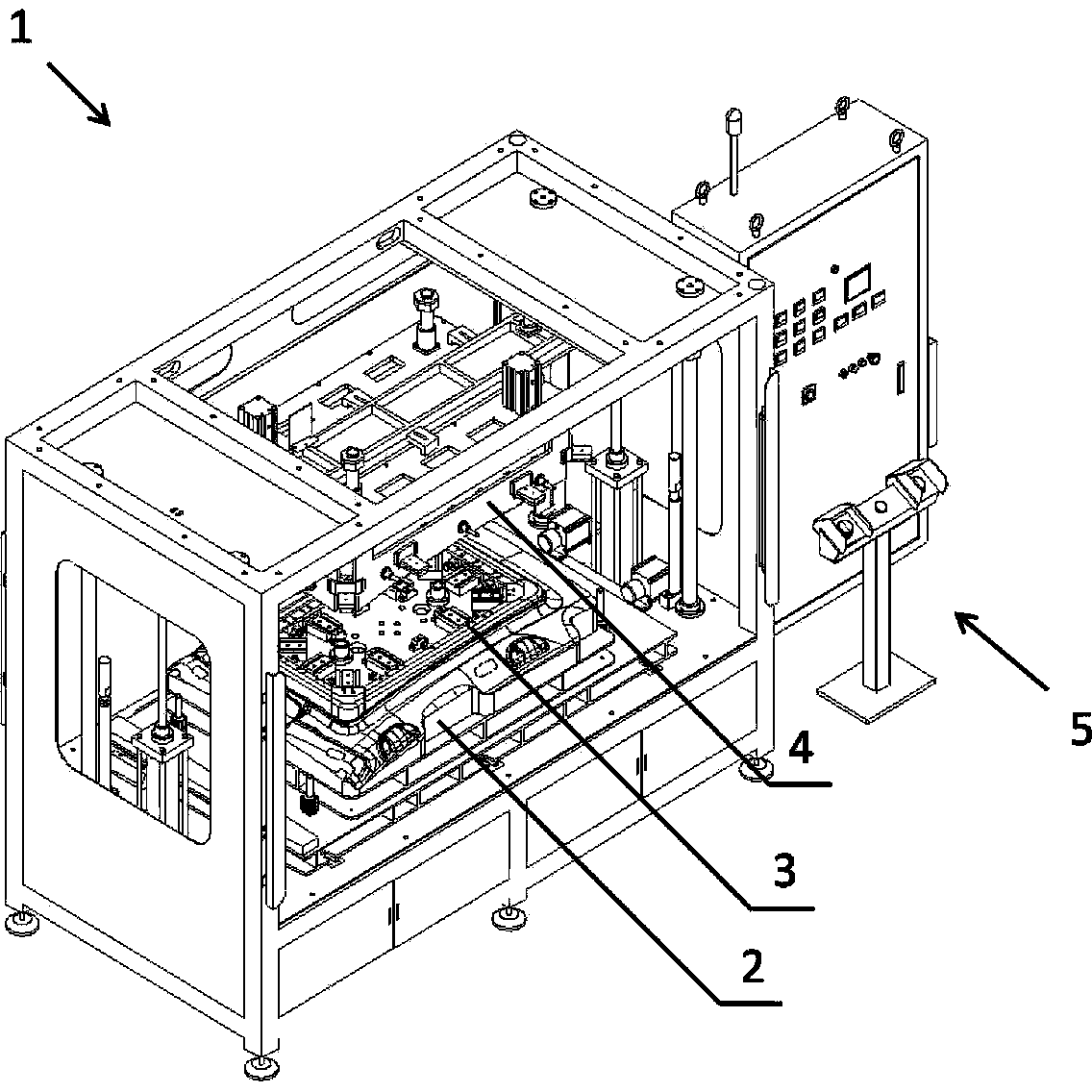

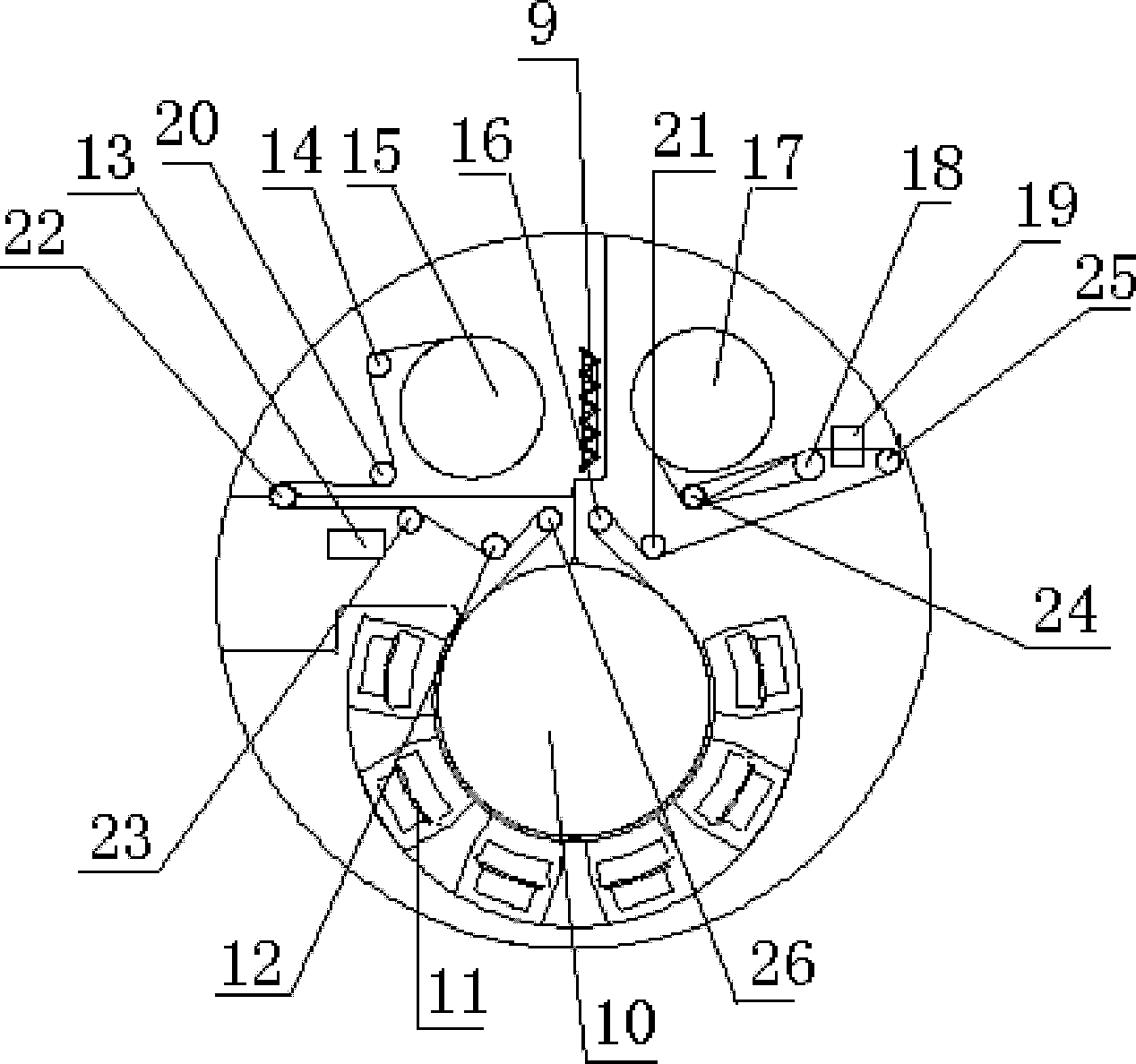

Magnetron sputtering reeling coater for large-area flexible substrate

ActiveCN102994965ALow costIncrease productivityVacuum evaporation coatingSputtering coatingCold airVacuum chamber

The invention relates to the technical field of high-vacuum continuous reeling coaters, and concretely discloses a magnetron sputtering reeling coater for a large-area flexible substrate. The coater comprises a circular vacuum chamber, a flexible substrate reeling system and magnetron sputtering sources, wherein the circular vacuum chamber is divided into an unreeling zone, a pretreatment zone, a rolling zone and a coating zone by separation plates; a cold air blast in the flexible substrate reeling system stretches into an inner ring wall in a semicircular coating zone, and the inner ring wall is matched with the outer wall of the cold air blast; a rolling mechanism guarantees a case that a substrate is unreeled, goes through the cold air blast and then enters substrate rolling; and the magnetron sputtering sources stretch into the coating zone in the circular vacuum chamber from a direction opposite to the flexible substrate reeling system in order to coat the substrate which goes through the cold air blast. The coater enables the coating of multilayer films to be once completed, and the wrinkling of plastic substrates to be difficult; and simultaneously the circular vacuum chamber is fixed, and the flexible substrate reeling system and the magnetron sputtering sources respectively stretch into or are dragged out from the vacuum chamber from two sides, so the operation and the maintenance of the coater are convenient.

Owner:SOUTHWESTERN INST OF PHYSICS

Bamboo fiber label tape and production method thereof

ActiveCN103590255ANot easy to wrinkleSoft touchSucessive textile treatmentsVegetal fibresAdhesiveEngineering

The invention relates to label tapes and production methods thereof, particular to a bamboo fiber label tape and a production method thereof. The label tape comprises a base cloth layer and an adhesive layer, the thickness of the label tape is in a range of 0.280-0.300 mm, the base cloth layer is made of a 100% bamboo pulp fiber material, the count of bamboo pulp fiber yarn forming the base cloth layer is 16-40, the warp density is 28-45 warps / cm, and the weft density is 19-35 wefts / cm. The production method comprises the steps of selecting a bamboo fiber semi-finished product as base cloth; performing anti-crease finishing; subjecting the base cloth to two-time immersion and two-time rolling treatment; performing pre-calendering treatment: a calendering surface is a stain-weave surface, the calendering temperature is 50 DEG C to 60 DEG C, the pressure is 10MPa to 12MPa, the calendering speed is 30 m / min to 35 m / min, and the thickness of the base cloth is calendered into 0.285 mm to 0.295 mm; performing coating treatment: a dry type coating method is adopted, coating a plain-weave surface of the base cloth with adhesive, scraping pulp by pulp scraping equipment, the adhesive spread is controlled within 5 g / m<2> to 10 gm<2>, and the total weight is 144 g / m<2> to 148 g / m<2>; and performing post-calendering treatment: the calendering temperature is 70 DEG C to 120 DEG C, the pressure is 10MPa to 12MPa, the calendering speed is 30 m / min to 35 m / min, and the thickness of the coated cloth is calendered into 0.280 mm to 0.300 mm. The label tape touches soft and can be used as a sewn-in label.

Owner:HUZHOU SINY LABEL MATERIAL

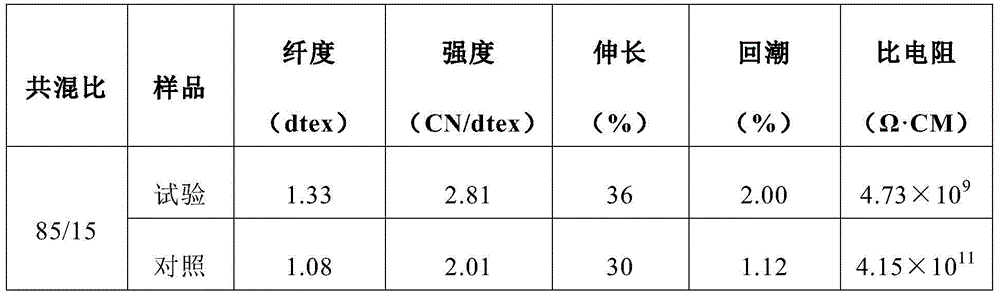

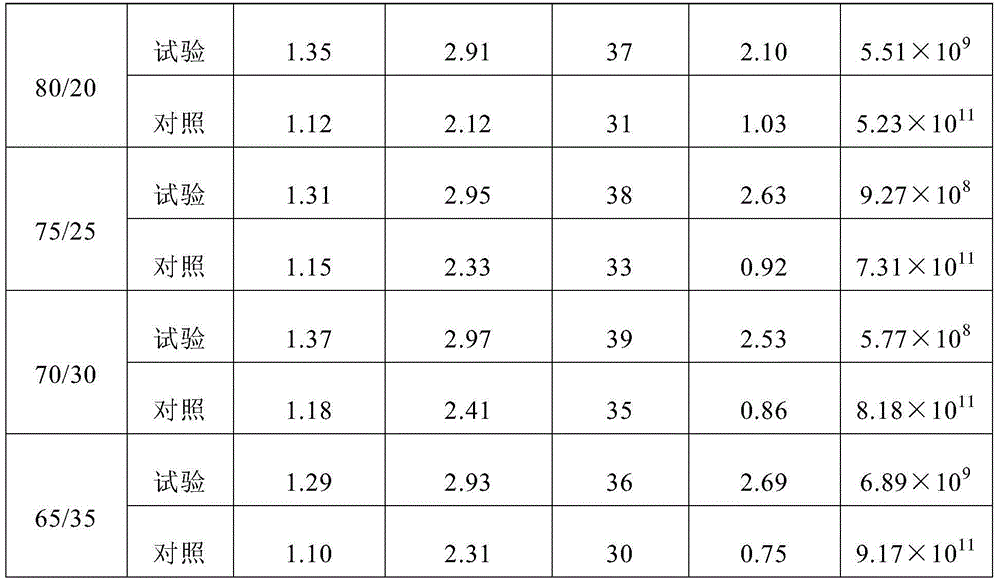

Acetate fiber and preparation method thereof

ActiveCN105002592AGood hygroscopicityHigh strengthConjugated cellulose/protein artificial filamentsMonocomponent synthetic polymer artificial filamentCellulose acetateAcrylic fibre

The invention relates to a fiber material, in particular to an acetate fiber and a preparation method thereof. The acetate fiber is composed of polyacrylonitrile and cellulose acetate. The mass ratio of the cellulose acetate to the polyacrylonitrile is an arbitrary ratio, preferentially, the ratio is 15-35 wt%:65-85 wt%, and more preferentially, the ratio is 15-30 wt%:70-85 wt%. The acetate fiber has the advantages that the defects that the acrylic fiber is bad in hygroscopicity, and static electricity is easily generated are overcome; the defects that the pure acetate fiber is low in strength and bad in serviceability are overcome; at the same time, the combination property of the acetate fiber is good.

