Patents

Literature

55results about How to "Oleophobic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

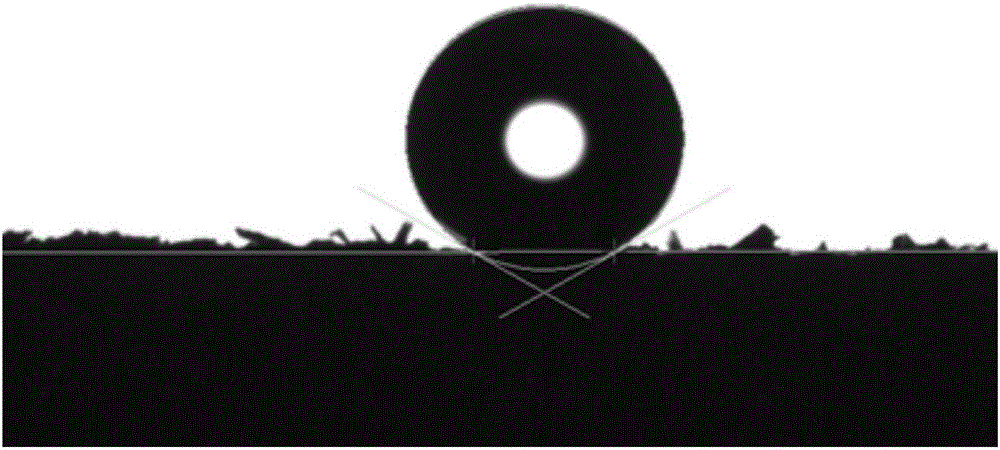

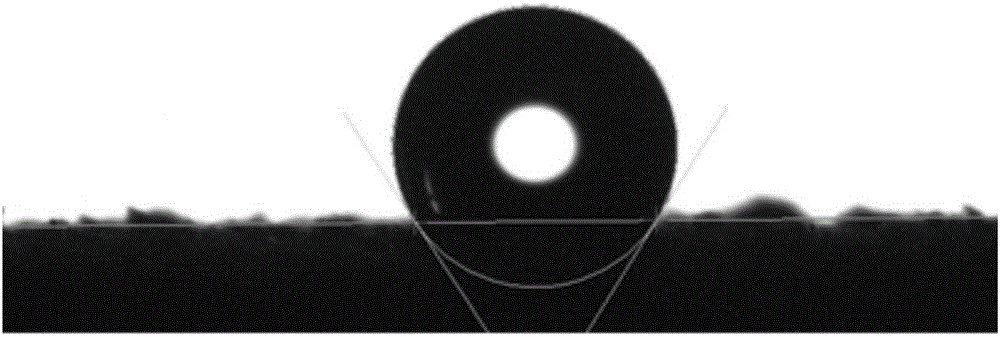

Preparation method of organic-inorganic hybrid super-hydrophobic and oleophobic wood modifier with mold-proof, sterilization, anti-flaming and weather-proof properties

ActiveCN105619558AImproved antiseptic performanceGood weather resistanceWood treatment detailsCoating impregnationWater basedEdible oil

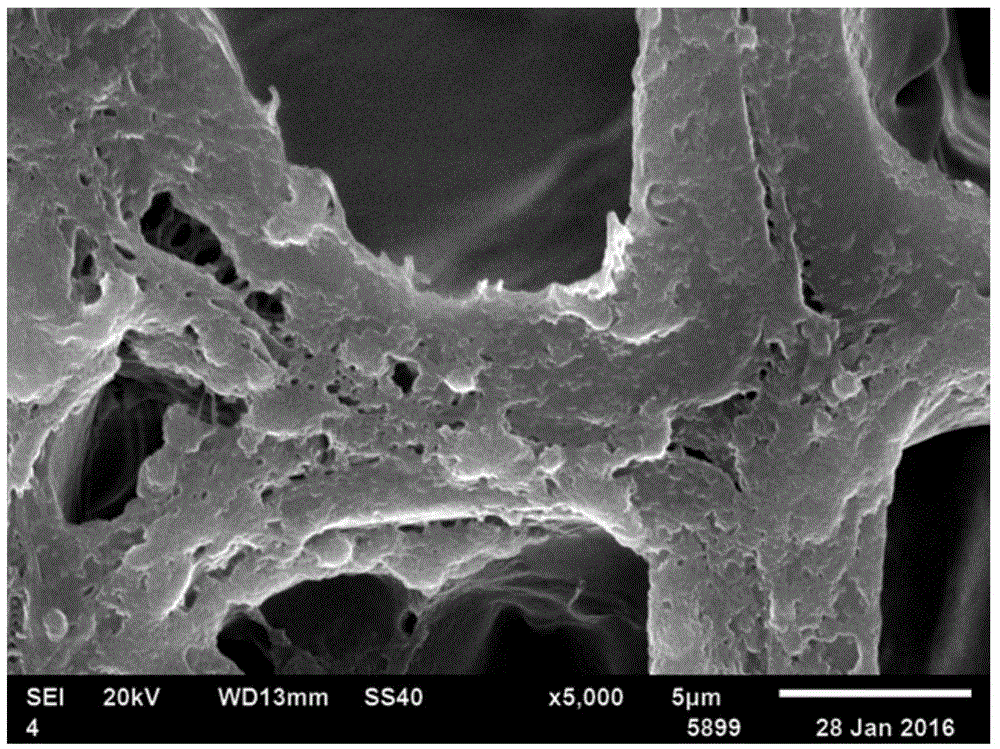

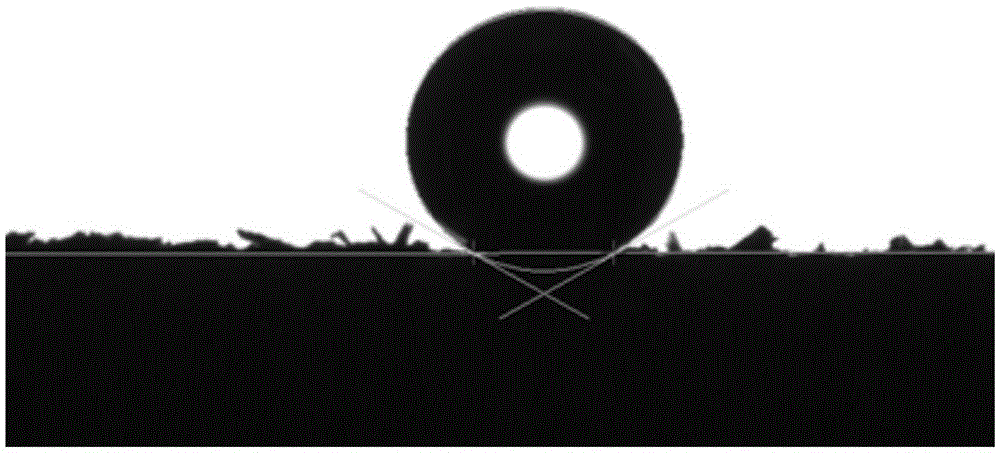

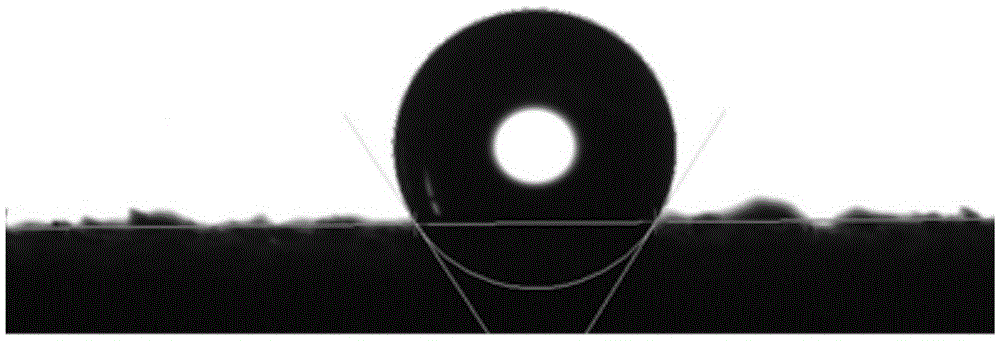

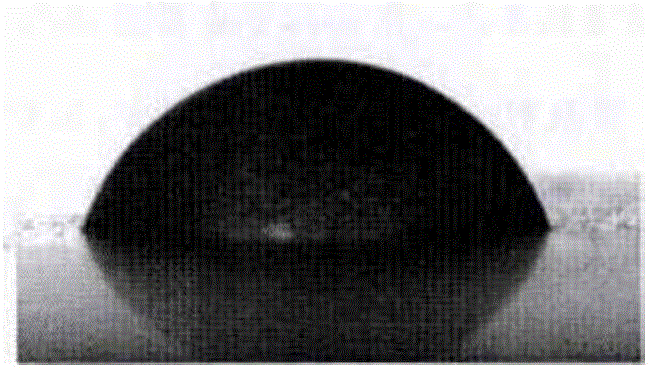

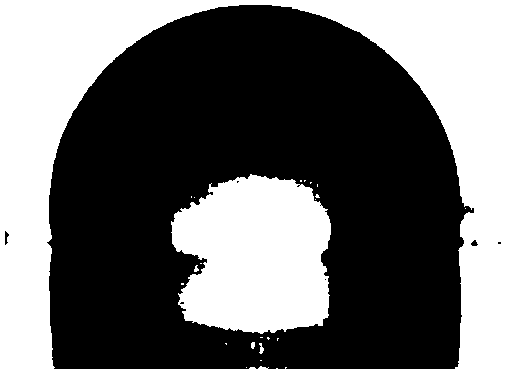

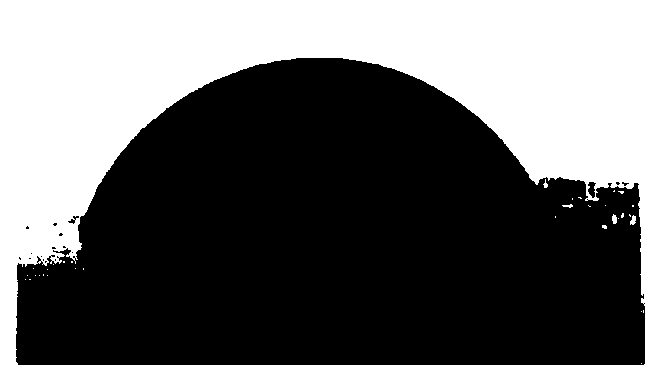

The invention relates to a preparation method of a wood modifier, in particular to a preparation method of an organic-inorganic hybrid super-hydrophobic and oleophobic wood modifier with mold-proof, sterilization, anti-flaming and weather-proof properties, and belongs to the field of preparation of wood modifiers. The preparation method aims to solve the technical problems that existing wood modifiers have high toxicity, special peculiar smells and poor run-away resisting capacity, pollute the environment and are simplex in function. The preparation method comprises the steps that organoalkoxysilane, deionized water and absolute ethyl alcohol are mixed; a functional reagent A is added for a reaction; a functional reagent B is added for a reaction; a fluorine-containing silane coupling agent is added for a reaction; a water-based fluorine-containing high-molecular compound, a curing agent and a functional reagent C are added, the mixture is stirred, and the modifier is obtained. The static water contact angle of the surface of wood modified by the modifier can reach 150 degrees or above, and the rolling angle is smaller than 10 degrees. The edible oil contact angle of the modified wood surface can reach 120 degrees or above, and modified wood surface has the oleophobic characteristic. In addition, the corrosion prevention and sterilization performance of the modified wood is improved by 90% or above, the weather resistance of the modified wood is improved by 10 times, and the anti-flaming performance of the modified wood is also remarkably improved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Anticorrosive pipeline paint and its prepn

InactiveCN1887993AShort curing timeImprove corrosion resistanceAnti-corrosive paintsPolyamide coatingsChemistryFluorocarbon

The anticorrosive pipeline paint consists of epoxy resin 100 weight portions, fluorocarbon resin 5-15 weight portions, nylon resin 5-15 weight portions, inorganic filler 10-40 weight portions and compound curing agent 10-25 weight portions. The preparation process includes the following steps: treating the inorganic filler with titanate coupler; mixing epoxy resin, fluorocarbon resin, nylon resin and compound curing agent and smelting and extruding in a double screw extruder; freezing and crushing to 100-300 mesh, adding the inorganic filler through stirring. The anticorrosive pipeline paint has the advantages of short curing period, high corrosion resistance, high strength, low friction coefficient, hydrophobicity and lipophobicity.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

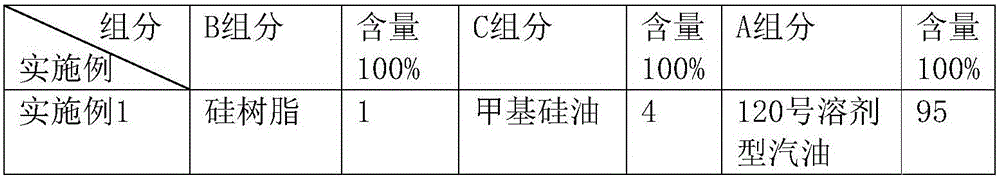

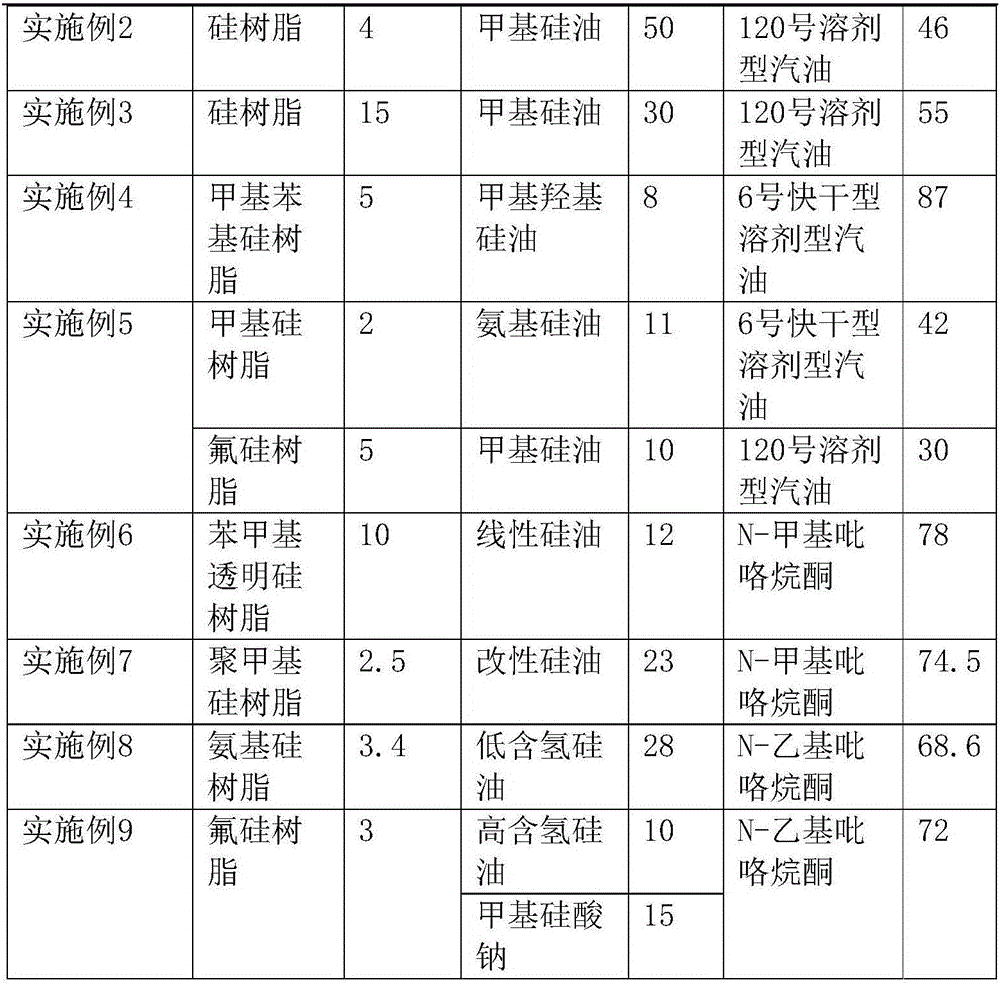

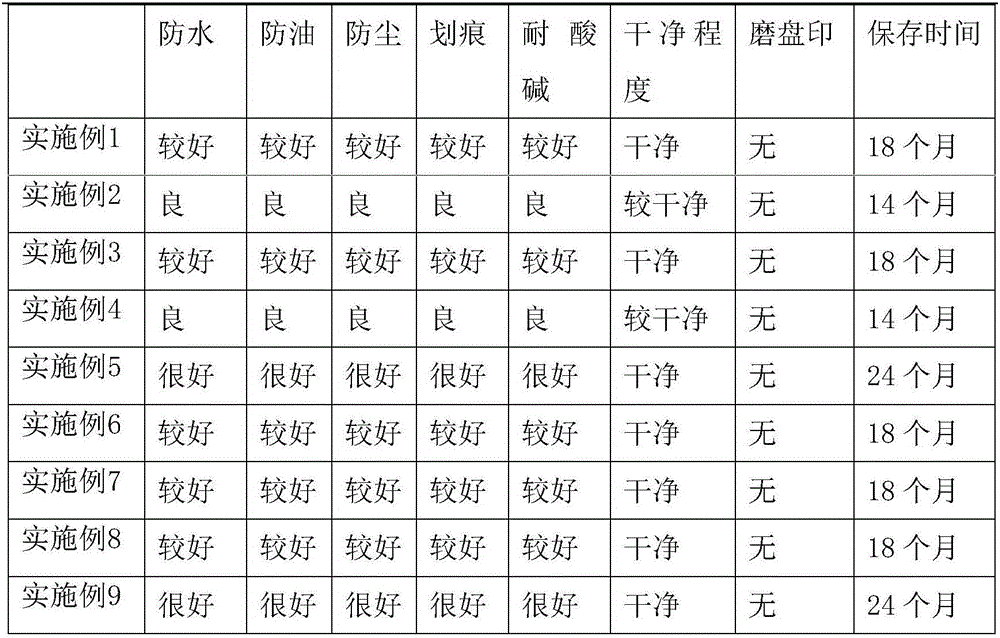

Matte brick stain-proofing agent and preparation method thereof

ActiveCN105860831AAntifoulingExtended service lifeAntifouling/underwater paintsPaints with biocidesOrganic solventBrick

The invention discloses a matte brick stain-proofing agent. The matte brick stain-proofing agent is prepared from a component A, a component B and a component C, wherein the component A is an organic solvent, the component B is silicon resin, and the component C is at least one of silicone oil and organosiloxane monomers. The invention further provides a preparation method of the matte brick stain-proofing agent. By compounding the components, the matte brick stain-proofing agent can achieve a good stain-proofing effect when used for performing stain-proofing treatment on the surfaces of matte bricks in follow-up application; besides, the matte brick stain-proofing agent has a very long shelf life and service life; moreover, the preparation technology is simple and easy to implement and can be conveniently applied to industrial production.

