Producing and making method of artificial jacquard high-low fur

An artificial and fur technology, applied in textiles and papermaking, heating/cooling fabrics, fabric surface trimming, etc., can solve the problem of inability to meet consumers' increasingly high requirements for artificial fur, small development space, and hair loss. Large and other problems, to achieve the effect of convenient processing, reduction of raw material waste, and strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention are described in detail below, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0017] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

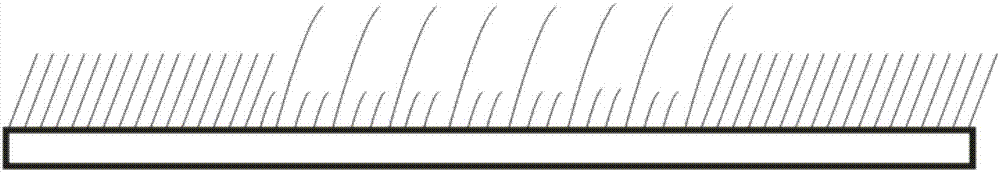

[0018] A production and preparation method of jacquard artificial hi-lo fur, the steps of which are:

[0019] (1) Selection of raw materials:

[0020] Choose black double-colored polyester top and white ordinary polyester top for jacquard weaving, and use 200dtex polyester filament DTY as the ground yarn. Among them, the black double-colored polyester top contains multifilaments composed of monofilaments of different shapes. These monofilaments produced by computer control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com