Patents

Literature

119results about How to "Soft and plump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of coating fabrics with high-peneration and waterproofing functions

InactiveCN1940174AImprove waterproof performanceGood moisture permeabilityTextiles and paperSocial benefitsOrganic solvent

This invention was a public high permeability high waterproof coating fabrics manufacturing methods, including polyurethane polymer, an organic solvent, allocation of water, as agent, crosslinking agents, other agents, water mixed into a fabric coating agents will be made of fabric coated with the coating in uniform as coating on the fabric, Fabric coating agent had dried occasion of the coating for drying processing steps. The invention manufactured coated fabric is not only an excellent waterproof and good moisture permeability but also has good rubbing sex and the feeling of fullness soft features. Product hydrostatic pressure 5000mm H2O over Al permeability to 8000g / m2 . 24hr above Tolerance washing and rubbing. Such coated fabric has broad prospects for sales, which can be used to produce rainwear, breathable, ski clothes, cool suits. Have greater economic and social benefits.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Watersoluble coating glue containing multiple coating modified poly-ammonium phosphate and uses on textile finishing

The invention discloses an aqueous coating adhesive containing multiple coating modified ammonium polyphosphate and applications thereof on fabric finishing. The single modified ammonium polyphosphate can not acquire excellent wash-resisting, immersion-resisting and durable fire retardant performance from the fabric, and can not even obtain dry and comfortable hand feeling. The invention is characterized in that the ammonium polyphosphate, which is modified by melamine, single silane or epoxy resin, is subjected to heating and backflow in an organic alcohol-like solvent, a silane coupling agent capable of being bonded with active groups in the modified ammonium polyphosphate is then added so that the surface of the ammonium polyphosphate experiences multilayer coating and has active hydrogen; the coated ammonium polyphosphate is added with a nonionic surfactant, water, a binder and aqueous closed polyurethane, the aqueous coating adhesive containing the multiple coating modified ammonium polyphosphate is obtained by means of dispersed grinding. The invention is coated on terylene or pure cotton fabrics, thus realizing the cross-linked film forming of the ammonium polyphosphate and the aqueous closed polyurethane and the aqueous binder, and obtaining waterproof and durable environmentally-friendly fire retardant coating fabric.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +1

Preparation method of solvent-free sofa furniture microfiber synthetic leather

InactiveCN106381721AStrong leather effectResistant to hydrolysisFurniture partsPolyurea/polyurethane coatingsCarbon compositesSurface layer

The invention discloses a preparation method of solvent-free sofa furniture microfiber synthetic leather, and is characterized in that an environmental-protection type polyether polymeric carbon composite type polyurethane resin is selected as a dry surface layer and a middle layer, a solvent-free layer is a foaming adhesive layer, a microfiber cloth base cloth pasted by a whole dry process and having good hand feeling and high chemical properties is selected for preparing the environmental-protection type sofa furniture leather having the excellent properties of strong real leather effect feeling, three-dimensional and full pattern, abrasion resistance, scratch resistance, hydrolysis resistance and the like; the solvent-free foaming layer is two-liquid type double-compound polyurethane and is composed of an isocyanate A component and a polyether polyol B component. The prepared solvent-free environmental-protection type sofa furniture leather has the advantages of simple leather preparation process, high efficiency and environmental protection, also has the characteristics of strong real leather effect feeling, three-dimensional and full pattern, full and soft hand feeling, wear resistance (wyzenbeek 400 thousand times), scratch resistance, hydrolysis resistance (8 years) and other high physical properties.

Owner:ANHUI ANLI MATERIAL TECH

Method for preparing abrasion-resistance high-hydrolysis-resistance negative-pressure texture-absorbing molded solvent-free polyurethane synthetic leather

The invention discloses a method for preparing abrasion-resistance high-hydrolysis-resistance negative-pressure texture-absorbing molded solvent-free polyurethane synthetic leather. The synthetic leather is prepared by selecting abrasion-resistance scraping-resistance closed high-solid-content poly-carbon type polyurethane resin as a dry-method surface layer and high-hydrolysis-resistance solvent-free polyurethane resin as a foaming layer through low-pressure pouring equipment and adhering to a cloth base; and molding textures of the synthetic leather by adopting a negative pressure texture absorbing process. The negative-pressure texture-absorbing molded solvent-free polyurethane synthetic leather has the characteristics of efficient and environment-friendly preparation process, no DMF, strong texture solid feeling, plump and soft hand feeling, excellent genuine leather effect, abrasion resistance (Valspar is 0.3 million times), super hydrolysis resistance (8-12 years) and other highphysical performances.

Owner:ANHUI ANLI MATERIAL TECH

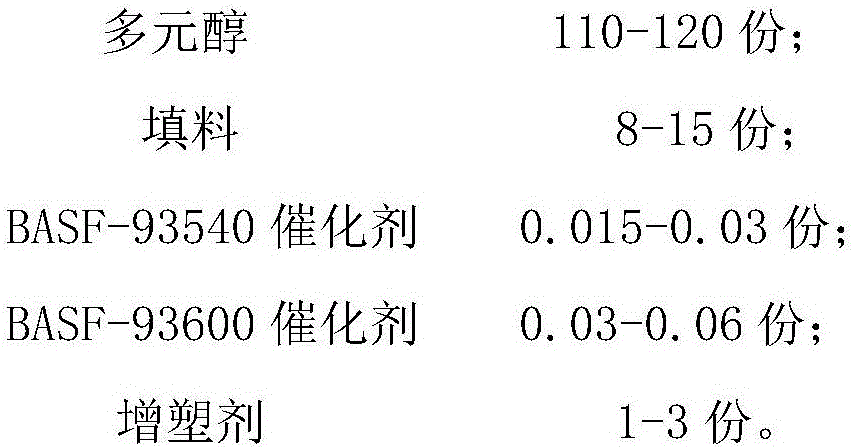

Solvent-free polyurethane resin used for sofa leather middle foaming layer and preparation method thereof

The invention discloses solvent-free polyurethane resin used for a sofa leather middle foaming layer and a preparation method thereof. The solvent-free polyurethane resin is formed by mixing componentA and component B according to the mass ratio of (1: 2) to (2: 1). The solvent-free polyurethane resin prepared in the invention does not contain any solvent, synthetic leather prepared as a middle layer is green, environmentally-friendly, soft and plump in hand feel, the physical performance can reach one hundred thousand times of bending at normal temperature without cracking, eighty thousand times of bending at the cold-resistant temperature of -10 DEG C without cracking, the peeling strength is more than 50 N / 3cm, and the retention rate of the peeling strength for 5 to 7 weeks under the constant temperature and humidity conditions of 70 DEG C and 95% humidity can reach 75%.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

Acrylic resin/SiO2 nano composite tanning agent and preparation method thereof

InactiveCN101240354ASoft and plumpImprove heat and humidity stabilityTanning treatmentAcrylic resinSolvent

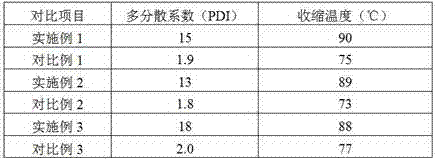

The invention relates to an acrylics / SiO2 nano-composite tanning agent. The nano-composite tanning agent appears to be light yellow or yellow semitransparent ropy liquid, the mass concentration is 20 to 35%, the viscosity is 500 to 1000MPa.s, the pH value is 5 to 8, and the storage stable period is over 12 months. With only 2% (relative to the leather weight) chromium powder, the nano-composite tanning agent can thicken the leather by 124.5%, the shrinkage temperature reaches to 95 DEG C.; compared with a chrome tanned leather, a leather tanned by the nano-composite tanning agent has a tensile strength, peeling strength and elongation at break improved by 51.8%, 8.2% and 13.3% respectively, has no obvious stratification or sedimentation during over 12 months of storage period. Water is used as solvent when prepared, which is low-cost and pollution-free; the preparing technology is simple, the reaction is mild, the polymerization process is easy to control, so that the nano-composite tanning agent is easy to realize industrial production, the synthesized material is inexpensive and easy to obtain as well.

Owner:HENAN UNIVERSITY

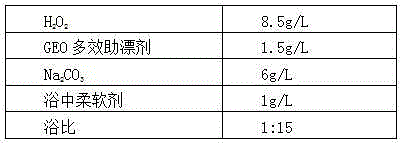

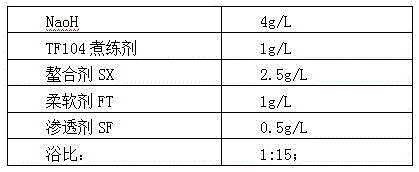

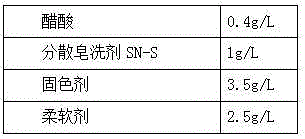

Energy and water saving dyeing method for seamless underwear

ActiveCN102561070AReduce residual rateHigh whitenessBiochemical fibre treatmentBleaching apparatusWater savingOxygen

The invention relates to an energy and water saving dyeing method for a seamless underwear. A seamless weft knitting weaving technology is used for achieving one-off weaving forming of the seamless underwear. The dyeing and finishing process of the seamless underwear after being woven includes oxygen bleaching by the liquor ratio of 1: 8-10, dyeing by the liquor ratio of 1: 12-15 and soaping by the liquor ratio of 1: 8-10. By means of the energy-saving dyeing and finishing technology of non-caustic-soda oxygen bleaching process, one-bath one-step dyeing process and biological enzyme soaping process, one-time accurate dyeing is achieved, one-bath one-step completion is achieved, processing time is shortened, and sewage discharge and treatment are reduced.

