Patents

Literature

118results about How to "Good oleophobic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super-amphiphobic polymer and super-amphiphobic surface prepared from super-amphiphobic polymer

InactiveCN102432742AGood scrub resistanceAccelerated corrosionWater-repelling agents additionPaper/cardboardPolymer scienceMicrosphere

The invention belongs to the field of macromolecule super-amphiphobic materials and discloses a super-amphiphobic polymer and a super-amphiphobic surface. The super-amphiphobic polymer is a random copolymer composed of structural units shown as a formula I and a formula II. The super-amphiphobic surface is obtained by comprising the following steps of: pre-processing a substrate material; placinga micro-balloon in a fluorine-containing solvent, and ultrasonically dissolving to obtain a micro-balloon supernatant solution; adding the super-amphiphobic polymer, a hydrochloric acid tetrahydrofuran solution and water into the micro-balloon solution while stirring, placing the substrate material, and reacting for 5-24 h; and taking out the substrate material, washing by using the fluorine-containing solvent, methanol and water in turn, drying in vacuum, and obtaining the super-amphiphobic surface. The super-amphiphobic polymer disclosed by the invention can give good surface hydrophobic ability and oleophobic ability to the substrate. Because the polymer has the characteristics of the fluorine-containing polymer so that the polymer can be chemically bonded with the surface of the substrate, the obtained super-amphiphobic surface has good scrubbing resistant property and corrosion resistant property.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Silicone polymer contact lens compositions and methods of use

InactiveUS20050288196A1Low vapor pressureImprove the immunitySenses disorderPharmaceutical delivery mechanismAlcoholCentistokes

The present invention is an eye preparation comprising a hydrophobic composition adapted for use on a contact lens inserted into a patient's eye and having a viscosity of 1 to 15,000 centistokes. The composition includes a silicone polymer, fluorinated silicone polymer, fluorocarbon polymer, fluorinated alcohol, or perfluorinated polyether composition, singly or blended, adapted to coat at least a portion of a contact lens inserted in a patient's eye. Silicone polymers for use in the invention include dimethicone, cyclomethicone, and silicone gums.

