A method and device for treating industrial wastewater

A technology for industrial wastewater and treatment methods, applied in natural water treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. The effect of reducing flushing water consumption, strong resistance to fouling and blocking, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

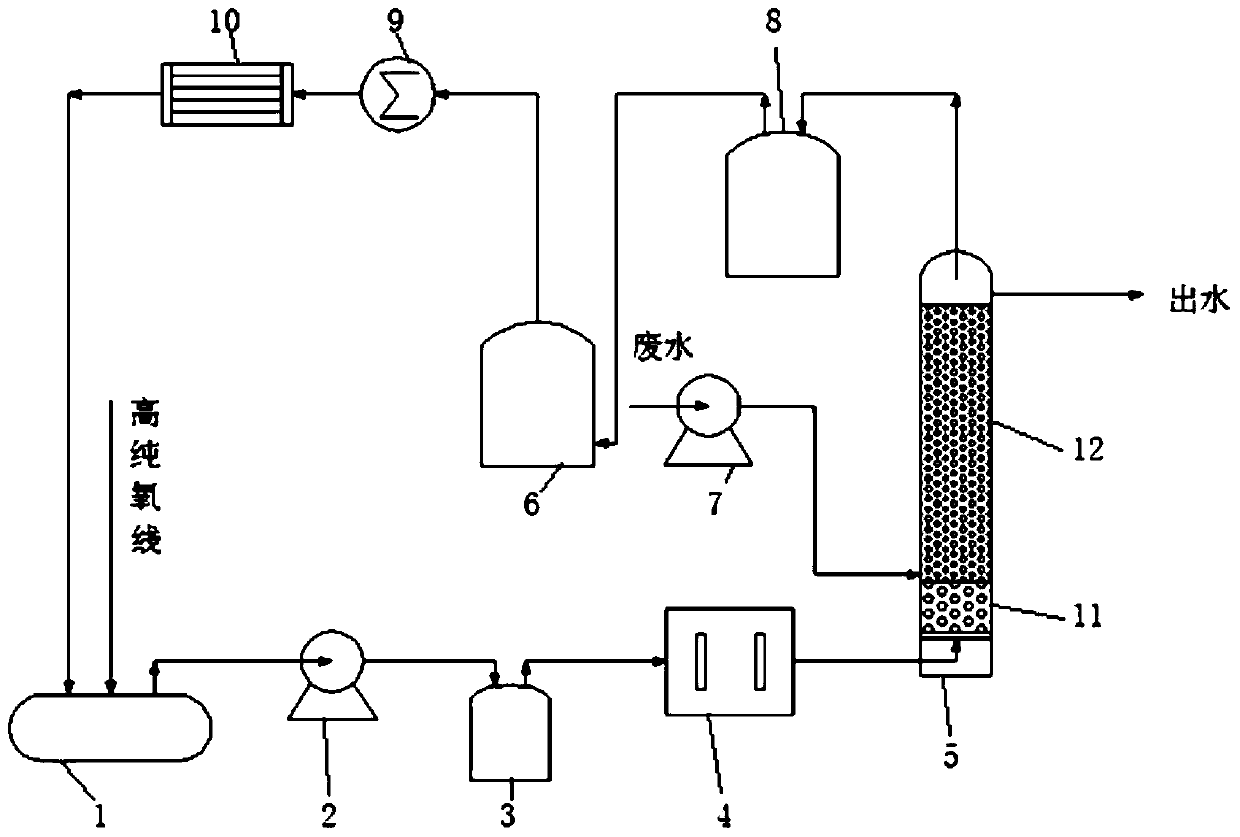

[0030] The refinery sewage produced by a petrochemical company in Xinjiang will produce a certain amount of concentrated liquid after being treated by a nanofiltration system. The company's high-salt, high-COD concentrated water also has the characteristics of high salt content, complex organic components, and poor biochemical properties. After testing, the salinity of the water is 1000-2500mg / L, and the COD is 100-250mg / L. First, the nanofiltration concentrated water enters the advanced oxidation reactor 5 through the sewage pump 7, and at the same time, it is passed into the advanced oxidation reactor 5. Ozone with a pressure of 0.1MPa and a concentration of 50mg / L, the pressure inside the advanced oxidation reactor 5 is 0.1MPa, and the advanced oxidation reactor 5 is provided with an obligatory catalyst layer 12 and a catalyst support layer 11 in sequence from top to bottom. Layer 11 is filled with an activated alumina-based heterogeneous catalyst with a particle size of 15 ...

Embodiment 2

[0033] This example is used to illustrate the advanced oxidation method for treating high-salt and high-COD concentrated water with tail gas circulation provided by the present invention.

[0034] Waste water was treated according to the method of Example 1, the difference was that the raw water was cut water from a heavy oil tank farm produced by a petrochemical company. After testing, the salinity of the water is 4500-6000mg / L, and the COD is 2000-3000mg / L. First, the cut water from the heavy oil tank area enters the advanced oxidation reactor 5 through the sewage pump 7, and at the same time passes through the advanced oxidation reactor 5. Ozone with a pressure of 0.3MPa and a concentration of 100mg / L is injected into the advanced oxidation reactor 5, and the internal pressure of the advanced oxidation reactor 5 is 0.2MPa. The advanced oxidation reactor 5 is provided with an obligatory catalyst layer 12 and a catalyst support layer 11 sequentially from top to bottom. The su...

Embodiment 3

[0037] This example is used to illustrate the advanced oxidation method for treating high-salt and high-COD concentrated water with tail gas circulation provided by the present invention.

[0038] Wastewater was treated according to the method of Example 1, except that the raw water was coking wastewater produced by a petrochemical company. After testing, the salinity of the water is 500-1000mg / L, and the COD is 2500-6000mg / L. First, the coking wastewater enters the advanced oxidation reactor 5 through the sewage pump 7, and at the same time, the pressure is fed into the advanced oxidation reactor 5. Ozone at 0.45MPa and a concentration of 150mg / L, the pressure inside the advanced oxidation reactor 5 is 0.2MPa, and the advanced oxidation reactor 5 is provided with an obligatory catalyst layer 12 and a catalyst support layer 11 in sequence from top to bottom, and the catalyst support layer 11 It is filled with active alumina-based heterogeneous catalysts with a particle size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com