Owner:GUANGDONG RUIYUAN TECH

Synthetic method for preparing retanning agent of modified starch for leather

This is the method of preparing the modified starch-based retanning agent of leather. It oxidates and decomposes the starch, then react with vinyl monomer to polymerize. This retannage is used to leather cure of retanning, after retanning the leather feels soft and comfortable, exquisite surface, color uniformity, augment ply efficiently, no color withdraw. This chrome tanning can be used before retanning, and it can increase the absorption of the augmet, and decrease the quantity of chrome in the waste solution. The modified starch-based retanning agent of leather is a product valuable to environment protection, and has a significant mean of decreasing industrial pollution.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of knitted wool-like warm fabric

InactiveCN105332155AGood dissipationHigh pectinWeft knittingBiochemical fibre treatmentYarnPolymer science

The invention relates to a preparation method of a knitted wool-like warm fabric. The preparation method comprises the following steps: (1) raw material selection; (2) spinning technology implementation; (3) weaving technology implementation; (4) printing, dyeing and after-finishing. The knitted wool-like warm fabric is formed by performing the after-finishing, such as knitting, dyeing, carbon grinding and softening, on hemp / cotton / polypropylene fiber blended yarns and polyolefin elastic fibers, namely confirmable elastic fibers, which serve as raw materials. By the adoption of hemp, a product can realize antibacterial, health care and anti-ultraviolet functions; cotton fibers are high in hygroscopicity and spinnability; the polypropylene fibers are poor in heat conductance and high in heat insulation property; by the blending of the three types of fibers, a product has the functions of heat insulation, moisture absorption, breathing, bacteria prevention and ultraviolet resistance; by the weaving of the polyolefin elastic fibers, the product is extremely high in elasticity and conformality. The product is soft, fine, breathable, relaxing, high in heat retention property and suitable for making high-end warm coats or skirts, is a high-quality antibacterial, health care and warm fabric which has a wide market development prospect.

Owner:JIANGSU YDTEX GRP LTD

Anti-ultraviolet elastic fabric and production method thereof

InactiveCN101942736ASoft and plumpNon-irritatingFibre treatmentWoven fabricsExtensibilityUltraviolet

The invention discloses an anti-ultraviolet elastic fabric. Warp and weft yarns of the fabric at least comprise one full dull yarn, wherein the weft yarn at least comprises one elastic yarn; and the prepared finished product has weft extensibility of 5 to 30 percent and elastic recovery of over 80 percent, is comfortable to wear and has high size stability. The finished product has transmittance resistance of over 95 percent; the anti-ultraviolet UPF value is over 50; and the fabric has cool feel and a moisture absorption and fast drying function and is an ideal recreational material for autumn and summer.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Method for synthesizing high molecular retanning dyeing auxiliary agents through enzyme catalysis

InactiveCN101870990AImprove permeabilityImprove absorption rateTanning treatmentDyeing processSodium bicarbonateDye absorption

The invention relates to a method for synthesizing high molecular retanning dyeing auxiliary agents through enzyme catalysis, which comprises the following steps: dissolving p-aminobenzene sulfonic acid and 2, 3-dihydroxy naphthalene-6-sodium sulfonate into de-ionized water, using a sodium bicarbonate solution for regulating the pH value of the system, and finally, obtaining the retanning dyeing auxiliary agents through co-polymerization reaction carried out under the horse radish peroxidase (HRP) catalysis. The invention uses HRP as catalysts of the polymerization reaction, and the HRP has the advantages of high efficiency, high selectivity and environment protection when being used for catalyzing the polymerization. The invention has the advantages that phenols or arylamines can carry out polymerization in ortho positions or para positions of hydroxide groups and amino groups for forming a polymer with directly connected C-C structures and large pi conjugated systems, the formaldehyde pollution in the traditional synthesized retanning agents is avoided, and at the same time, the products with the conjugated systems contain a large number of auxochromic groups such as -NH2, -OH and -SO3H and the like. Retanning leather is full and soft, and the dye absorption rate is higher than 99 percent, and in addition, the retanning dyeing auxiliary agents have obvious dyeing aid effect.

Owner:SHAANXI UNIV OF SCI & TECH

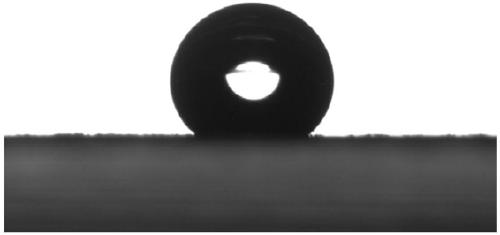

Preparation and application method for polyurethane modified acrylate water repellent

ActiveCN108978226AHigh bond strengthAvoid cold crispy hot stickyLiquid repellent fibresIsocyanateEmulsion

The invention discloses a preparation and application method for a polyurethane modified acrylate water repellent, and belongs to the technical field of macromolecules. According to the preparation and application method, an emulsion polymerization technology is adopted, diisocyanate, polymer dihydric alcohol and a hydrophilic chain extender are subjected to pre-polymerization and chain extension,an end-capping reagent is added for end-capping, then neutralization is carried out, water is added for emulsification, in the absence of an emulsifier, a product and an aliphatic acrylate monomer are subjected to copolymerization so as to prepare an anionic polyurethane modified acrylate composite emulsion, and the anionic polyurethane modified acrylate composite emulsion is used for textile finishing. The preparation and application method has the advantages that a long alkane chain endows fabric with the water repellent property, after the fabric is treated, a layer of water repellent filmis formed on the surface of the fabric, so that the water repellent capacity of the fabric is greatly improved, and polyurethane is added, the fabric can be endowed with the soft and full hand feeling; and in addition, the VOC emission amount is extremely low, and the method is suitable for environmental protection requirements.

Owner:高青如意纺织有限公司

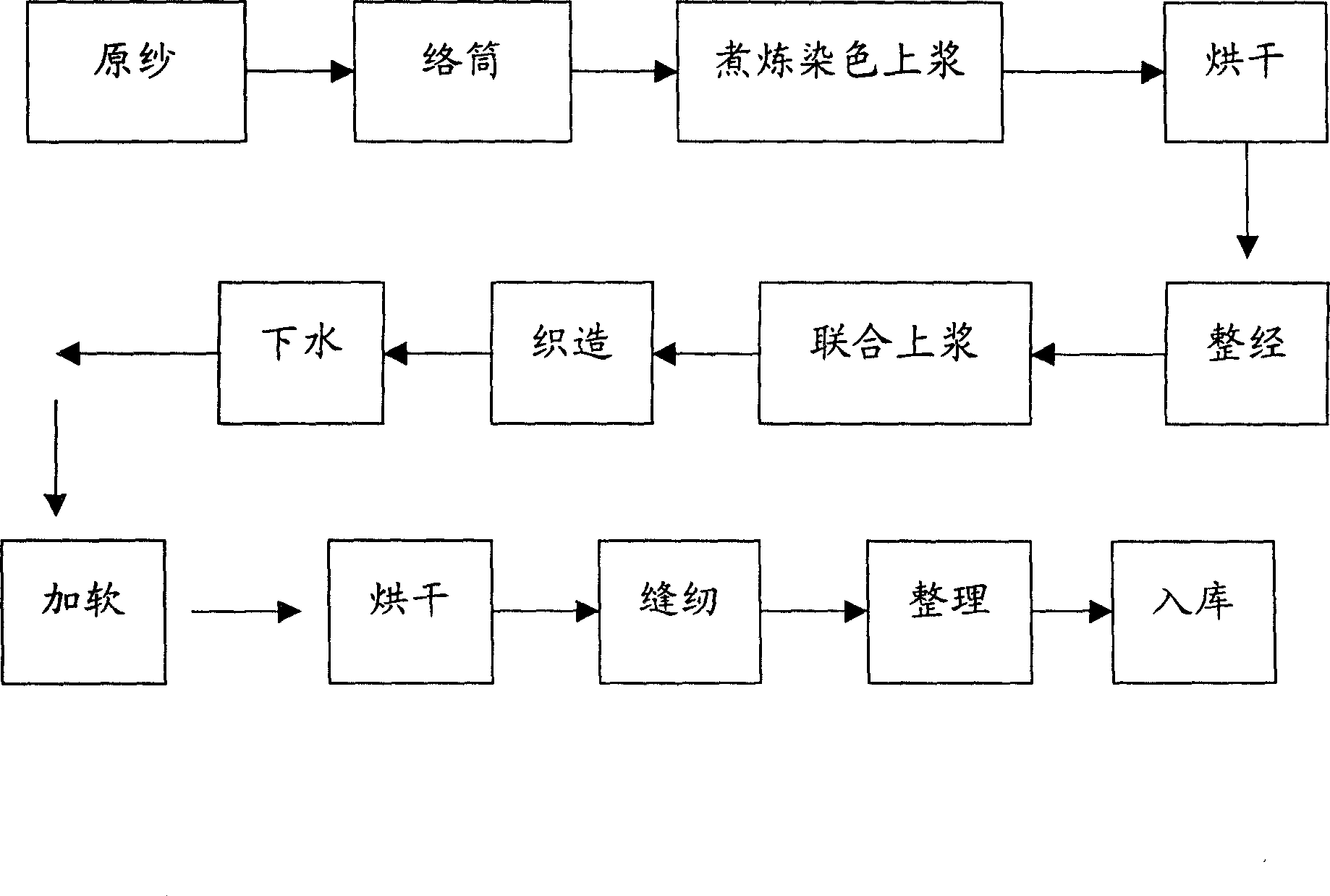

Low-count untwisted ultra-soft bath towel and manufacturing method thereof

InactiveCN101100780AHave healthSafeBathroom accessoriesWoven fabricsSofteningManufacturing engineering

The invention relates to low count zero twist super soft bath towel and manufacturing method. It includes the following steps: boiling rinsing; neutralizing; oxidizing; dying; soap boiling; ferment washing; softening. The product of the invention has the advantages of soft feel, health, safe, beautiful appearance etc.

