Anti-haze and anti-pollution-flashover coating as well as preparation method and application thereof

An anti-fouling flashover coating and anti-fog technology, applied in antifouling/underwater coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve problems such as inability to guarantee, and achieve strong self-cleaning effect, strong resistance, and strong self-cleaning performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

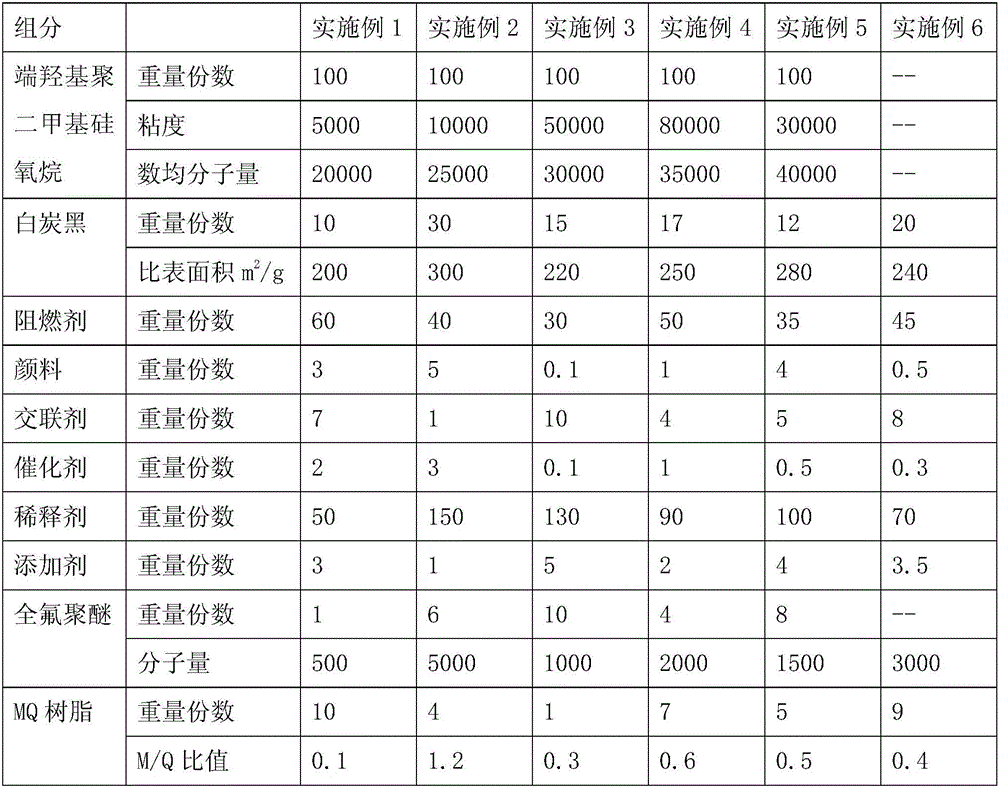

[0083] The main material is 100 parts by weight of hydroxyl-terminated polydimethylsiloxane;

[0084] Reinforcing materials are white carbon black and MQ resin, the dosage is shown in Table 1

[0085] (1) Premixing of base rubber: fully mix the main material, white carbon black and flame retardant in the reaction kettle according to the selected parts by weight, the stirring rate is 400 rpm, and the stirring time is 4h to obtain the mixture;

[0086] (2) Low molecular weight removal: Stir the mixture under vacuum at 100-150°C for 2 hours to obtain a premix;

[0087] (3) Blending of cross-linking agent and catalyst: add selected cross-linking agent and catalyst in parts by weight to the premix, and continue to mix and stir, the stirring speed is 400 rpm, and the stirring time is 2h to obtain the intermediate material .

[0088] (4) Mixing of diluent and MQ resin: add selected diluent and MQ resin in parts by weight to the intermediate material, and fully mix and stir at a sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com