Owner:河北艾科瑞纤维有限公司

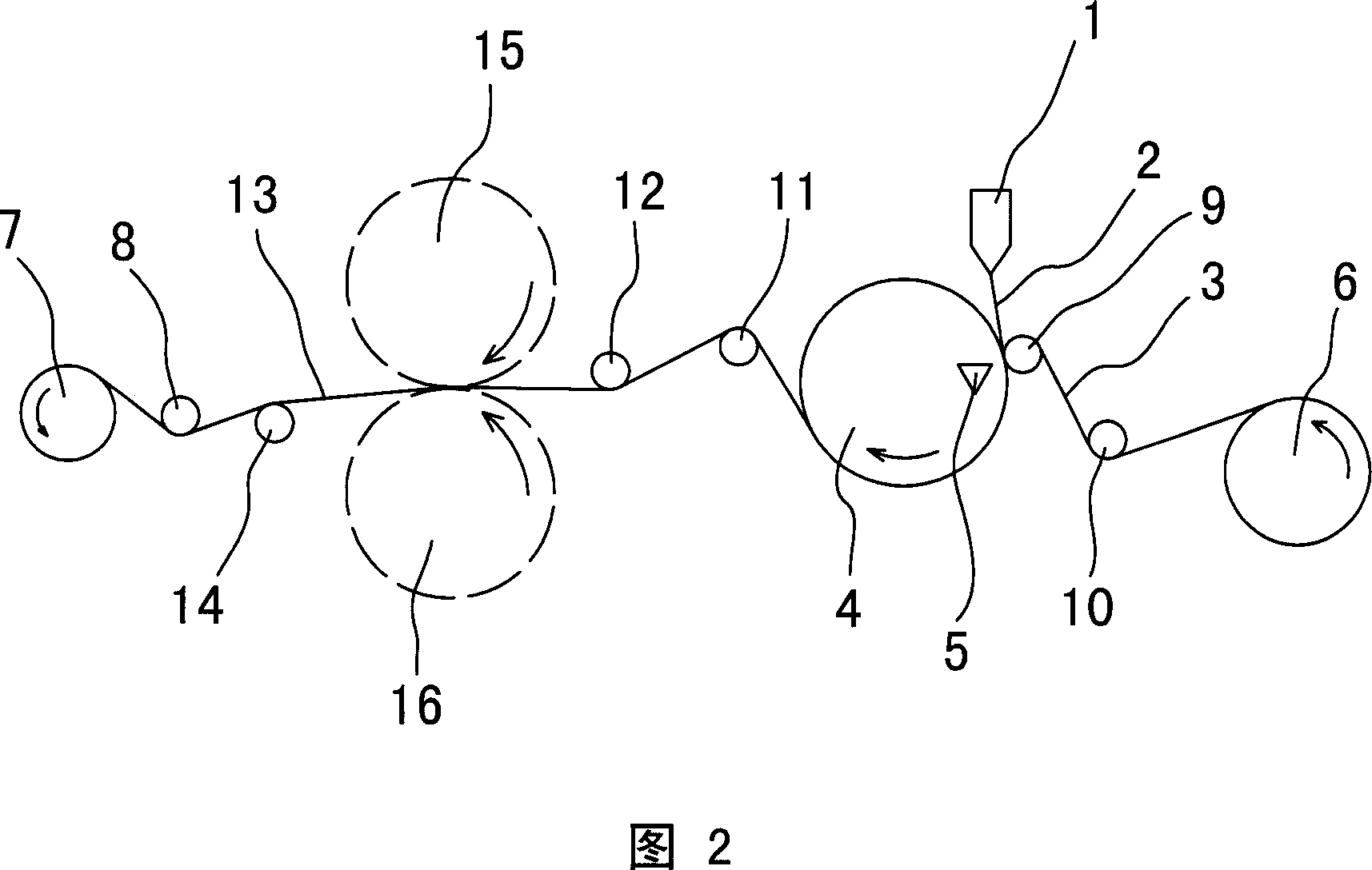

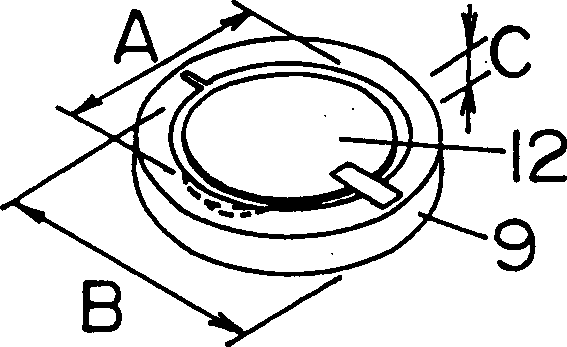

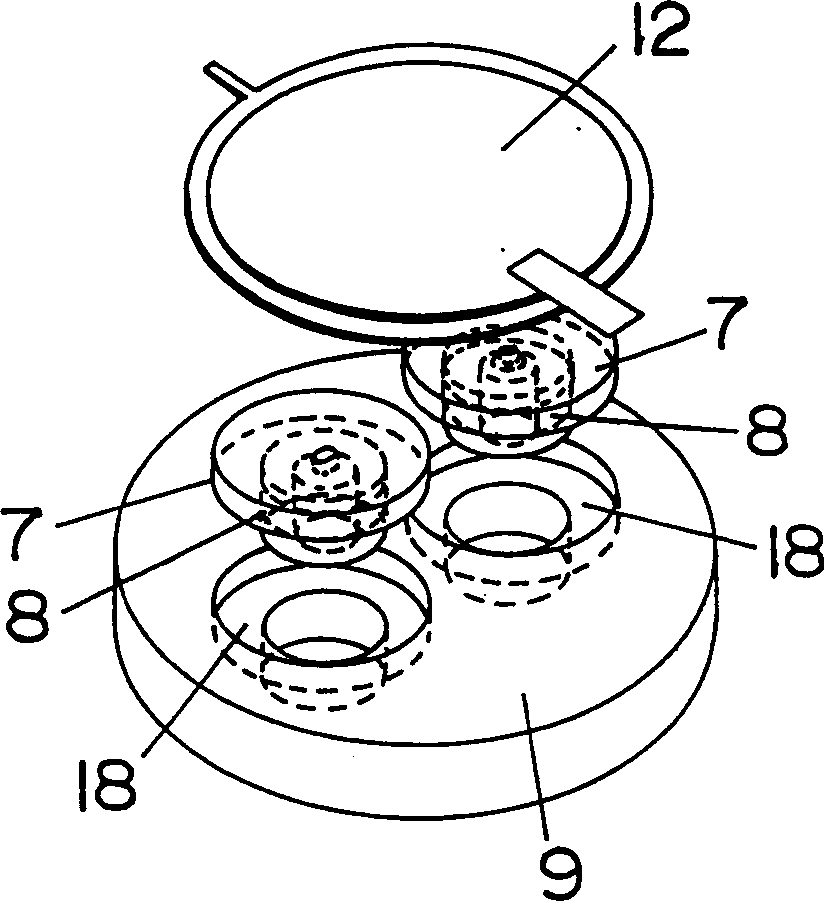

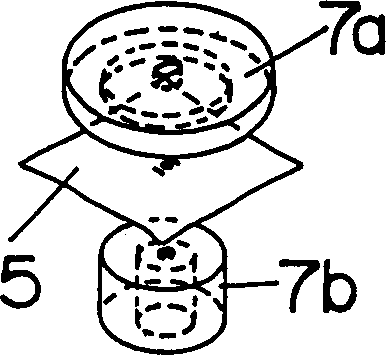

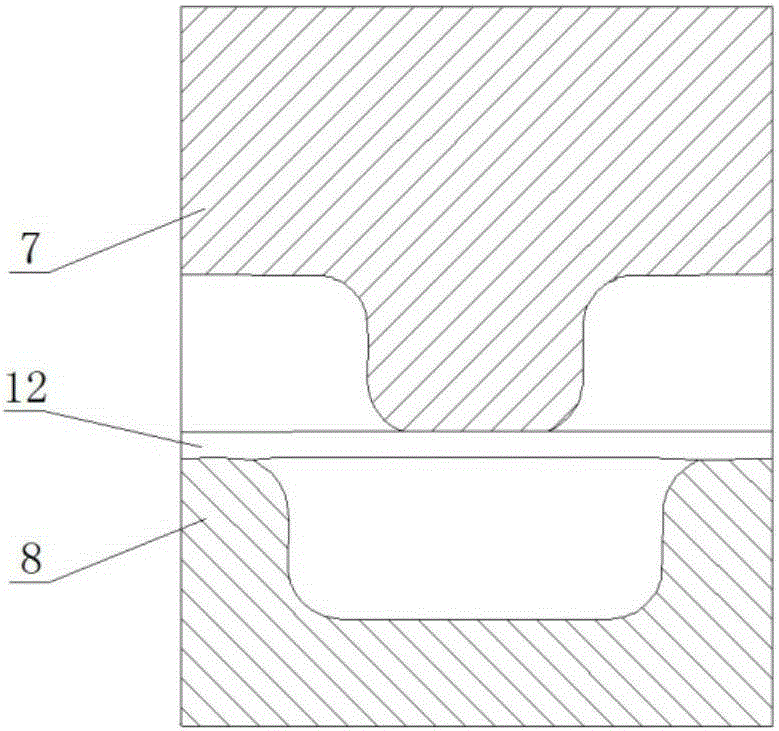

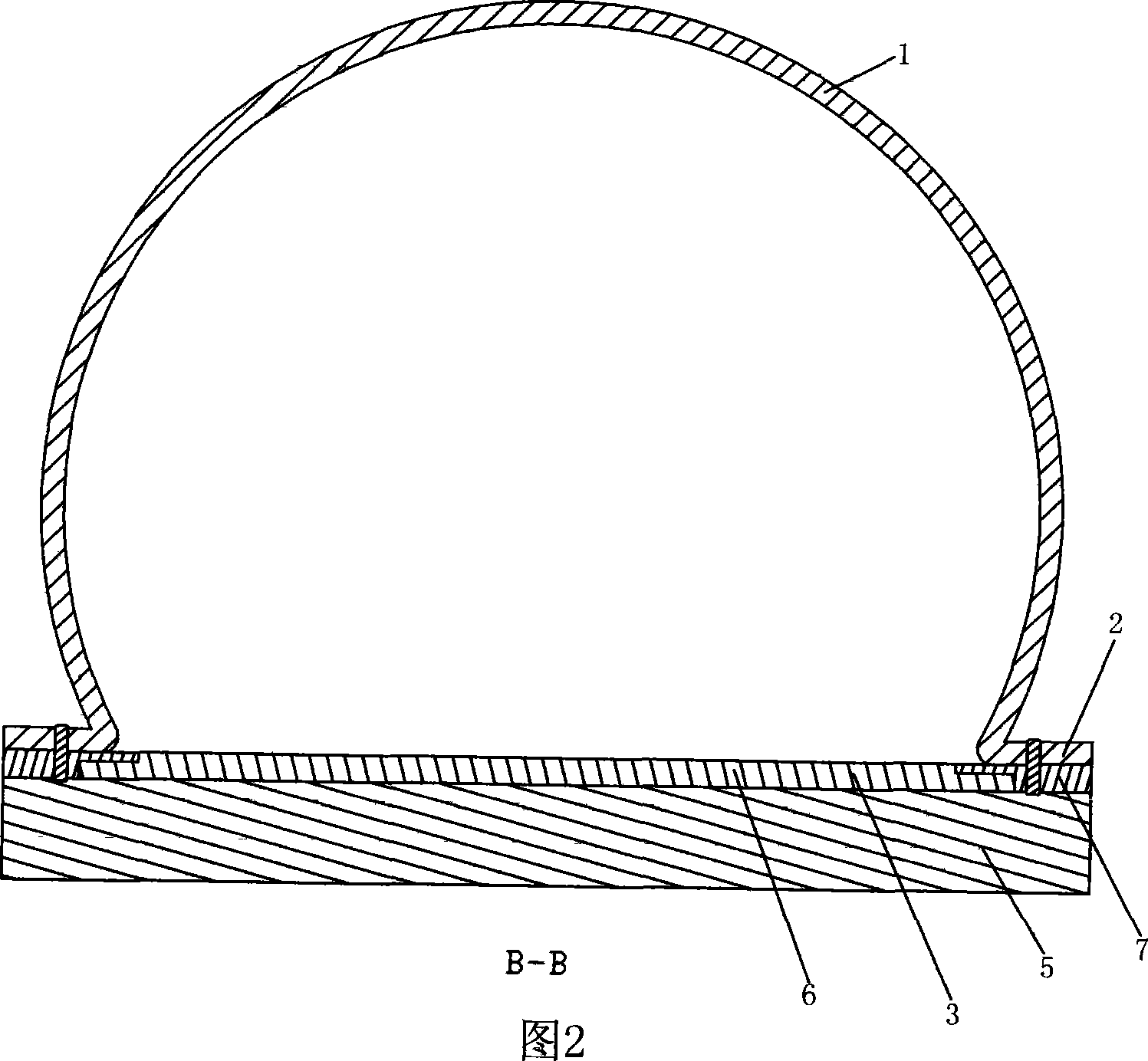

Pump and its mfg. method

InactiveCN1382909AImprove material utilizationEasy to operatePositive displacement pump componentsFlexible member pumpsPump chamberPressure difference

A pump and its manufacturing method, the pump has a pump chamber (1), suction-side and discharge-side flow paths (2) and (3) communicating with the pump chamber (1), the pump chamber (1) and the flow path A check valve unit (8) is arranged between (2) and (3). The check valve unit (8) is connected by a check valve membrane (5) formed by a thin film and a check valve frame (7) with a pipeline (6) passing through a pressure difference switch using the check valve membrane (5). ) is unitized. The pump has a compact structure, is easy to manufacture, and has high efficiency and reliability.