Owner:GUANGDONG NADE NEW MATERIALS CO LTD

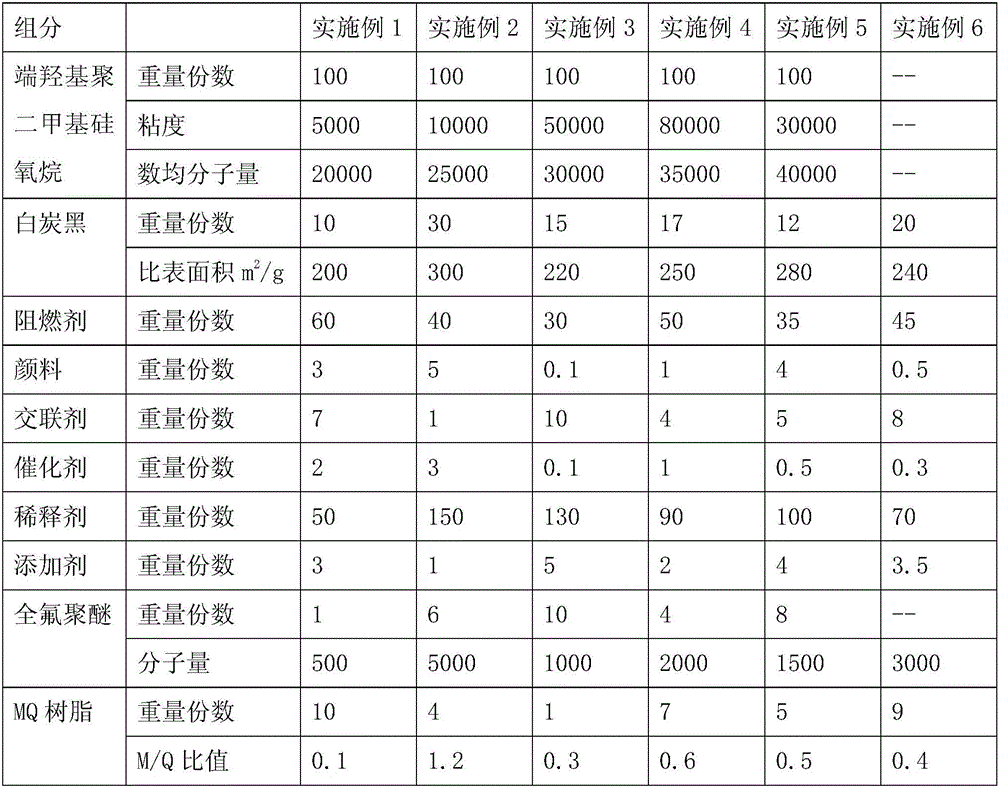

Anti-haze and anti-pollution-flashover coating as well as preparation method and application thereof

ActiveCN106085219AImprove hydrophobicityGood oleophobic effectFireproof paintsAntifouling/underwater paintsParticulatesVulcanization

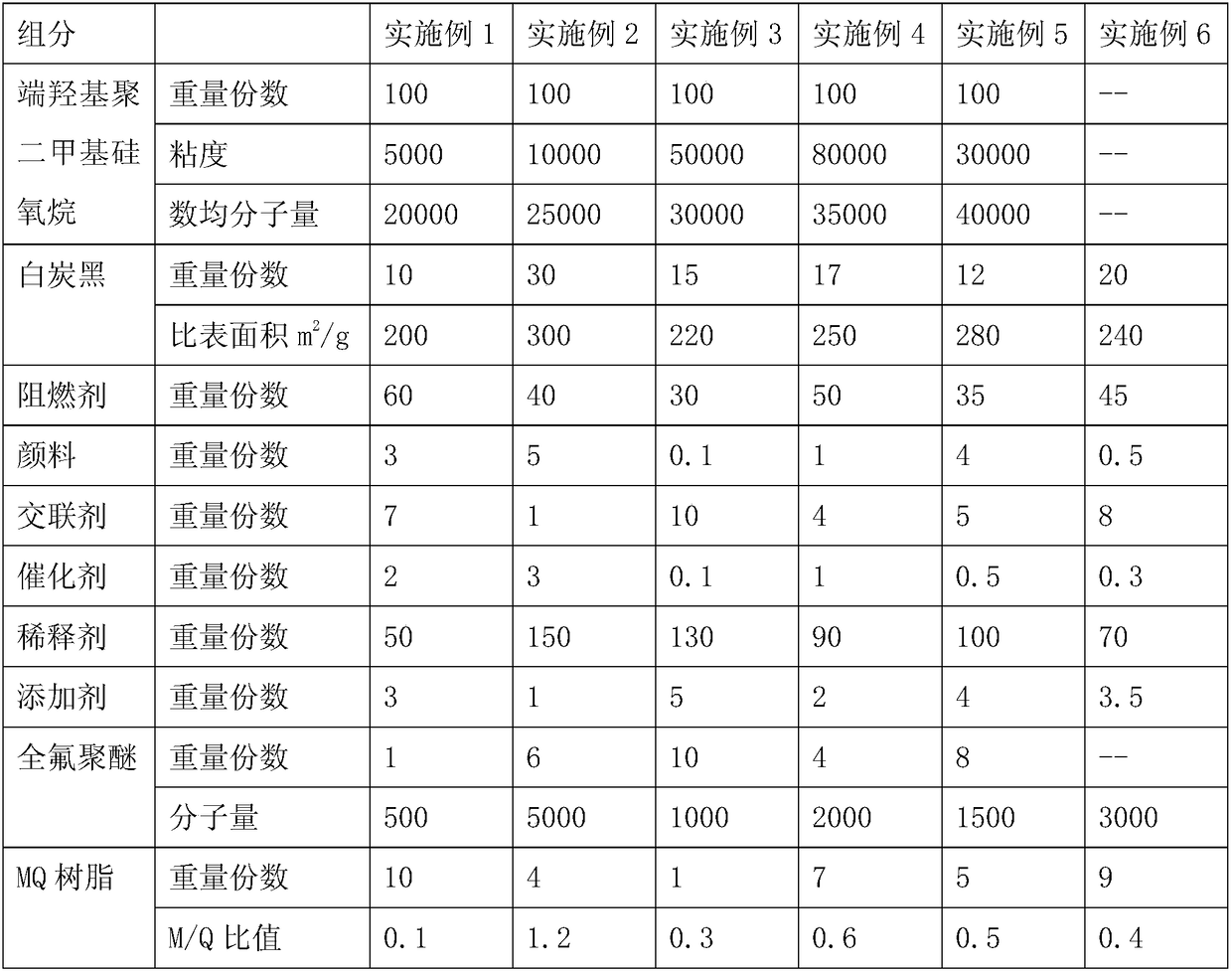

The invention discloses an anti-haze and anti-pollution-flashover coating as well as a preparation method and an application thereof and belongs to the technical field of chemical coatings. White carbon black and MQ resin are taken as reinforcing materials of the anti-haze and anti-pollution-flashover coating. Compared with the traditional RTV (room temperature vulcanization) silicone coatings, the anti-haze and anti-pollution-flashover coating has double-phobic technological advantages including hydrophobic and oleophobic, has a self-cleaning function on dust particulate matters, can prevent adhesion of organic fouling, resists weather and salt-spray corrosion, thereby having the anti-haze performance..

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +1

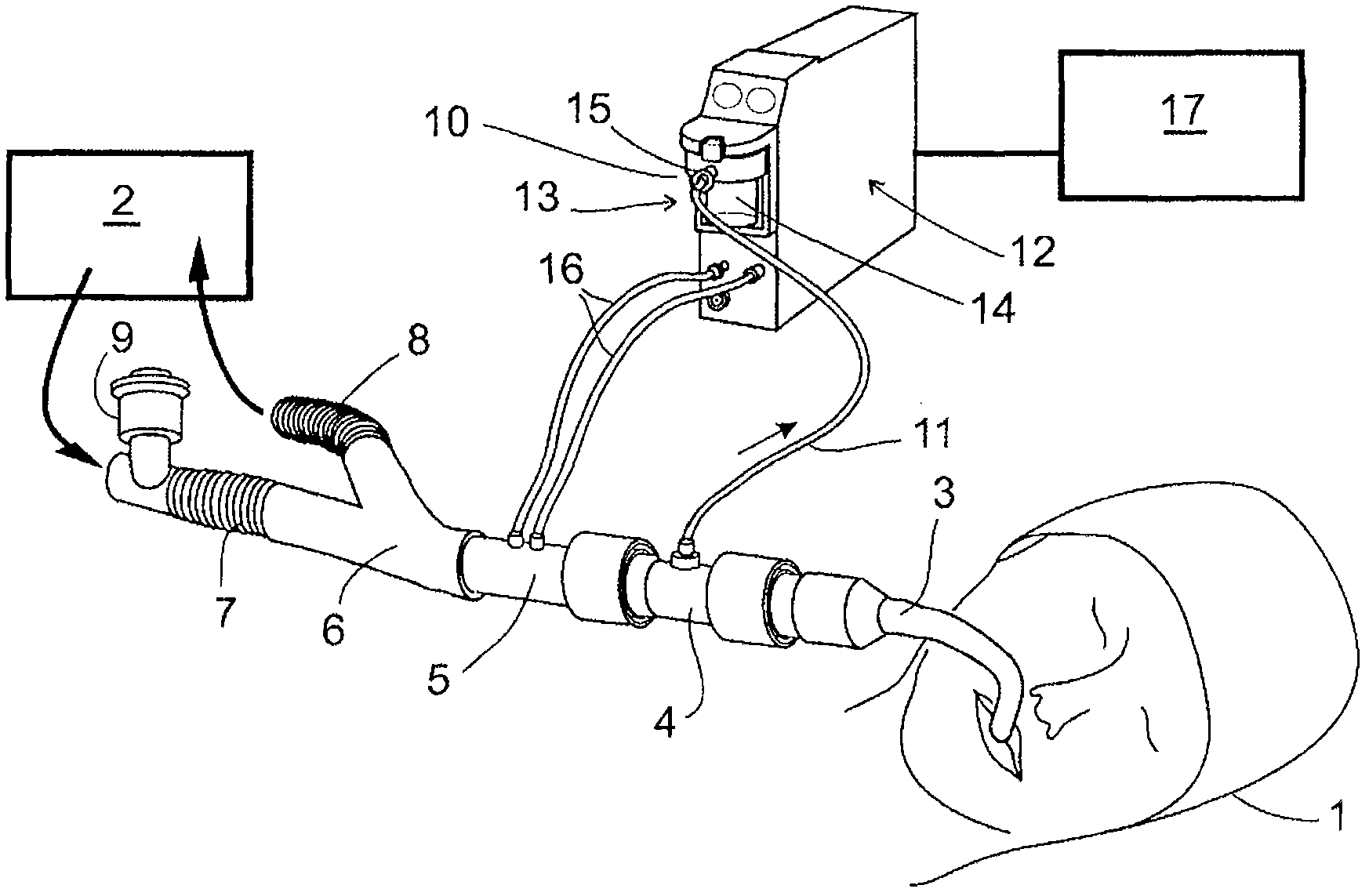

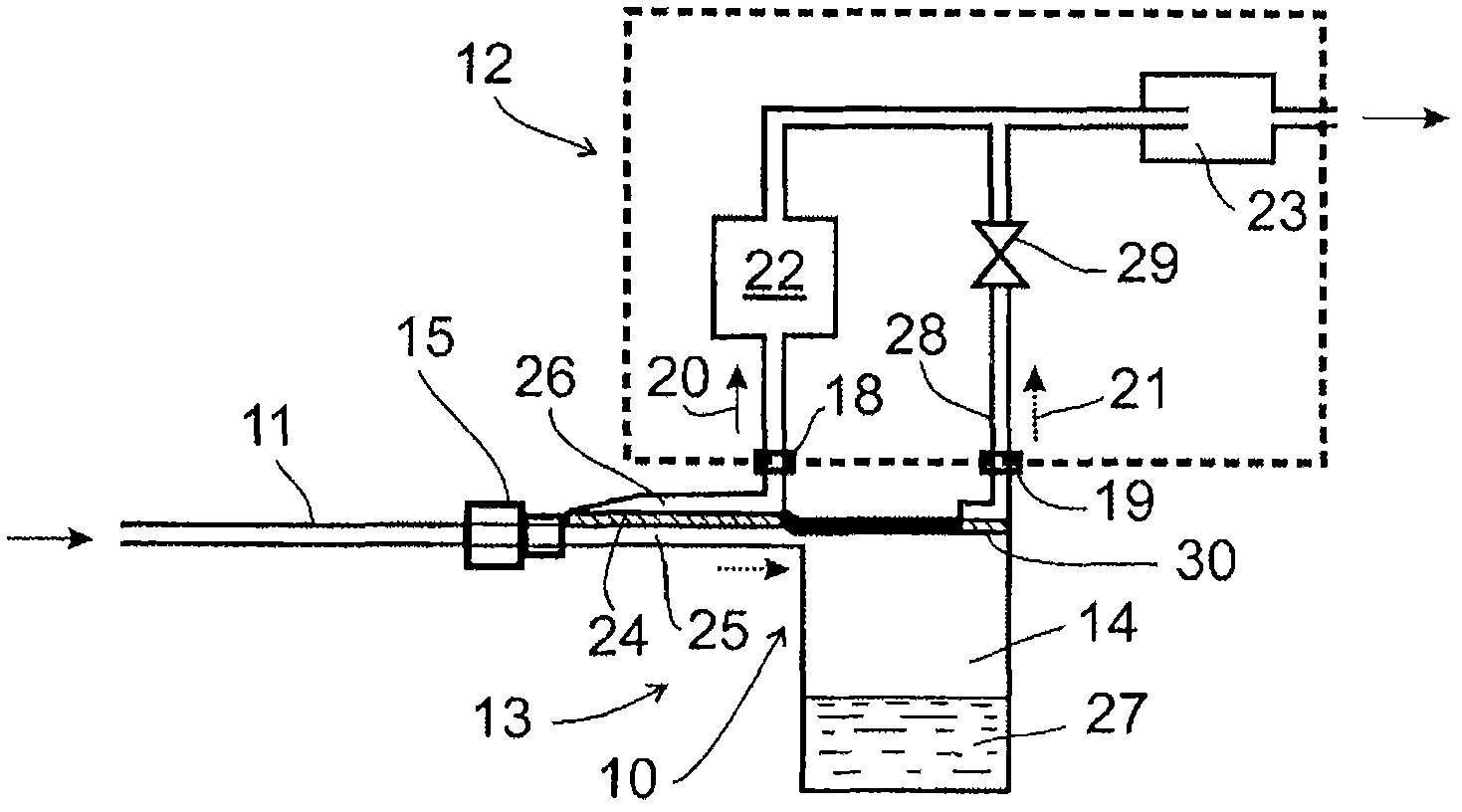

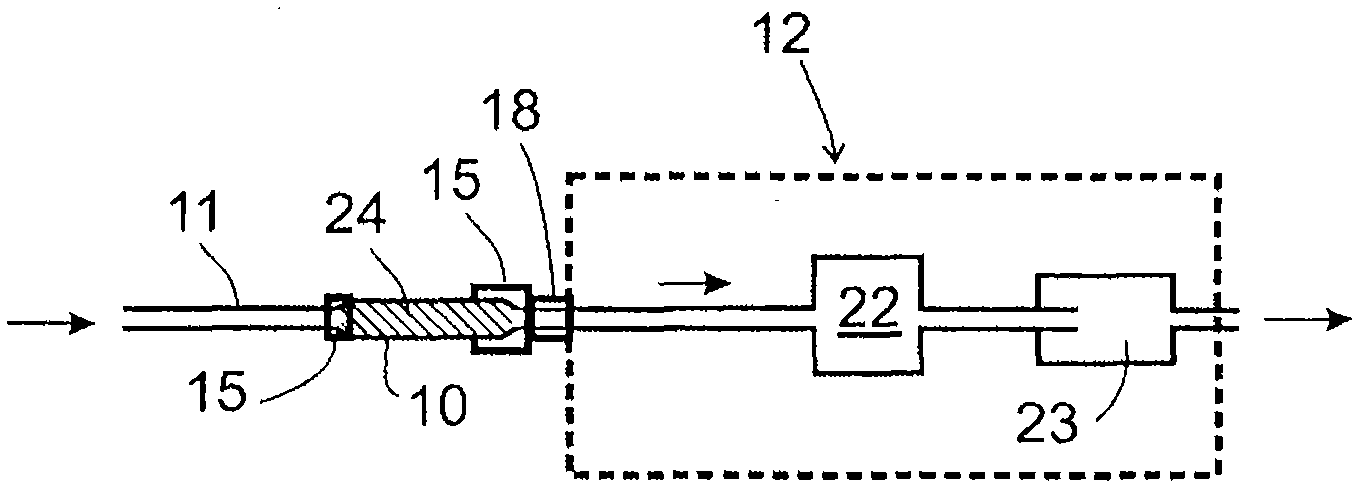

Liquid separation apparatus for removing a liquid from a respiratory gas and respiratory gas analyzing system

ActiveCN102600669AEasy to removeHydrophobicRespiratorsDispersed particle filtrationBreathing gasEngineering

A liquid separation apparatus for removing a liquid from a respiratory gas is disclosed herein. The liquid separation apparatus includes a housing (10) having an input (15) for delivering a sample withdrawn from the respiratory gas and a first output (18) for discharging at least part of the sample of the respiratory gas and a first filter (24) with a hydrophobic property for removing the liquid from the gas sample flowing through the input and first output of the housing. The first filter (24) also having an oleophobic property to improve a removal of the liquid in case a surface tension of the liquid is lower than a surface tension of bodily fluids. Also a respiratory gas analyzing system including the liquid separation apparatus is disclosed.