Owner:SUNVIM GROUP

Method for preparing aldehyde-containing polyurethane-acrylate resin tanning agent

The invention relates to a method for preparing an aldehyde-containing polyurethane-acrylate resin tanning agent. The aldehyde-containing polyurethane-acrylate resin tanning agent is prepared from a polymerizable nonionic polyurethane oligomer and unsaturated aldehyde by carrying out radical copolymerization in distilled water. The tanning agent contains aldehyde group, can be combined with a covalent bond of hide collagen fibers, has obvious tanning function, can make leather obtain higher hydrothermal stability when reducing the use amount of a chrome tanning agent, has excellent selective filling property, can make the leather have soft and plump hand feeling and exquisite grain, can be assorted with the chrome tanning agent to use in the low pH value environment of chrom tanning and chrome retanning, is favorable to adsorption fixation of the chrome tanning agent, can obviously reduce content of chromium salt in chrom tanning liquid waste so as to greatly reduce pollution of the tanning liquid waste to the environment, is a novel multifunctional environment-friendly leather tanning material and is suitable for tanning processing of sofa leather, instep leather, clothing leather and the like.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Regenerated fiber blended knitted fabric and preparation method thereof

The invention provides a regenerated fiber blended knitted fabric and a preparation method thereof. Blended yarn includes, by mass, 35% of regenerated cotton fiber and 65% of regenerated polyester fiber, the transverse density of the knitted fabric is 71 / 10 cm, and the longitudinal density of the knitted fabric is 39 / 10 cm. Therefore, the regenerated fiber blended knitted fabric has the advantagesof cotton and terylene, is full and soft in hand feeling, good in air permeability, excellent in elasticity and wear resistance under dry and wet conditions, good in stiffness and shape retention property and not easy to wrinkle and can be rapidly dried and free of ironing after washing, waste turns into treasure, the production cost is reduced, and the short supply of natural fibers is made up for. Besides, the regenerated fiber blended knitted fabric prepared by the preparation method is detected according to the relevant standards, the detection result shows that the developed product is free of formaldehyde and has good environmental protection characteristics; the color fastness to washing and the fastness to rubbing of the fabric are higher than the standards, the production processof the product is feasible, and the product quality and functions can reach the advanced level in China.

Owner:JIANGYIN XIANGFEI APPAREL

Preparation method of modified casein for leather finishing

The invention discloses a preparation method of modified casein for leather finishing. The preparation method comprises the following steps: adding part of boiled water into a reaction kettle, and adding ammonia water, casein, TX-10 and Turkey red oil; adding part of caprolactam assistant 1 into part of boiled water; adding the rest caprolactam assistant 2 into part of boiled water; adding ammonium persulfate assistant 3 into part of boiled water; adding a formula amount of sodium benzoate assistant 4 into part of boiled water; adding phenol assistant 5 into part of boiled water; adding the assistant 1, the assistant 3 and glycol into the reaction kettle; dripping the assistant 2 into the reaction kettle, and slowly heating; adding the assistant 4, the assistant 5 and glycerol into the reaction kettle; and stirring, and then, discharging. The modified casein prepared by the invention has the advantages of bright coating, high-temperature ironing resistance and the like, is suitable for polishing, and is used for surface finishing of light leather to enable the light leather to have the characteristics of full and soft hand feeling, good elasticity, cold resistance, strong bonding force, good water resistance and the like.

Owner:刘连生

Velvety composite filament wash-faded plus material

InactiveCN102605632ASoft and plumpUniform and stable sanding on the surfaceRougheningFiberWater based

The invention discloses a velvety composite filament wash-faded plus material. The plus material comprises a bottom fabric layer consisting of polyester and nylon composite fibers and cotton fibers, and a wash-faded layer coated on the surface of the bottom fabric layer, wherein the wash-faded layer is formed by scraping a layer of wash-faded slurry on the surface of the bottom fabric layer; and the wash-faded slurry is prepared by the following components in parts by weight: 10 parts of water-base resin, 90 parts of water, 2.5 parts of PTF thickening agent, 0 to 0.3 part of poly aziridine crosslinking agent, 0.2 to 0.3 part of organic silicon flatting agent, 0.1 to 0.2 part of polyether defoamer and 3 to 6 parts of water-based environment-friendly color paste. The plus material has a soft, plump and compact hand feeling; the surface has uniform, stable, velvety and comfortable fluff condition, and has high moisture permeability; simultaneously, by combining with a wash-faded style, the composite filament plus material is environment-friendly and non-toxic; moreover, the wash-faded effect is uniform, durable and stable; and the plus material has rinsing and scrubbing resistance, and cannot be whitened and misted after being washed for a plurality of times.

Owner:HUAHAN QUANZHOU NEW FABRIC DEV

Secondary recycling method of pigskin chrome-free combination tannage waste liquid

InactiveCN102312023AIncrease delayAvoid reduced absorptionHeat recovery systemsTanning treatmentPulp and paper industryWaste management

The invention discloses a secondary recycling method of pigskin chrome-free combination tannage waste liquid, comprising the following steps: using a vegetable tanning agent to carrying out penetration and tanning, after finishing the balance, discharging the solution; adding glutaraldehyde in tanning, collecting the waste solution, when the second batch of tanning begins, adding the first waste solution and supplementing the vegetable tanning agent, discarding after the tanning; and then adding aldehyde-containing waste liquid recycled by the first time and supplementing aldehyde for tanning, after the tanning, discharging the tanning solution. So, a circulation is finished, and a pollution discharge is reduced. According to the invention, the combination of the vegetable tanning agent and the aldehyde tanning agent are used for carrying out respective tanning on rawhide, each tanning agent is used for tanning according to certain proportion and order, and the two tanning agent form a cooperative effect, the shrinkage temperature can reach more than 90 DEG C, the produced leather presents light yellow without dying, is soft and full hand feel and very good elasticity, and has good aging resistance, sweat resistance, and flame retardation performance. The invention provides a new approach for present industrial production of chrome-free-tanned leather of tannery.

Owner:温州复亿实业有限公司

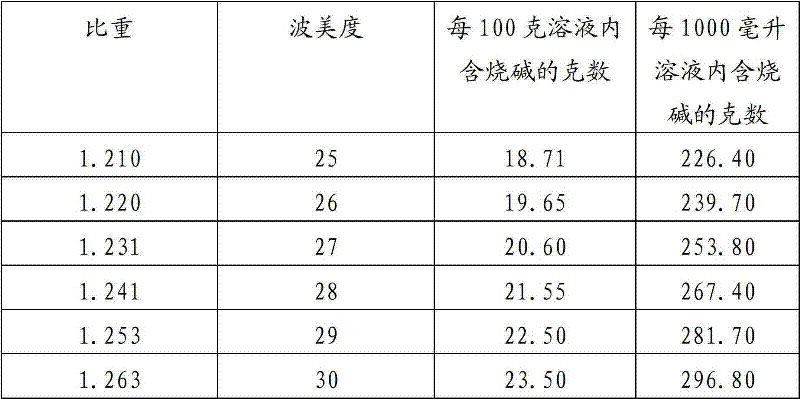

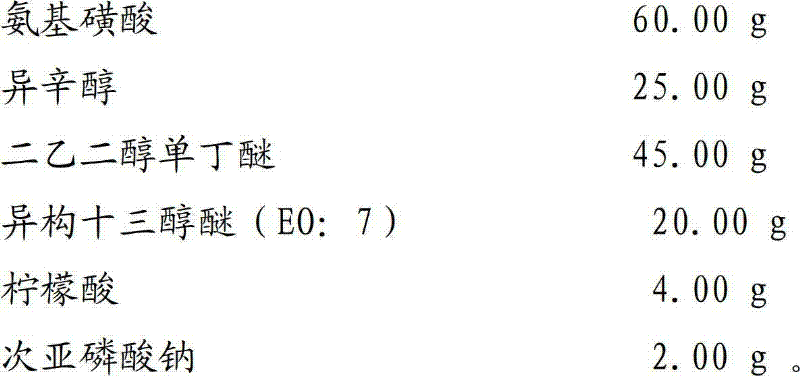

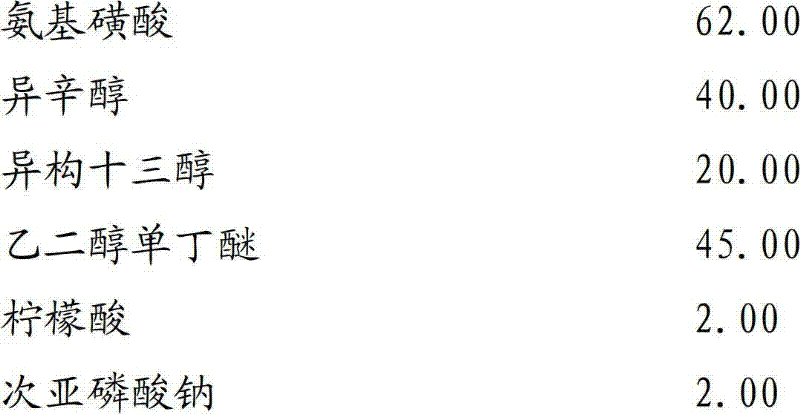

Alkali-resisting penetrating agent for cotton fabric mercerization

InactiveCN102653921AGood dimensional stabilitySoft and plumpVegetal fibresInorganic saltsAqueous sodium hydroxide

The invention relates to an alkali-resisting penetrating agent for cotton fabric mercerization. The penetrating agent is characterized by comprising the following ingredients in parts by weight: 60-100 parts of sulfamic acid, 25-80 parts of fatty alcohol, 45-150 parts of (EO:7-10) fatty alcohol ether and 2-45 parts of catalyst. A preparation method of the alkali-resisting penetrating agent comprises the following steps: putting the fatty alcohol and the fatty alcohol ether in proportion into a three-opening bottle of 500ml, starting stirring, adding the catalyst and the sulfamic acid, powering on a condenser for backflow, heating to 120 DEG C, performing heat preservation for 120 minutes, adding 100 parts of soft water slowly when the temperature is less than 100 DEG C, and stirring uniformly and subsequently regulating the pH value to 8-8.5 by use of a sodium hydroxide water solution. The alkali-resisting penetrating agent provided by the invention has the beneficial effects that the investment is less, three wastes (waste air, waste water and industrial residual) are prevented, the product is low in color, and the inorganic salt content is low.