Owner:MATSUSHITA ELECTRIC WORKS LTD

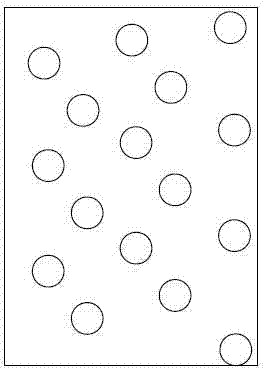

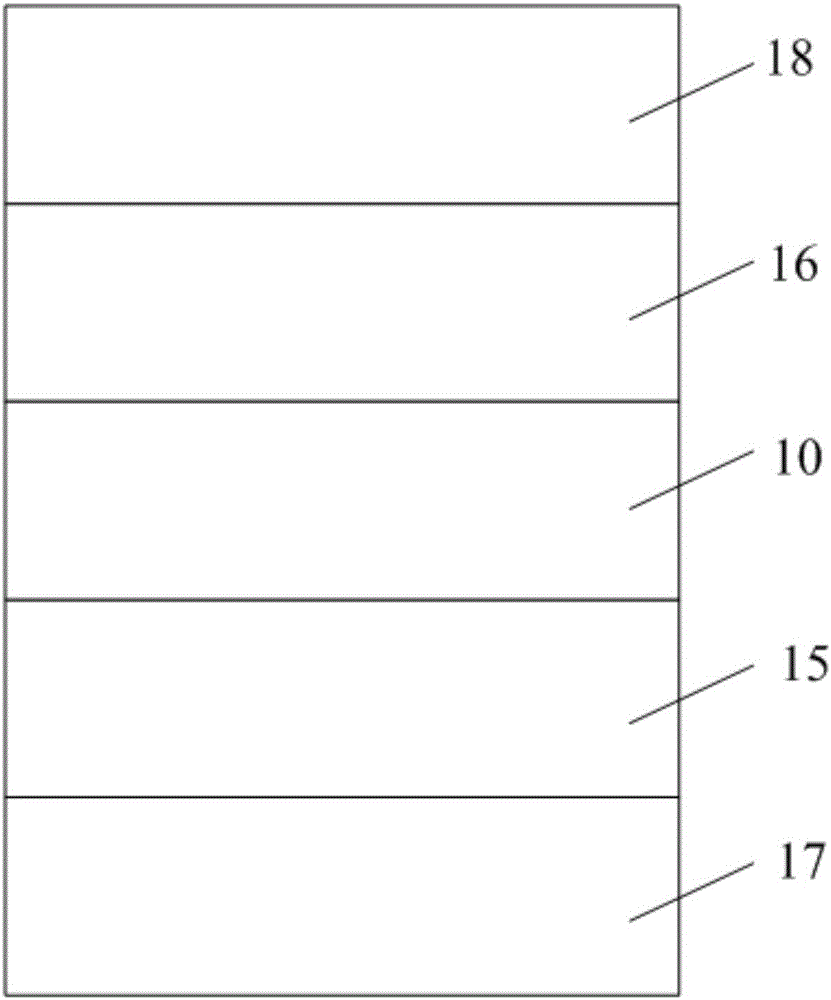

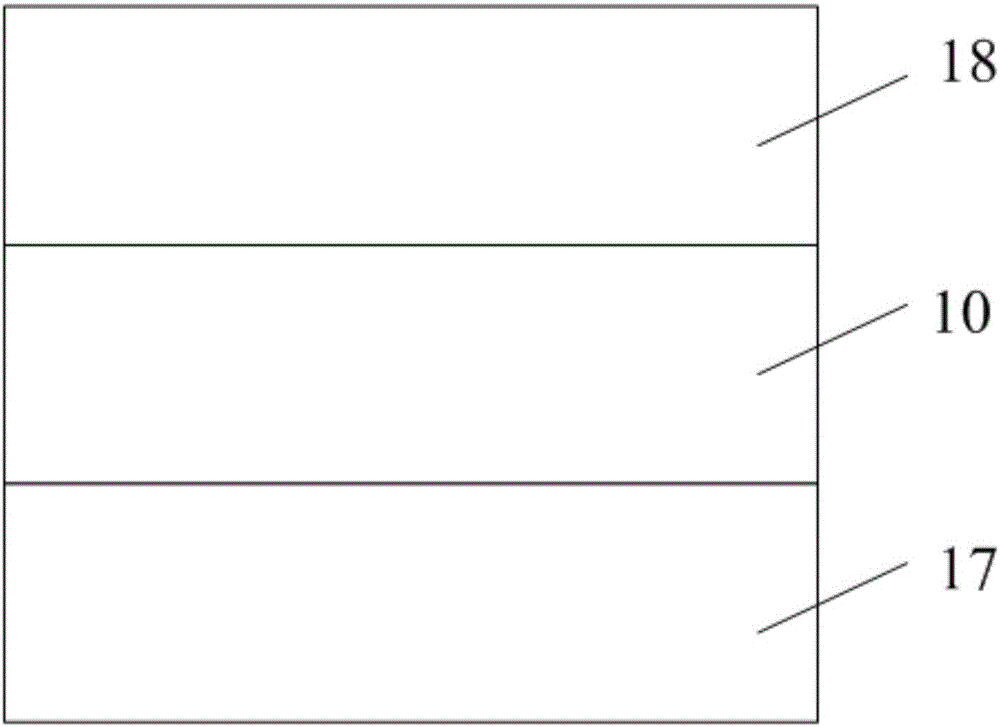

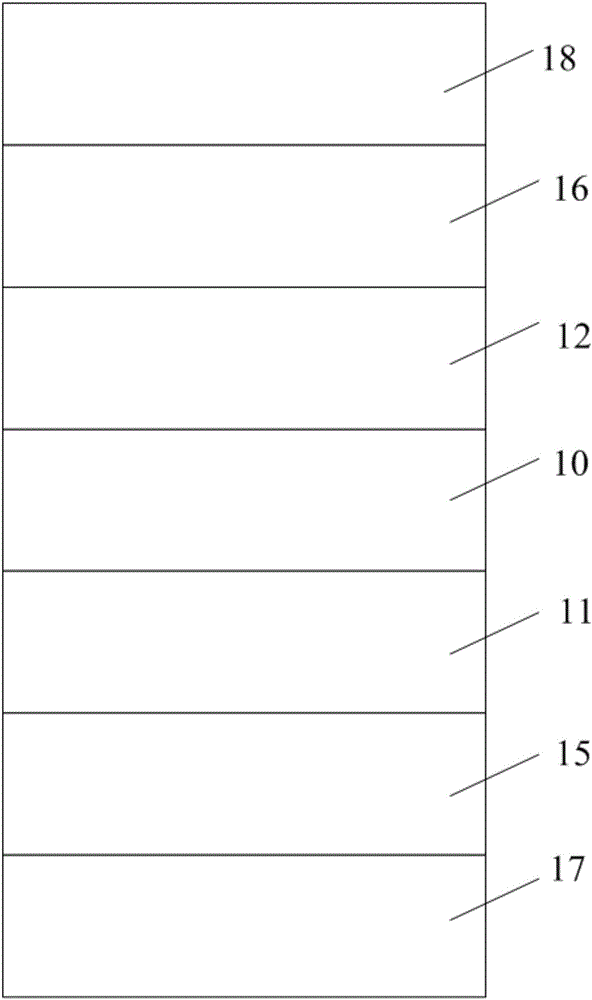

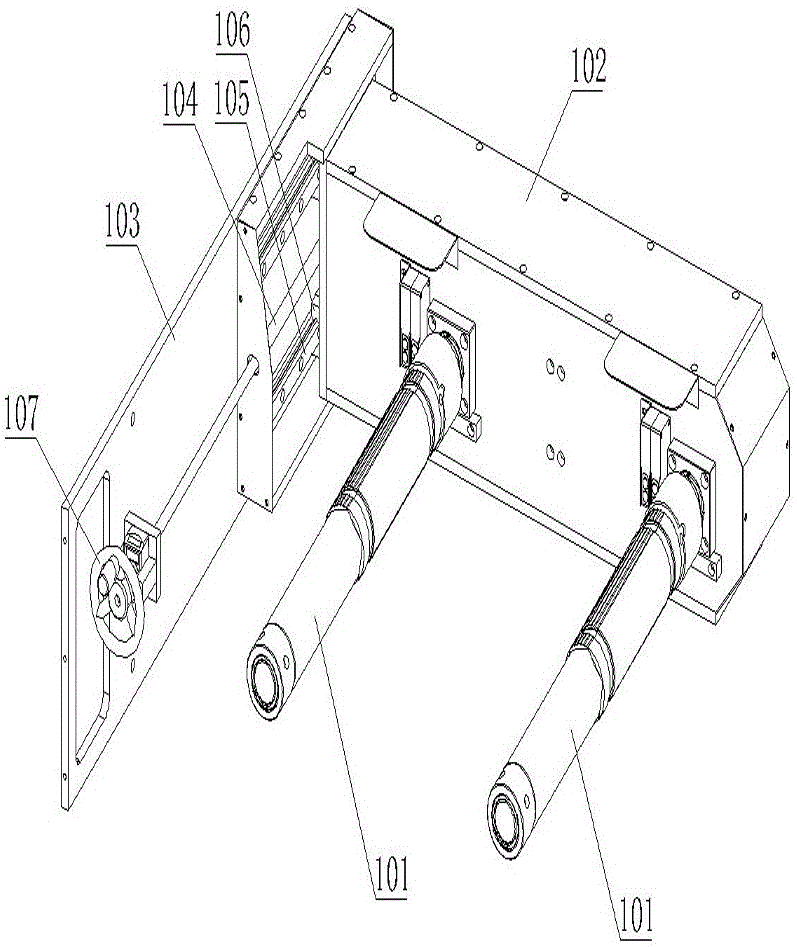

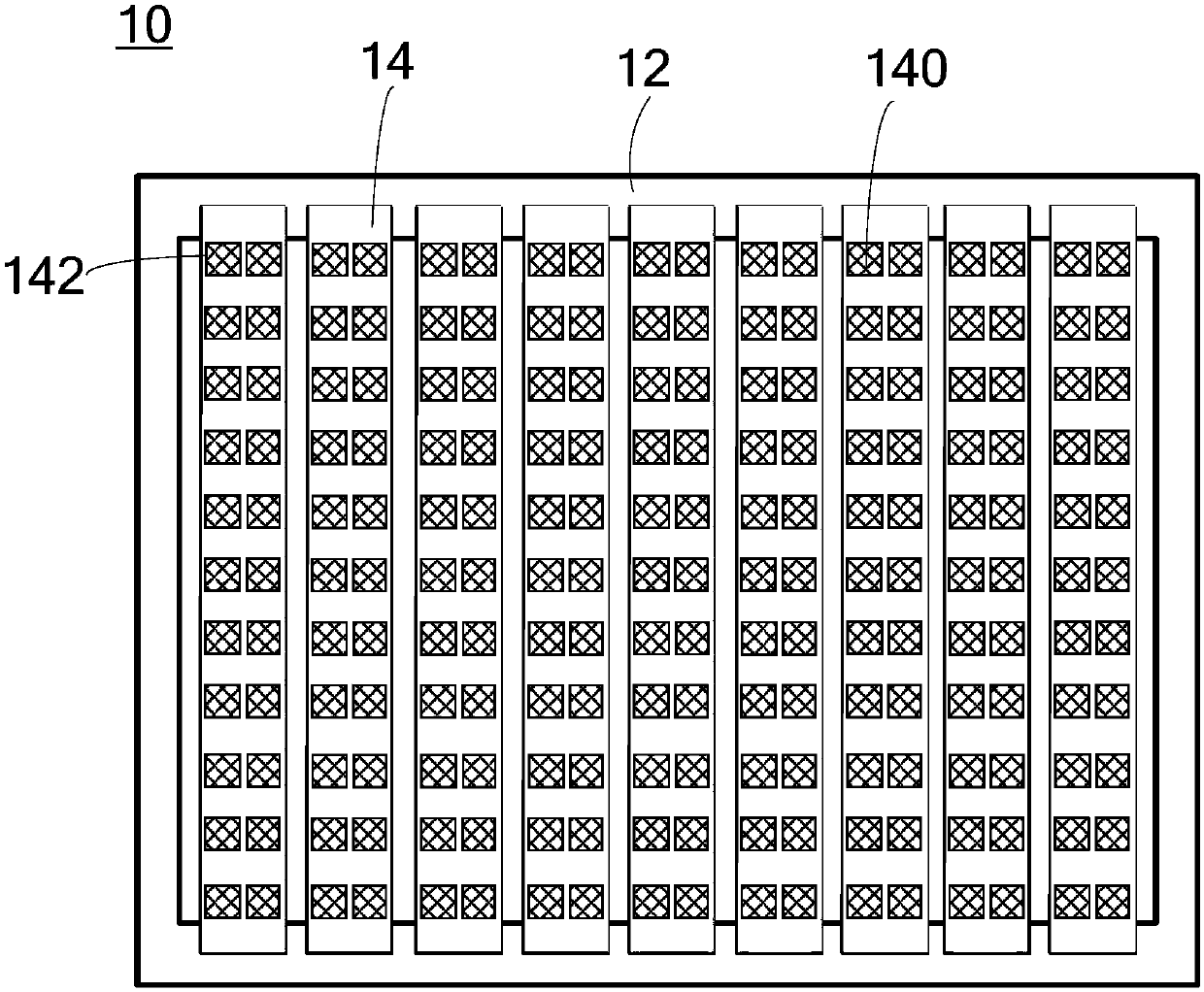

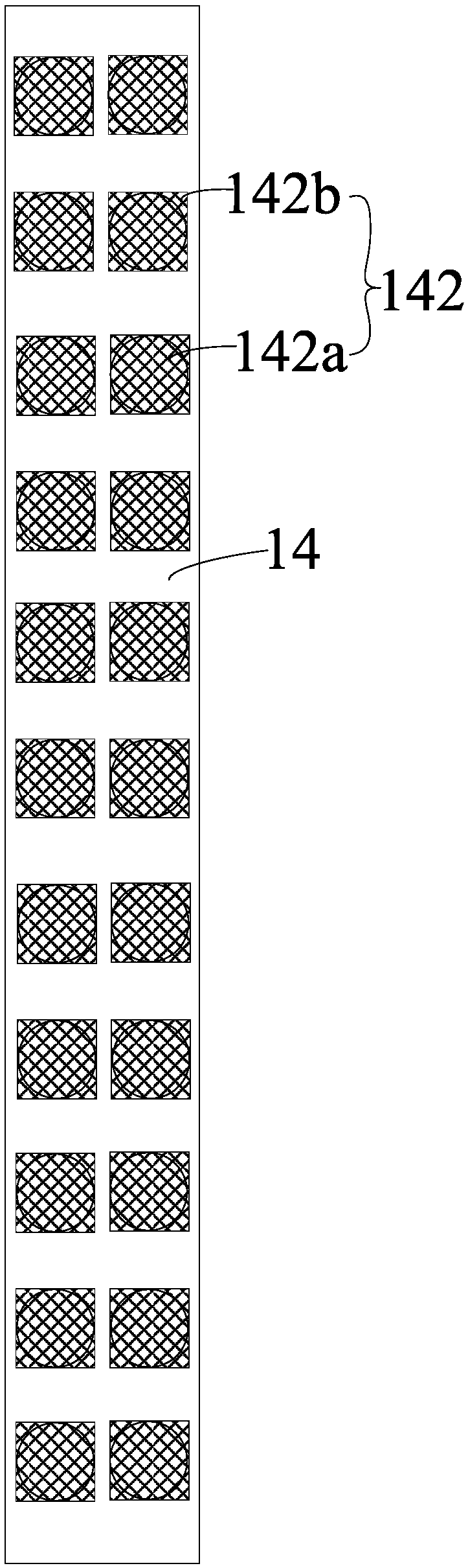

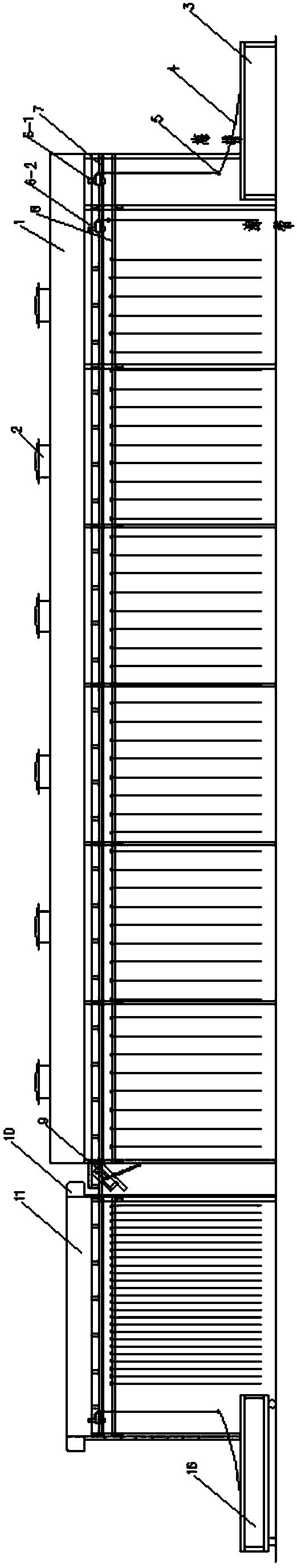

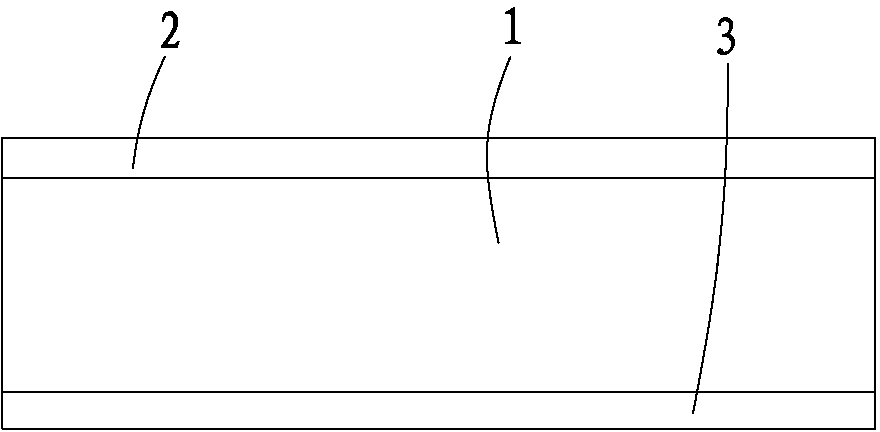

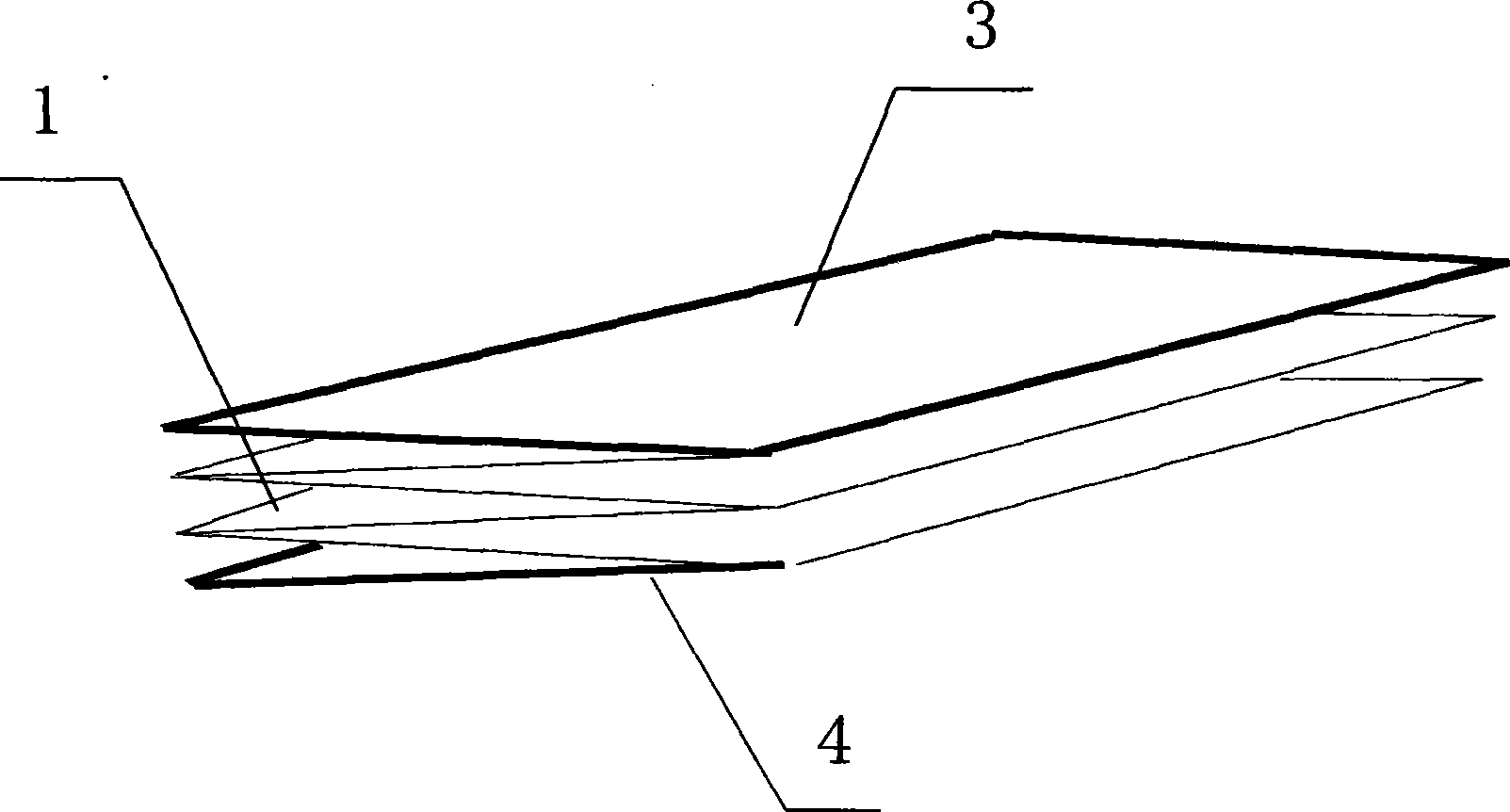

Quantum dot film and preparation method therefor

InactiveCN105870305AReduce manufacturing costNot easy to wrinkleSemiconductor devicesQuantum dotQuantum

The invention provides a quantum dot film and a preparation method therefor. The preparation method for the quantum dot film comprises the steps of step S1, putting liquid quantum dot glue on a carrier or in the carrier, and solidifying the liquid quantum dot glue to form a quantum dot layer, wherein the quantum dot layer has a first surface and a second surface which are arranged in opposite; the carrier is in contact with the first surface; and the surface opposite to the first surface is the second surface. In the preparation process of the quantum dot film, the liquid quantum dot glue is solidified firstly to form the quantum dot layer; then other film layers are arranged on the quantum dot layer; due to the solidifying step in advance, the flowing of the liquid quantum dot glue is avoided, so that an extremely accurate die and an accurate processing technology for controlling the uniformity are not required in the subsequent preparation process, and a relatively low preparation cost of the quantum dot film is realized; and in addition, due to the quantum dot layer formed by solidification in advance, the quantum dot film is not wrinkled easily.

Owner:NANJING TECH CORP LTD

Quick clothes drying device used for tailoring

InactiveCN107604614AKeep dryNot easy to wrinkleTextiles and paperSpin-dryersEngineeringInjection air

The invention relates to a clothes drying device, in particular to a quick clothes drying device used for tailoring. In order to achieve the technical purposes that clothes are quickly dried, difficult to wrinkle and not prone to bacteria breeding, the quick clothes drying device used for tailoring comprises a bottom plate and the like; L-shaped supports are in bolted connection with the top of the bottom plate in a bilaterally symmetrical mode, a box is in bolted connection with the inner sides on the tops of the L-shaped supports, a driving device is arranged on the left side on the top of the bottom plate, a rotating device is arranged on the bottom of the box, and a rotating part of the rotating device is located in the box. In the quick clothes drying device, the rotating device is driven by the driving device to rotate, and the clothes are driven by the rotating device to rotate, so that the clothes are dried; an air injection device is arranged, so that the clothes drying effectis further improved.