Owner:OCULARIS PHARMA

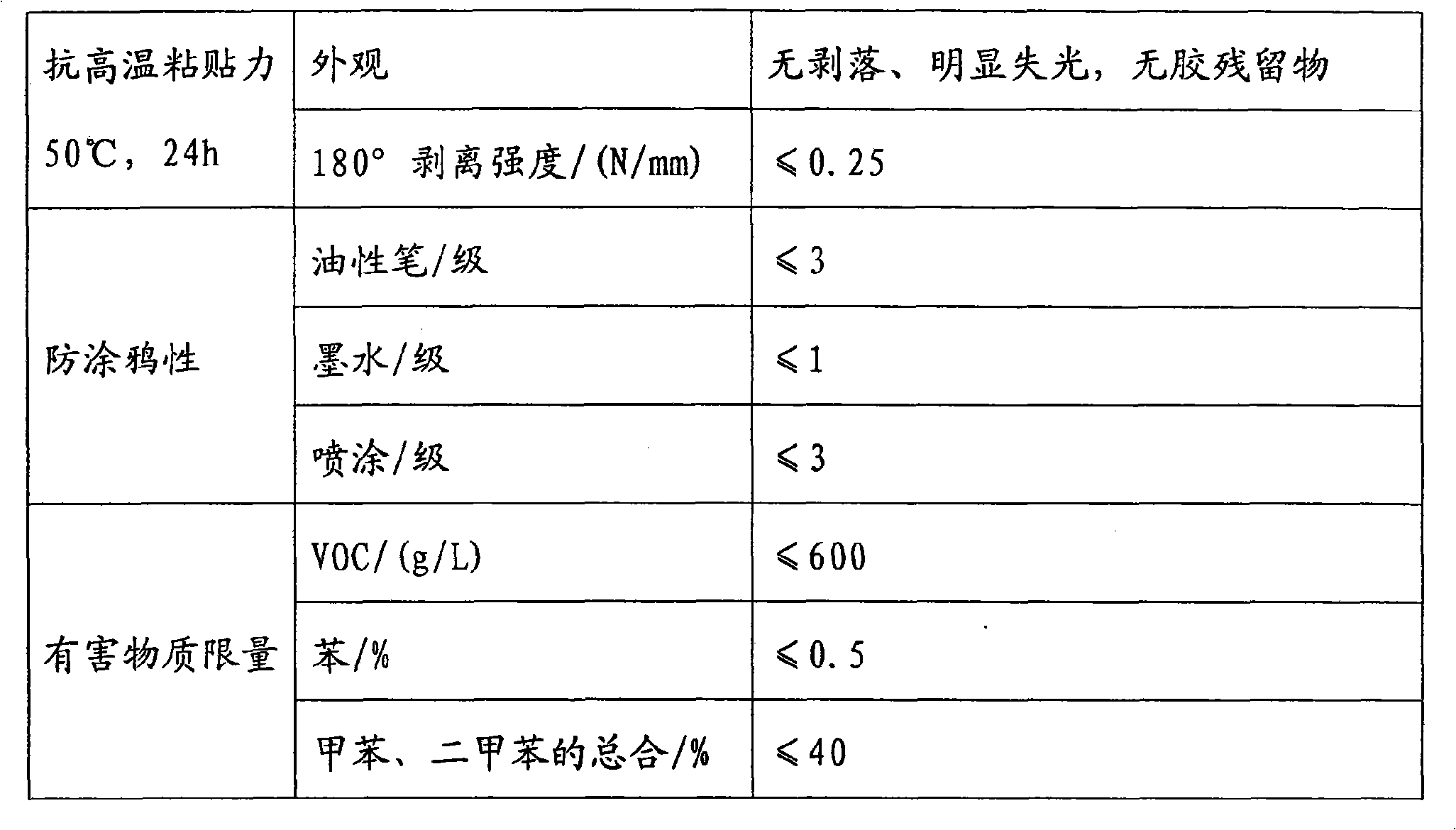