Owner:天津达一琦精细化工有限公司

Eight-woof single-face plain cloth jacquard weave double-layer towel set and manufacturing method thereof

InactiveCN101100779AStable clampingBeautiful appearanceDomestic applicationsWoven fabricsEngineeringSoftening

The invention relates to eight-weft single side plain cloth pattern double layer covering cloth and manufacturing method. It includes the following steps: boiling-off; dying; starching; drying; beaming; bonding starching; weaving; softening; drying; sewing; collating; storing. The product of the invention has the advantages of soft feel, strong stereo sensation, standard formaldehyde content and pH value etc.

Owner:SUNVIM GROUP

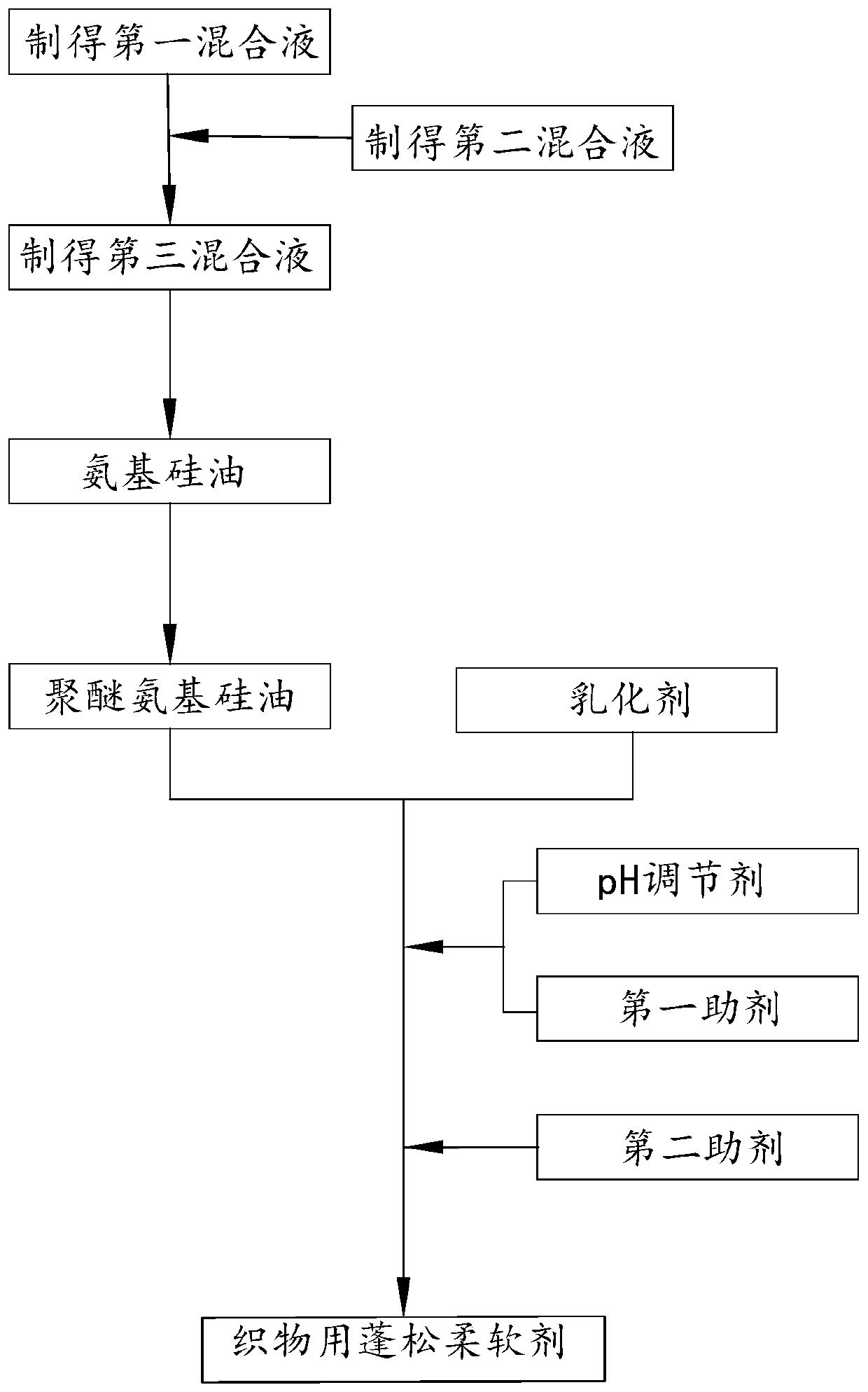

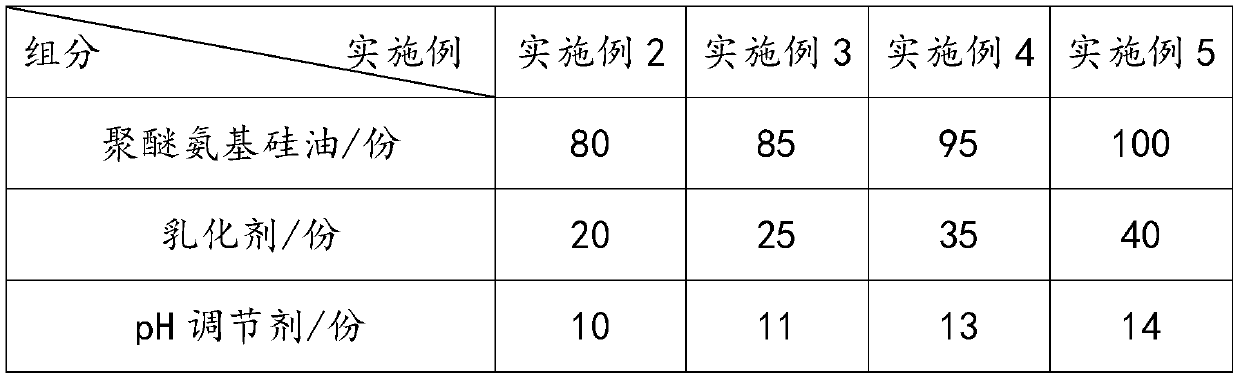

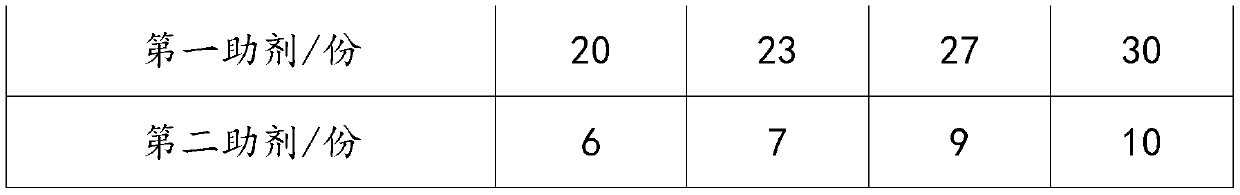

Fluffy softening agent for fabric and preparation method thereof

InactiveCN110184822AFluffy softener, used to improve the fluffy softness of polyether silicone oilImprove hydrophilicityStain/soil resistant fibresBiochemical fibre treatmentEpoxyEther

The invention relates to a fluffy softening agent for a fabric and a preparation method thereof, and relates to the technical field of textile auxiliaries. The softening agent is prepared from, by weight, 80-100 parts of polyether aminopolysiloxane oil, 20-40 parts of an emulsifying agent and 10-14 parts of a pH regulator; the polyethe aminopolysiloxane oil is prepared from, by weight, 30-34% of amino silicon oil, 20-24% of allyl polyoxyethylene propene epoxy ether, 10-14% of allyl polyoxyethylene polyoxypropylene amine ether, 8-12% of methyl hexafluorobutyl acrylate, 10-14% of glycidyl dodecyl dimethyl ammonium chloride and 10-14% of isopropanol. By mixing the polyether aminopolysiloxane oil, the emulsifying agent and the pH regulator, the fluffy softening agent for the fabric is obtainedfor improving the fluffy softness of polyether silicone oil.

Owner:绍兴柯桥欧利助剂有限公司

Method for synthesizing retanning agent modified by starch in use for leather

A composition method for a modified starch retuning agent used in leather is to oxidize and degrade the starch and then to be reacted with vinyl monomers in graft copolymerization reaction to finish the production, the retanned leather is plentiful and soft, if it is used before chrome tannage, then the absorption rate is increased obviously in chrome tannage so as to reduce the used level of Cr and it content in chrome tannage waste solution.