Owner:GENERAL ELECTRIC CO

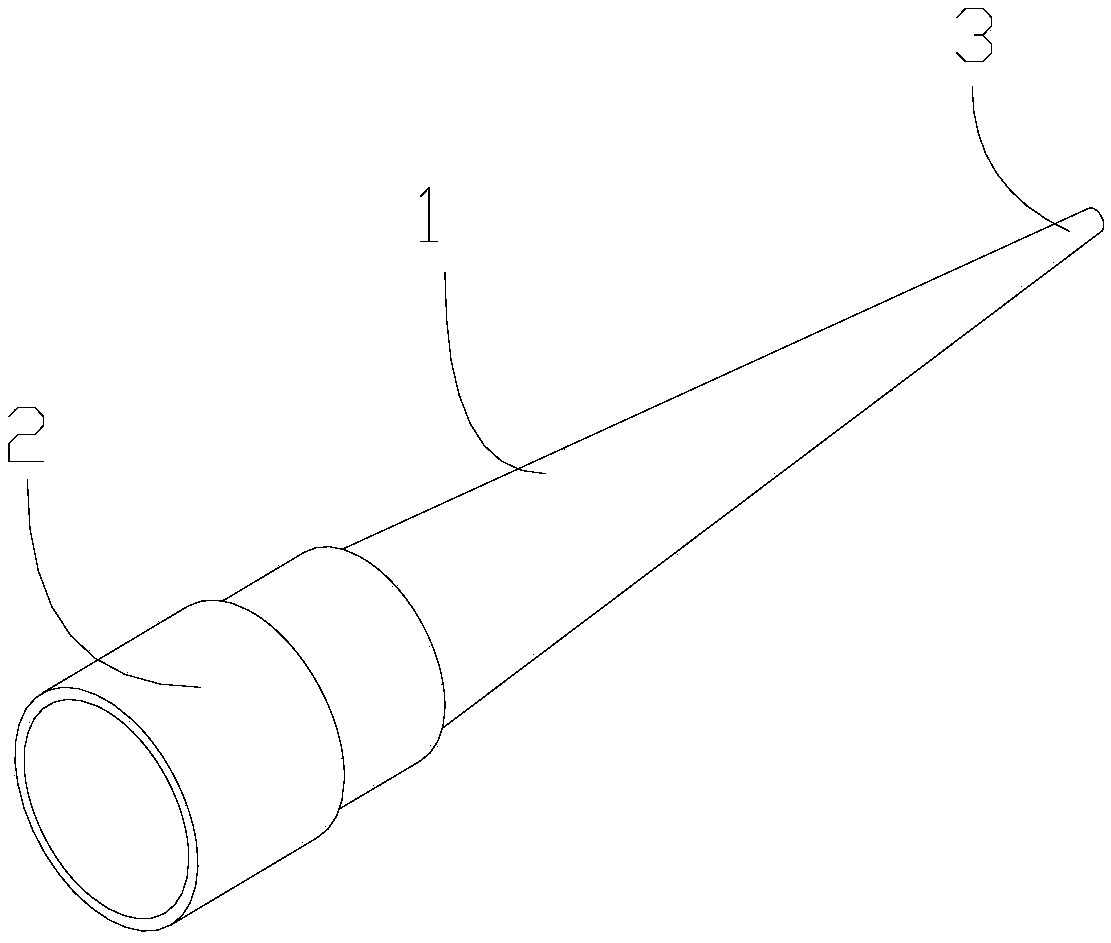

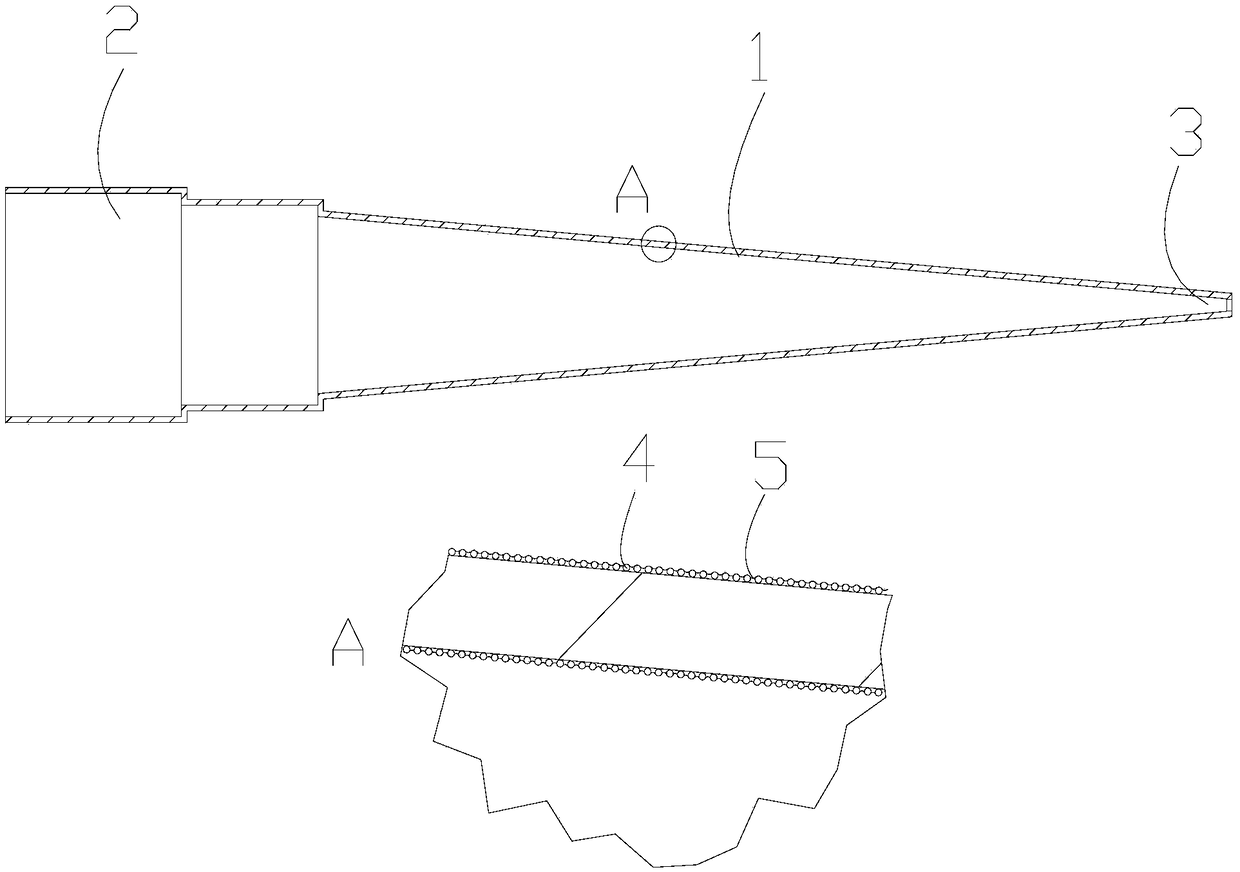

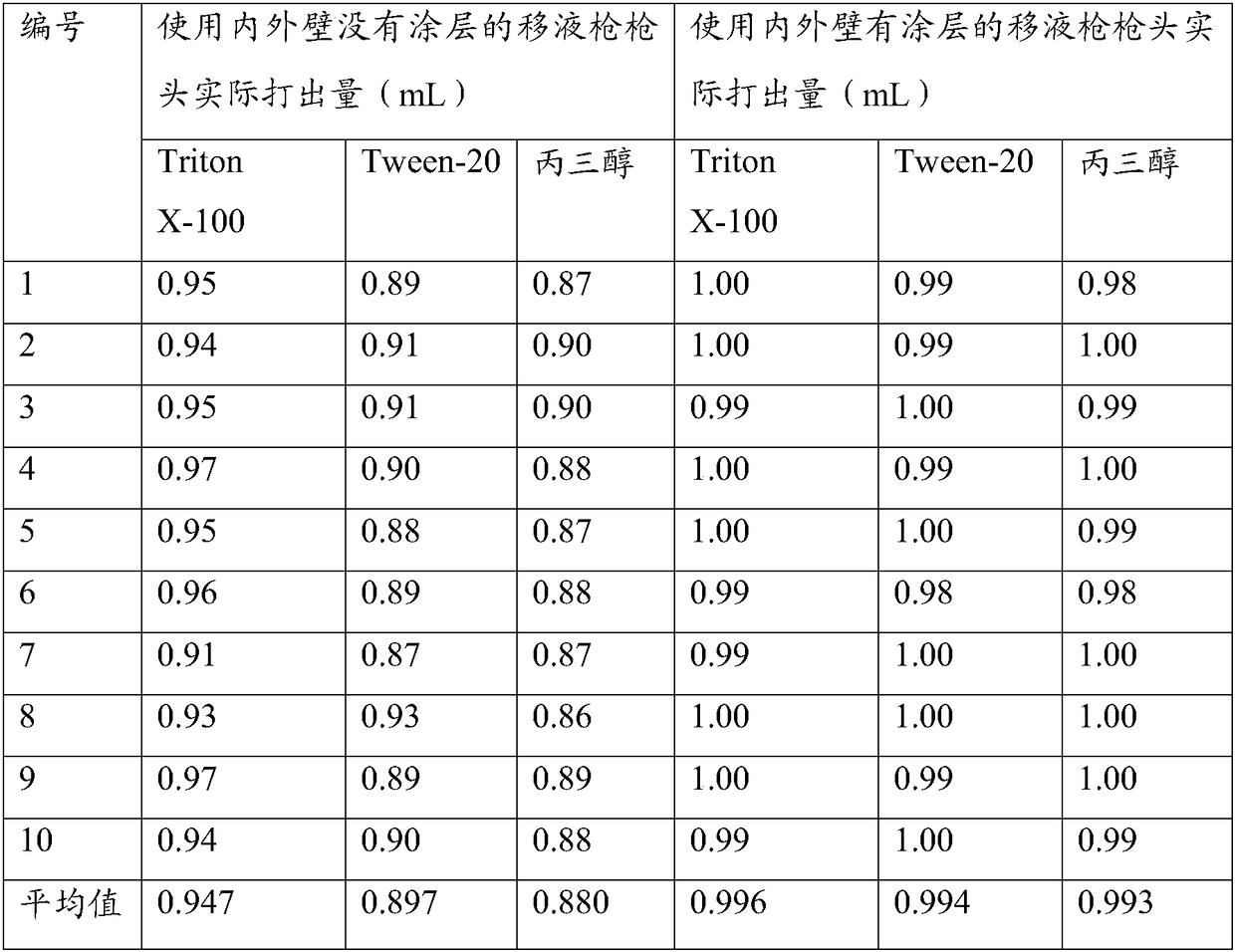

Pipette tip for sucking viscous liquid and preparation method thereof

The invention discloses a pipette tip for sucking viscous liquid. The pipette tip for sucking viscous liquid comprises a pipette tip body which is of a hollow tubular structure, and further comprisesa composite layer and a hydrophobic oil layer. The composite layer is arranged on the surface of the inner and outer tube walls of the pipette tip body, the composite layer comprises an amino acrylicresin and inorganic nano-particles; the surface of the composite layer has a nano-sized protruding structure formed by combining the amino acrylic resin and the inorganic nano-particles; the hydrophobic oil layer is arranged on the composite layer, and the hydrophobic oil layer comprises fluoroalkyl silane. The invention also discloses a preparation method of a pipette tip for sucking viscous liquid. The pipette tip for sucking viscous liquid disclosed the invention not only has good hydrophobicity, but also has oleophobicity, and is mainly used for sucking viscous liquid, effectively reducingthe residue of droplets on the surface of the tip, so that the volume of the droplets dropped is more precise; the spraying method is used to distribute the inorganic nano-particles evenly and make the coating thickness uniform, which is suitable for large-scale standardized production.

Owner:CHINA NAT INST OF STANDARDIZATION

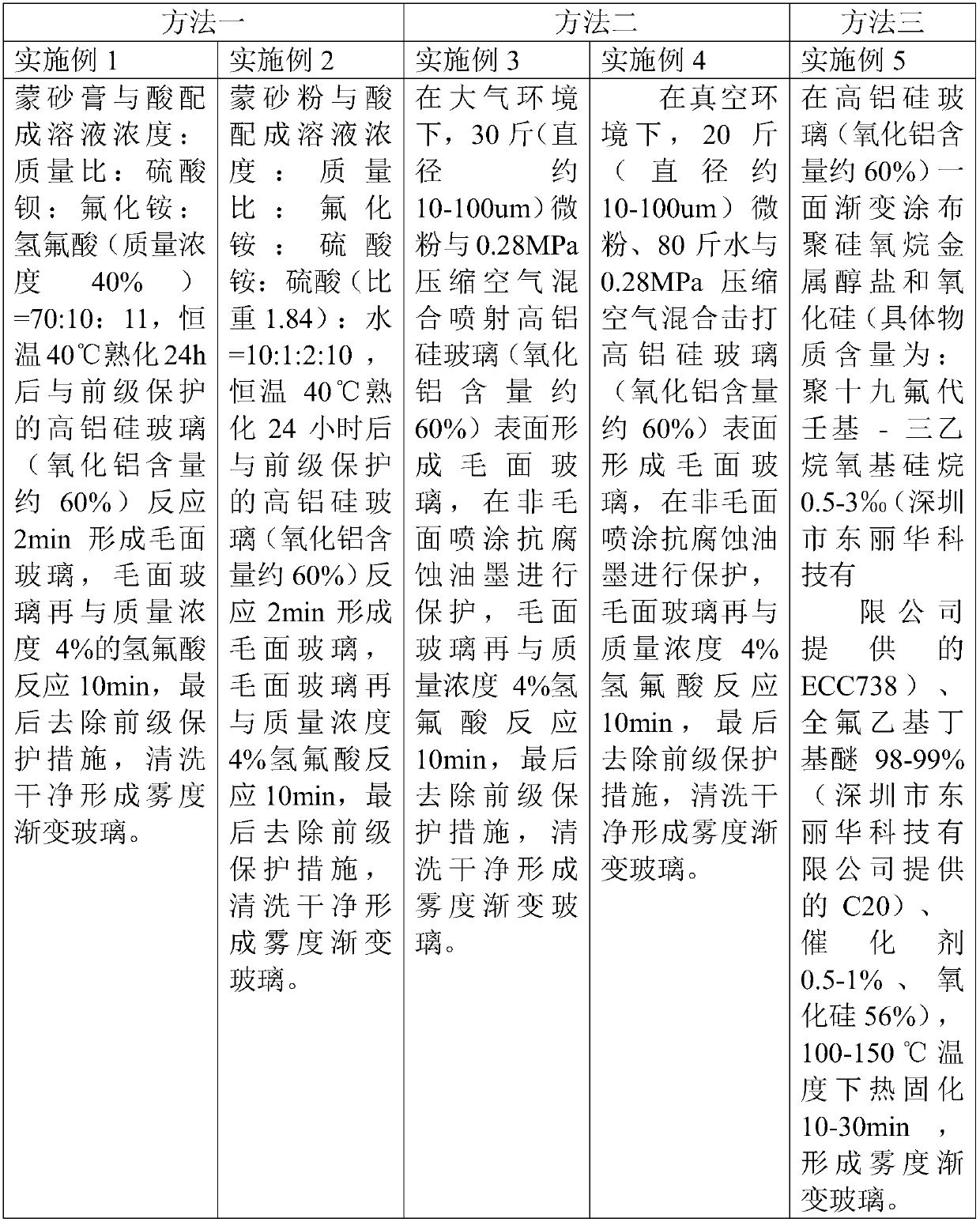

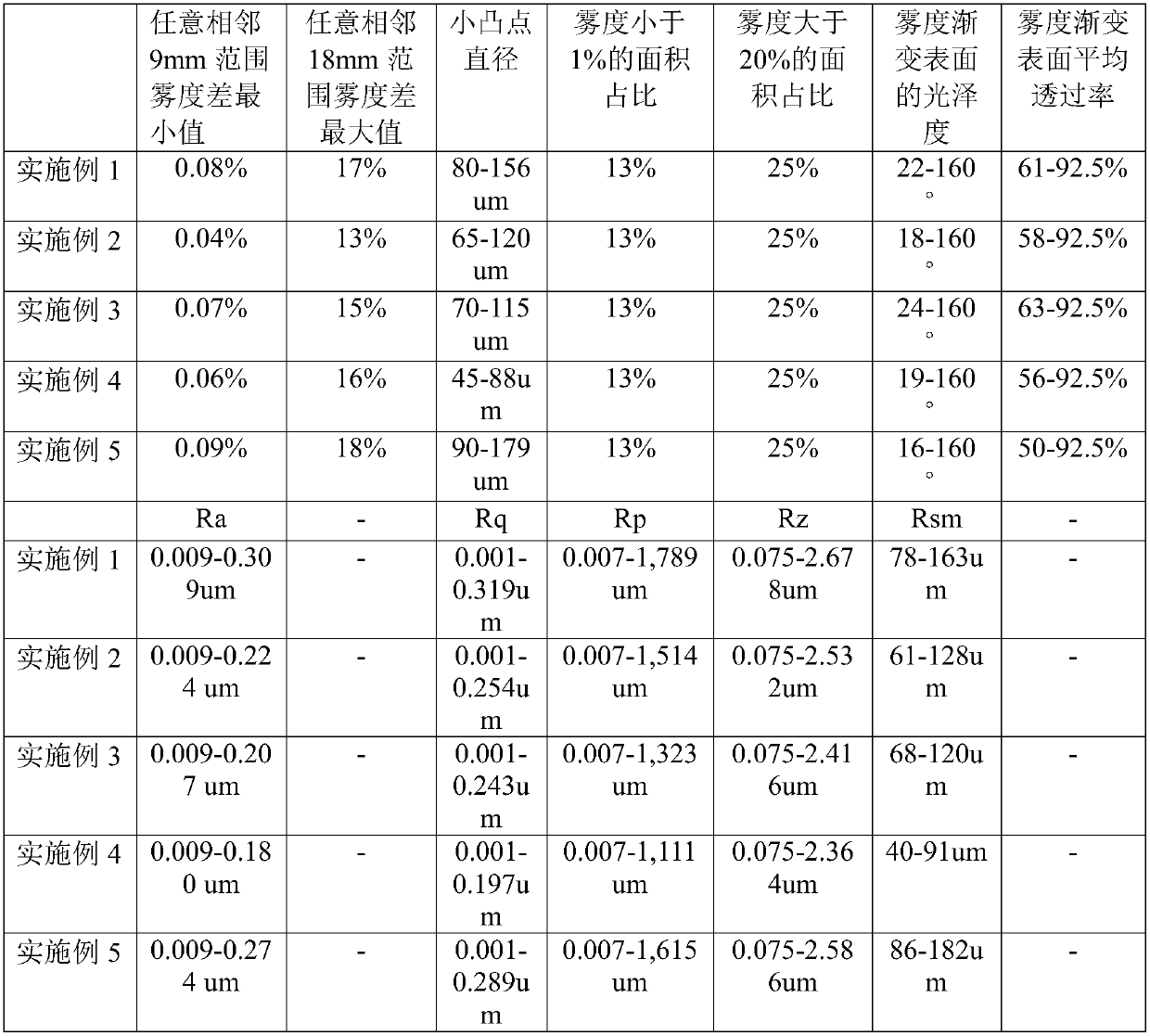

Haze gradient glass, manufacturing method thereof and glass device manufactured by using haze gradient glass

ActiveCN111087169AOleophobicAnti-dirty effectGlass/slag layered productsMechanical engineeringCover glass

The invention discloses a haze gradient glass, a manufacturing method thereof and a glass device manufactured by using the haze gradient glass. The haze of at least one surface of the haze gradient glass is gradually, naturally and continuously changed to form a haze gradient surface; wherein the minimum value of the haze difference is 0.01% in any adjacent 9mm range on the haze gradient surface,the maximum value of the haze difference is 25.00% in any adjacent 18mm range on the haze gradient surface, the haze gradient surface is provided with continuous irregular small convex point structures, and the diameter range of the continuous irregular small convex points is 10-350 [mu]m. The area with the haze smaller than 1% on the haze gradient surface at least accounts for 10% of the total area; and the area with the haze greater than 20% on the haze gradient surface at least accounts for 10% of the total area. A mobile phone rear cover haze gradient glass device prepared from the haze gradient glass not only can meet the requirements of high-speed communication signals, but also can meet the pursuit of consumers for cool, fashionable and aesthetic feeling in appearance, and comparedwith a common white glass rear cover glass device, the rear cover haze gradient glass device has the effects of dirt resistance, skid resistance and good hand feeling in performance.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