Owner:晋江诺研机械设计有限公司

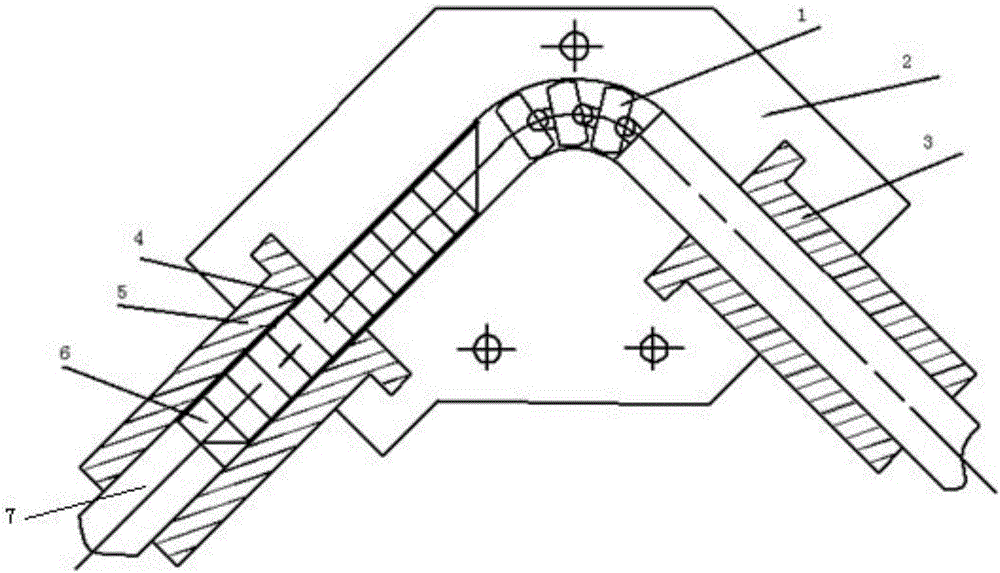

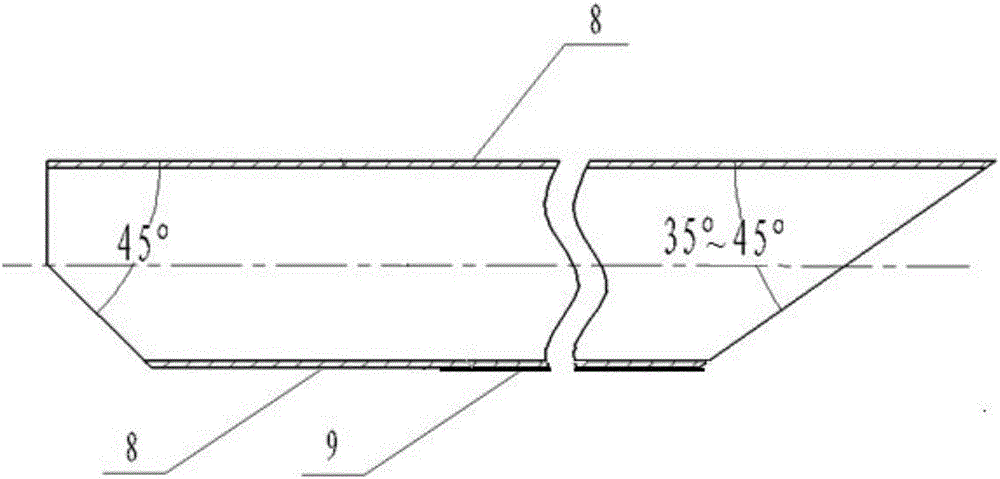

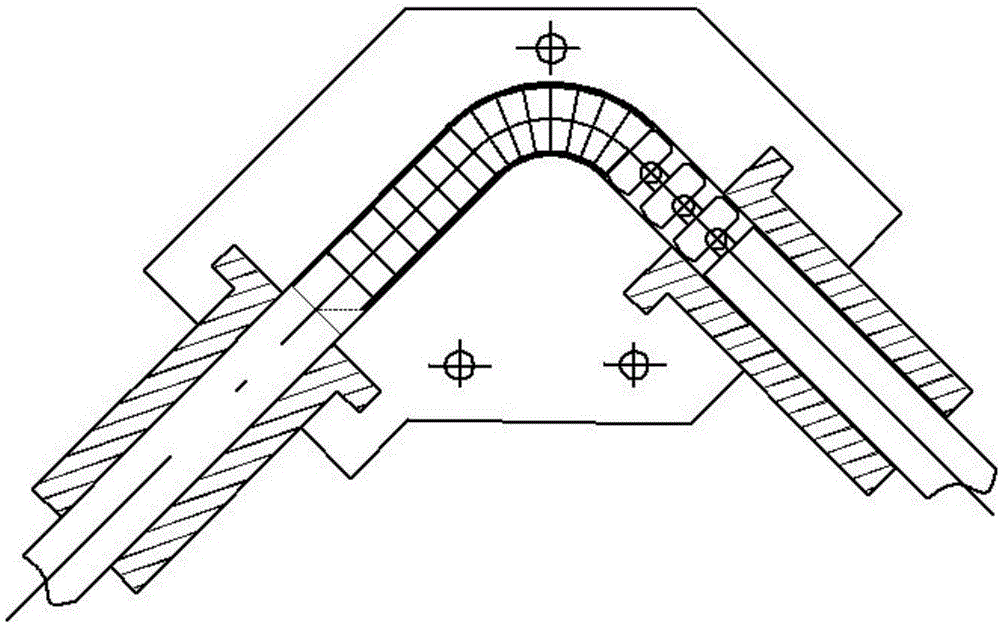

Bending formation method of small-curvature bending radius L type thin-wall aluminum alloy bent pipe

The invention discloses a bending formation method of a small-curvature bending radius L type thin-wall aluminum alloy bent pipe. Two ends of the bent inner side of a long pipe blank of an aluminum alloy thin-wall pipe blank are grooved by 35-45 degrees; a protective agent is coated at the external of the pipe blank; oily molybdenum disulfide is sprayed in the semi-cylindrical surface of an area from the from part of the bent inner side of the pipe blank to the front part pi D, so that a material on the bent inner side of the pipe is facilitated to flow and to improve wrinkling; a traditional polyurethane round bar is replaced; multiple polyurethane cylinder blocks are filled in the pushed end of the pipe blank; and compared with an integral polyurethane filler rod, the taking out is easier after formation, and the forming efficiency is improved. Meanwhile, the polyurethane cylinder blocks with proper hardness, thickness and diameter facilitate internal support of the bent pipe, and are not liable to generate wrinkles on the bent inner side; and the jacking force of a core head is reinforced during forming to supply enough internal pressure into the pipe through a filler to force a lot of materials to flow to the front groove so as to prevent wrinkling to form the qualified small-curvature bending radius L type thin-wall aluminum alloy pipe.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for dyeing yarns of superfine-denier lyocell and long stapled cotton to obtain high-count fabrics

ActiveCN104928824ASoft drapeImprove appearance and textureDyeing processWoven fabricsEngineeringLyocell

The invention provides a method for dyeing yarns of superfine-denier lyocell and long stapled cotton to obtain high-count fabrics. The method includes steps of carrying out a spinning technological process (1); carrying out a weaving technological process (2). The spinning technological process (1) includes (1.1), manufacturing combed cotton silver from long stapled cotton warps; (1.2), manufacturing lyocell pre-drawn silver from the superfine-denier lyocell; (1.3), mixing the lyocell pre-drawn silver and the combed cotton silver with each other to obtain lyocell and cotton blended yarns. The weaving technological process (2) includes (2.1), weaving the lyocell and cotton blended yarns to obtain warp yarns; (2.2), weaving the lyocell and cotton blended yarns to obtain weft yarns; (2.3) weaving the warp yarns manufactured in the step (2.1) and the weft yarns manufactured in the step (2.2) to obtain grey cloth, examining and repairing the grey cloth, mercerizing the grey cloth, carrying out silk-like finishing on the grey cloth, pre-shrinking and setting the grey cloth to obtain finished products and checking and warehousing the finished products. The method has the advantages of capability of manufacturing fabrics for business shirts, diversified product weaves and specifications, stable product quality, high durability, good elasticity, difficulty in wrinkling and convenience in caring and washing.

Owner:ANHUI HUAMAO TEXTILE

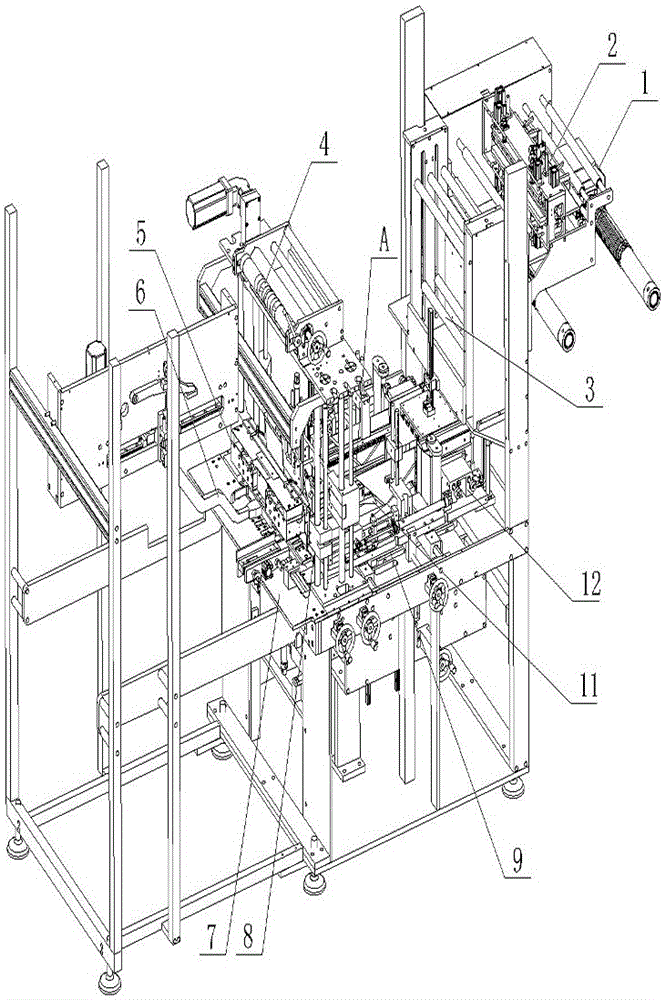

Three-dimensional packaging machine

ActiveCN106347731ANot easy to wrinkleMeet high-speed production requirementsWrapping material feeding apparatusWrappingThin membraneEngineering

The invention discloses a three-dimensional packaging machine. The three-dimensional packaging machine is characterized in that a thin film conveyed by a film conveying part passes through a float guide rail, and is downwards conveyed out by a traction guide roll at fixed length; a film cutting part is arranged under the traction guide roll, and is used for cutting the thin film at fixed length; a box feeding platform is arranged under the film cutting part, and a material push part is arranged at the back side of the box feeding platform, and is used for forwards pushing a row of paper boxes on the box feeding platform into a package forming passage; a left edge folding part, a right edge folding part, an upper edge folding part and a lower edge folding part are arranged on the package forming passage, the left edge folding part and right edge folding part are used for folding the left and right edges of a thin film package, and the upper edge folding part and lower edge folding part are used for folding the upper and lower edges of the thin film package; bottom sealing parts are arranged at the bottom parts of the left edge folding part and right edge folding part, and are used for sealing the bottom seals of the thin film package; side sealing parts are arranged at the front sides of the upper edge folding part and lower edge folding part and are used for sealing the side seals of the thin film package; a traction part is arranged at the bottom part of the package forming passage, and is used for forwards pushing and conveying the paper boxes in the package forming passage. The three-dimensional packaging machine has the advantages that the package quality is good, and the production speed is high; the problem of shutdown and material storage in the prior art is solved.

Owner:浙江春余机械有限公司

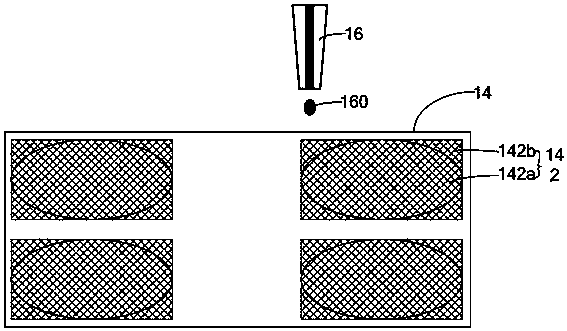

Manufacturing method of mask plate and mask plate

ActiveCN107740041AUniform tensile forceAlleviate poor color mixingSolid-state devicesVacuum evaporation coatingEngineeringColor mixing

The invention relates to the technical field of display, in particular to a manufacturing method of a mask plate and the mask plate. The manufacturing method of the mask plate comprises the steps as follows: a mask having multiple pixel openings is obtained, the pixel openings are arranged into at least one rectangular pattern area, and each rectangular pattern area comprises a first area corresponding to a display area of a display panel and a second area except the first area; the mask and a mask frame are aligned, and the mask is fixed on the mask frame; the pixel openings in each second area are blocked, and the mask plate is formed. According to the technical scheme, the condition that wrinkles are produced easily during stretching of the mask can be relieved, so that the problems ofpoor color mixing of the display panel and reduction of the product yield can be solved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