Owner:SHAANXI UNIV OF SCI & TECH

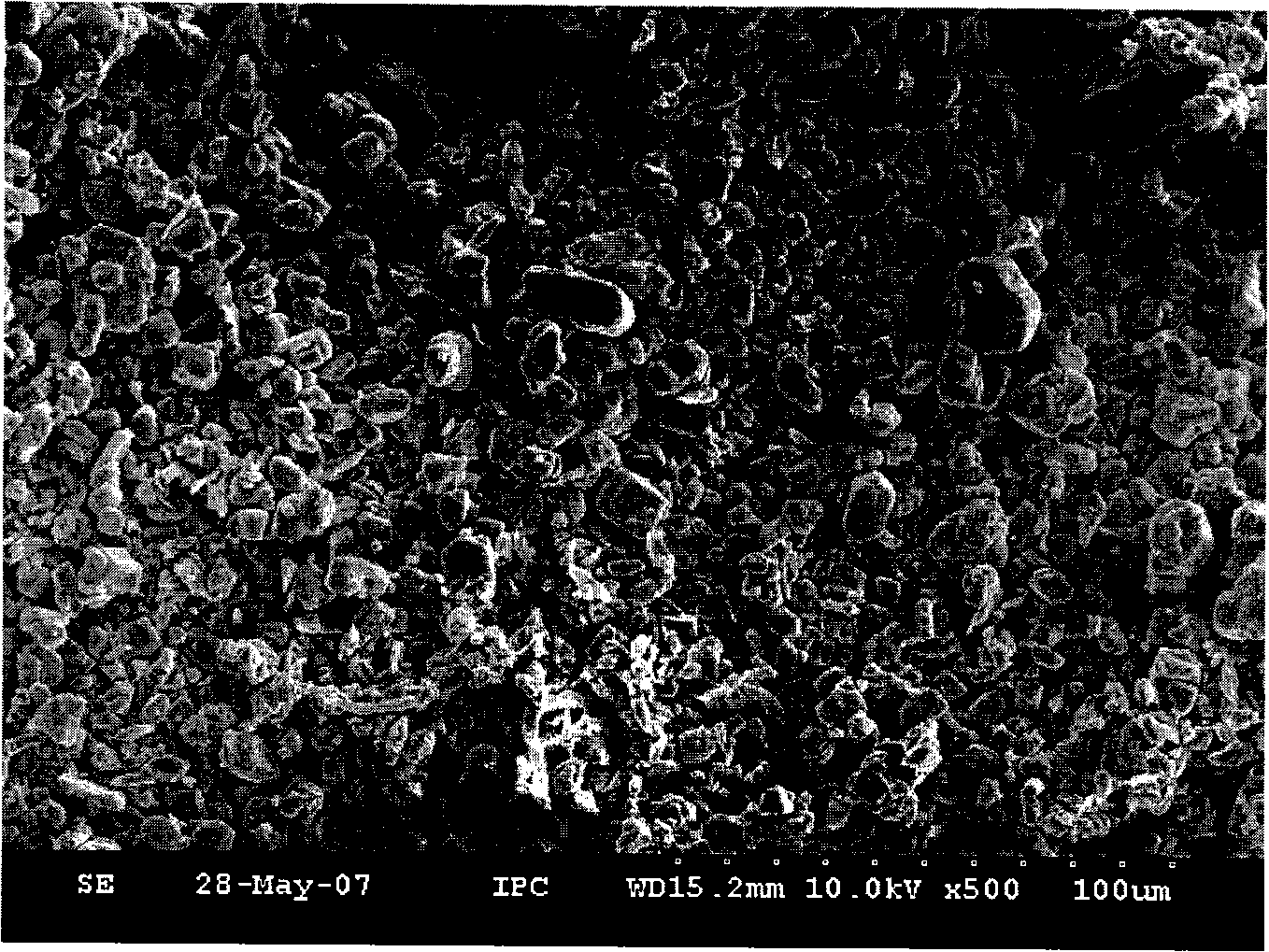

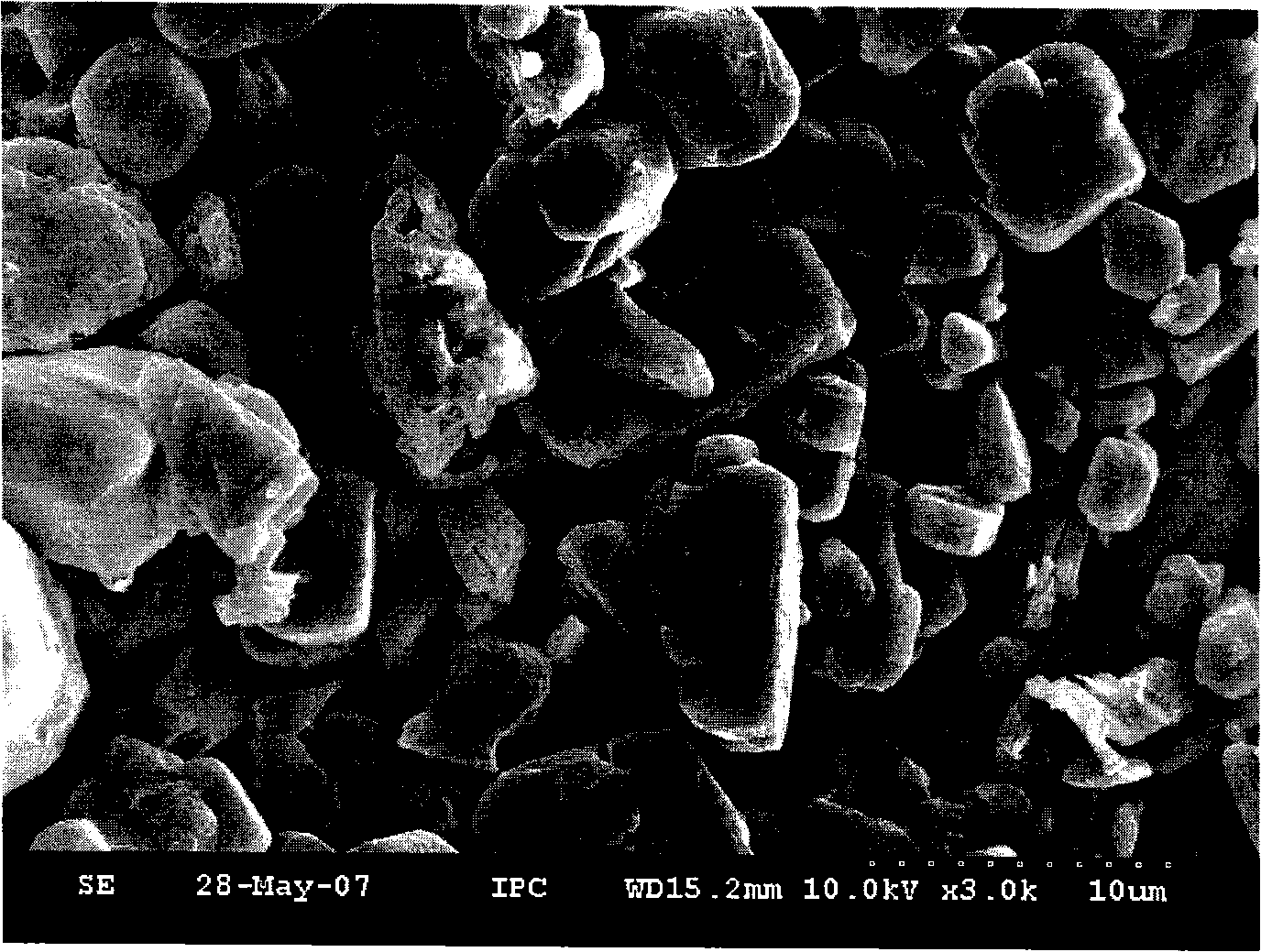

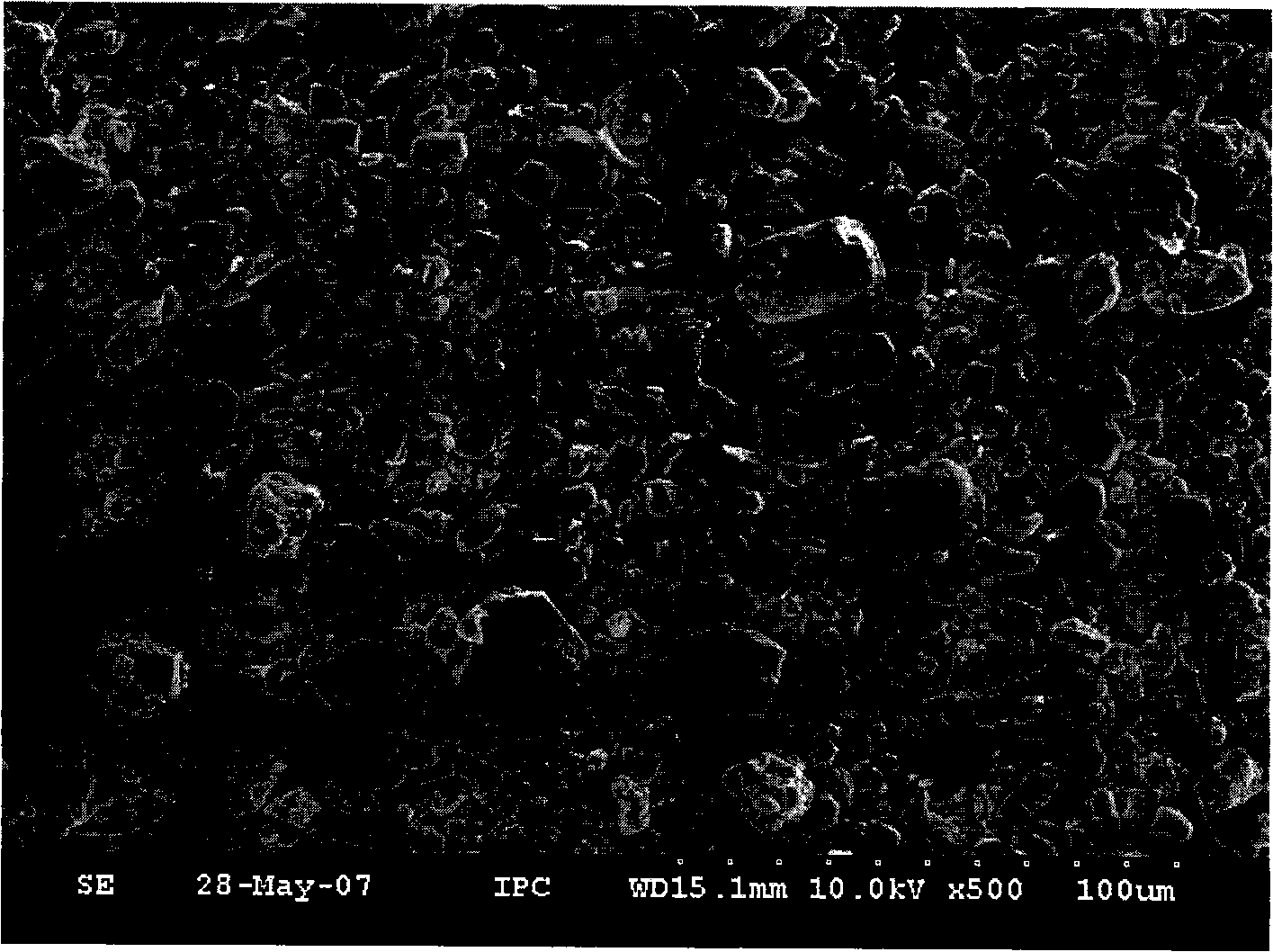

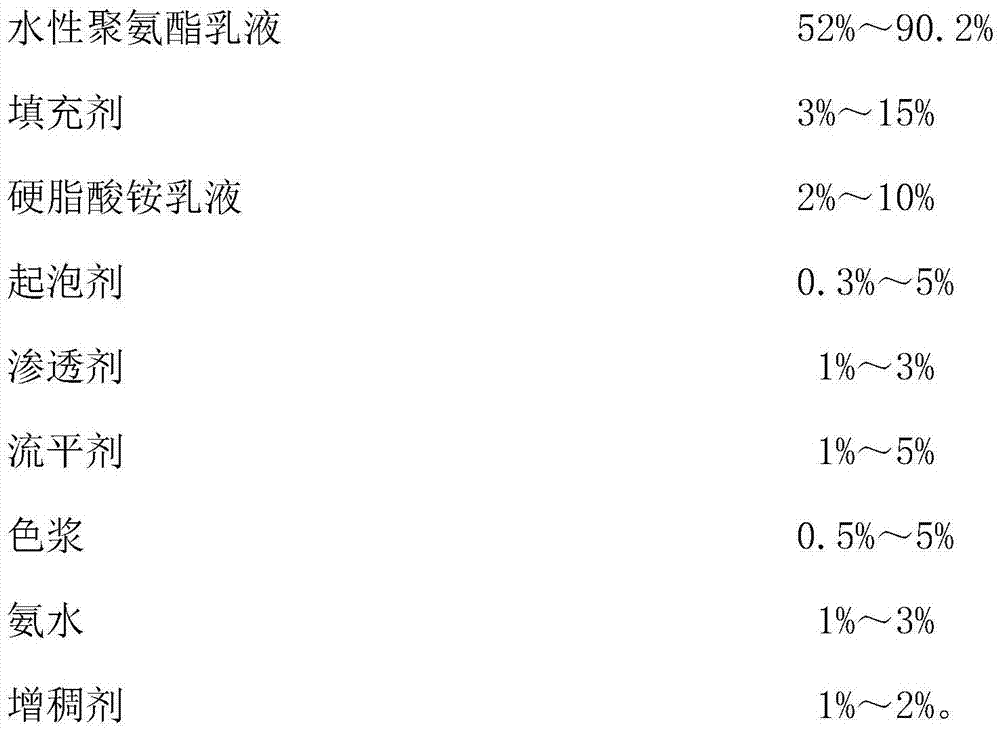

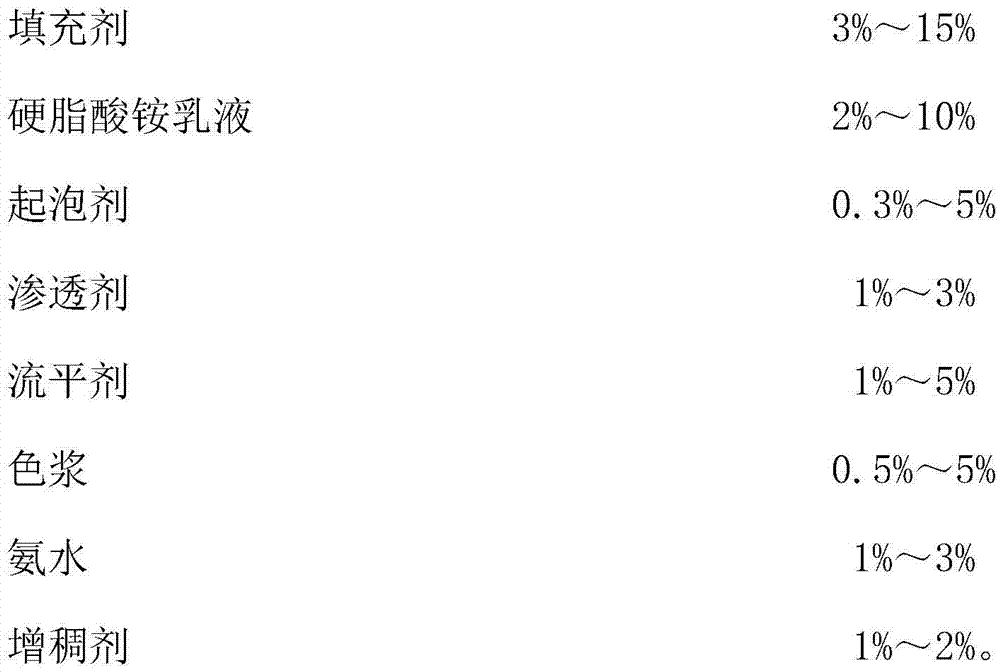

Formula and process for producing ecological synthetic leather by adopting waterborne polyurethane foaming coating

The invention discloses a formula for producing ecological synthetic leather by adopting a waterborne polyurethane foaming coating. The formula comprises coating liquid, wherein the coating liquid is prepared from the following components at ratio: 52%-90.2% of waterborne polyurethane emulsion, 3%-15% of a filling agent, 2%-10% of ammonium stearate emulsion, 0.3%-0.5% of a foaming agent, 1%-3% of a penetrating agent, 1%-5% of a flatting agent, 0.5%-5% of color paste, 1%-3% of ammonia water and 1%-2% of a thickening agent. The process comprises the following steps: adding the raw materials in the formula; stirring and filtering; adjusting viscosity to obtain the coating liquid; preparing the coating liquid into a coating foam body; coating the coating foam body to leather base cloth; drying to obtain foaming bass; and carrying out after-treatment to obtain the polyurethane ecological synthetic leather. The product is strong in skin feeling, soft in hand feeling and good in stripping resisting fastness; the moisture content in the coating liquid is relatively low so that drying energy consumption and water resources are greatly saved; and no sewage and waste gas are produced in a production process and the environment-friendly performance is good.