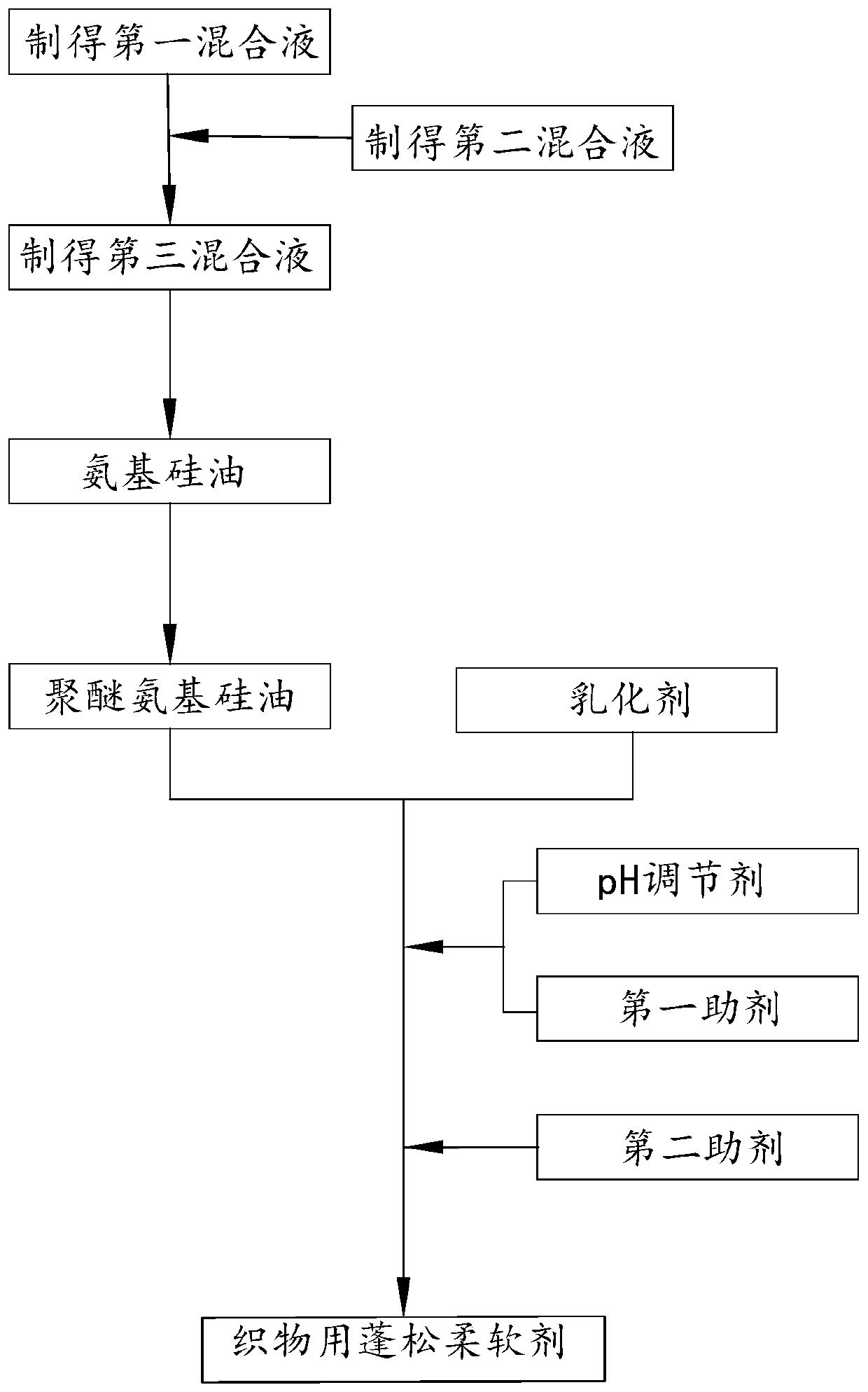

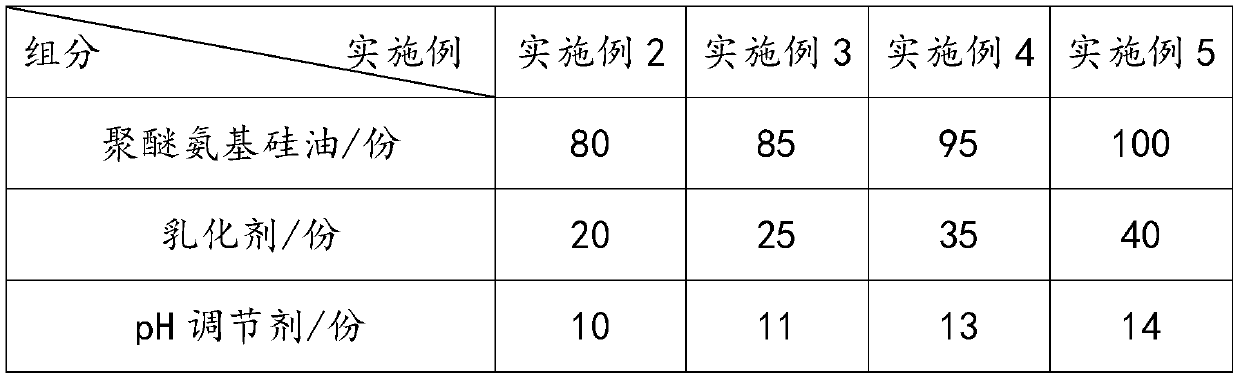

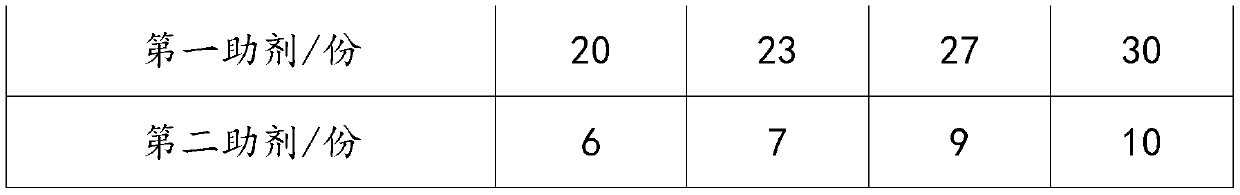

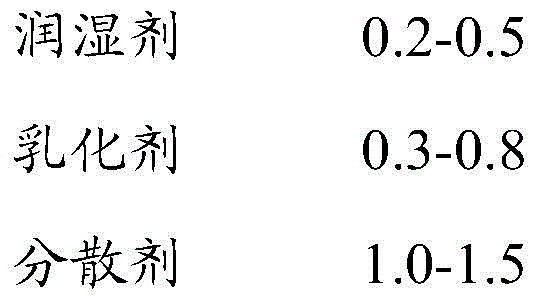

Fluffy softening agent for fabric and preparation method thereof

InactiveCN110184822AFluffy softener, used to improve the fluffy softness of polyether silicone oilImprove hydrophilicityStain/soil resistant fibresBiochemical fibre treatmentEpoxyEther

The invention relates to a fluffy softening agent for a fabric and a preparation method thereof, and relates to the technical field of textile auxiliaries. The softening agent is prepared from, by weight, 80-100 parts of polyether aminopolysiloxane oil, 20-40 parts of an emulsifying agent and 10-14 parts of a pH regulator; the polyethe aminopolysiloxane oil is prepared from, by weight, 30-34% of amino silicon oil, 20-24% of allyl polyoxyethylene propene epoxy ether, 10-14% of allyl polyoxyethylene polyoxypropylene amine ether, 8-12% of methyl hexafluorobutyl acrylate, 10-14% of glycidyl dodecyl dimethyl ammonium chloride and 10-14% of isopropanol. By mixing the polyether aminopolysiloxane oil, the emulsifying agent and the pH regulator, the fluffy softening agent for the fabric is obtainedfor improving the fluffy softness of polyether silicone oil.

Owner:绍兴柯桥欧利助剂有限公司

PS@TiO2 structured color film with non-iridescent effect as well as preparation method and application thereof

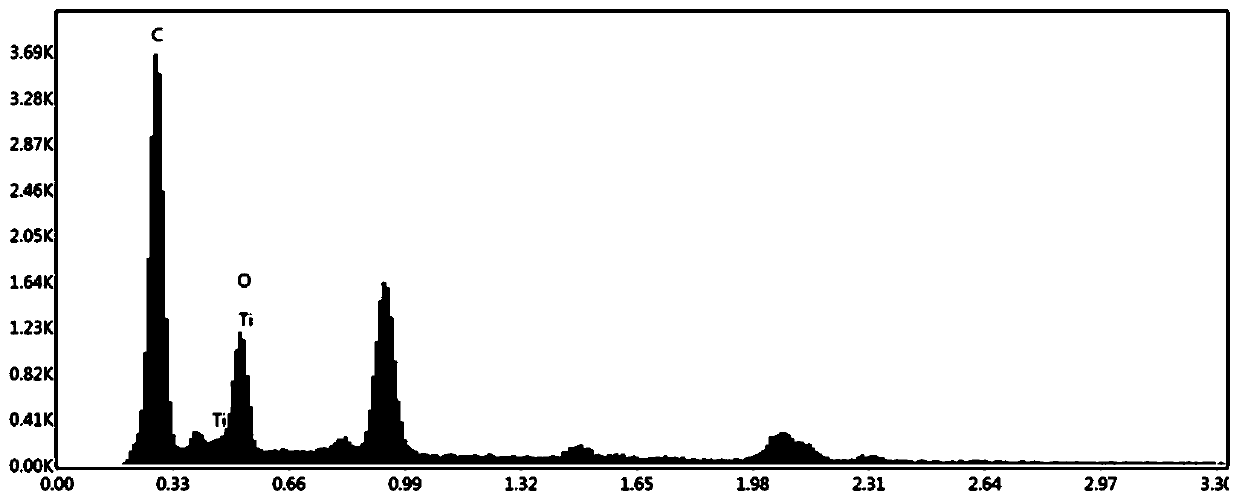

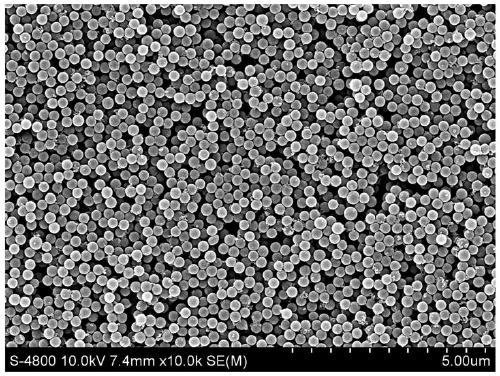

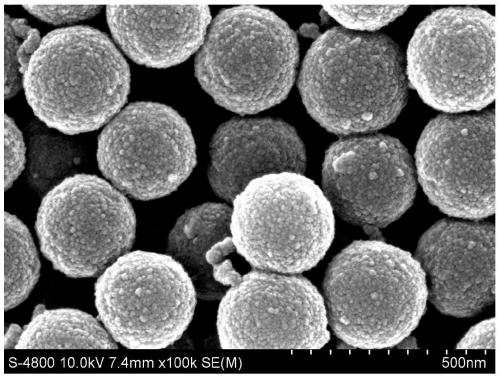

ActiveCN109928643AUniform particle sizeUniform sphericityCoatingsMicrospherePhotonic crystal structure

The invention provides a PS@TiO2 structured color film with a non-iridescent effect as well as a preparation method and application thereof, and the preparation method comprises: uniform particle sizeand monodisperse PS@TiO2 microspheres are firstly prepared by a soap-free liquid polymerization and mixed solvent method, the surface of the PS microspheres is coated with good sphericity degree TiO2nanoparticles with a diameter of about 8 nm uniformly, and a TiO2 shell layer having a thickness of about 10 nm is formed; the TiO2 shell layer is evenly mixed with a carbon black material to obtaina mixture, and the structured color film is obtained by spraying the mixture with a spray gun. The color of the film does not change with the change of the viewing angle, the color is stable to display and is not easy to fade; and the film has broad application prospects in the field of color display, and expands the types of amorphous photonic crystal structure color film materials. The preparation method has the advantages of simple preparation method, strong repeatability, environmental protection safety and non-toxicity; the spraying method has low requirements on a substrate and film coating environment, and is suitable for constructing the structured color film which does not change in color with the change of the viewing angle on various material surfaces, the spraying method can beused for preparing in a large area, and industrialization is easy to realize.

Owner:SHAANXI UNIV OF SCI & TECH

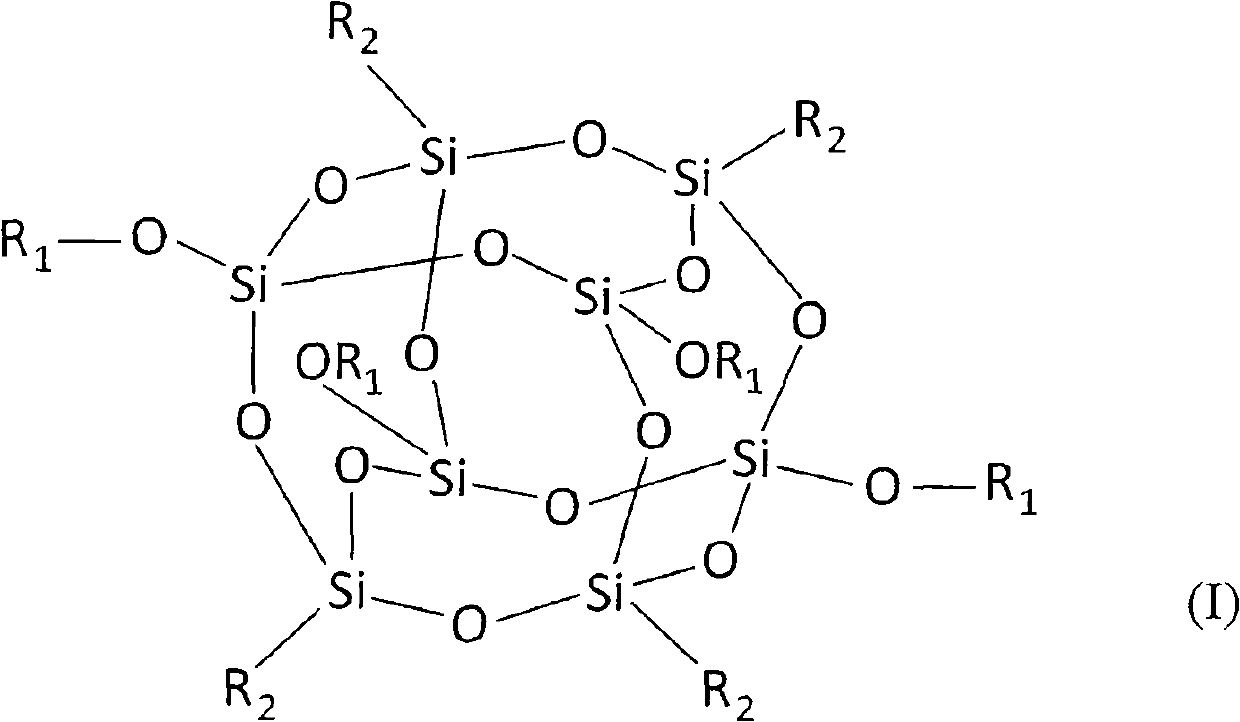

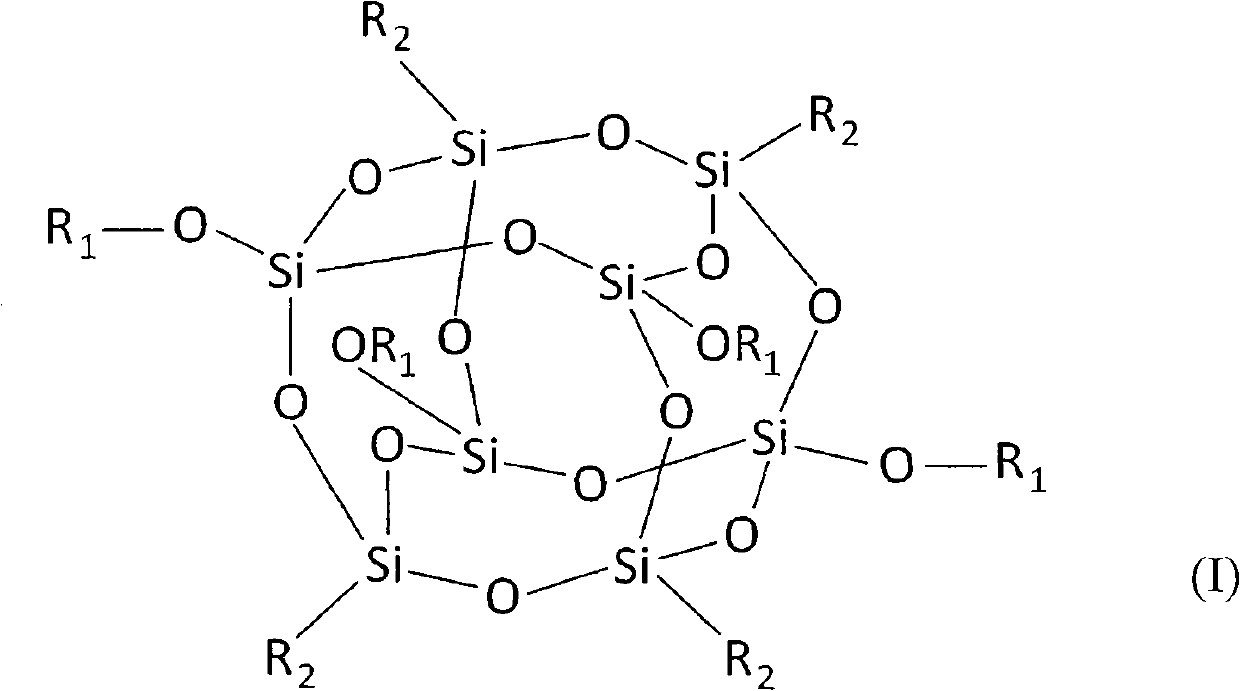

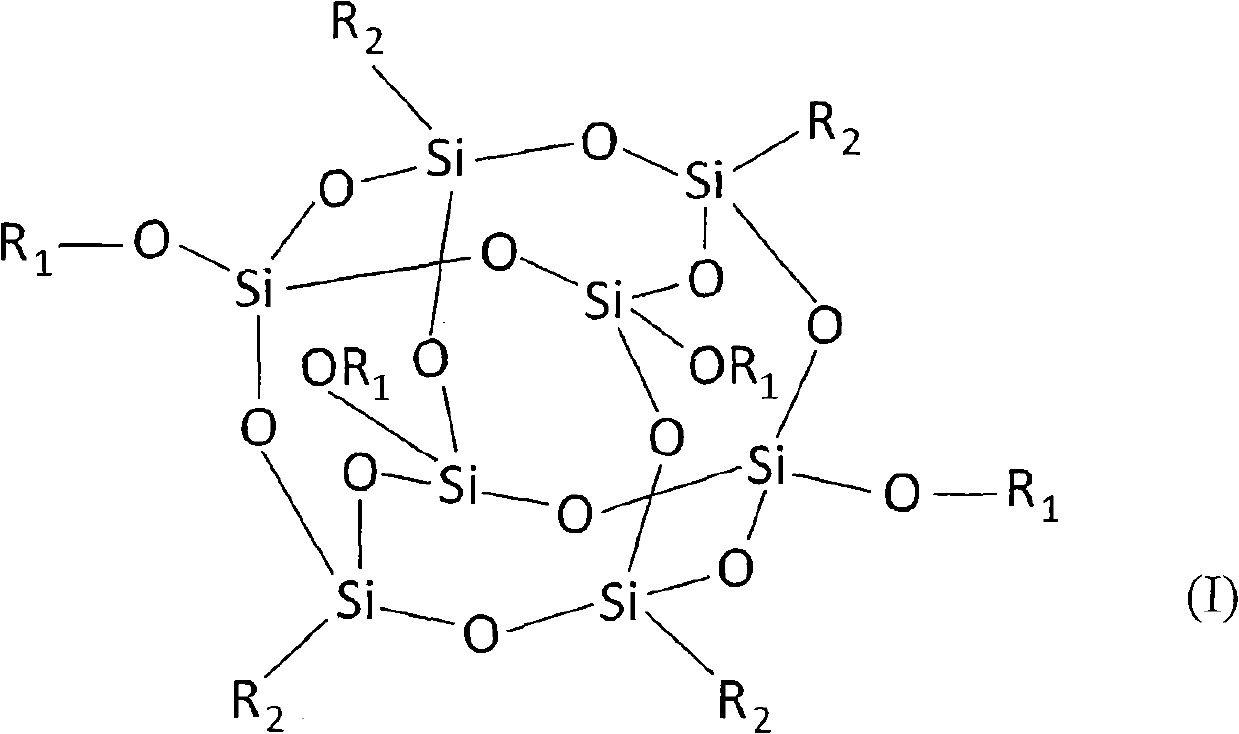

Surface coating with both hydrophobicity and oleophobic property and touch control panel

InactiveCN102558930AHydrophobicOleophobicCoatingsInput/output processes for data processingChemical structureAcyl group

The invention relates to a surface coating with both hydrophobicity and oleophobic property and a touch control panel coated by the surface coating. The surface coating comprises nano particles of chemical structures shown as formula (I): R1 may be halogen, hydrogen, alkyl, alkoxy, hydroxyl, alkenyl, alkyne, acyl, acryl, carboxyl, alkoxycarbonyl or aromatic oxycarbonyl, R2 may be a fluorine-containing group. The touch control panel comprises a conductive layer or an outer cover plate coated by the surface coating with both hydrophobicity and oleophobic property. When the surface coating is coated on the outer cover plate or the conductive layer of the touch control panel, the touch control panel is easy to clean, can resist greasy dirt, can prevent fingerprint generation, and has excellent anti-glare properties by virtue of the excellent hydrophobicity and oleophobic property of the surface coating.