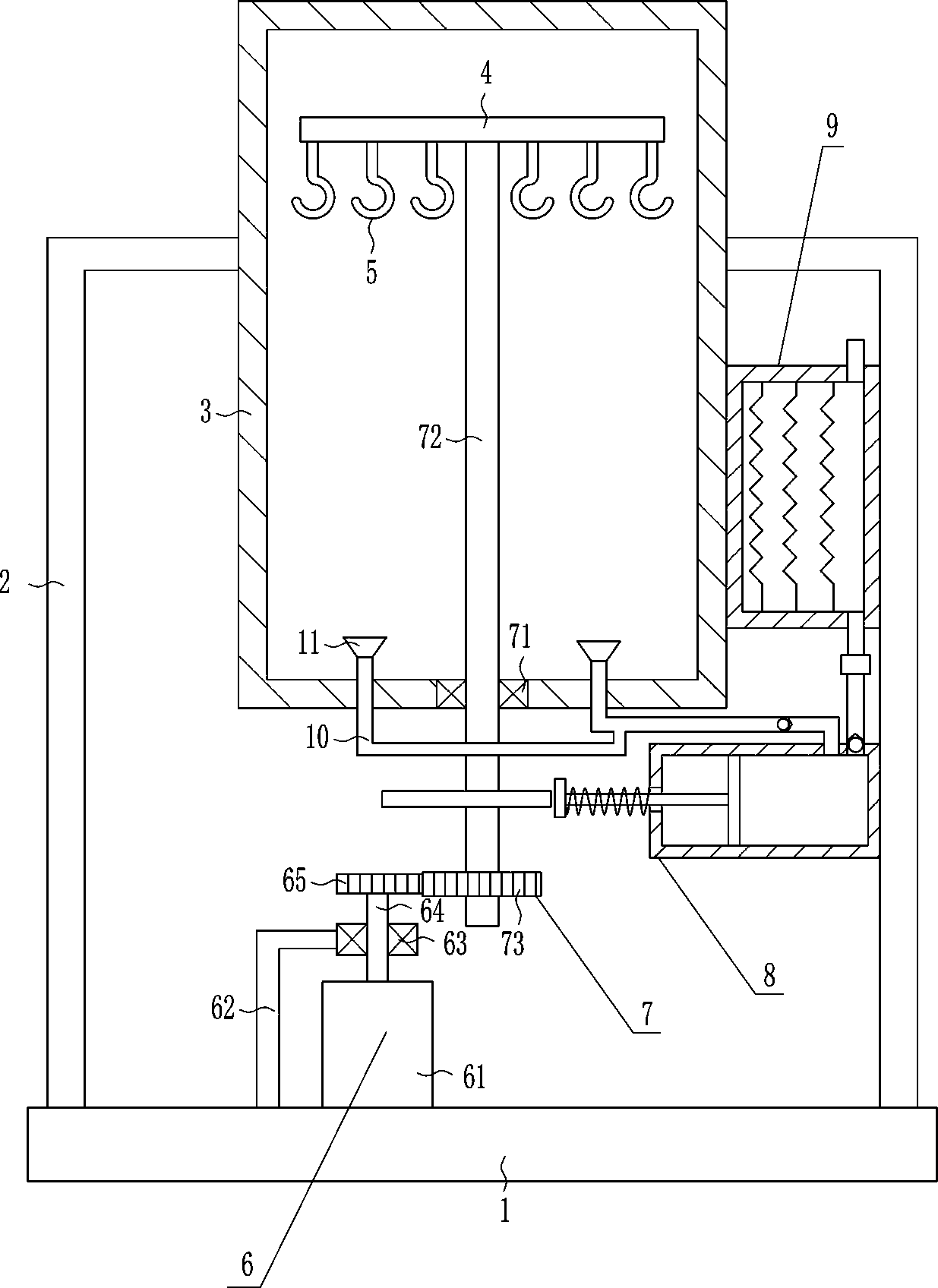

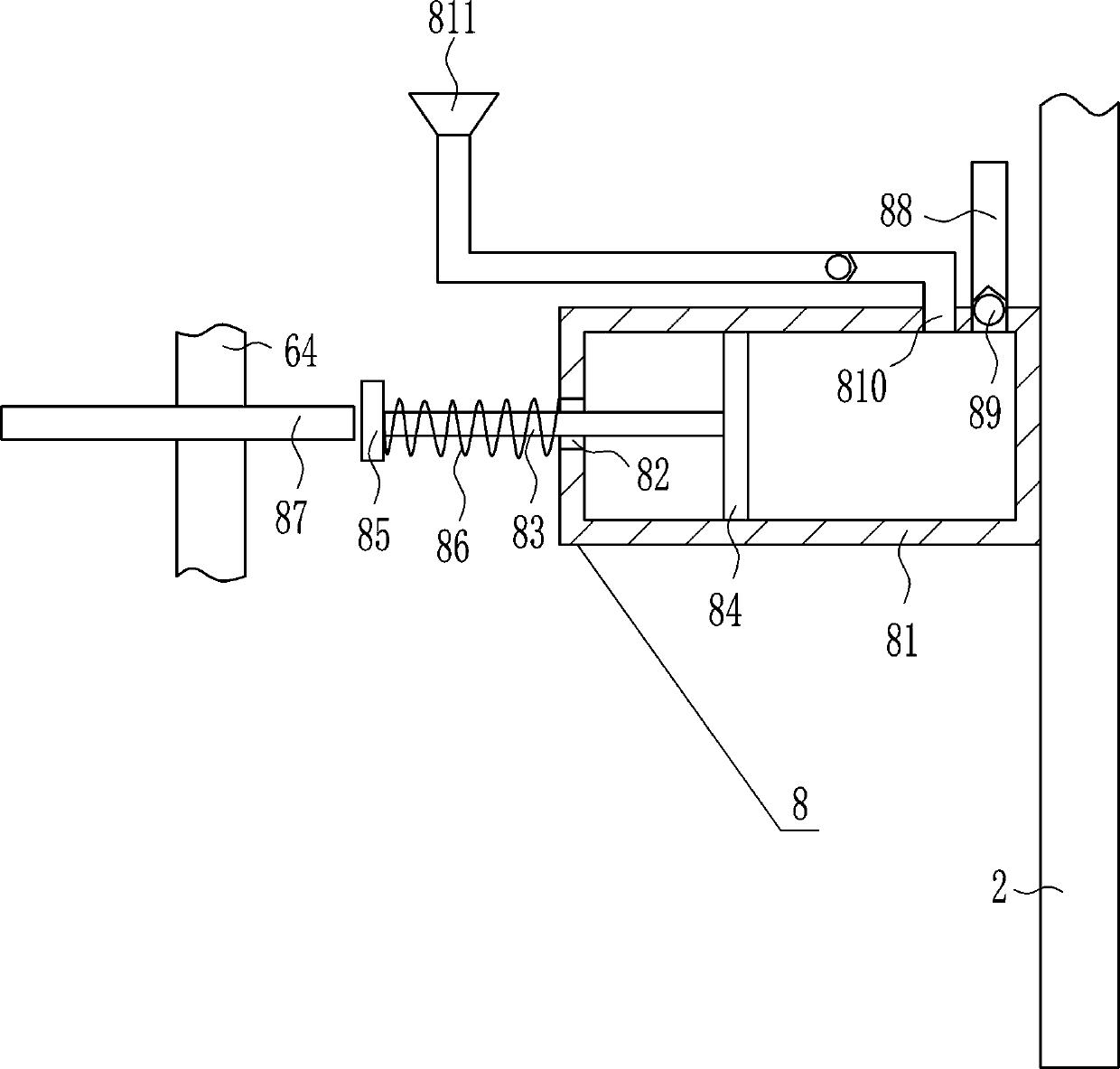

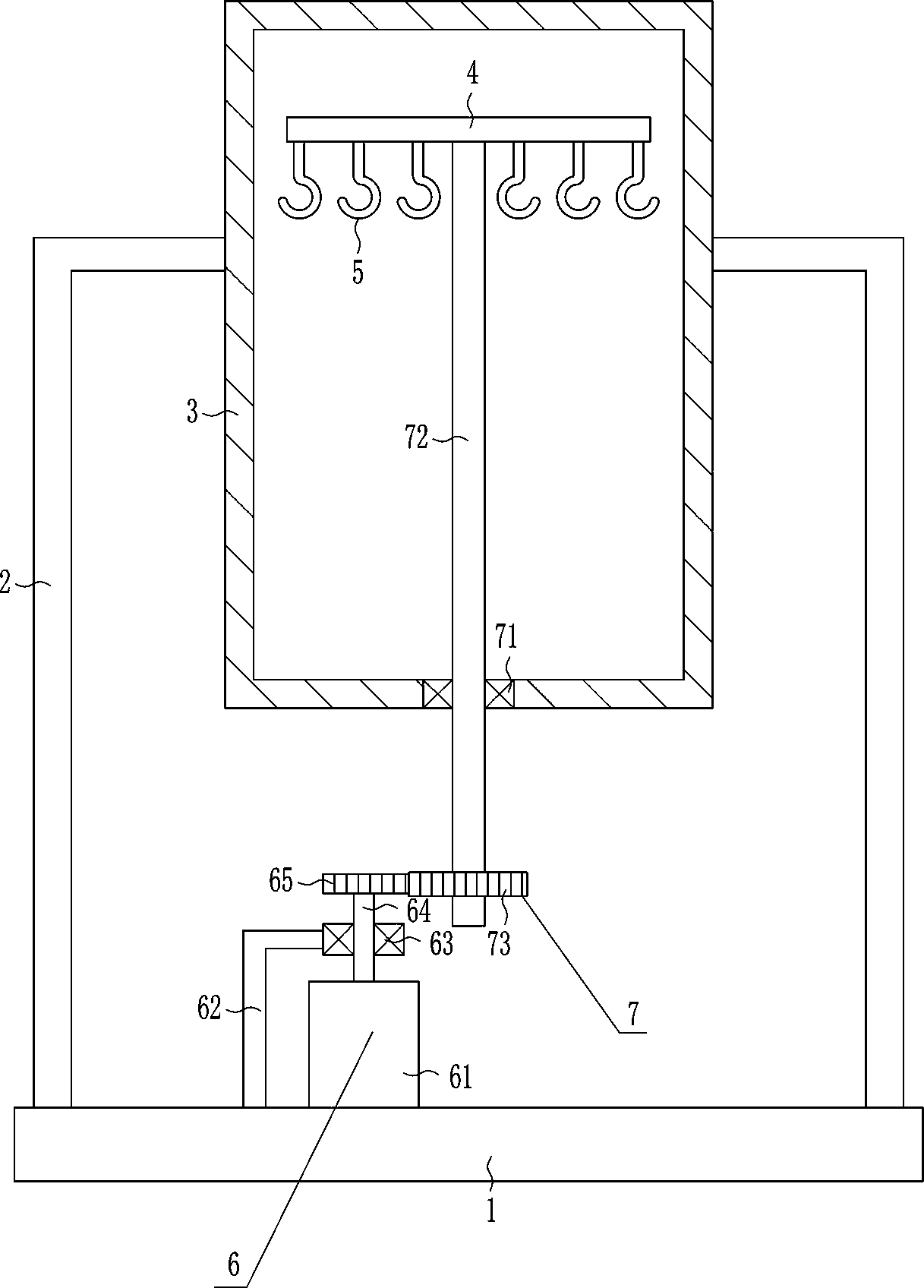

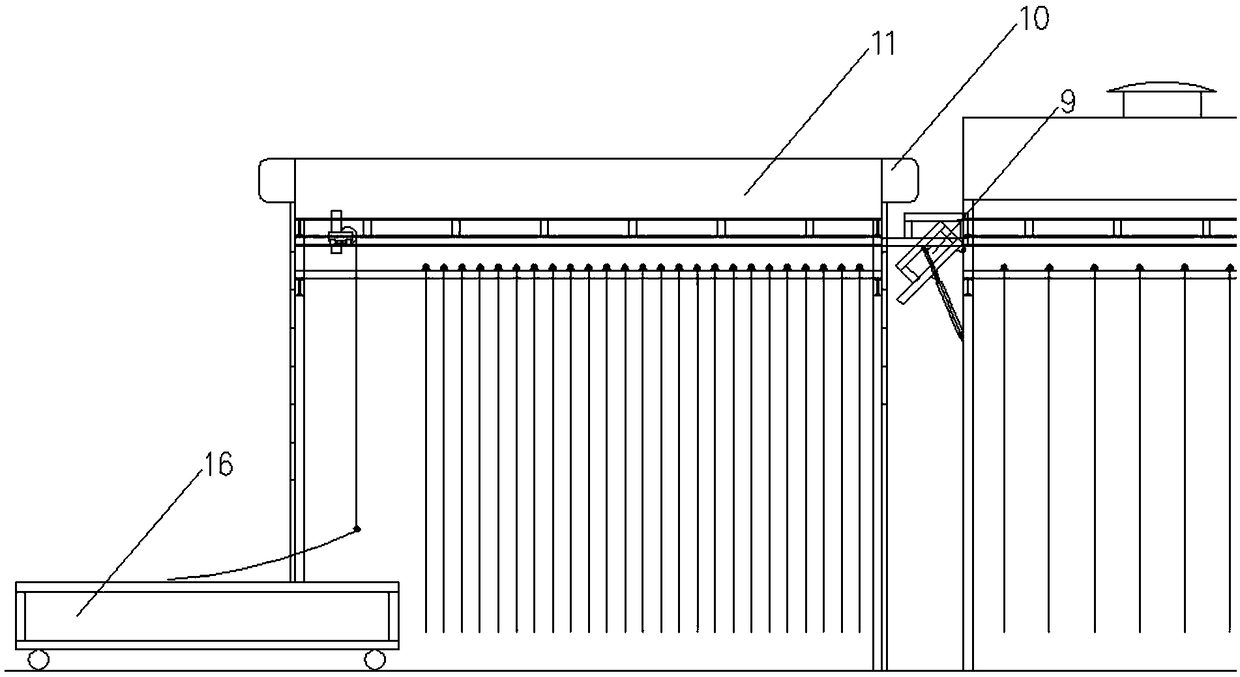

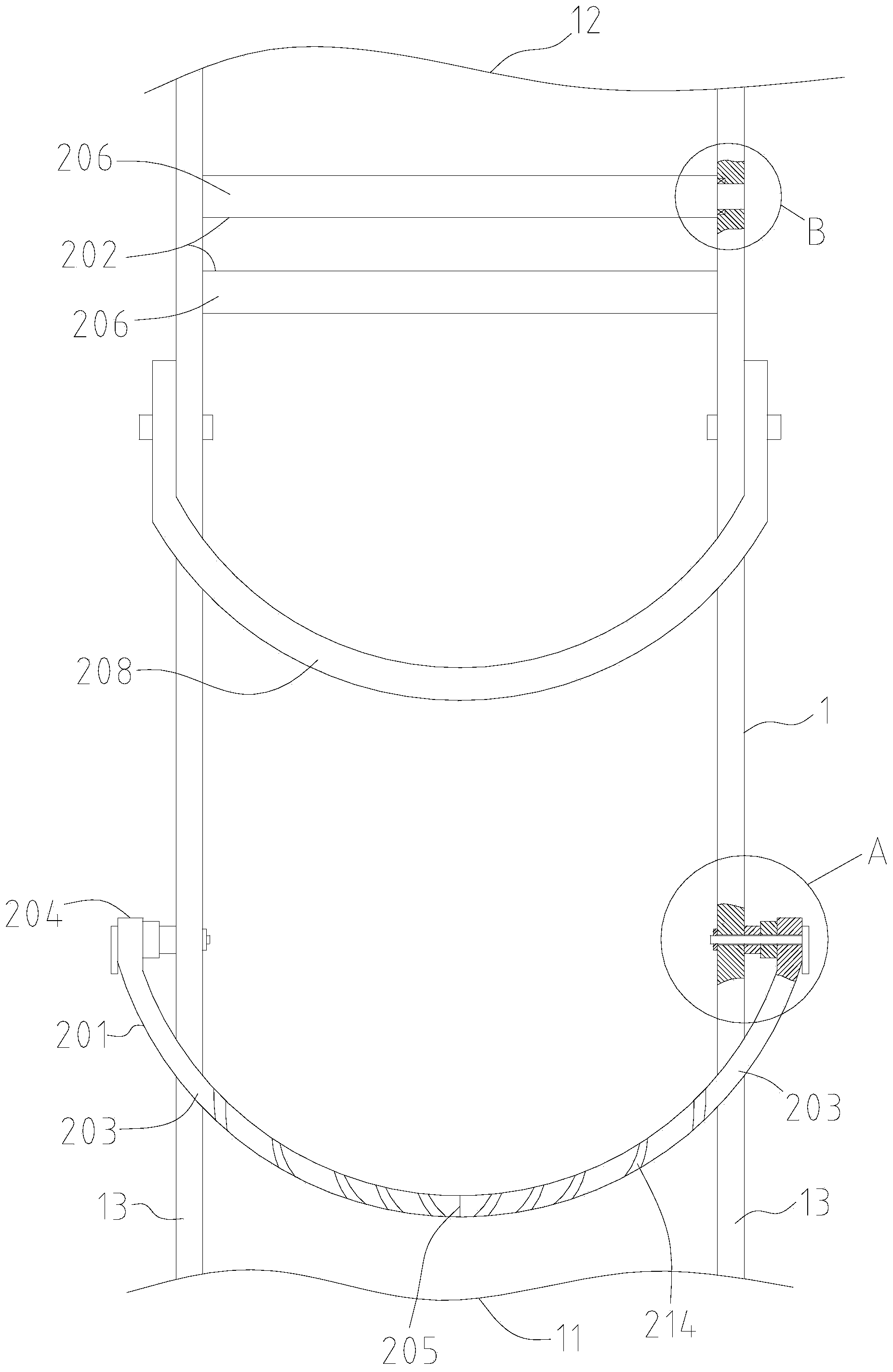

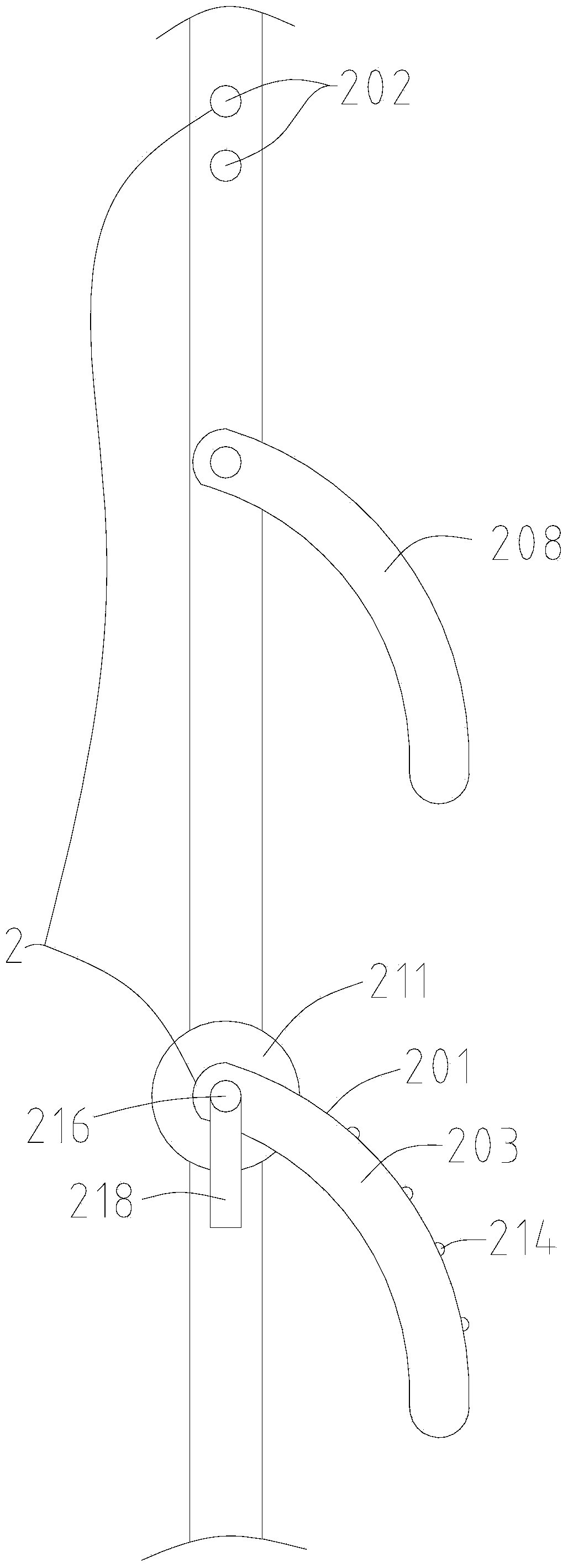

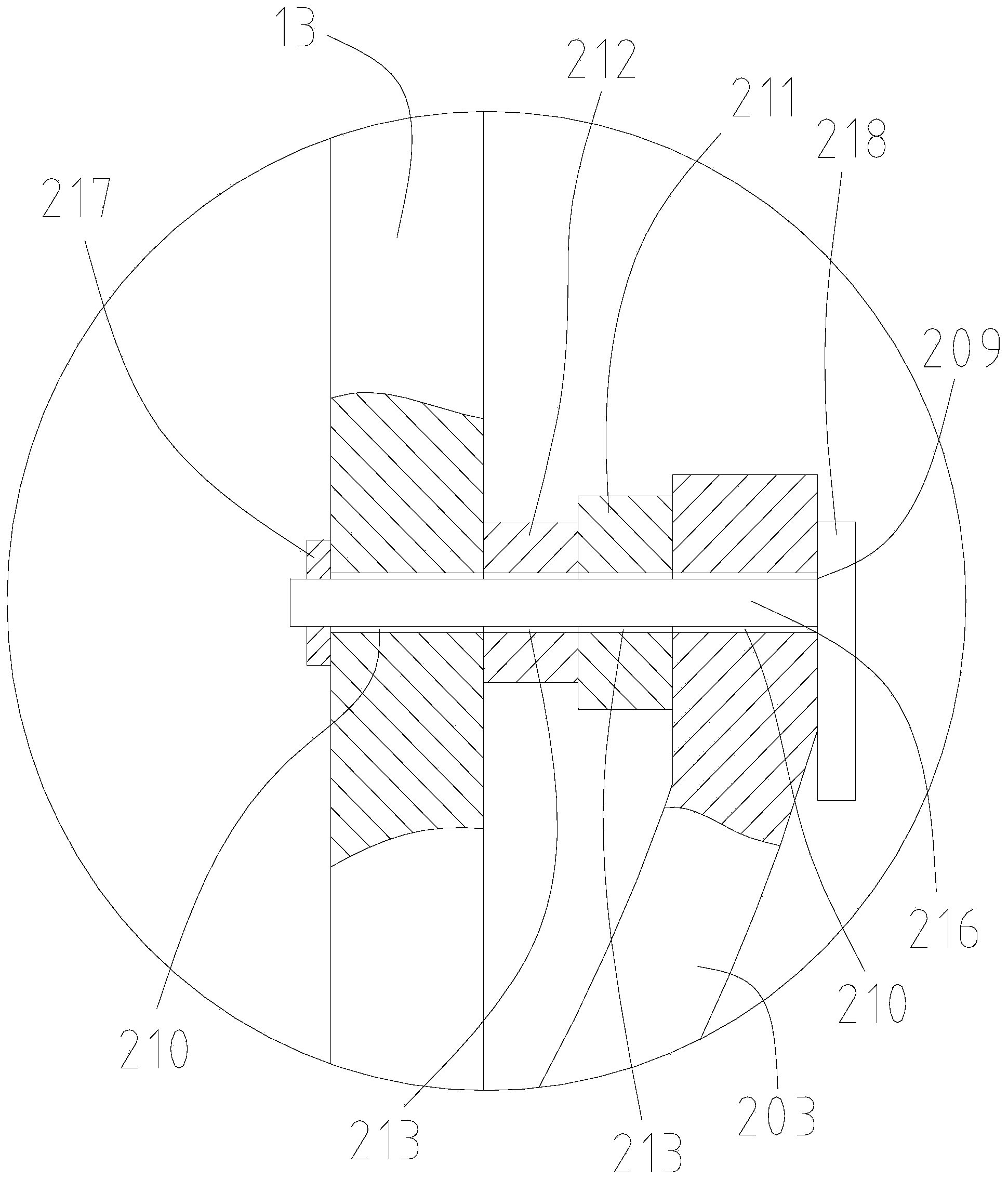

Kelp hanging, airing and drying device and working method thereof

ActiveCN109028817AReduce energy consumptionSave water consumptionDrying chambers/containersDrying machines with local agitationEngineeringAir drying

The invention relates to a kelp hanging, airing and drying device. The kelp hanging, airing and drying device comprises an air drying shed and a drying chamber which are arranged in sequence in the Xdirection; a horizontal guide rail is arranged at the part, under a transparent sunshine plate, at the internal top of the air drying shed in the X direction; an airing rack is fixedly arranged underthe horizontal guide rail in the X direction; a first elevator elevates an airing rod to a height larger than the height of the airing rack after the airing rod is firmly sucked, and then moves the airing rod moves in the X direction to place the airing rod in an initial placing position on the airing rack; after a second elevator reaches the initial position and elevates the airing rod to a position higher than the airing rack after firmly sucking the airing rod, the second elevator moves to a program setting position in the air drying shed; a turnover guide rail capable of smoothly jointinghorizontal guide rails of the drying chamber and the air drying shed is arranged at the docking part of the drying chamber and the air drying shed; and the second elevator can automatically convey theairing rods, on which kelp is hung, along the air drying shed and the drying chamber in sequence. According to the kelp hanging, airing and drying device, as two drying modes of air drying and heat pump drying are combined in an optimized manner, dehumidifying energy consumption is greatly saved, and the drying labor intensity of kelp is also reduced.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI +1

Printed and embroidered seamless wall fabric and manufacturing method thereof

ActiveCN105804345ALow viscosityEvenly dispersedCovering/liningsDyeing processBiochemical engineeringMembranous layer

The invention belongs to the technical field of facing decoration materials and particularly relates to printed and embroidered seamless wall fabric and a manufacturing method thereof. The wall fabric comprises a cloth layer, a glue film layer and a raw paper layer or non-woven layer, wherein the glue film layer is located between the cloth layer and the raw paper layer; the surface, making contact with the glue film layer, of the cloth layer is a smooth surface, and the other surface of the cloth layer is provided with printed patterns; and embroidered patterns are arranged on the cloth layer, and the cloth layer is soaked or coated with a waterproof and mouldproof agent. The wall fabric is formed by conducting printing and embroidering on base cloth and then conducting shaping. The wall fabric manufactured through the manufacturing method has the advantages of being easy to stick, not prone to wrinkles, various in style and long in service life.

Owner:ZHEJIANG LIANXIANG EMBROIDERY CO LTD

Antistatic cotton-polyester blend clothing material

InactiveCN1811034AHigh cotton contentImprove breathabilityOther chemical processesWoven fabricsPolyesterFiber

The antistatic cotton-polyester blend clothing material contains cotton of 21*21 count in 50-70 wt%, chemical fiber of 127*66 or 45 / 2*21 count in 29-49 wt% and conducting fiber of 130*66 count in 1 wt%. It has high cotton content and embedded conducting fiber resulting in excellent antistatic effect, high permeability from proper cotton / polyester ratio, certain brightness, high stiffness, high color fastness and fire retarding function, and can meet the requirement of antistatic clothing for workers in petrochemical and other industry.

Owner:YI HE STOCK

Cloth spreading device for shaping machine