Owner:宋金火

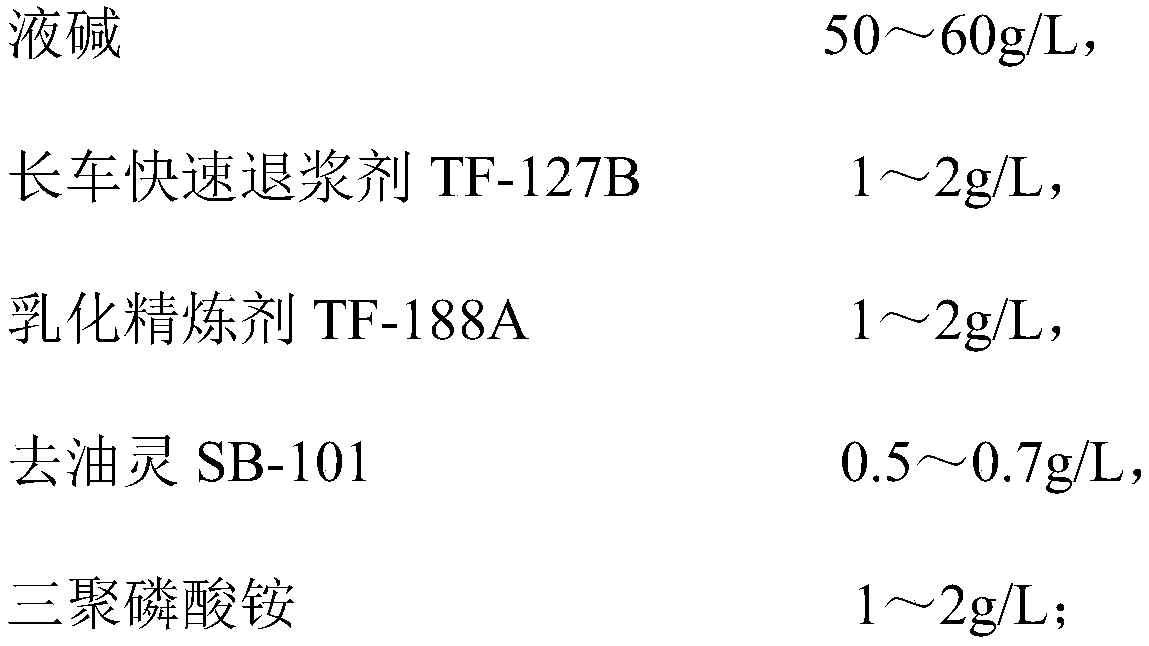

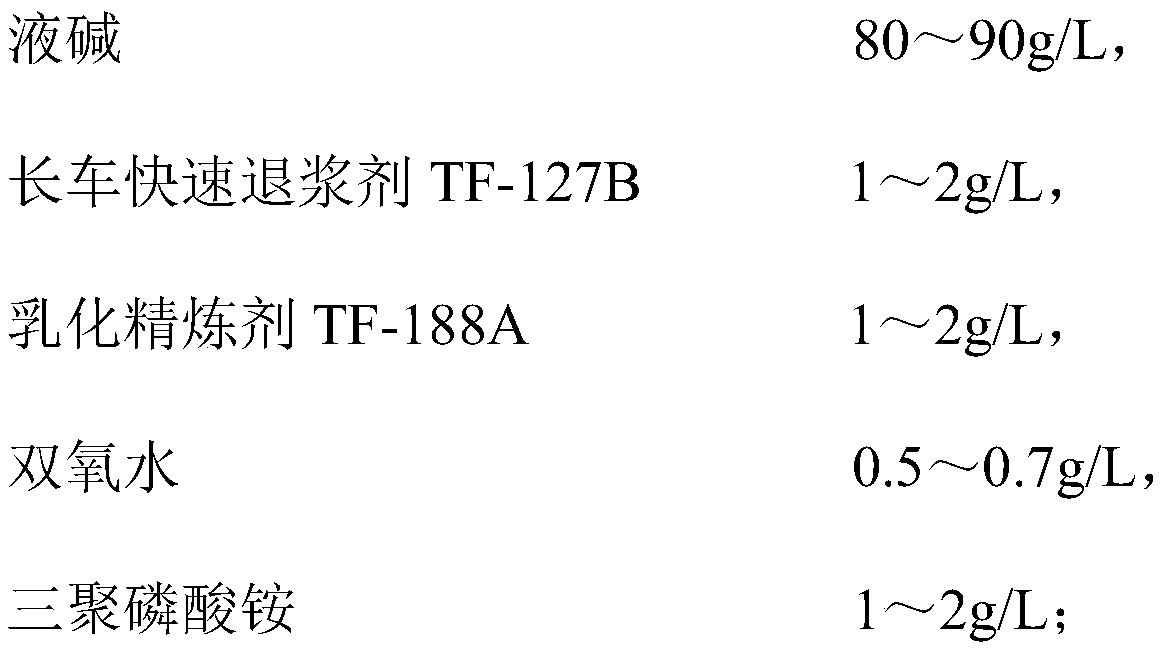

Pretreatment process for memory T400 fabric based on biological based material

InactiveCN109594323ASoft and plumpGuarantee the quality of dyeingFibre treatmentDry-cleaning apparatus for textilesMelamine phosphateProcess engineering

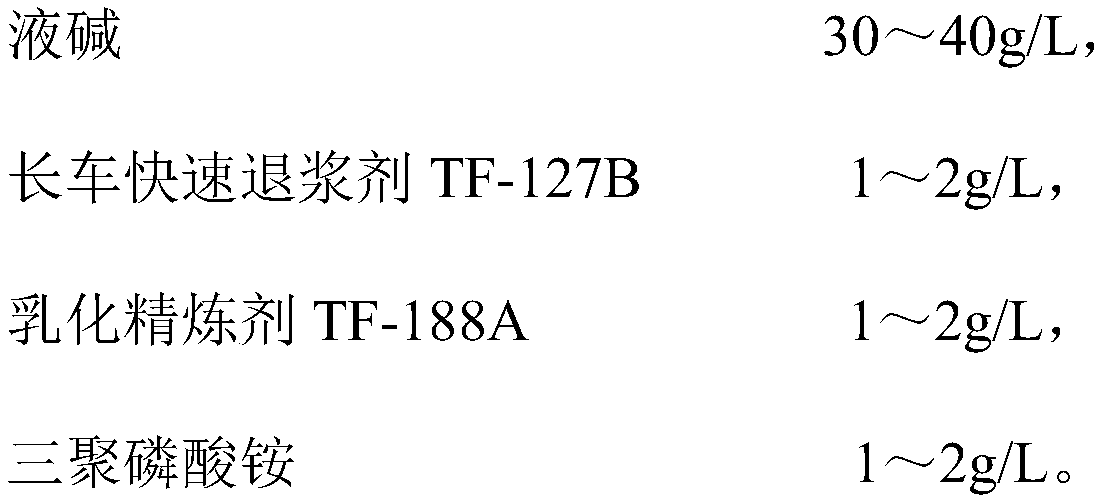

The invention discloses a pretreatment process for a memory T400 fabric based on a biological based material. The pretreatment process comprises a first open width desizing process, a cold rolling process and a second open width desizing process which are carried out in sequence, wherein a desizing aid used in the first open width desizing process has a formula of a 50-60g / L liquid caustic soda, a1-2g / L long-vehicle rapid desizing agent TF-127B, a 1-2g / L emulsification refining agent, a 0.5-0.7g / L oil remover SB-101 and 1-2g / L melamine phosphate; a rolling treatment liquid used in the cold rolling process has a formula of a 80-90g / L liquid caustic soda, a 1-2g / L long-vehicle rapid desizing agent TF-127B, a 1-2g / L emulsification refining agent, a 0.5-0.7g / L hydrogen peroxide and 1-2g / L melamine phosphate; a desizing aid used in the second open width desizing process has a formula of a 30-40g / L liquid caustic soda, a 1-2g / L long-vehicle rapid desizing agent TF-127B, a 1-2g / L emulsification refining agent and 1-2g / L ammonium triphosphate. By adopting the pretreatment process, an appropriate pretreatment process is made, various impurities on a fabric can be removed, smooth later dyeing procedures can be ensured, and the softness of the fabric can be also ensured.

Owner:SHENGHONG GRP CO LTD

All-component wide-distribution organic polyaldehyde tanning agent and preparation method thereof

ActiveCN107217116AExcellent tanning performanceDoes not reduce tannabilityTanning treatmentPre-tanning chemical treatmentIodideIodine

The invention relates to an all-component wide-distribution organic polyaldehyde tanning agent and a preparation method thereof. The preparation method is characterized in that firstly, periodate is utilized to perform hydroformylation on polysaccharide and derivatives thereof under a proper condition, so as to retain all components of hydroformylated polysaccharide; secondly, an inorganic reducing agent is utilized to efficiently convert an iodine-containing compound into solid molecular iodine, and the solid molecular iodine is filtered and recycled; and finally, the hydroformylation product filtrate is subjected to heat treatment, so that the residual iodide is separated out in the form of steam, further absorbed by a NaOH solution and recycled, and the all-component wide-distribution organic polyaldehyde tanning agent is obtained. According to the all-component wide-distribution organic polyaldehyde tanning agent and the preparation method thereof, the technical problems that the conventional hydroformylated polysaccharide tanning agent is too narrow in molecular weight distribution and poor in tanning property, or contains the iodine-containing compound and affects the overall performance of leather after tanning are solved; besides, the prepared tanning agent retains all components of hydroformylated polysaccharide, the molecular weight distribution is wide, the shrinkage temperature of leather / fur after tannage can reach 85-90 DEG C, and the treated leather is pure white, full and soft.