Owner:高丰有限公司

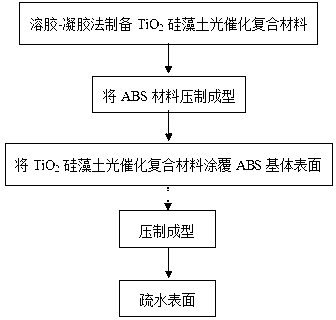

ABS hydrophobic and oleophobic material with surface loaded by TiO2/diatomite, and preparation method thereof

InactiveCN103275456AEasy to useOleophobicOrganic-compounds/hydrides/coordination-complexes catalystsFungicidesCompression moldingPollution

The invention provides an ABS hydrophobic and oleophobic material with surface loaded by TiO2 / diatomite, and a preparation method thereof. The ABS hydrophobic and oleophobic material is composed by the following raw materials by mass: 98-99.9% of an ABS resin and 0.1-2% of a TiO2 / diatomite composite photocatalytic material. The ABS hydrophobic and oleophobic material with the surface loaded by TiO2 / diatomite is obtained by the steps of A. firstly preparing the TiO2 / diatomite composite photocatalytic material, B. dispersing the TiO2 / diatomite composite photocatalytic material in ethanol to form a suspension liquid, and C. coating the suspension liquid on the surface of a mold, then keeping ABS resin particles at the temperature of 100-140 DEG C for 10-30 min, and compression molding at the temperature of 150-180 DEG C; or keeping the ABS resin particles at the temperature of 100-140 DEG C for 10-30 min, compression molding at the temperature of 150-180 DEG C, then coating the suspension liquid obtained by the step B on the surface of the compression molded ABS resin material, and then compression molding at the temperature of 150-180 DEG C. The ABS hydrophobic and oleophobic material has the characteristics of super-hydrophobic surface self-cleaning effect and self-cleaning capacity. The preparation method is simple in process, simple in operations, small in investment, low in operation cost and no pollution to environment.

Owner:KUNMING UNIV OF SCI & TECH

Acrylate-modified calcium carbonate filler capable of improving machinability and preparation method thereof

InactiveCN106675111AIncreased machinability and high pressure resistanceGood padding and reinforcementPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsAmmonium sulfateIon

The invention relates to an acrylate-modified calcium carbonate filler capable of improving machinability, which is characterized by being prepared from the following raw materials in parts by weight: 200 parts of nano calcium carbonate, 6-8 parts of 3-aminopropyltriethoxysilane, 20-25 parts of iron stearate, 10-12 parts of molybdenum disulfide, 6-8 parts of para-polyphenylene, 12-15 parts of sodium p-styrenesulfonate, 5-6 parts of poly(butylene succinate), 4-5 parts of sodium diisopropylnaphthalene sulfonate, 25-30 parts of methyl acrylate, 10-12 parts of ammonium persulfate, 35-45 parts of 2-morpholinoethyl methacrylate, 12-15 parts of titanium diisopropoxide bis(acetylacetonate), an appropriate amount of methanol and an appropriate amount of deionized water. The calcium carbonate filler provided by the invention has the advantages of fineness, uniformity, high whiteness, low wear rate, oleophobicity and good optical property and the like.

Owner:ANHUI JIUZISHAN PLASTIC

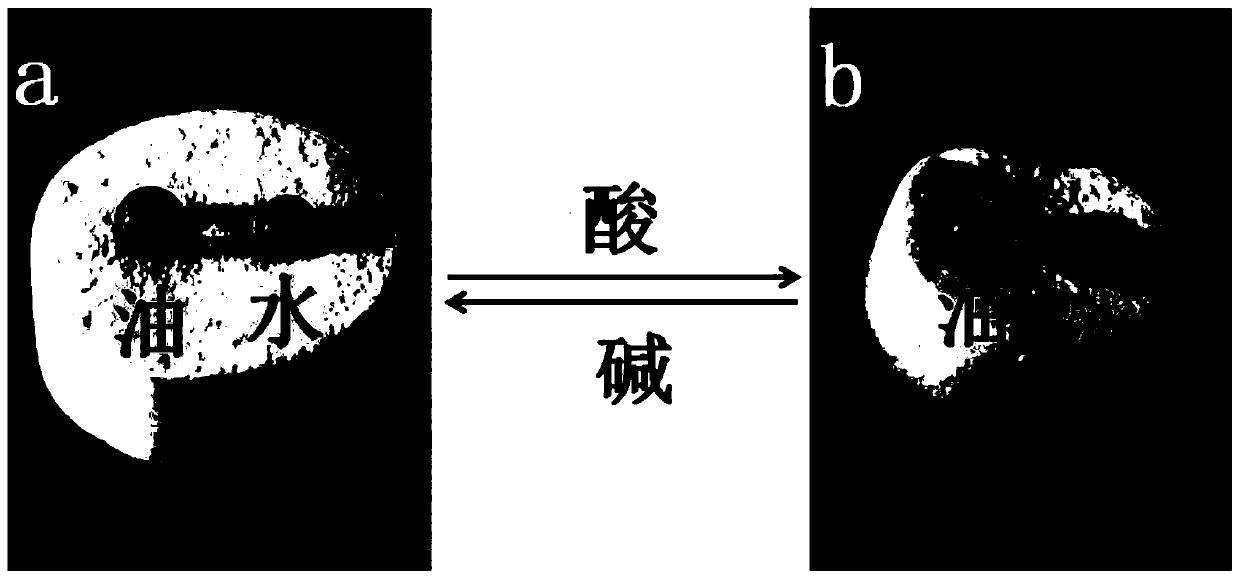

Porous polymer with lipophobicity and pH responsiveness as well as preparation and application thereof

ActiveCN110655607AOleophobicPH responsiveOther chemical processesLiquid separationMethacrylateOil phase

The invention relates to a preparation method of a porous polymer with hydrophobicity, lipophobicity and pH responsiveness. The method comprises the following steps of: adding an oil phase into an aqueous phase, and uniformly mixing to obtain an oil-in-water emulsion, wherein the aqueous phase comprises a water-soluble emulsifier, a water-soluble monomer, a pH responsive monomer, a water-soluble crosslinking agent, a water-soluble initiator and water, and the pH responsive monomer comprises amino-containing methacrylate and / or amino-containing acrylate monomers; performing interfacial initiation polymerization reaction on the oil-in-water emulsion at 30-80 DEG C to obtain the porous polymer with hydrophobic and oleophobic properties and pH responsiveness after the reaction is completed. The porous polymer is treated with a solution with pH of 0 to 4 to obtain a hydrophilic and oleophobic porous polymer. The hydrophilic and oleophobic porous polymer is reversibly converted to the hydrophobic and oleophobic porous polymer after treatment with a solution with pH of 9 to 13. By using the polymer, the functions of pH-controllable collection, removal and the like of water solutions froman oil-water solution mixture can be realized.

Owner:SUZHOU UNIV

Preparation of fluorine-containing organosilicone modified anti-graffiti paint

ActiveCN109054571AEasy to paintEnvironmental protectionAntifouling/underwater paintsPaints with biocidesPolyesterWater based

The invention relates to preparation of fluorine-containing organosilicone modified anti-graffiti paint, in particular to preparation of organosilicone polyester modified cyclopropyl resin. The resin,namely cationic resin, can be used in both aqueous paint and electrophoretic paint, plays an anti-graffiti self-cleaning role in the electrophoretic paint, and is prepared from a fluorine-silicon modified emulsion and high-performance color paste in a ratio of 6:1. The preparation has the advantages that paint products have high storage stability; the paint has high salt spray resistance, high weather resistance and high functionality after electrophoretic coating, and is applicable to painting of kitchens and places with high self-cleaning requirements; the paint is water-based two-componentanti-graffiti electrophoretic paint, and is convenient to apply, environmentally friendly and safe to use; the surfaces of boards are smooth and bright, the functionality is high, and the stability of tank liquor is also high; coatings have high mechanical property, acid-alkali resistance, weather resistance and salt-pray resistance.

Owner:HAOLISEN CHEM TECH (JIANGSU) CO LTD

Acrylic ester modified calcium carbonate packing with good self-lubrication property and preparation method of acrylic ester modified calcium carbonate packing

InactiveCN106634052AImprove self-lubricationGood padding and reinforcementPigment treatment with macromolecular organic compoundsPigment physical treatmentIonAmmonium sulfate

The invention discloses acrylic ester modified calcium carbonate packing with a good self-lubrication property. The acrylic ester modified calcium carbonate packing is characterized by being prepared from the following raw materials in parts by weight: 200 parts of nano calcium carbonate, 6-8 parts of octadecyl trimethyl ammonium chloride, 20-25 parts of vitric, 10-12 parts of decabromodiphenyl ethane, 6-8 parts of poly butylene tertephehalate, 12-15 parts of sodium styrene sulfonate, 5-6 parts of sodium di(2-ethyl-hexyl)sulfosuccinate, 4-5 parts of sorbitan fatty acid ester, 25-30 parts of crylic acid, 10-12 parts of ammonium persulfate, 35-45 parts of hydroxyethyl methylacrylate, 12-15 parts of diacetone-acryloamide, a proper amount of methanol and a proper amount of deionized water. The acrylic ester modified calcium carbonate packing disclosed by the invention has the advantages of being fine, uniform, high in whiteness, low in abrasion rate, oleophobic, good in optical property and the like.

Owner:ANHUI JIUZISHAN PLASTIC

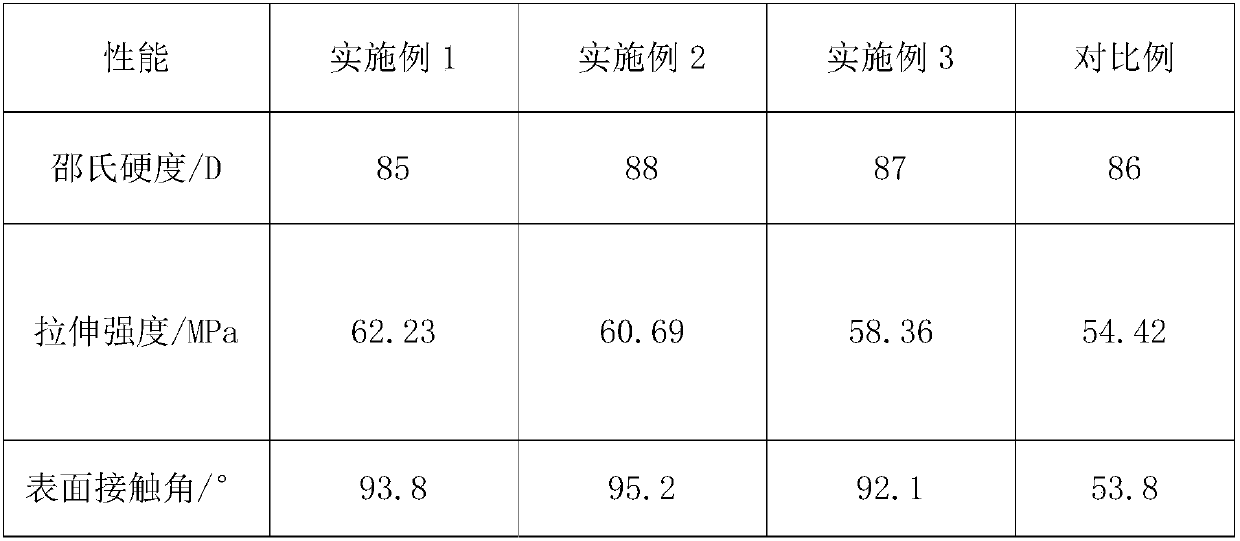

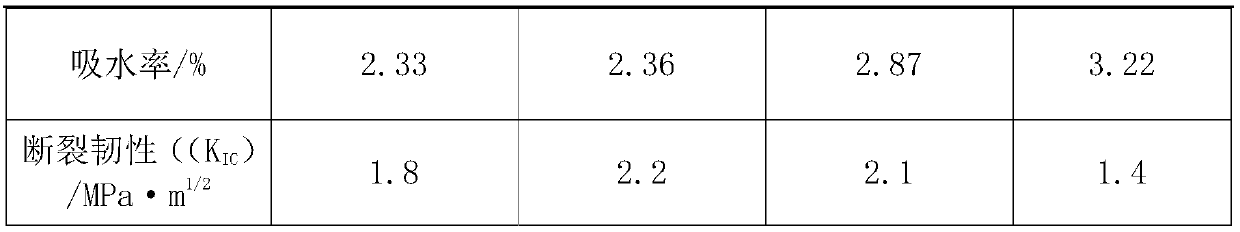

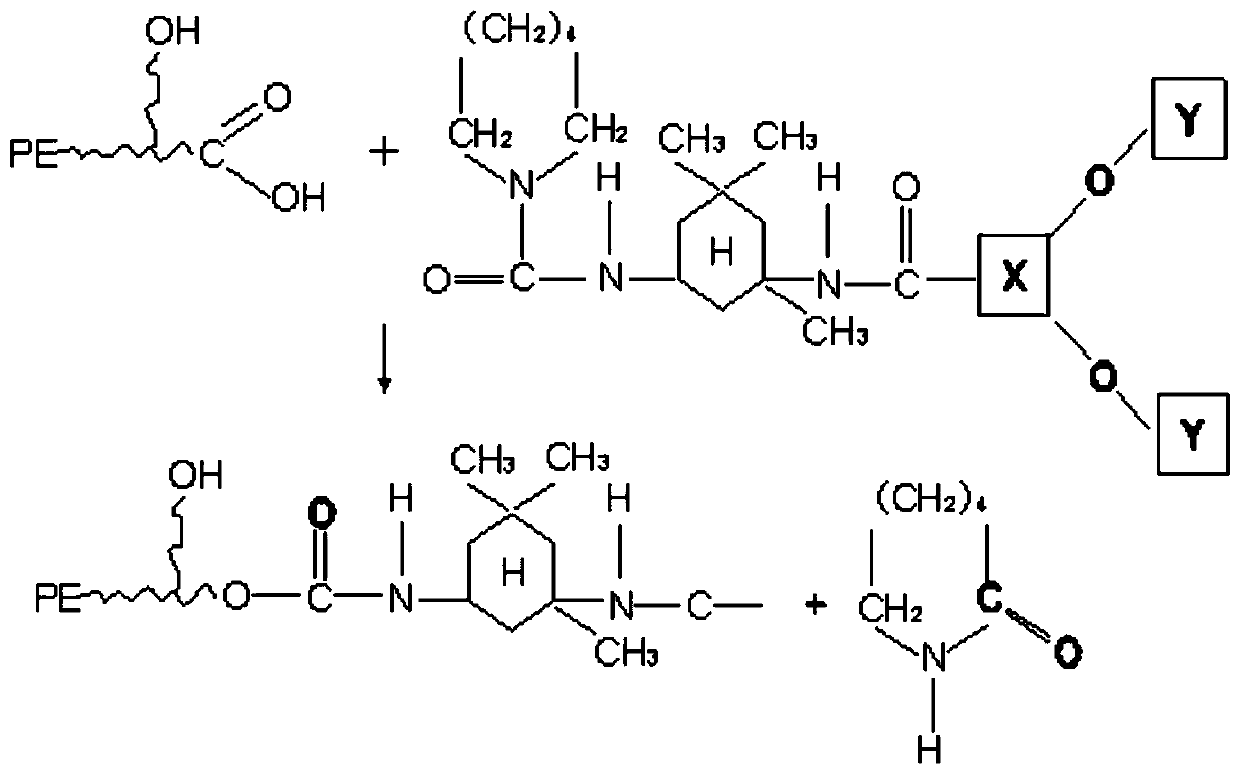

Preparation method of polyurethane modified phenolic resin composition for semiconductor packaging

ActiveCN109679046ALower dielectric constant and water absorptionImprove surface propertiesEpoxy resin adhesivesChemistryChemical Linkage

The invention provides a preparation method of polyurethane modified phenolic resin. The obtained polyurethane modified phenolic resin is suitable for semiconductor packaging. According to the methodprovided by the invention, an organic fluorine group and a polyurethane group are bonded in a phenolic resin compound through chemical bonds by controlling a ratio of the organic fluorine group to thepolyurethane group in the phenolic resin, thereby realizing effective dispersion of the organic fluorine group and the polyurethane group in phenolic resin, and the mechanical properties and surfaceproperties of a polyurethane modified phenolic resin material can be effectively adjusted. By applying the polyurethane modified phenolic resin as a curing agent to modification of an epoxy resin composition, the modulus of the epoxy resin composition can be greatly reduced, and meanwhile, the processability and solder resistance of the epoxy resin composition in the semiconductor packaging can beimproved. The polyurethane modified phenolic resin for semiconductor packaging provided by the invention also has necessary fluidity, filling property and flame retardancy.

Owner:NINGBO DUNHE TECH CO LTD

Preparation method of anti-fouling composite insulator shed rubber

InactiveCN107400370ASolve the problem of adsorption pollutionInhibition of hydrationPlastic/resin/waxes insulatorsTitanium chlorideComposite insulators

The invention relates to a preparation method of anti-fouling composite insulator shed rubber. The method comprises the following steps: (1) prefabricating a super-hydrophobic mixed nano powder material, namely adding nano-silica, nanometer titania, nano calcium phosphate and nano zinc oxide to a fluidized bed reactor, carrying out dewatering and drying, introducing silazane and alkyl siloxane into the fluidized bed reactor in an airflow form, carrying out fluidization reaction, vacuumizing and removing volatile matters to prepare a mixed nano powder material; and (2) refining the rubber for a shed, namely adding fluorinated polyimide, fluorinated silicone rubber and methyl vinyl silicone rubber to a rubber mixing mill, mixing and then adding the super-hydrophobic mixed nano powder for refining, adding aluminum oxide, barium oxide and zinc oxide superfine powder for refining; adding ferrocene, aluminum chloride, titanium chloride, tetrakis dimethyl amino hafnium and ammonium iodide and mixing at constant temperature; adding a peroxide vulcanization initiator, mixing at the constant temperature until an even effect is achieved; and transferring the material to a twin-screw extruder and extruding to prepare the shed rubber.