The invention relates to an accessory of a spinning device, in particular to a cloth spreading device for a shaping machine. At least one pair of V-shaped cloth guide rods used for spreading cloth are arranged to be a cloth spreading support, the V-shaped cloth guide rods are in the involute shape and protrude out of the plane where the support body is located, the cloth guide rods have the good guiding effect and can well spread the cloth in the specific using process, and the cloth is not prone to wrinkling in the conveying process; due to the fact that a middle rod is arranged, the cloth spreading device for the shaping machine can remotely convey the cloth, and the cloth is not prone to wrinkling in the cloth conveying process; in addition, due to the fact that a correction rod is arranged, before entering the next working procedure, the cloth will be corrected by the correction rod, and it is ensured that the cloth is completely spread when entering the next working procedure; due to the fact that the correction rod is connected to the support body in a rotating mode, the correction rod rotates flexibly, and the phenomenon that the cloth wrinkles due to the uneven stress is avoided.

Owner:HUZHOU CHENGXIN TEXTILE PRINTING & DYEING

Plastic bag packaging machine

The invention discloses a plastic bag packaging machine comprises a plastic bag feeding belt and a goods to be packaged conveying belt. The plastic bag feeding belt is mounted on a machine frame, and the machine frame is provided with a bag expanding structure. The plastic bag packaging machine is characterized in that the bag expanding mechanism comprises symmetrically-mounted sliders which are mounted on both sides of the end portion of the goods to be packaged conveying belt; swing arms are hinged to the sliders; air cylinders are mounted on the machine frame, and the push rods of the air cylinders are connected with the sliders. By means of the structure, when goods to be packaged are fed into plastic bags, the swing arms can contract first to facilitate flatness maintaining of the plastic bags and further facilitate subsequent bending edge sealing of the plastic bags, so that the plastic bag packaging machine has the advantages of good packaging effects and high efficiency.

Owner:邵万敏

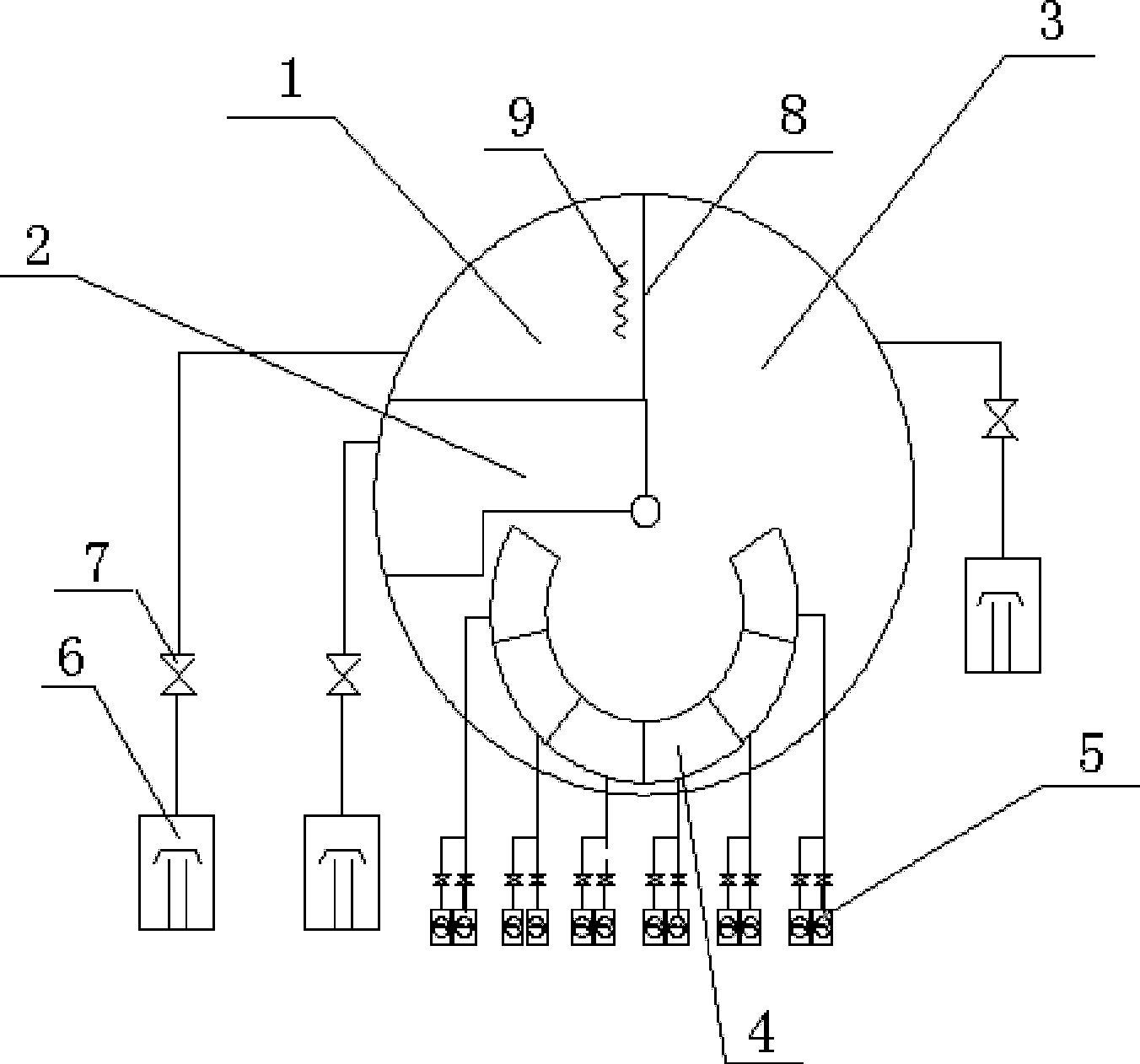

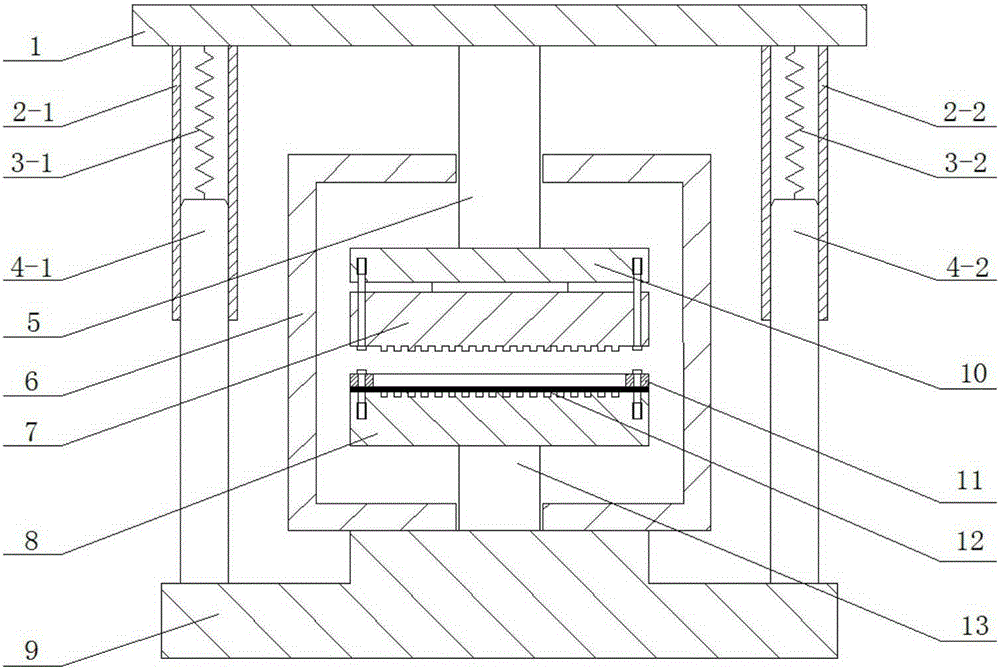

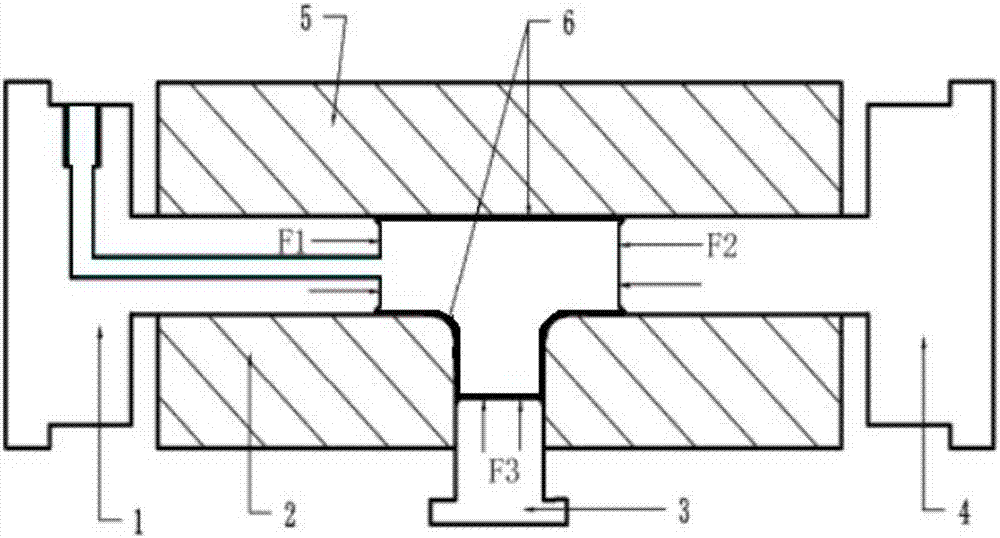

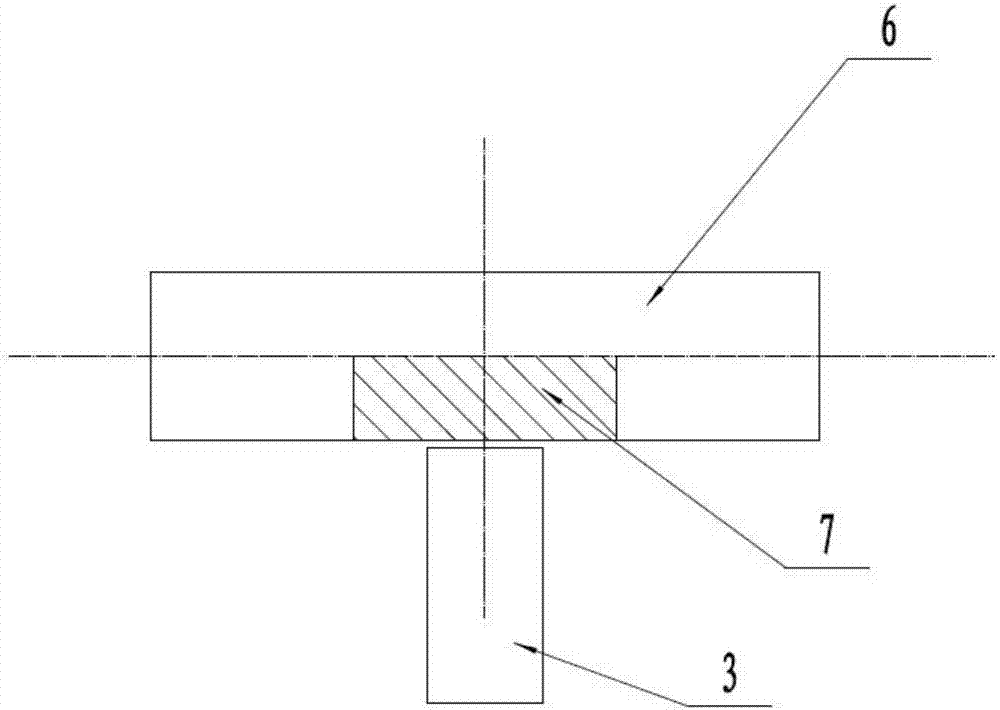

Super-plastic forming device and process of metal bipolar plate for proton exchange membrane fuel cell

InactiveCN105161731AAvoiding the disadvantages of cold formingReduce residual stressCell electrodesControl systemEngineering

The invention relates to a bipolar plate forming technology, in particular to super-plastic forming device and process of a metal bipolar plate for a proton exchange membrane fuel cell. The device comprises a pressure plate, guide sleeves, springs, guide posts, a pressing rod, an environmental box, an upper template, a lower template, a base, a connection plate, a blank pressing plate, a metal plate and a support rod. The process implemented by the device comprises the following steps: (1) opening the environmental box; (2) fixing a metal sheet of a processed part on the lower template; (3) closing the environmental box, determining the super-plastic forming temperature according to a processed plate and inputting the super-plastic forming temperature into a control system; (4) setting the stroke and the movement rate of the upper template according to the super-plastic strain rate and flow channel shape of the processed plate; (5) starting a circuit system and the environmental box, starting a pressure forming machine to move downwards, and finishing stamping; (6) starting the upper template of a press to reversely return back to the initial position; and (7) opening the environmental box, and cooing and taking out a formed part. According to the super-plastic forming device and process, the material is effectively prevented from rebounding, and the forming accuracy and the dimensional accuracy are ensured.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for manufacturing composite non-woven fabric collar interlining

InactiveCN104997203AWith fragrance functionMask the smell of sweatGarmentsNon-woven fabricsInterliningNonwoven fabric

The invention relates to the field of non-woven fabric adhesive interlinings, and discloses a method for manufacturing a composite non-woven fabric collar interlining. Composite non-woven fabrics serve as the grey cloth. The method comprises following steps: (1) manufacturing the non-woven fabrics; (2) preprocessing the grey cloth; (3) dispensing the non-woven fabrics; and (4) baking the non-woven fabrics so as to obtain the composite non-woven fabric collar interlining. Compared with a conventional collar interlining, the composite non-woven fabric collar interlining is high in hygroscopicity and air permeability, stiff in texture and low in cost, can give out fragrance, and has a simple manufacturing process.

