Anti-doodling polyurethane powder paint, preparation method and application thereof

A polyurethane powder and anti-graffiti technology, applied in the field of coatings, can solve the problems of strong pollution of silicone resin, insufficient surface hardness, and easy damage of the surface, and achieve good anti-graffiti effect, convenient operation, and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

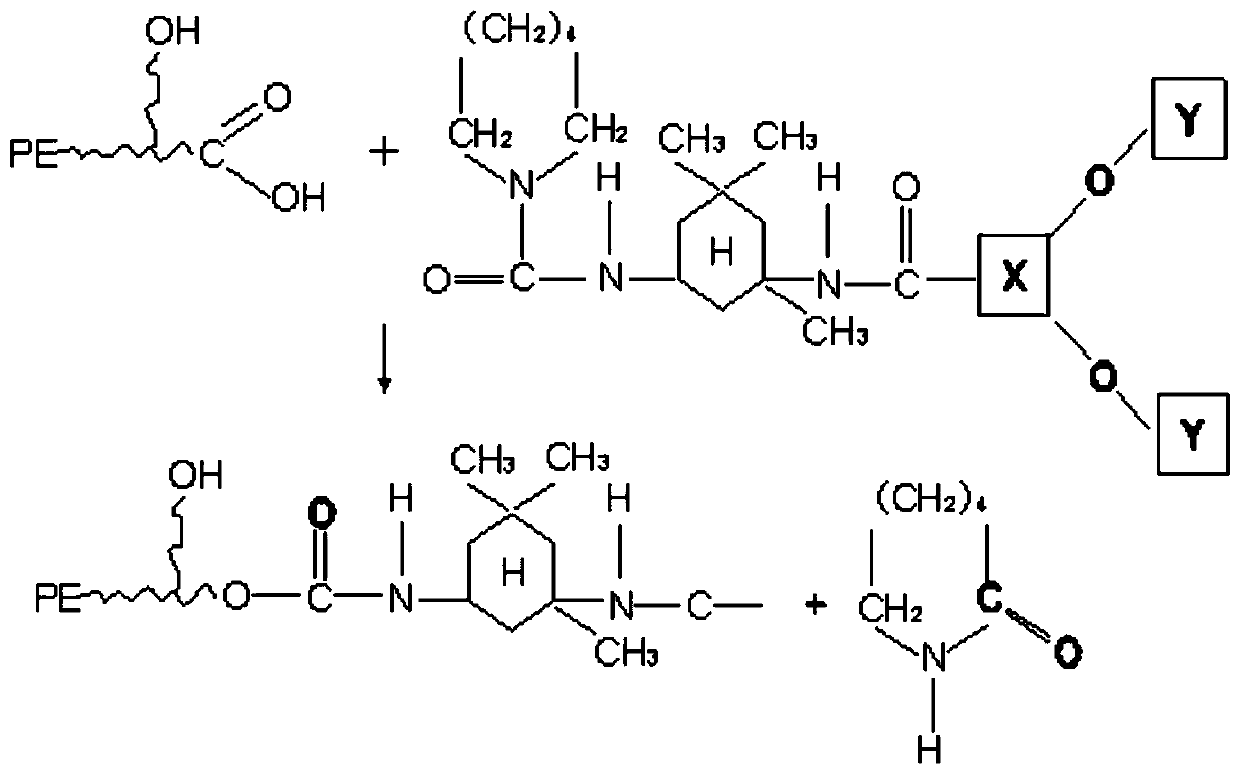

Method used

Image

Examples

Embodiment 1

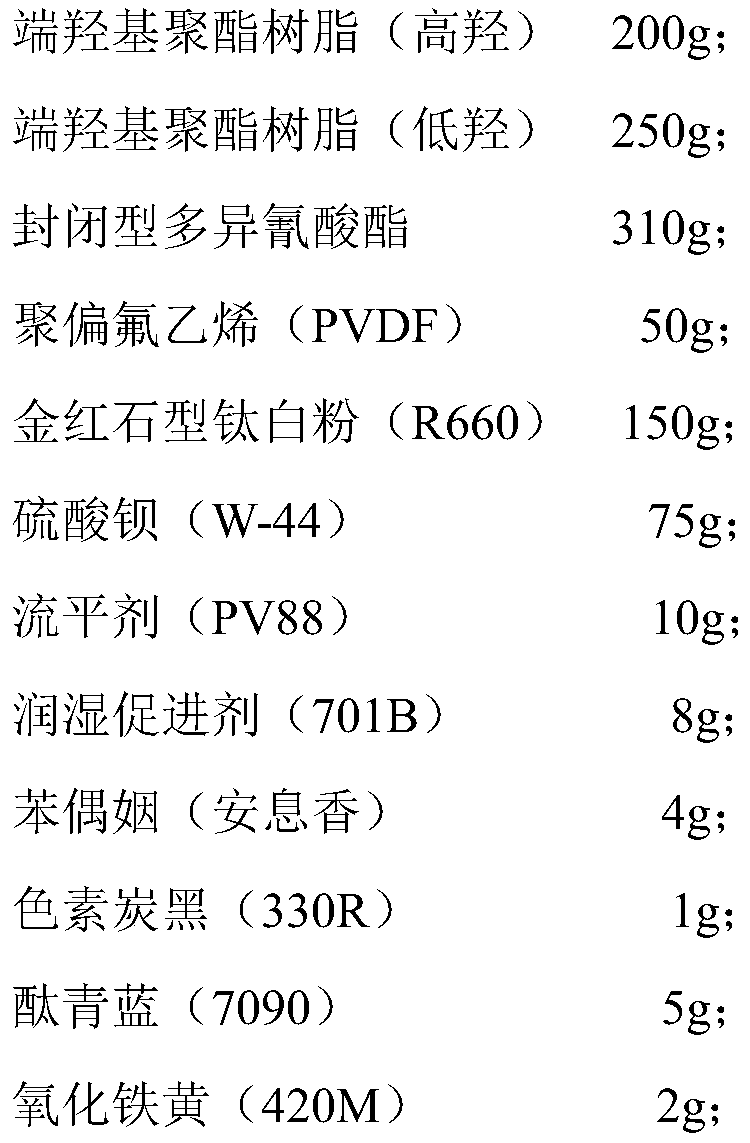

[0029] A kind of polyurethane powder coating of the present invention, its raw material comprises following each component:

[0030]

[0031] Among them, the hydroxyl value of the high hydroxyl-terminated polyester resin is 280-320, and the hydroxyl value of the low-hydroxyl-terminated polyester resin is 35-45.

[0032] The preparation method of the polyurethane powder coating of the present embodiment, comprises the steps:

[0033] (1) After pre-mixing the components of the polyurethane powder coating in proportion, a mixed material is obtained;

[0034] (2) The mixed material obtained in the step (1) is melt-extruded (90°C in the front area of the screw, 105°C in the rear area of the screw), pressed into tablets (thickness of the pressed tablets is about 1mm), crushed, and crushed through 180 meshes. Sieve to obtain the polyurethane powder coating.

[0035] After testing, the particle size distribution of the polyurethane powder coating is 5 μm-100 μm, and the D50 i...

Embodiment 2

[0041] A kind of polyurethane powder coating of the present invention, its raw material comprises following each component:

[0042]

[0043]

[0044] Among them, the hydroxyl value of the high hydroxyl-terminated polyester resin is 280-320, and the hydroxyl value of the low-hydroxyl-terminated polyester resin is 35-45.

[0045] The preparation method of the polyurethane powder coating of the present embodiment, comprises the steps:

[0046] (1) After pre-mixing the components of the polyurethane powder coating in proportion, a mixed material is obtained;

[0047] (2) The mixed material obtained in the step (1) is melt-extruded (90°C in the front area of the screw, 105°C in the rear area of the screw), pressed into tablets (thickness of the pressed tablets is about 1mm), crushed, and crushed through 180 meshes. Sieve to obtain the polyurethane powder coating.

[0048] After testing, the particle size distribution of the polyurethane powder coating is 5 μm-100 μm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com