Owner:HEBEI SILICON VALLEY CHEM CO LTD

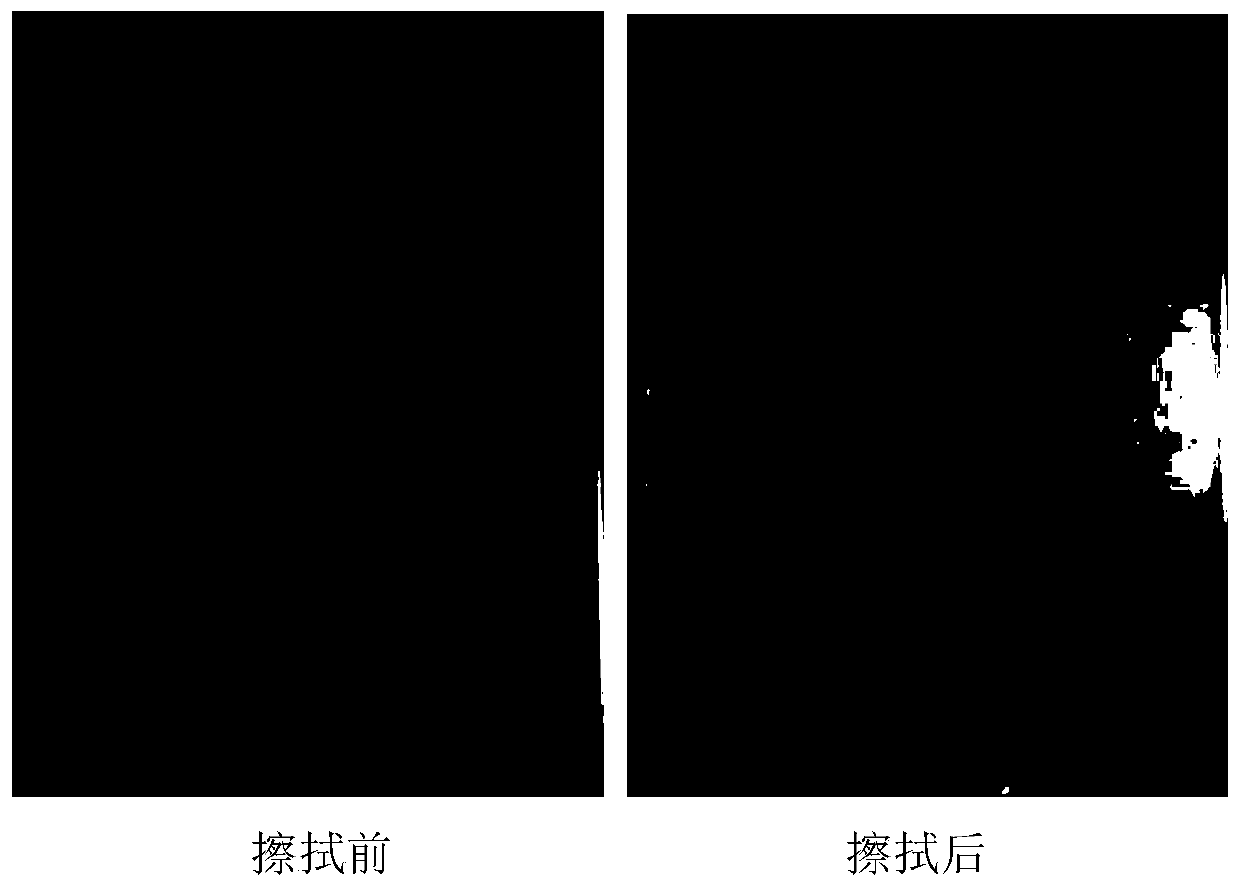

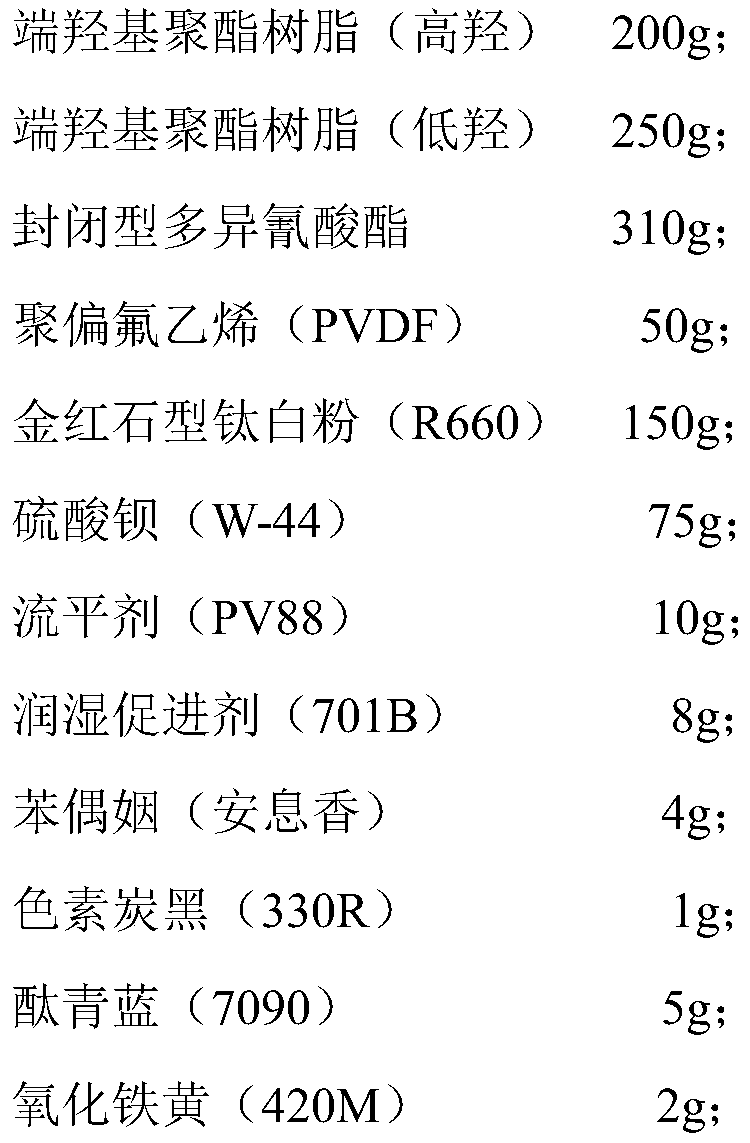

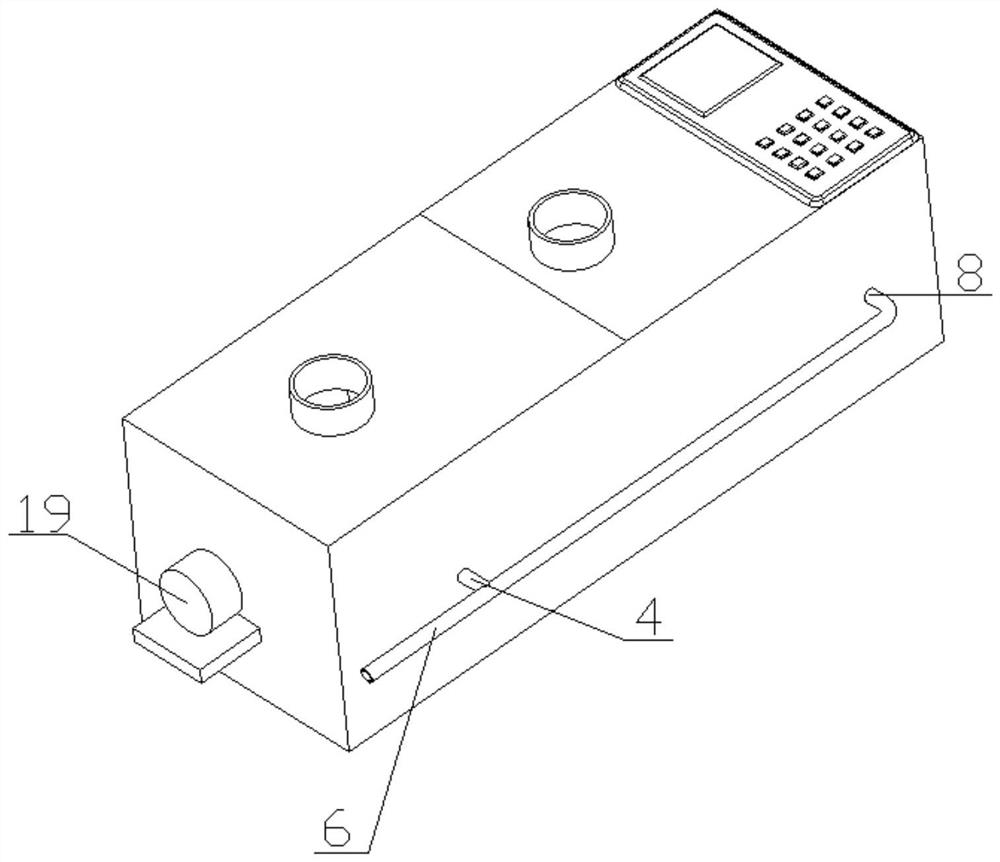

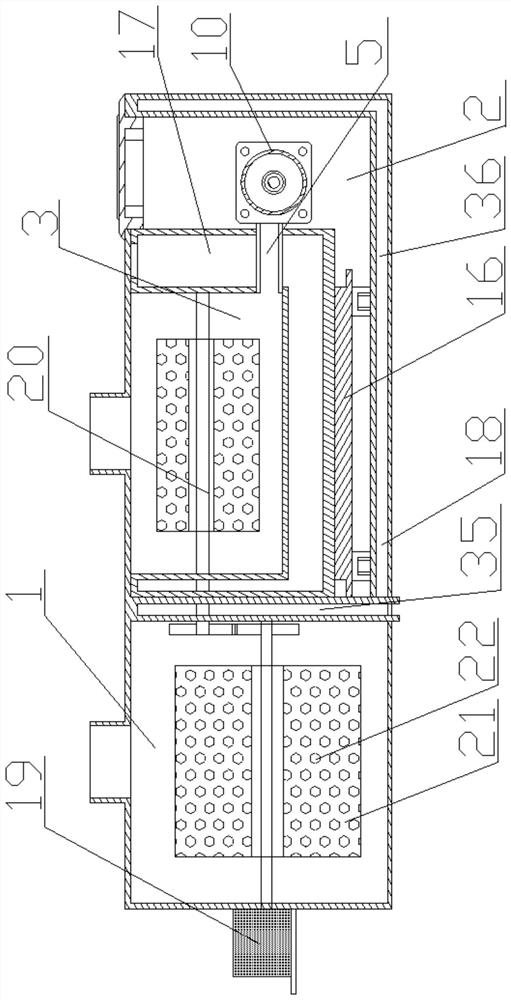

Anti-doodling polyurethane powder paint, preparation method and application thereof

InactiveCN110669420AStrong anti-fouling abilityEasy to cleanAntifouling/underwater paintsPaints with biocidesPolyvinylidene fluorideBenzoin

The invention discloses an anti-doodling polyurethane powder paint, which comprises the following raw materials by mass: 400-500 parts of hydroxyl-terminated polyester resin, 200-250 parts of closed polyisocyanate, 40-60 parts of polyvinylidene fluoride, 120-150 parts of rutile titanium dioxide, 60-70 parts of barium sulfate, 8-10 parts of a leveling agent, 8-10 parts of a wetting accelerator, 3-5parts of benzoin, 1 part of pigment carbon black, 0.5 part of phthalocyanine blue and 2 parts of iron oxide yellow. After the powder paint is coated to form a film, the surface hardness is high (up to 4H), the surface is hardly damaged in the repeated wiping process, and also has the characteristics of hydrophobicity, oleophobicity, strong anti-fouling ability, easy cleaning and good anti-doodling effect. The invention also discloses a preparation method characterized by convenient operation, low cost and short making period, and application of spraying the polyurethane powder paint to a metal surface and performing curing into a film by high-temperature baking.

Owner:HUNAN LIANXIN SCI & TECH CO LTD

Phase-change microbial capsule grouting method for seepage prevention of fractured rock mass

PendingCN112324465ATo achieve anti-seepageOvercoming prejudices that cannot be usedUnderground chambersTunnel liningMicroorganismParaffin wax

The invention discloses a phase-change microbial capsule grouting method for seepage prevention of fractured rock mass. The method comprises the following steps of, S1, determining a grouting hole site on a rock mass fracture, and drilling to form a grouting hole; S2, mixing a paraffin capsule with boosting oil to obtain a first mixture; S3, mixing a microbial capsule with water to obtain a secondmixture; S4, heating the first mixture, and keeping the temperature of the first mixture at 35 - 40 DEG C; and S5, continuously injecting the second mixture into the rock mass fractures through a grouting device, and meanwhile, the intermittently injecting the first mixture into the rock mass fractures through the grouting device. The paraffin capsule and the boosting oil are used for storing heat in advance, then the first mixture and the second mixture are simultaneously and continuously injected into the rock mass fracture through the grouting device, liquid-solid phase change can be generated through precooling of the paraffin capsule, and heat is released, so that the effect of increasing the fracture temperature is achieved, a good environment is provided for microorganism growth, and rock mass seepage prevention in the alpine region is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

High-wear-resistant high-hardness nanoscale titanium crystal coating liquid and preparation method thereof

ActiveCN104073033AHigh hardnessImprove wear resistanceWax coatingsAdditivesPhysical chemistryTrimethylolpropane

The invention discloses high-wear-resistant high-hardness nanoscale titanium crystal coating liquid and a preparation method thereof. The coating liquid comprises the following components by weight percent: 30%-60% of wax-doped TiO2, 2%-8% of a dispersant, 20%-40% of a hydroxyl solvent and 20%-50% of an alkyl solvent, wherein the hydroxyl solvent is, for example, trimethylolpropane; the alkyl solvent is, for example, dodecylbenzene; the dispersant is, for example, Troysol 98c. The preparation method comprises the following steps: heating, displacing, performing wax mixing, and forming. The coating liquid has the characteristics of improving the hardness, brightening the surface, avoiding oxidation and the like, is long-acting and has a safety protection effect; the coating liquid is simple to prepare and low in cost, can be applied to coating protection and lubricating oil protection, and is suitable for the fields of machinery such as vehicles and household appliances, buildings and others.

Owner:昆仑中天(广州)创新科技有限公司

Preparation method of silica gel baking pad with good oleophobicity

The invention discloses a preparation method of a silica gel baking pad with good oleophobicity, and relates to the technical field of food silica gel. The method comprises the following steps: (1) mixing vinyl silicone oil, hydrogen-containing silicone oil, rosin resin graft modified hydrogen-containing silicone oil, an inhibitor, a catalyst, modified nano silicon dioxide and a silane coupling agent to prepare liquid silica gel; (2) allowing the liquid silica gel obtained in the step (1) to stand, and performing treatment on the liquid silica gel after standing by adopting ultrasonic waves toobtain pretreated liquid silica gel; and (3) injecting the pretreated liquid silica gel obtained in the step (2) into a mold, performing drying until the liquid silica gel in the mold forms a semi-solidified state, and putting the semi-solidified silica gel in a plasma reaction chamber. The method provided by the invention can prepare the silica gel baking pad with excellent performance by rationally proportioning the raw materials of the silica gel baking pad, and the silica gel baking pad prepared by the method has oleophobicity.

Owner:史雪芳

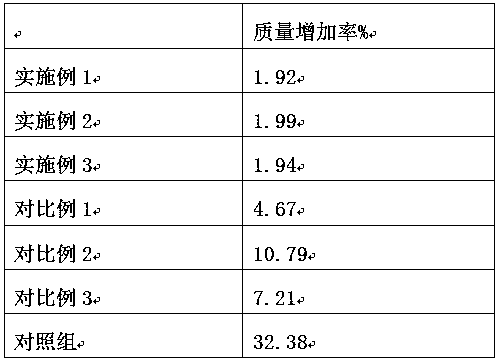

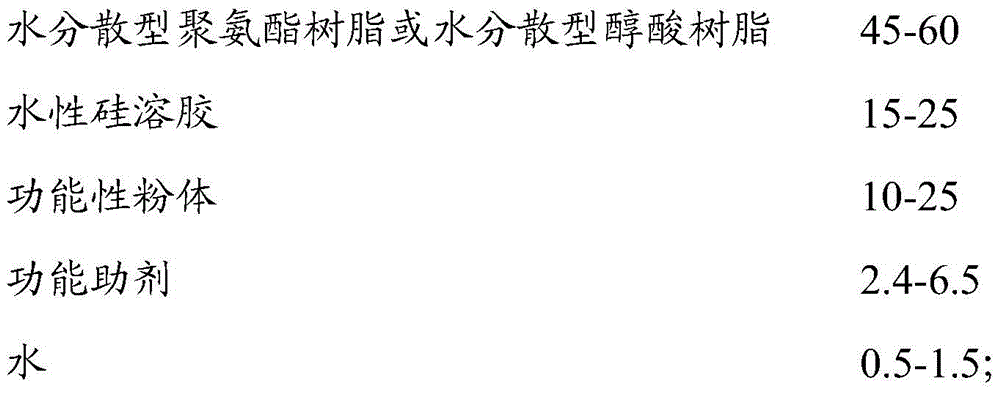

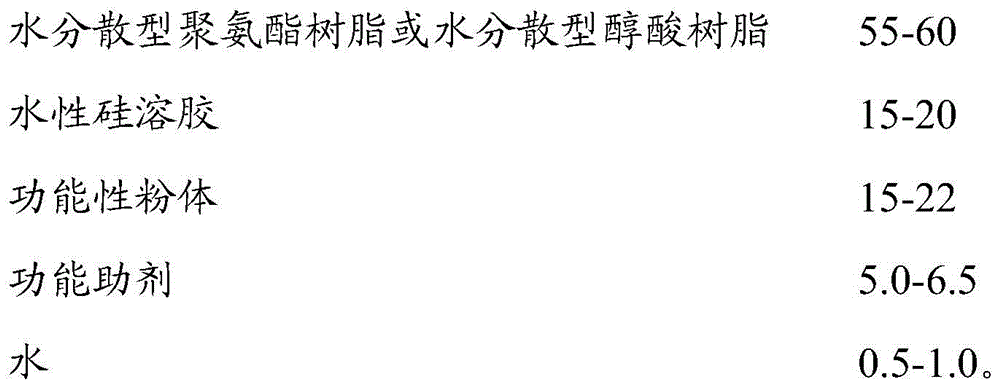

Self-cleaning water-based wood topcoat and preparation method thereof

InactiveCN104403541BLow costSelf-drying at low temperaturePolyurea/polyurethane coatingsPolyester coatingsWater basedNetwork structure

The invention discloses a self-cleaning water-based woodware finish paint and a preparation method thereof. The self-cleaning water-based woodware finish paint comprises the following raw material components in parts by weight: 45-60 parts of water-dispersed polyurethane resin or water-dispersed alkyd resin, 15-25 parts of water-based silica sol, 10-25 parts of functional powder, 2.4-6.5 parts of a functional additive and 0.5-1.5 parts of water, wherein the functional powder comprises the following raw materials in parts by weight: 25-50 parts of nanometer talcum powder, 25-50 parts of nanometer calcium carbonate and 25-50 parts of nanometer kaolin. According to the water-based woodware finish paint, the property that the stability of the water-based silica sol is high is utilized, nanoscale aperture and a continuous three-dimensional network structure are adopted, and a nanometer filling material is added, so that the finally formed film has lower surface energy, the water-based woodware finish paint which can be dried in air and is lower in cost, healthy and safe, is prepared, the defect that the coating can easily shrink when being dried is overcome, and the coating can achieve the characteristics of being self-cleaning, antifouling, hydrophobic, oleophobic and the like.

