Fluffy softening agent for fabric and preparation method thereof

A softener and fluffy technology, applied in the field of fabric fluffy softener and its preparation, can solve problems such as poor fluffy softness, and achieve the effects of lasting softness, improving emulsifying effect, and soft and plump hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

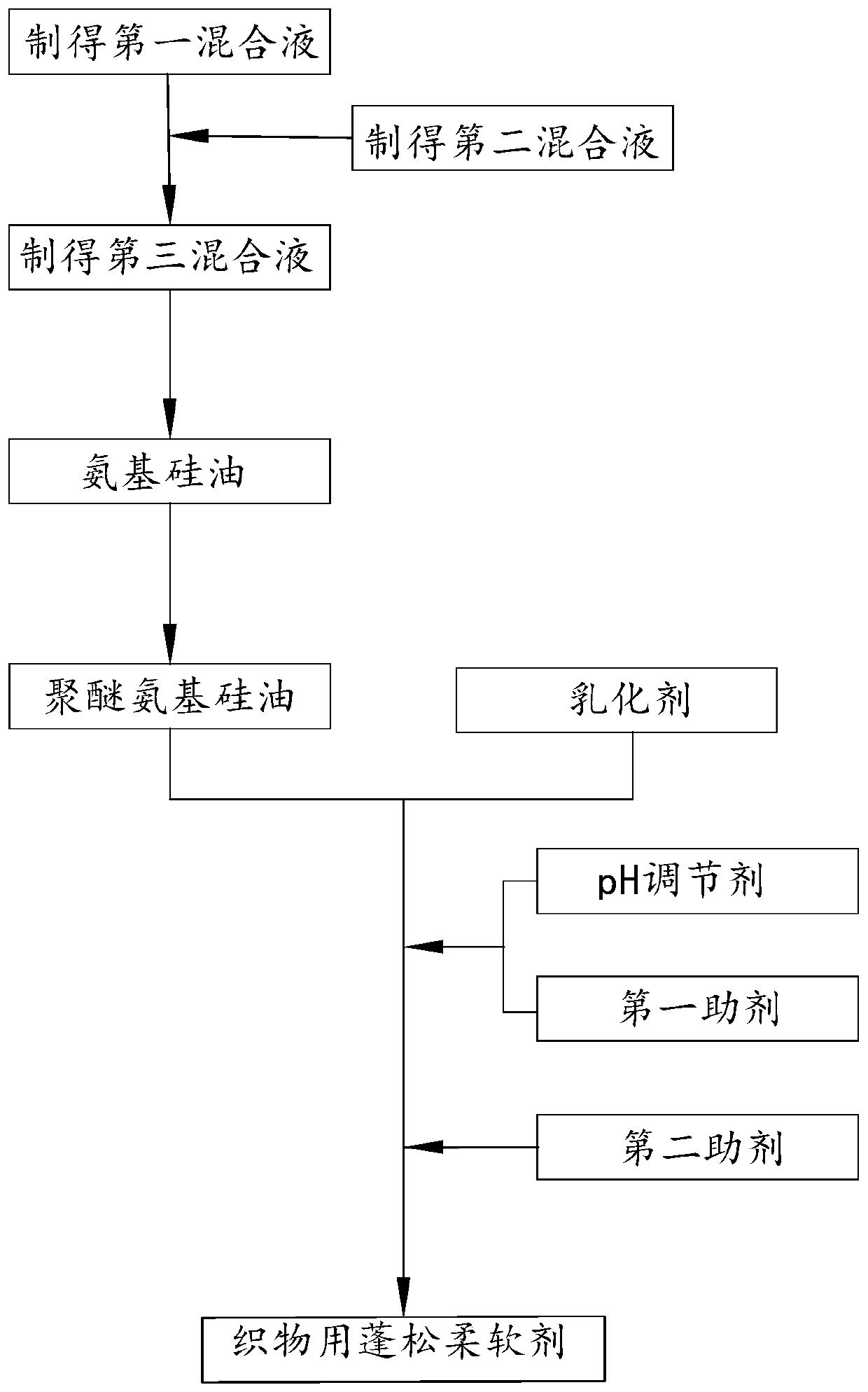

[0085] refer to figure 1 , the invention discloses a fluffy and softening agent for fabrics and a preparation method thereof, comprising the following preparation steps:

[0086] 1) Prepare emulsifier in proportion: after mixing 18% fatty acid sorbitan, 22% polysorbate, 45% cetylpyridinium bromide and 15% isopropanol, the emulsifier is prepared;

[0087] Prepare the pH regulator in proportion: after mixing 25% sorbic acid, 30% glacial acetic acid, 30% sodium dihydrogen phosphate and 15% acidic sodium pyrophosphate, the pH regulator is prepared;

[0088]Prepare the first auxiliary agent in proportion: after mixing evenly 10% degraded chitosan, 52% citric acid, and 38% sodium hypophosphite, the first auxiliary agent is prepared;

[0089] Prepare the second additive in proportion:

[0090] A. Prepare plant extract in proportion: 0.5% green tea extract, 0.2% aloe extract, 0.4% comfrey root extract, 0.2% golden chamomile extract, 0.2% purslane extract, 0.3 % guava leaf extract, ...

Embodiment 1

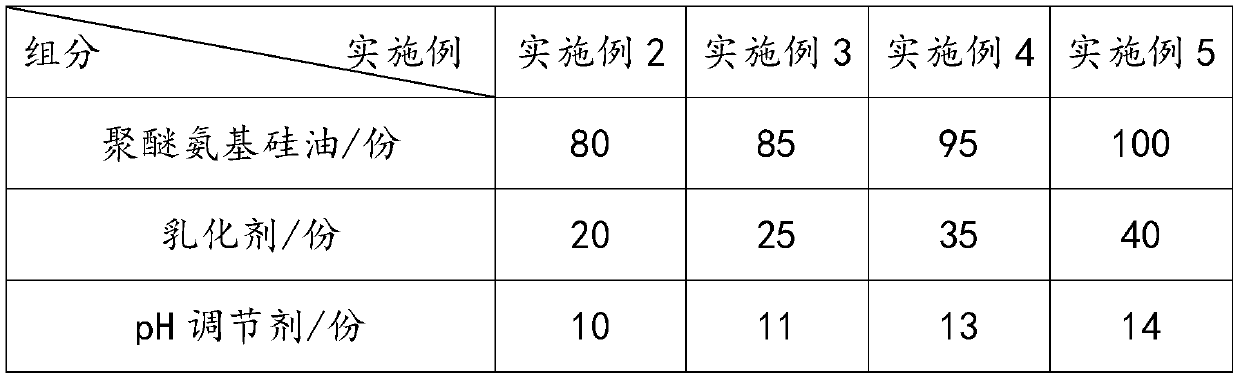

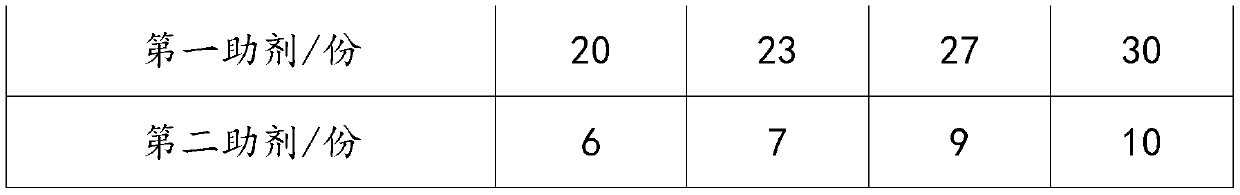

[0110] The difference between embodiments 10-13 and embodiment 1 is that the amino silicone oil comprises the following raw materials in weight percent:

[0111]

[0112]

[0113] The difference between Embodiment 14-17 and Embodiment 1 is that the first auxiliary agent includes the following raw materials in weight percentage:

[0114]

[0115] The difference between embodiment 18-21 and embodiment 1 is that emulsifying agent comprises following weight percentage agent raw material:

[0116]

[0117] The difference between Embodiment 22-25 and Embodiment 1 is that the pH regulator comprises the following raw materials in weight percent:

[0118]

[0119] The difference between Embodiment 26-29 and Embodiment 1 is that the second auxiliary agent includes the following percentage raw materials:

[0120]

[0121] The difference between Embodiment 30-33 and Embodiment 1 is that the plant extract comprises the following raw materials in percentage:

[0122] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com