Owner:CHANGXING HONGBO TEXTILE

High-thermal conductivity graphite heat-dissipation membrane making technology

The invention relates to a high-thermal conductivity graphite heat-dissipation membrane making technology. The technology comprises preparing a graphite mold from high purity graphite, selecting a natural graphite paper as a base material, stacking the cut natural graphite papers in the graphite mold, putting the graphite mold into a high temperature graphitization furnace, carrying out high temperature purification four times, cutting a polymer film to obtain sheets, crosswise stacking the sheets and the purified natural graphite papers in the graphite mold, putting the graphite mold with the raw materials into a carbonizing furnace, putting the carbonized material into the graphitization furnace, cutting the graphitized raw material according to specifications, stacking the graphitized raw material and a release film, putting the stacked materials into a double-roller calendar and carrying out lamination to obtain a high-thermal conductivity graphite film with the smooth surface, uniform thickness and good flexibility. The high-thermal conductivity graphite heat-dissipation membrane has the smooth surface, uniform thickness and good flexibility.

Owner:黄志良

Current collector structure of positive electrode of lithium ion battery and battery including structure

InactiveCN103384012AAvoid corrosionReduce thicknessElectrode carriers/collectorsSecondary cellsElectrical batteryLithium-ion battery

The invention especially relates to a current collector structure of a positive electrode of a lithium ion battery, which belongs to the technical field of lithium ion batteries. The structure comprises an aluminum alloy layer and an aluminum layer coated over the aluminum alloy layer, wherein the aluminum layer comprises a first aluminum layer and a second aluminum layer, and the aluminum alloy layer is arranged between the first aluminum layer and the second aluminum layer. Compared with an aluminum foil current collector structure with same thickness, the structure provided by the invention has higher strength, so the thickness of the current collector of the positive electrode is reduced, and energy density of the battery is increased; the upper surface and the lower surface of the aluminum alloy layer are respectively coated by the first aluminum layer and the second aluminum layer, so corrosion of the positive electrode to the material of the body of the aluminum alloy layer is prevented, and the problems of crumpling and strip breakage hardly occur. Moreover, the invention also discloses the lithium ion battery.

Owner:DONGGUAN AMPEREX TECH

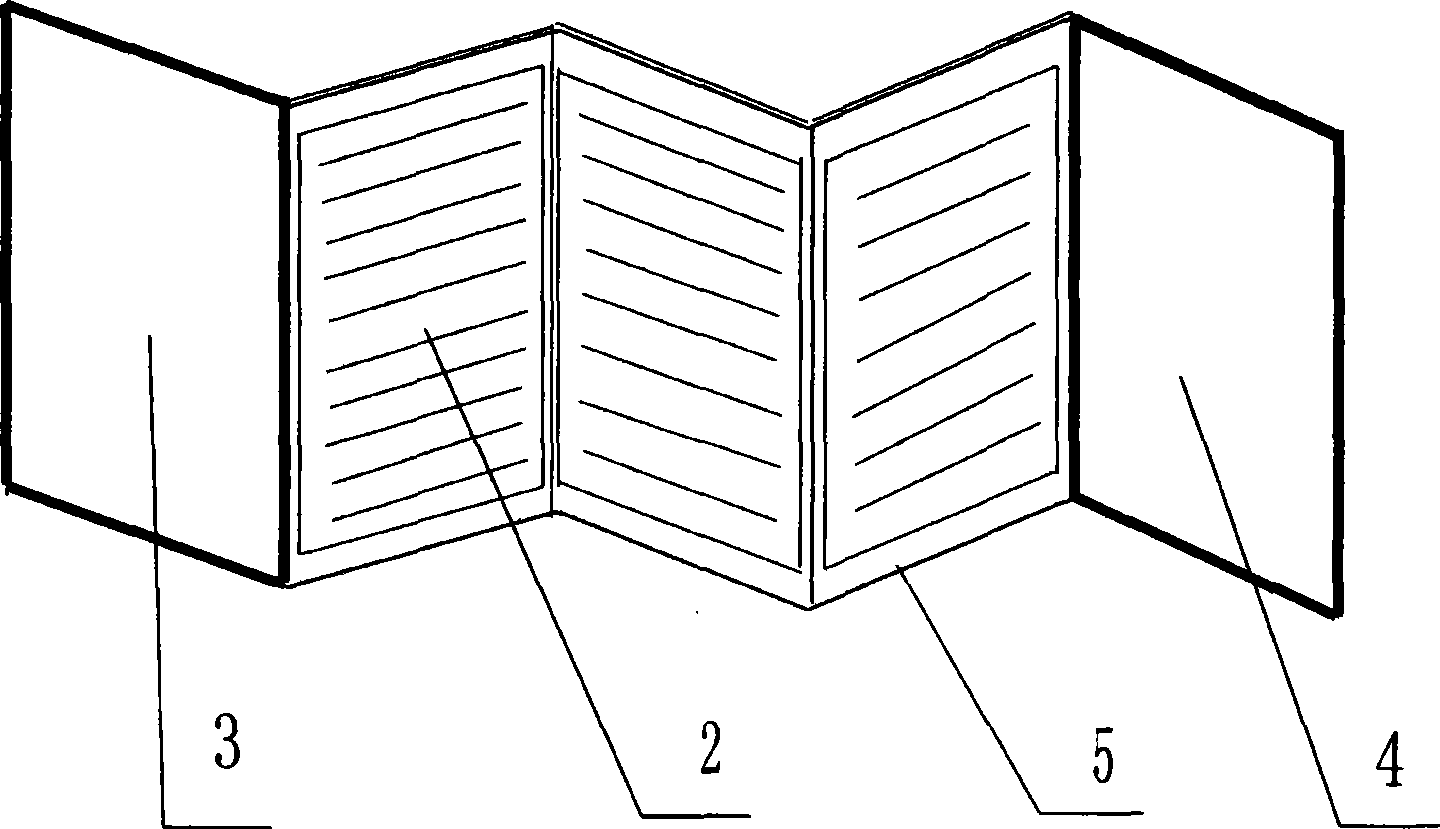

Card list with folding interleaf

The invention discloses a folding interleaf card album, which comprises a folding rectangle interleaf layer, a cover and a back cover, wherein the folding rectangle interleaf layer is formed by folding a plurality of continuously connected single-page small rectangle interleaves in an organ type; each single-page small rectangle interleaf has a hollow cavity which is provided with an opening and has a double-layer or three-layer transparent structure, and a card with a corresponding size to the hollow cavity can be put into the hollow cavity from the opening; and the card can be printed with knowledge or information contents in advance, and also can be blank to be used for recording important knowledge or information contents in learning, life and work at any moment. The album has the advantages of easy carrying, fewer drapes and easy unfolding and page turning; and the information contents can be renewed at random, and the cards can be classified, filed and stored according to different information contents, or can be used continually or discarded after using. The album is portable, so that a user can learn and remember multiple kinds of knowledge or record various important information contents at any moment in daily life and work by making use of spare time at ordinary times.