Owner:广州益景春环保材料科技有限公司

A kind of anti-fog type antifouling flashover coating and its preparation method and application

ActiveCN106085219BImprove hydrophobicityGood oleophobic effectFireproof paintsAntifouling/underwater paintsParticulatesPolymer science

The invention discloses an anti-haze and anti-pollution-flashover coating as well as a preparation method and an application thereof and belongs to the technical field of chemical coatings. White carbon black and MQ resin are taken as reinforcing materials of the anti-haze and anti-pollution-flashover coating. Compared with the traditional RTV (room temperature vulcanization) silicone coatings, the anti-haze and anti-pollution-flashover coating has double-phobic technological advantages including hydrophobic and oleophobic, has a self-cleaning function on dust particulate matters, can prevent adhesion of organic fouling, resists weather and salt-spray corrosion, thereby having the anti-haze performance..

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +1

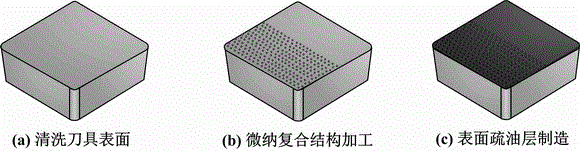

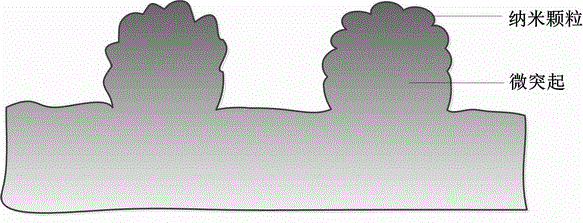

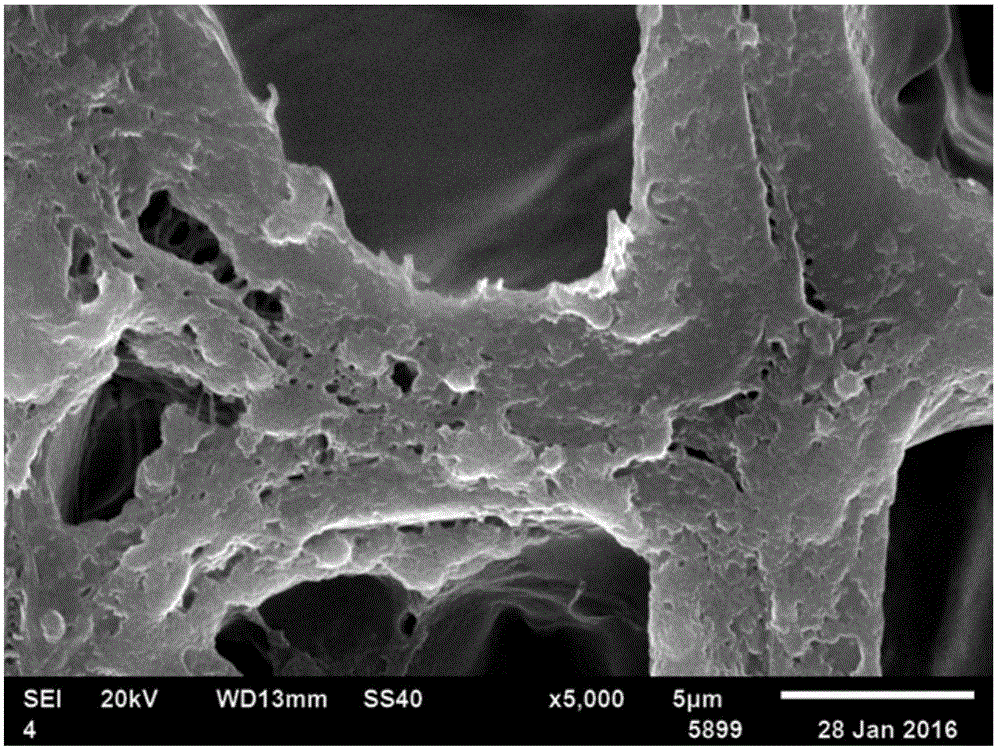

Preparation method of oleophobic cutter with micro-nano composite structure surface

ActiveCN105619041AImprove lubrication statusReduce frictionAustenitic stainless steelSurface finishing

The invention discloses a preparation method of an oleophobic cutter with a micro-nano composite structure surface, and belongs to the technical field of manufacturing of mechanical cutting tools. A micro-nano composite structure can be machined on the surface of a cutter by using a laser processing technology, and is micron projections formed on the surface of the laser-processed cutter and nano particles on the micron projections; and a certain surface treatment is performed for the composite structure to form an oleophobic cutter surface with the micro-nano composite structure. Under the lubricating condition, because of lipophobicity of the cutter surface, cutting liquid can be supplied to a cutter-chip interface more quickly, the lubricating state of a cutting area can be improved, the friction force of the cutter-chip interface is reduced, the guarantee is provided for friction reduction and wear reduction of the cutter, the cutting temperature can be lowered, and the bonding phenomenon of the cutter surface is relieved; and the oleophobic cutter can be widely applied to cutting and high-speed cutting of difficult cutting materials (such as titanium alloys, ultrahigh-strength steel, austenitic stainless steel), so that the cutter durability and the workpiece surface quality can be greatly improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Nano antifouling coating and preparation method thereof

InactiveCN107936635AOleophobicEnhanced oleophobic propertiesAntifouling/underwater paintsPaints with biocidesFiberMicrosphere

The invention provides a nano antifouling paint and a preparation method thereof, which relate to the field of paint. Prepared from the following raw materials by weight: 35-45 parts of propylene emulsion, 5-10 parts of kaolin, 3-5 parts of diatomaceous earth, 5-8 parts of talcum powder, 5-10 parts of ceramic fiber, 3-5 parts of hollow glass Microspheres, 5-10 parts of paraffin oil, 20-30 parts of glycerin solution, 5-10 parts of sodium hydroxide solution, 5-8 parts of coalescent, 10-15 parts of acrylic acid. The invention provides a nano antifouling paint and a preparation method thereof, which can make the prepared paint have better oil repellency, thereby achieving antifouling effect.

Owner:合肥华福土工合成材料有限公司

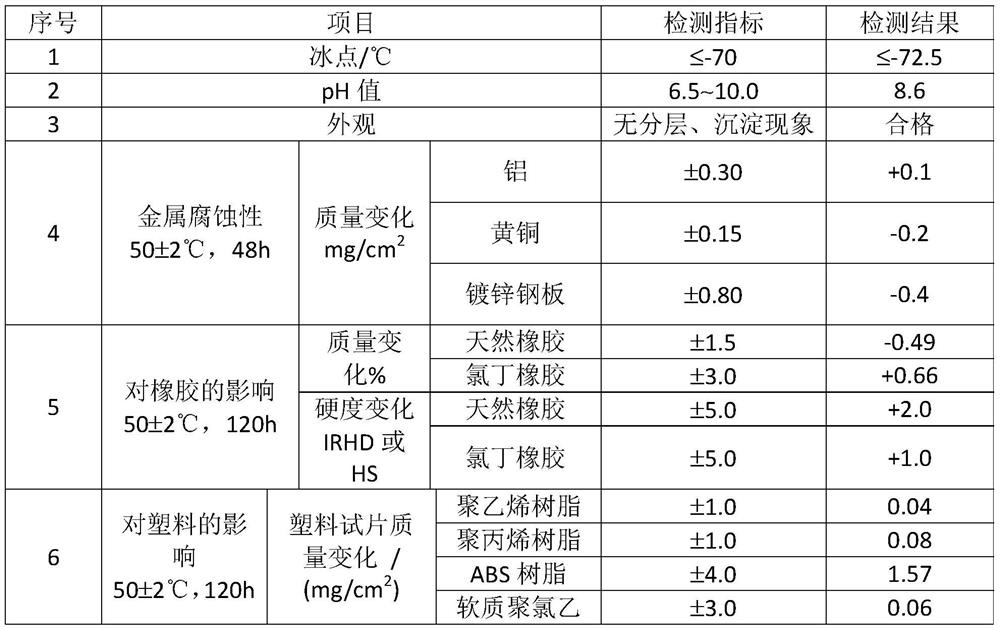

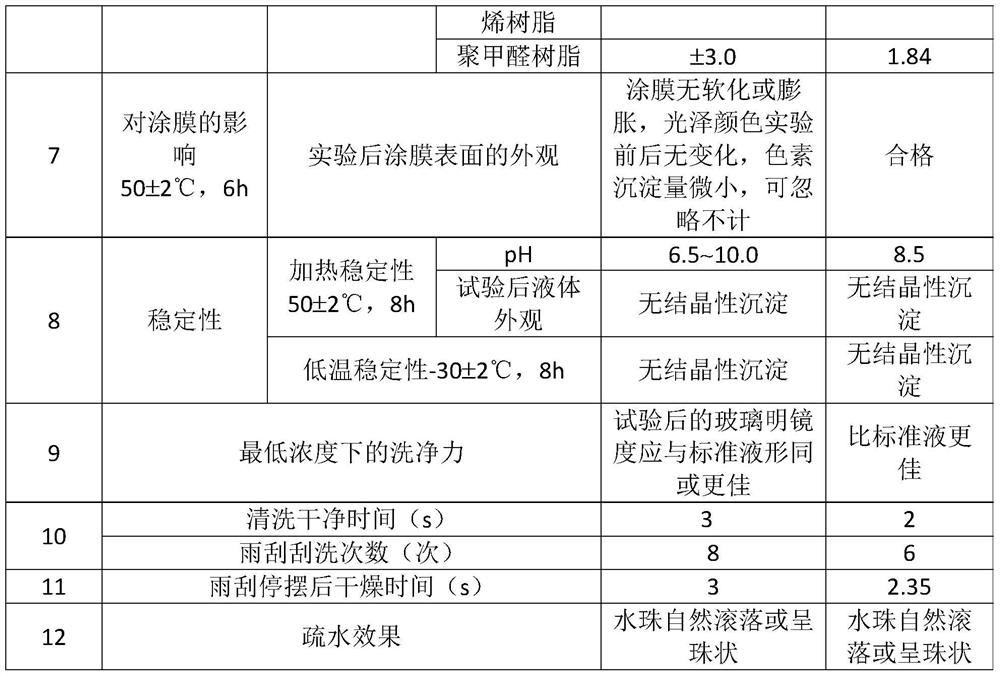

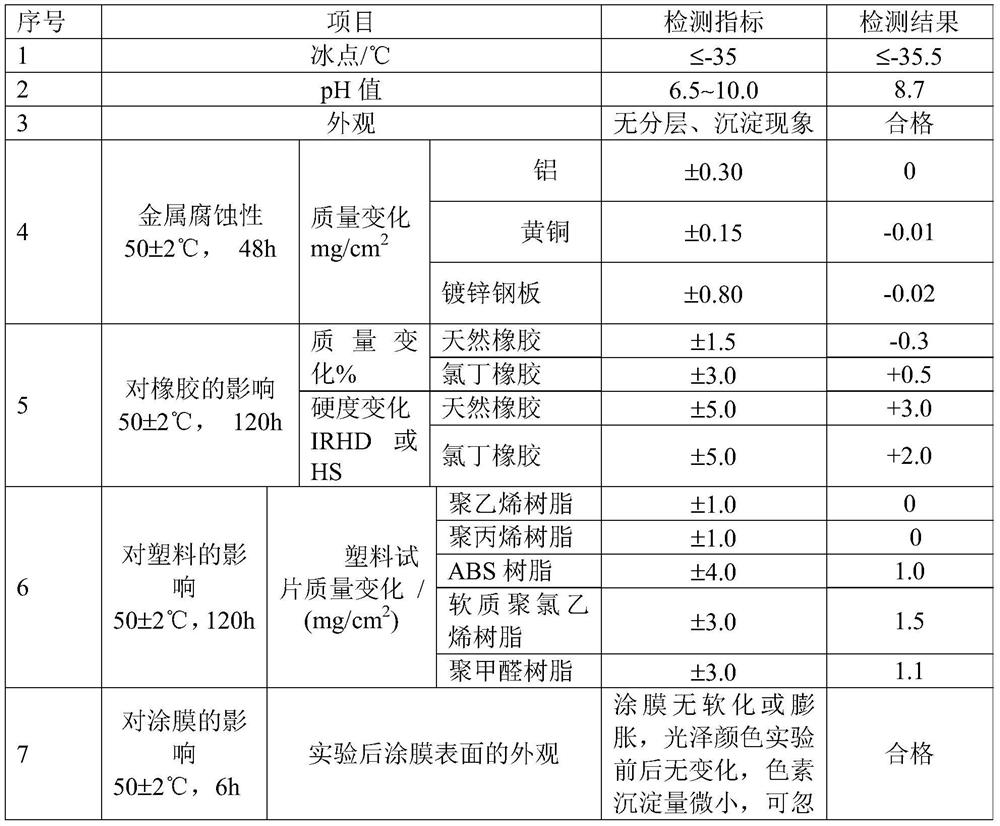

Glass cleaning solution, and preparation method and application thereof

PendingCN113046197AReduce surface tensionReduce dispersionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsBetaineActive agent

The invention relates to the field of glass cleaning solutions, and discloses glass cleaning solution, and a preparation method and application thereof. The glass cleaning solution contains a zwitterionic surfactant and / or a nonionic surfactant, alcohol and water; the zwitterionic surfactant is selected from one or more of cocamidopropyl betaine, alkyl dimethyl betaine and dodecyl ethyoxyl sulphobetaine, and the zwitterionic surfactant is selected from one or more of cocamidopropyl betaine, alkyl dimethyl betaine and dodecyl ethyoxyl sulphobetaine; and the nonionic surfactant is selected from one or more of perfluoroalkyl polyoxyethylene ether, fluorinated alkyl sulfonate and fluoroalkyl polysiloxane. The glass cleaning solution is high in cleaning capacity, can form a hydrophobic film with high light transmittance on the surface of glass after cleaning, can meet the use requirements under the working condition of low temperature of -35 DEG C to -100 DEG C, and does not precipitate or crystallize after being stored for 2 years or more in an environment from room temperature to low temperature.

Owner:张家港迪克汽车化学品有限公司

Formula for novel antimicrobial nylon seal

The invention discloses a formula for a novel antimicrobial nylon seal. The formula comprises, by weight, 100 parts of nylon, 5 to 10 parts of a luffa seed extract, 4 to 6 parts of an antimicrobial fig extract, 0.5 to 0.8 part of a flexibilizer and 0.6 to 1 part of a plasticizer. The nylon seal provided by the invention has an antimicrobial effect and oleophobic performance and is especially applicable to refrigerator door seals.

Owner:青岛永卓真塑料制品有限公司

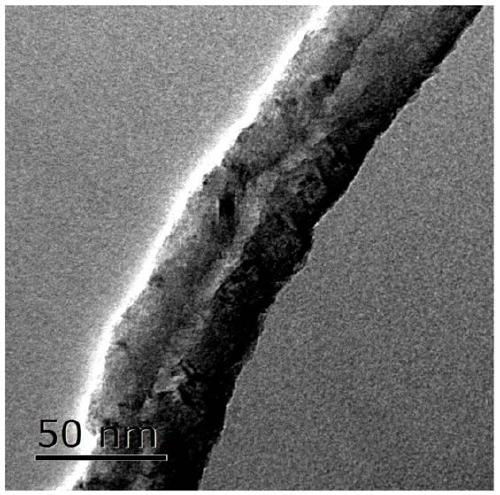

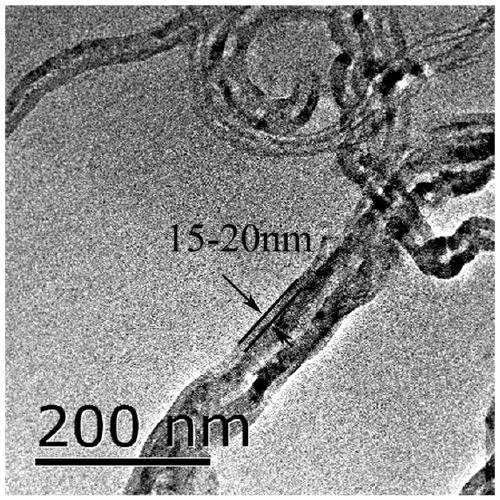

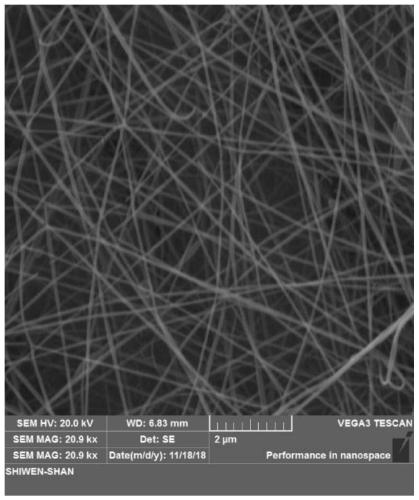

Styrene-maleic anhydride copolymer/carbon nanotube non-woven fabric and preparation method thereof

InactiveCN109763258AHigh mechanical strengthExtend the life cycleFibre typesFilament/thread formingN dimethylformamideCarbon nanotube

The invention discloses a styrene-maleic anhydride copolymer / carbon nanotube non-woven fabric and a preparation method thereof. The preparation method comprises the following steps: 1), preparing acidified carbon nanotubes; 2), preparing carbon nanotube / PSMA; 3), dissolving the carbon nanotube / PSMA obtained in the step 2) in N,N-dimethylformamide to obtain a spinning solution; 4), electrospinningthe spinning solution to obtain a non-woven fabric; 5), spraying a fluorocarbon surfactant solution to the non-woven fabric obtained in step 4). According to the non-woven fabric, the carbon nanotubescan be uniformly dispersed in a styrene-maleic anhydride copolymer by surface functionalization, and mechanical strength of the non-woven fabric is enhanced; in the electrospinning process, the endsof the carbon nanotubes can be exposed from the surfaces of fibers, and the surfaces of the fibers are endowed with a heterostructure; the surface of each fiber can contain fluorine atoms by interaction between the fibers and a fluorocarbon surfactant, so that the oleophobic property of the fiber non-woven fabric can be maximized, and oil-water separation is facilitated..