Owner:SICHUAN UNIV +1

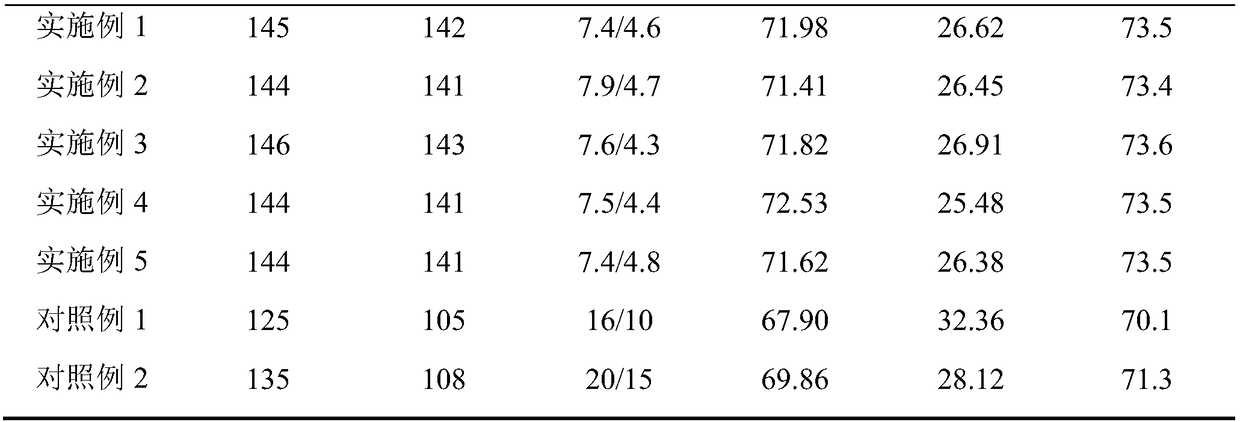

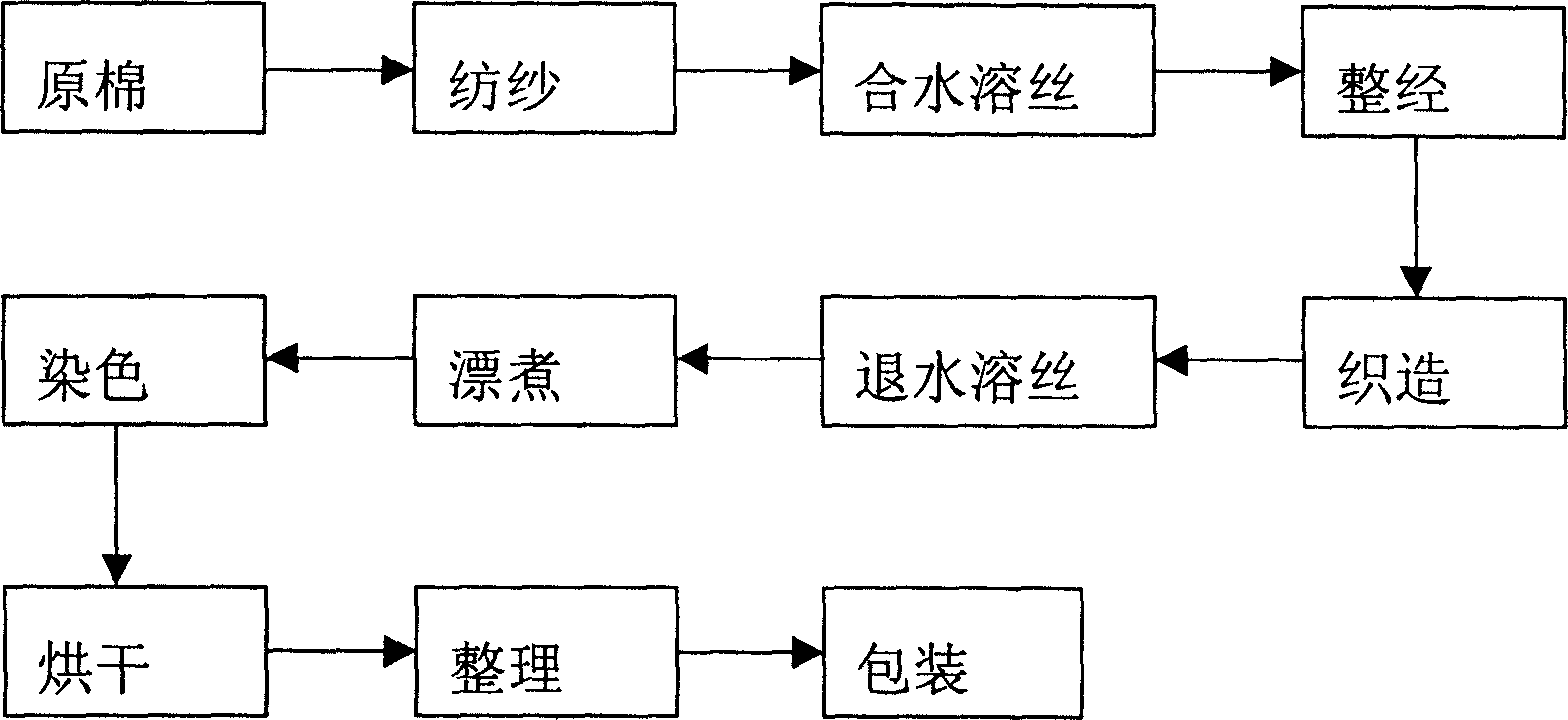

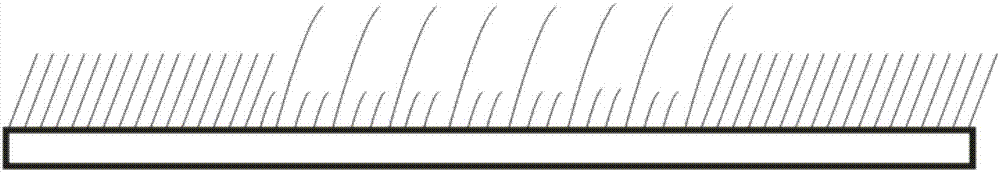

Pure-white modal wide pile fabric and production method thereof

ActiveCN105780256ASoft and plumpSimple processLiquid/gas/vapor open-width material treatmentSolvent-treatmentBreaking strengthEngineering

The invention discloses a pure-white modal wide pile fabric and a production method thereof.The technical process includes: slight singeing, enzyme desizing by a dye jigger, Bu-gong tea saponin scouring and bleaching by the dye jigger, drying, napping, anti-shrinking finishing, tentering, mechanical pre-shrinking, and inspecting and packaging.The front of this fabric is provided with a layer of loose piles, and after weft-wise washing, the fabric is -3% to +1.0% in size variation rate, > / =82% in reflectivity and > / =260 N in breaking strength.The process is simple, operating is convenient, and the product has excellent properties.

Owner:NANTONG JINSHAIDA SPECIAL FAB CO LTD

Preparation method of dual-purpose hide for hair and leather by formaldehyde-free chrome-free tanning

ActiveCN104109723AAvoid destructionReduce usageTanning treatmentPre-tanning chemical treatmentAlumFatty aldehyde

The invention discloses a preparation method of dual-purpose hide for hair and leather by formaldehyde-free chrome-free tanning. The method mainly comprises the following improved operation steps: degreasing: degreasing by using a mixed solution of sodium chloride, sodium carbonate, TS-80 degreaser and JA-50 degreaser; pickling: carrying out secondary pickling by using sodium chloride, HAC penetrant, formic acid, 535 acidic softening enzyme, sulfuric acid and TS-80 degreaser; and tanning and retanning: carrying out tanning and retanning by using a tanning agent containing an aluminum tanning agent and a tanning extract, a fatty aldehyde tanning agent is used for primary tanning before tanning, and no aluminum tanning agent or alum is used in the tanning and retanning process of the raw hide subjected to primary tanning. By using the formaldehyde-free chrome-free tanning process, the product is free of heavy metals or free formaldehyde; the degreasing procedure is reinforced, thereby avoiding using the dry washer; and the spreading process is used instead of the traditional bath tanning process in the tanning and retanning procedure, thereby saving abundant water and reducing the use of the tanning extract.

Owner:SICHUAN DEHUA LEATHER MFG

Double-side raised bleached resin lining and production method thereof

The invention discloses a double-side raised bleached resin lining and a production method thereof. The production procedure includes the steps of seam turning, refining, bleaching, double-side galling, blueing whitening anti-shrinkage one-bath dyeing and finishing and mechanical pre-shrinking. The process is convenient to operate, the product is excellent in performance, double sides are each provided with a layer of loose fluff, and the content of free and hydrolyzed formaldehyde is smaller than or equal to 35 mg / kg; the warp and weft washing dimensional stability is -0.6% to +0.5%. After the resin lining and clothes fabric are compounded, the hand feeling of the fabric is quite soft and plump.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD

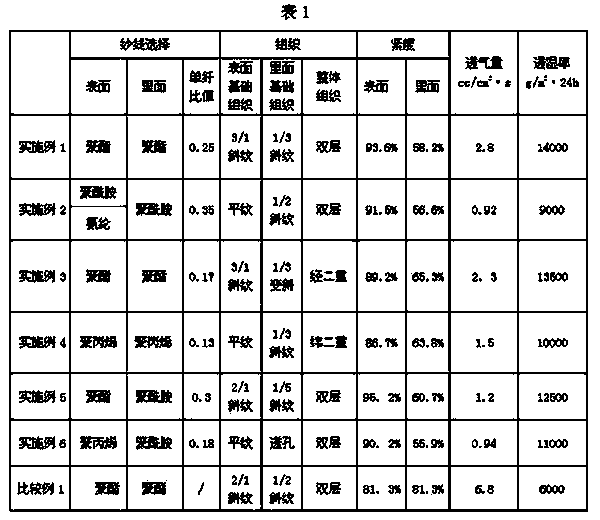

Windproof breathable fabric

The invention discloses windproof breathable fabric. The surface of the fabric is made of fine fibers, the inner layer of the fabric is made of coarse fibers, the structure of the fabric can be a warp-backed weave or a weft-backed weave or a double-layer weave, the surface tightness ranges from 85 percent to 100 percent, the inner layer tightness ranges from 55 percent to 70 percent, and the single fiber fineness ratio of the fine fibers to the coarse fibers ranges from 0.1 to 0.8. The air permeability is measured to be less than or equal to 3cc / cm<2> / s according to the standards of JISL1096, and the moisture permeability is measured to be 8000-15000g / m<2> / 24h according to the standards of GB / T12704.2. The fabric is low in production cost, good in moisture permeability, good in windproof performance, soft in hand feel, stiff and smooth, good in resilience and particularly suitable for manufacturing of high-end casual coat products.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Producing and making method of artificial jacquard high-low fur

ActiveCN107475879AReduce wasteSoft and plumpWeft knittingHeating/cooling textile fabricsYarnPolyester

The invention discloses a producing and making method of artificial jacquard high-low fur. A ground yarn woven knitted base fabric is made on a computerized jacquard artificial fur making machine by adopting polyester low-stretch yarns, double-different-color polyester wool tops and common polyester wool tops are adopted as jacquard velvet yarns, the double-different-color polyester wool tops and the common polyester wool tops are fed by adopting a one-spacing one-path alternated configuration mode, the computerized jacquard artificial fur making machine controls the double-different-color polyester wool tops to form monofilaments in different cross-section shapes, jacquard patterns are selectively formed on knitted loops of the knitted base fabric, and the woven and formed gray fabric produces the high-low stereoscopic fluff impression of a jacquard effect on the jacquard patterns through heat setting. The produced imitated fur is good in effect, does not need multiple times of shearing later, brings full and soft hand feeling, is resistant to abrasion and washing, does not mold, is not damaged by moths, is convenient to cut, sew and process, is wider in application range compared with natural fur and is suitable for clothing, wall carpets, shoes and hats and various fur and feather toys, and raw material waste is reduced.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com