Owner:邢庆龙

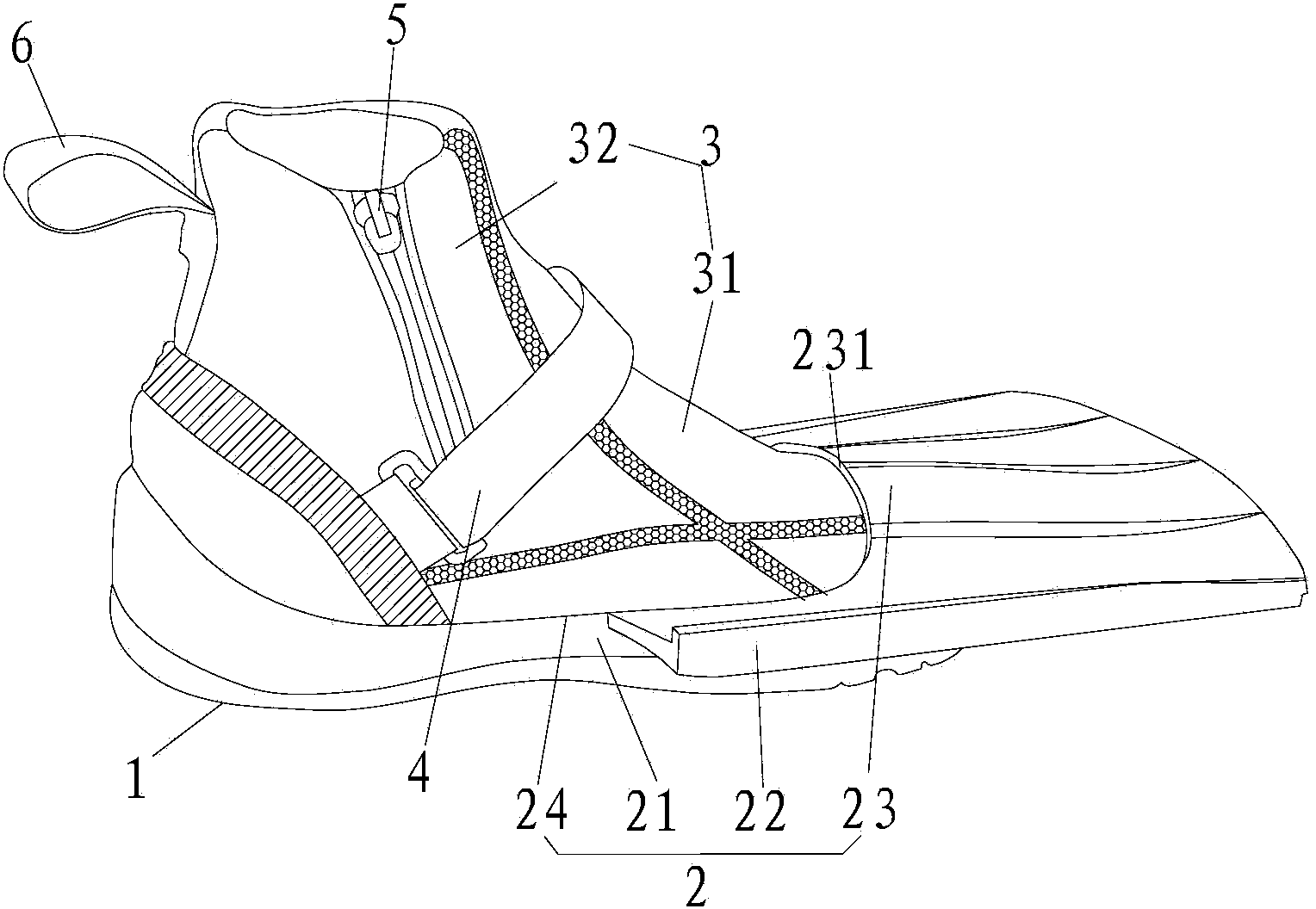

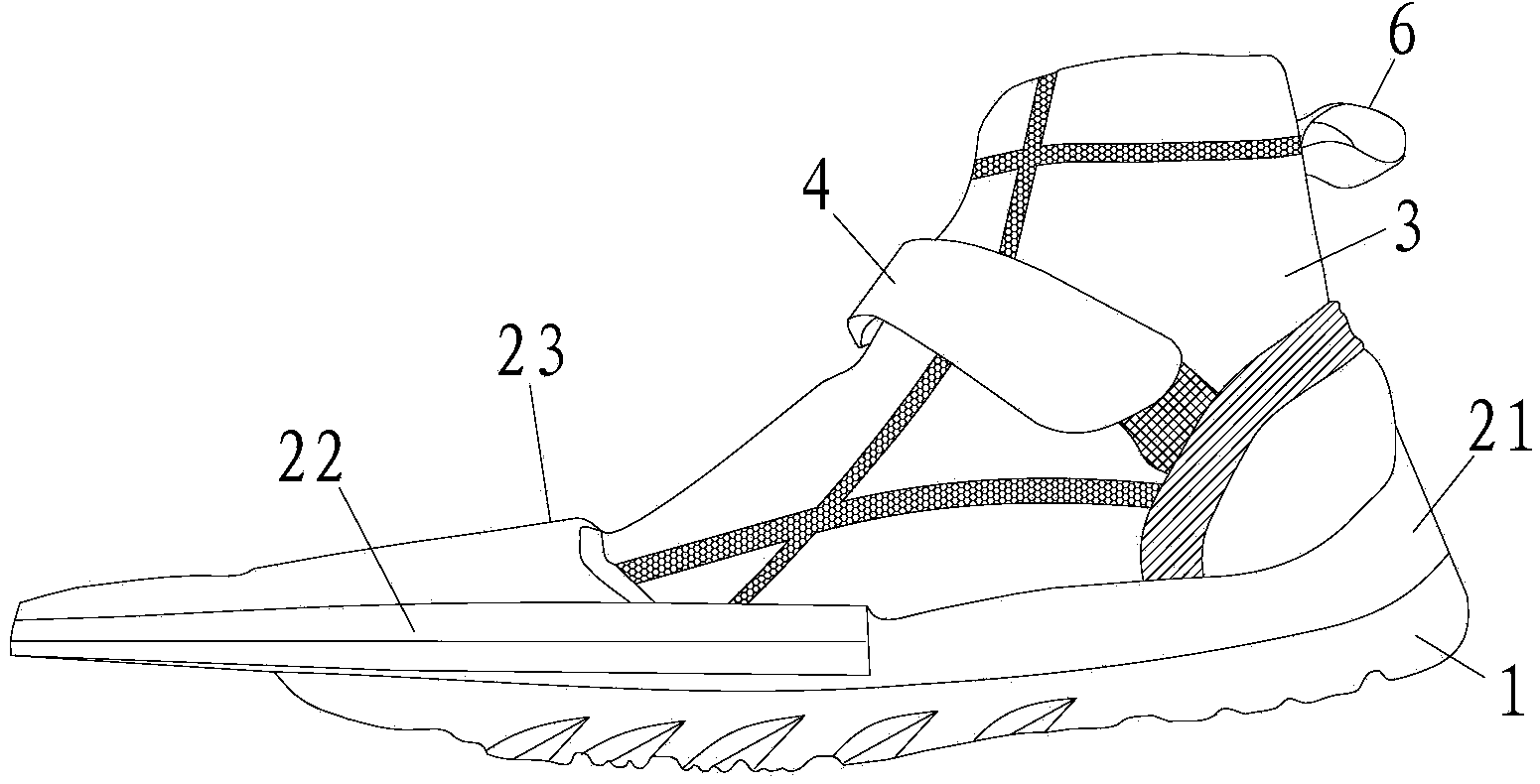

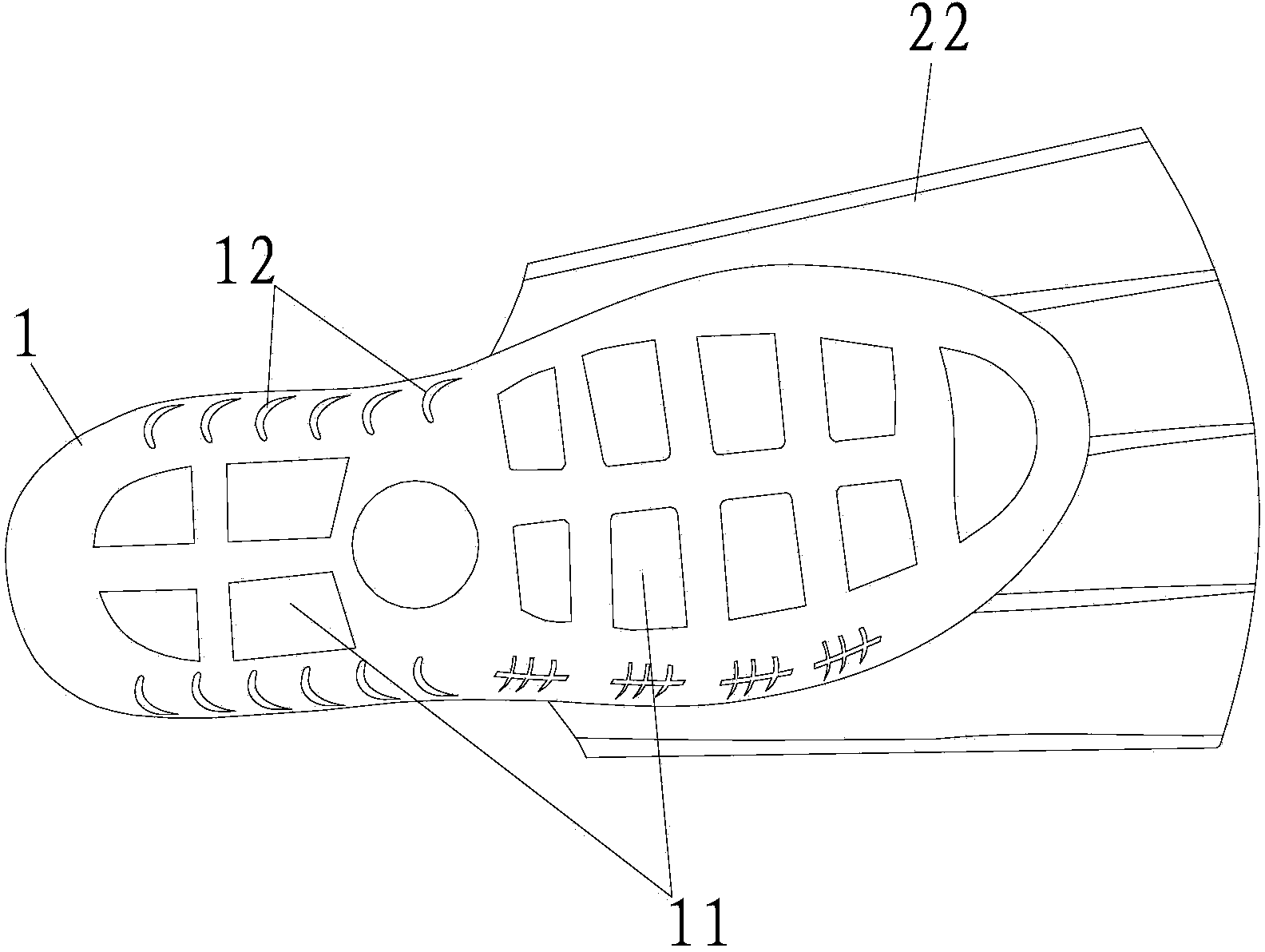

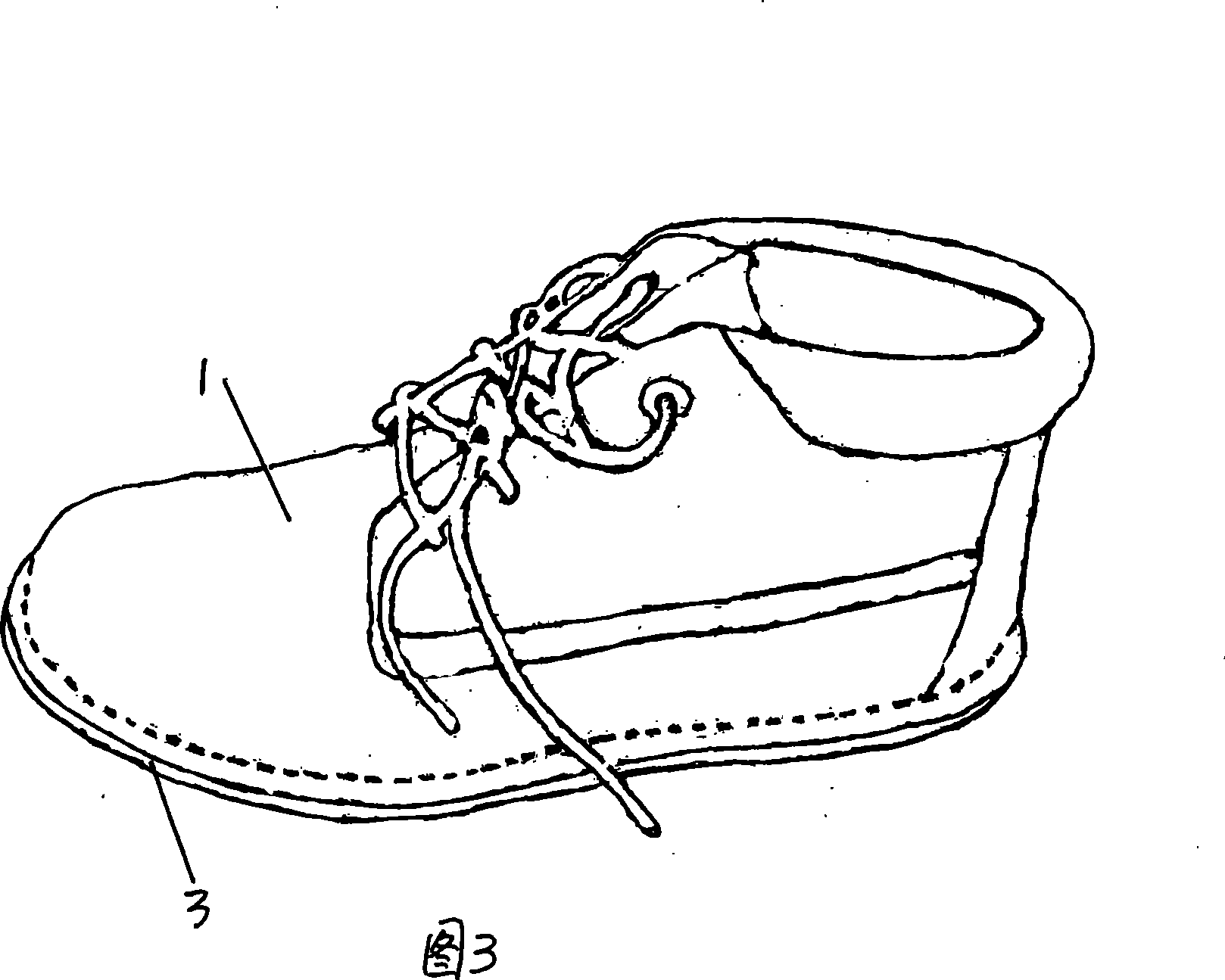

Flippers

The invention discloses a pair of flippers. Each flipper comprises an outsole, a mid-sole and a shoe vamp which are arranged in sequence from bottom to top, wherein the shape and the size of the outsole are matched with those of a foot of a human body; the outsole is a rubber outsole made of rubber; the mid-sole comprises a supporting part matched with the outsole in shape and size and a web-shaped swimming part outwards extending along the edge of the foot sole part of the supporting part; the mid-sole is a polyurethane mid-sole made of polyurethane; the shoe vamp is formed by stitching a diving suit fabric; the mid-sole is integrally formed by the polyurethane by an upper connection injection molding technology and is integrally connected with the shoe vamp and the outsole respectively in the upper connection injection molding process; a containing cavity for containing the whole foot of the human body is formed between the supporting part of the mid-sole and the shoe vamp. The invention discloses the flippers which are simple in structure and convenient to use; the flippers can be used during diving and walking on the land and have the characteristics of softness, durability, shock absorption, slippage resistant and wearing comfortability.

Owner:广州市宏来鞋业有限公司

Regenerated fiber blended knitted fabric and preparation method thereof

The invention provides a regenerated fiber blended knitted fabric and a preparation method thereof. Blended yarn includes, by mass, 35% of regenerated cotton fiber and 65% of regenerated polyester fiber, the transverse density of the knitted fabric is 71 / 10 cm, and the longitudinal density of the knitted fabric is 39 / 10 cm. Therefore, the regenerated fiber blended knitted fabric has the advantagesof cotton and terylene, is full and soft in hand feeling, good in air permeability, excellent in elasticity and wear resistance under dry and wet conditions, good in stiffness and shape retention property and not easy to wrinkle and can be rapidly dried and free of ironing after washing, waste turns into treasure, the production cost is reduced, and the short supply of natural fibers is made up for. Besides, the regenerated fiber blended knitted fabric prepared by the preparation method is detected according to the relevant standards, the detection result shows that the developed product is free of formaldehyde and has good environmental protection characteristics; the color fastness to washing and the fastness to rubbing of the fabric are higher than the standards, the production processof the product is feasible, and the product quality and functions can reach the advanced level in China.

Owner:JIANGYIN XIANGFEI APPAREL

Method for hydraulic forming of tee pipe using teflon film local lubrication

ActiveCN107020315AImprove the lubrication effectReduce cleaning costsShaping toolsEngineeringLubrication

The invention discloses a method for hydraulic forming of a tee pipe using teflon film local lubrication. A rectangular teflon film is designed according to the diameter of a pipe billet and the diameter of a tee pipe branch pipe, the center portion, where the tee pipe branch pipe is to be formed, of the pipe billet is symmetrically wrapped with the teflon film to replace the mode that the outside of the entire pipe is coated with oily lubricant or completely wrapped with lubricating fluid in the prior art, and thus operation is made more convenient. Moreover, in the forming process, the branch pipe position can be better lubricated, materials can flow into a branch pipe mold cavity quickly, and fracturing caused by insufficient supplementing of the branch pipe forming materials is avoided. Meanwhile, due to the fact that the back portion of the branch pipe is not wrapped with a thin film, friction is large, the material flowing speed is low, and wrinkling cannot happen easily.

Owner:NANCHANG HANGKONG UNIVERSITY

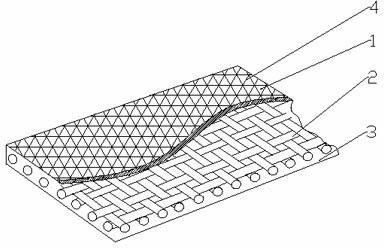

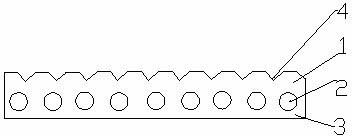

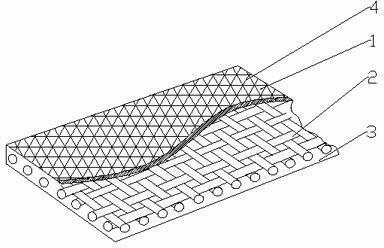

Fresh-keeping separating layer cyclically used in rubber tyre manufacturing

InactiveCN102602016AReduce manufacturing costSolving Recycling ProblemsTyresSurface layerSingle fiber

The invention relates to a fresh-keeping material used in a fresh-keeping technology in rubber tyre manufacturing. The material comprises two plastic surface layers, and one plastic fiber woven net positioned between the two plastic surface layers. The plastic surface layers are prepared by using a tape-casting method. When the plastic surface layers are cured, the plastic fiber woven net is subject to one-step hot pressing composition, such that the fresh-keeping material is obtained. A single-fiber cross-section of the plastic fiber woven net is round, and has a diameter of 0.05-0.35mm. Vertical and horizontal center-to-center spacings between the single fibers are 10-35 times the diameter of the single fiber. Because the single fibers of the plastic fiber woven net is processed through a single-direction stretching treatment, and the cross sections of the single fibers are round, a fresh-keeping separating layer with the plastic fiber woven net has high tensile strength. With the technical scheme provided by the invention, the tensile strength of the fresh-keeping separating layer is improved, and the elongation rate is reduced. The fresh-keeping separating layer is advantaged in that: after hot-pressing curing, the structure of the fresh-keeping separating layer is firm, and the fresh-keeping separating layer is prevented from stretching, deformation, or damage. Also, waste recovery can easily be carried out. The thickness of the fresh-keeping separating layer is 0.2-1mm.

Owner:卢建忠 +1

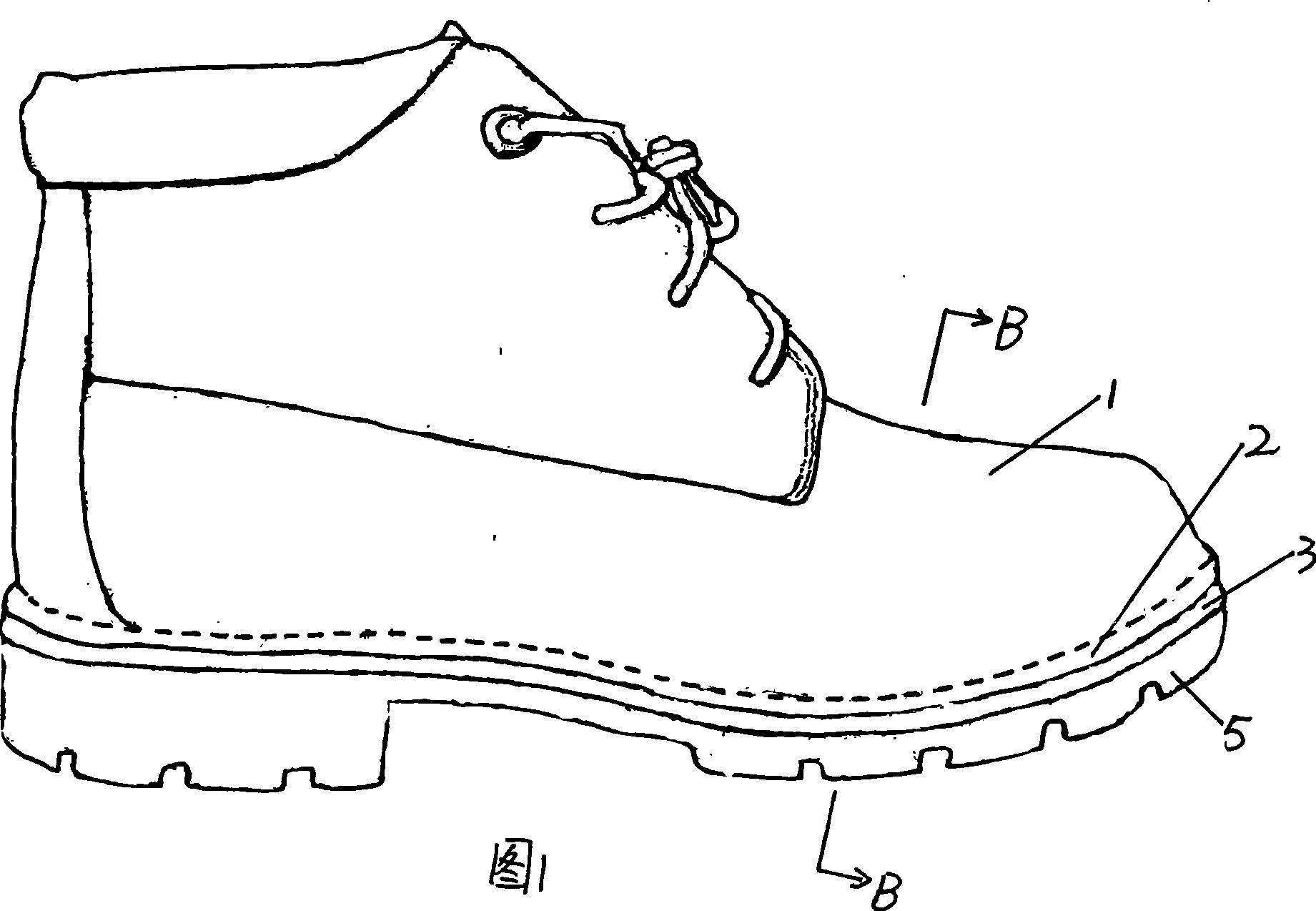

Last type leather welt sandals turning-outwards shoes, manufacture method thereof and special last pushing seat

The invention discloses a put-on last leather welt stitch-down shoe which comprises a vamp, a stitch-down edge formed by stitching down the edge of the lower end of the vamp, a leather midsole stitched with the underside of the stitch-down edge, an outsole adhered to the underside of the leather midsole, a midsole enclosed in the leather midsole, and a leather welt which can be stitched with the stitch-down edge of the vamp and is fixed and adhered to the edge of the midsole. A making method of the shoe comprises the following steps: A. molding a toe cap; B. stitching the midsole and the leather welt to form a combination leather midsole; C. adhering the stitch-down edge 10mm from the vamp state foot to the outside edge of the leather midsole in flush, and fixedly connecting the stitch-down edge of the vamp and the leather midsole into a whole body by an outside welt stitching; D. steaming the vamp to be soft, put-on last, and pushing the last with a last pushing seat; E. removing the last; F. adhering the outsole and pressing sole; G. finely grinding the edge; and H. cleaning up. The put-on last stitch-down shoe is softer, lighter and more convenient with less cost. The leather midsole in the method is formed by stitching the genuine leather midsole and the leather welt, thus the leather midsole is softer and lighter than the existing midsoles and has lower cost.

Owner:GOLDEN CHANG INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com