Owner:WUHAN INSTITUTE OF TECHNOLOGY

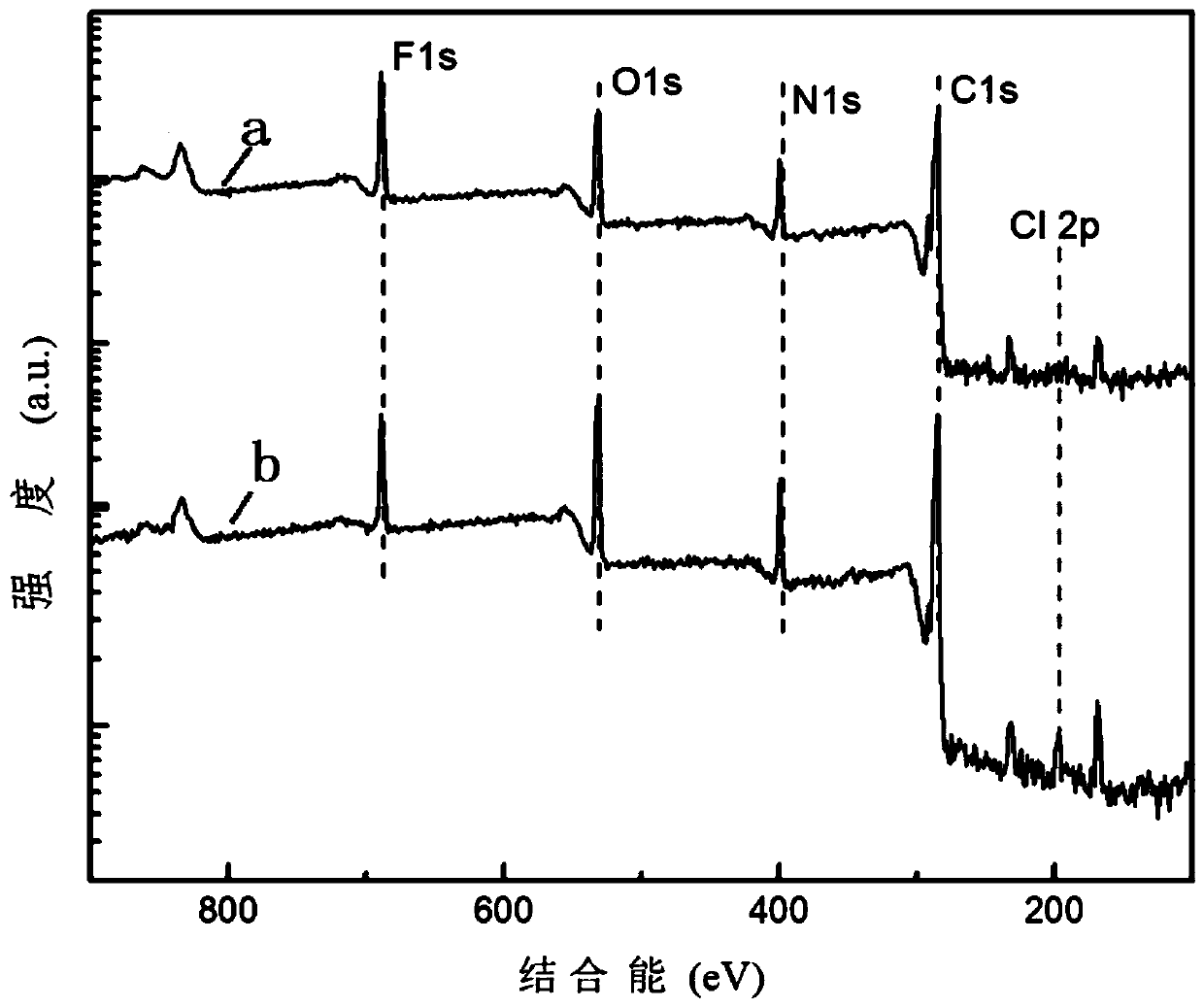

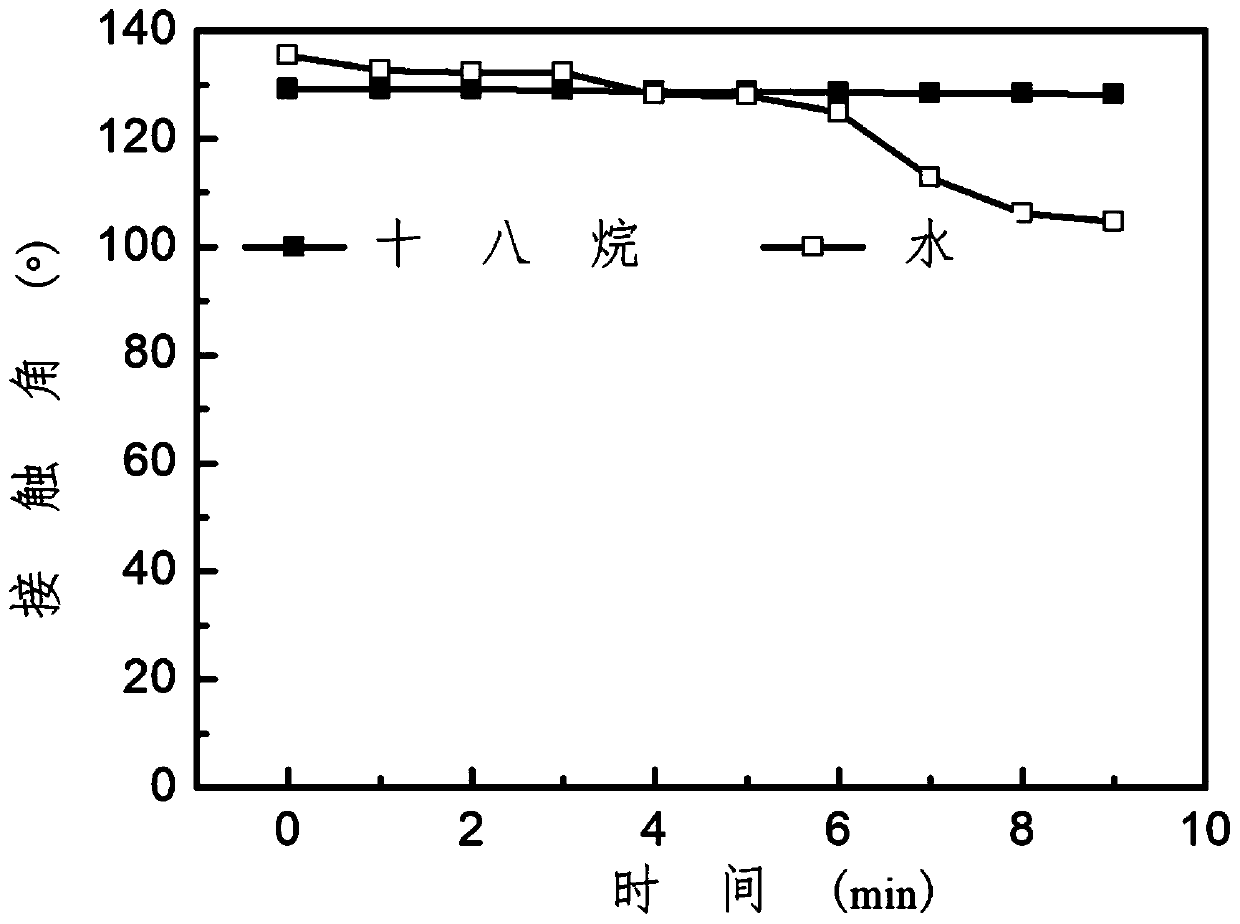

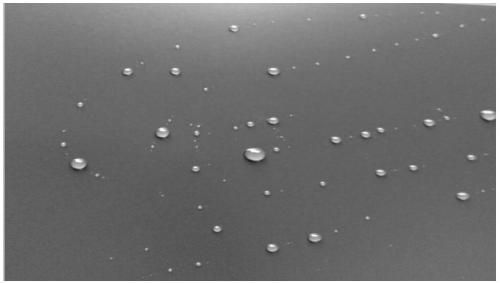

Preparation method of organic-inorganic hybrid superhydrophobic, oleophobic, mildew-proof, bactericidal, flame-retardant and weather-resistant wood modifier

ActiveCN105619558BImproved antiseptic performanceGood weather resistanceWood treatment detailsCoating impregnationWater basedEdible oil

The invention relates to a preparation method of a wood modifier, in particular to a preparation method of an organic-inorganic hybrid super-hydrophobic and oleophobic wood modifier with mold-proof, sterilization, anti-flaming and weather-proof properties, and belongs to the field of preparation of wood modifiers. The preparation method aims to solve the technical problems that existing wood modifiers have high toxicity, special peculiar smells and poor run-away resisting capacity, pollute the environment and are simplex in function. The preparation method comprises the steps that organoalkoxysilane, deionized water and absolute ethyl alcohol are mixed; a functional reagent A is added for a reaction; a functional reagent B is added for a reaction; a fluorine-containing silane coupling agent is added for a reaction; a water-based fluorine-containing high-molecular compound, a curing agent and a functional reagent C are added, the mixture is stirred, and the modifier is obtained. The static water contact angle of the surface of wood modified by the modifier can reach 150 degrees or above, and the rolling angle is smaller than 10 degrees. The edible oil contact angle of the modified wood surface can reach 120 degrees or above, and modified wood surface has the oleophobic characteristic. In addition, the corrosion prevention and sterilization performance of the modified wood is improved by 90% or above, the weather resistance of the modified wood is improved by 10 times, and the anti-flaming performance of the modified wood is also remarkably improved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

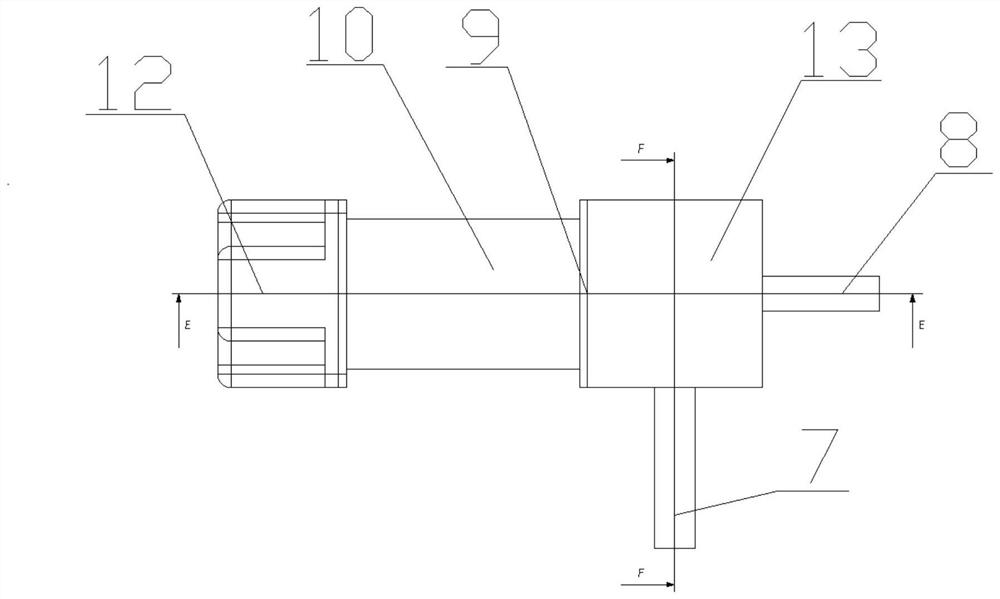

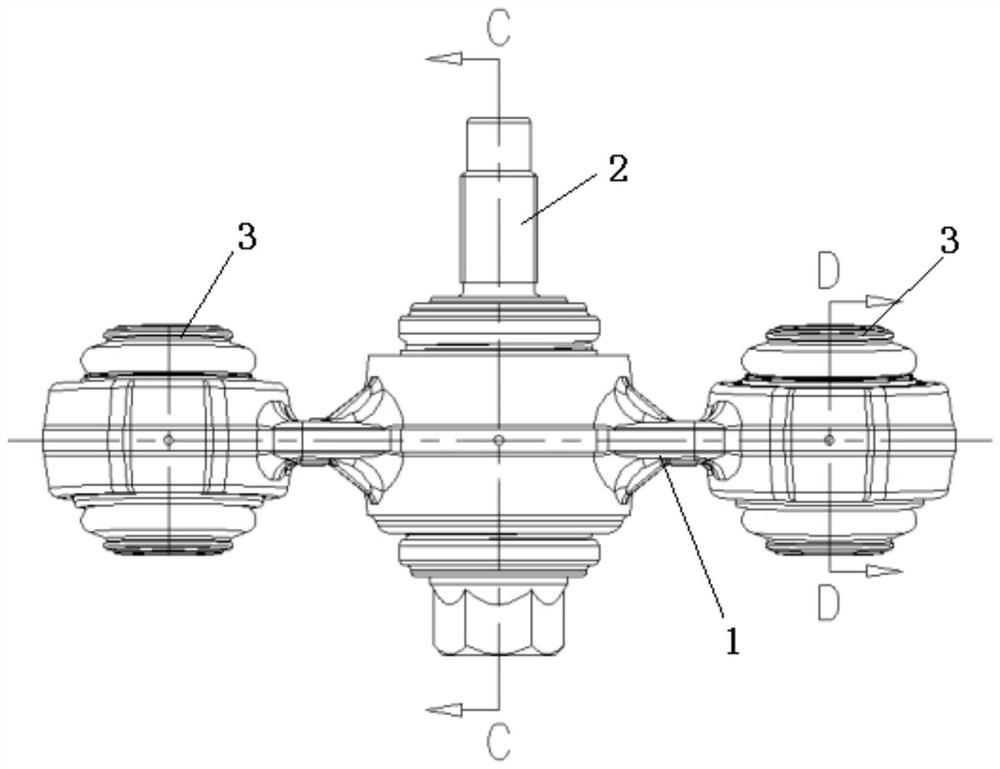

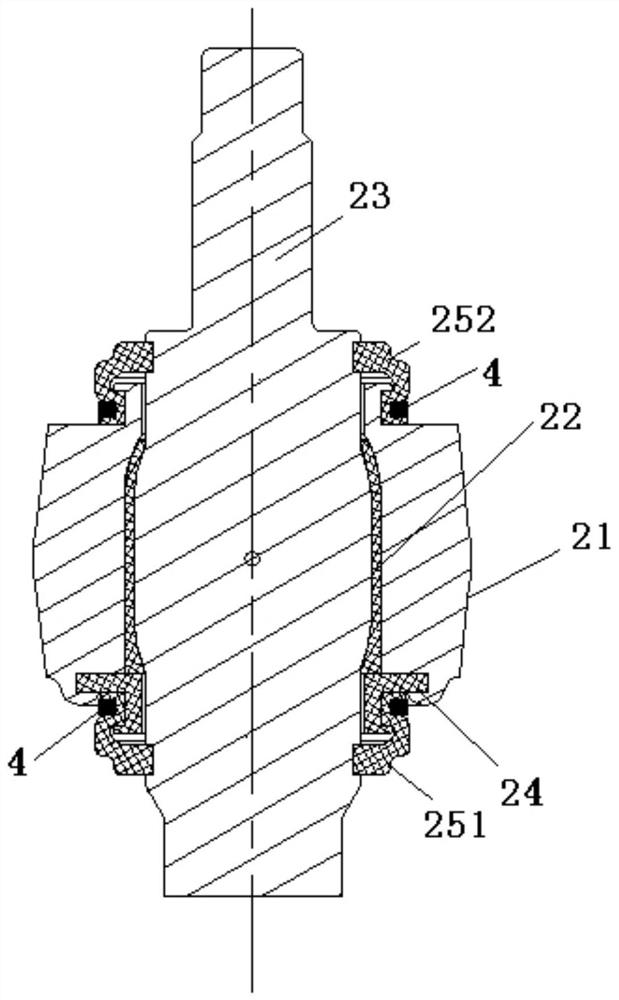

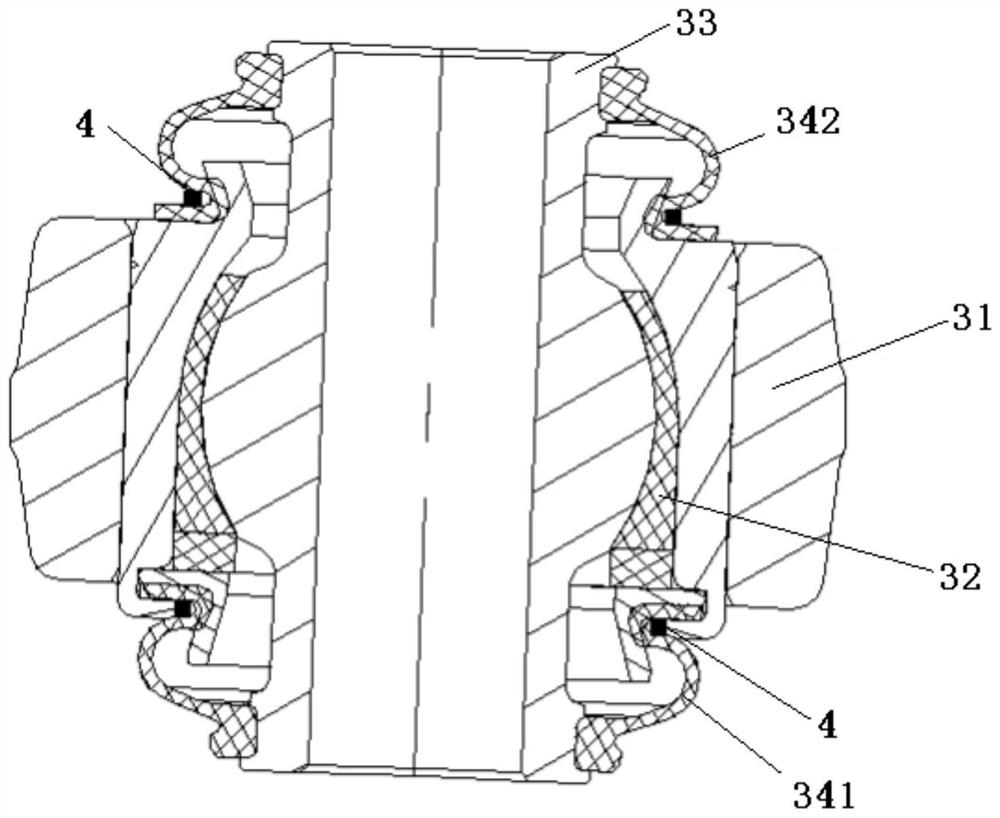

A t360 suspension link bracket

ActiveCN113431903BIncreased durabilityReduce usageSuspensionsEngine sealsStructural engineeringMechanical engineering

The invention relates to the field of auto parts, in particular to a T360 suspension link bracket. A T360 suspension link bracket of the present invention includes a backspin transverse tie rod body, a middle mechanism is provided in the middle of the backspin transverse tie rod body, side mechanisms are arranged on both sides of the backspin transverse tie rod body, and the middle mechanism includes a middle spherical hinge bushing, The middle ball seat is set in the middle ball joint bushing, the pin is set in the middle ball seat, and the bottom of the pin and the middle ball seat is provided with a compression ring, and the first dust cover is provided between the compression ring and the pin, and the pin There is a second dust cover on the top of the middle ball joint bushing, the side mechanism includes a side ball joint bushing, a side ball seat is set in the side ball joint bushing, a bolt seat is set in the side ball seat, and the bolt seat There is a third dust cover at the bottom of the side ball joint bushing, and a fourth dust cover is provided at the top of the plug seat and the side ball joint bushing. The material of the dust cover is oleophobic polytetrafluoroethylene film. rubber.

Owner:SOMIC AUTOMOTIVE COMPONENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com