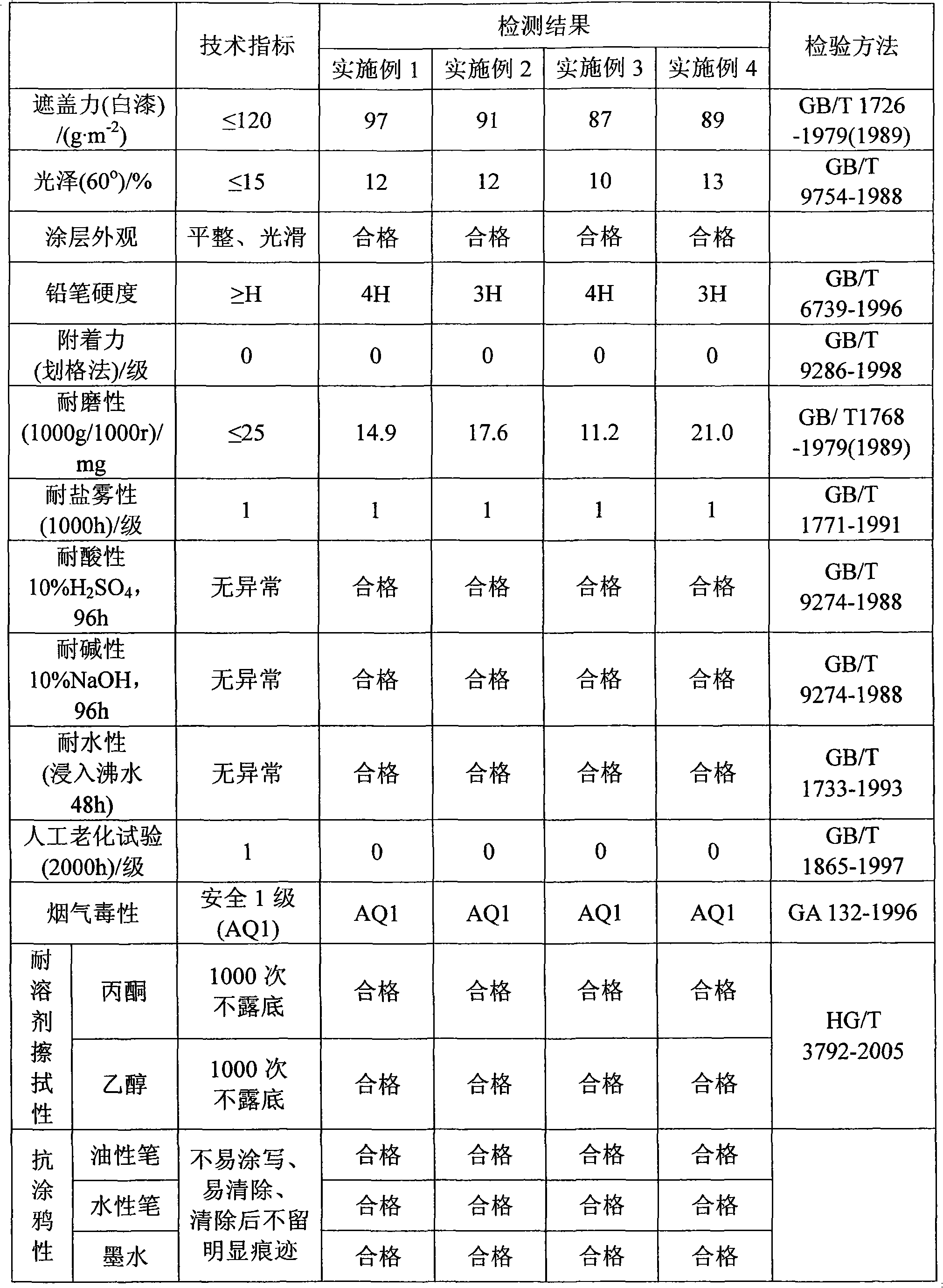

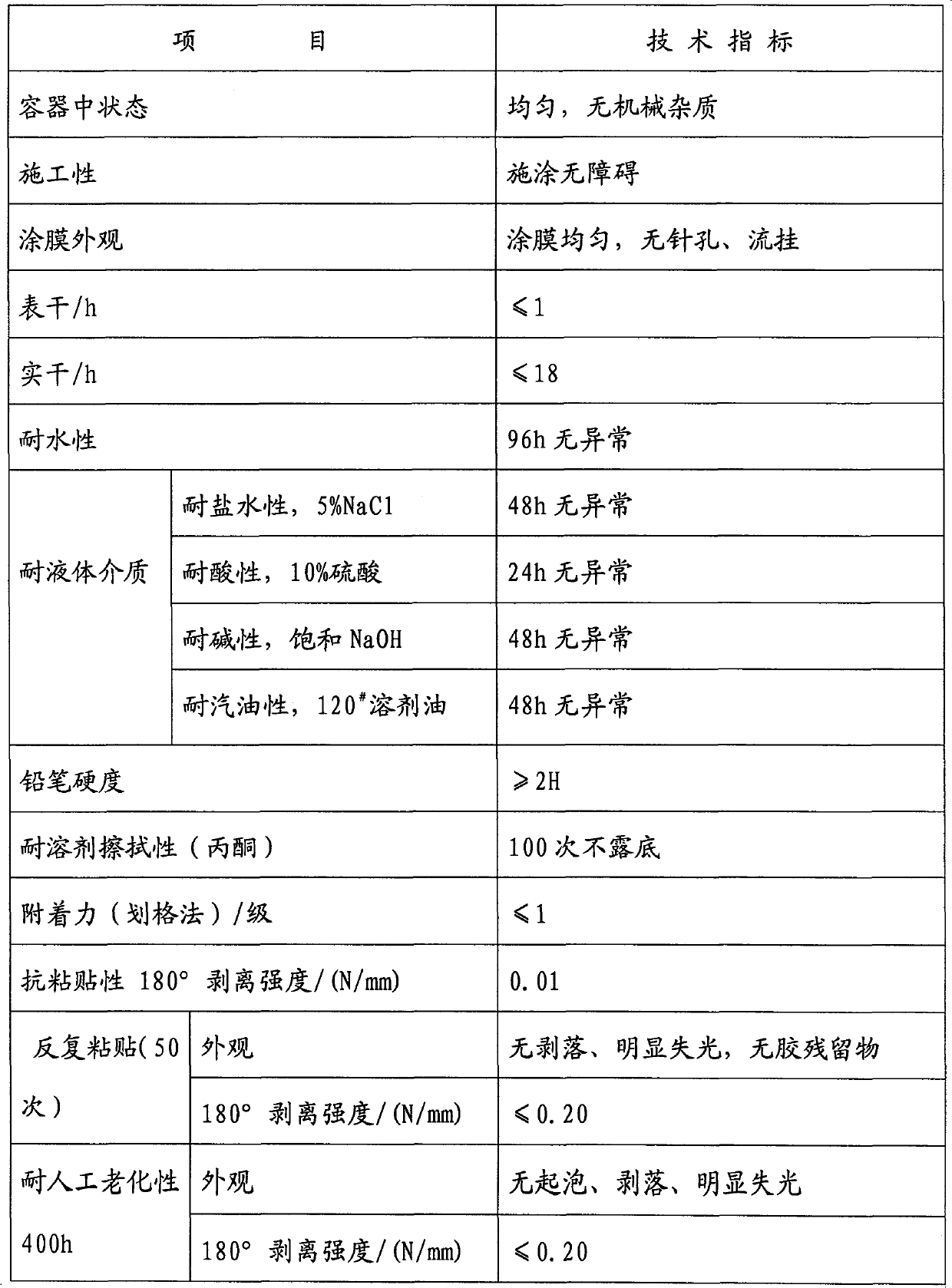

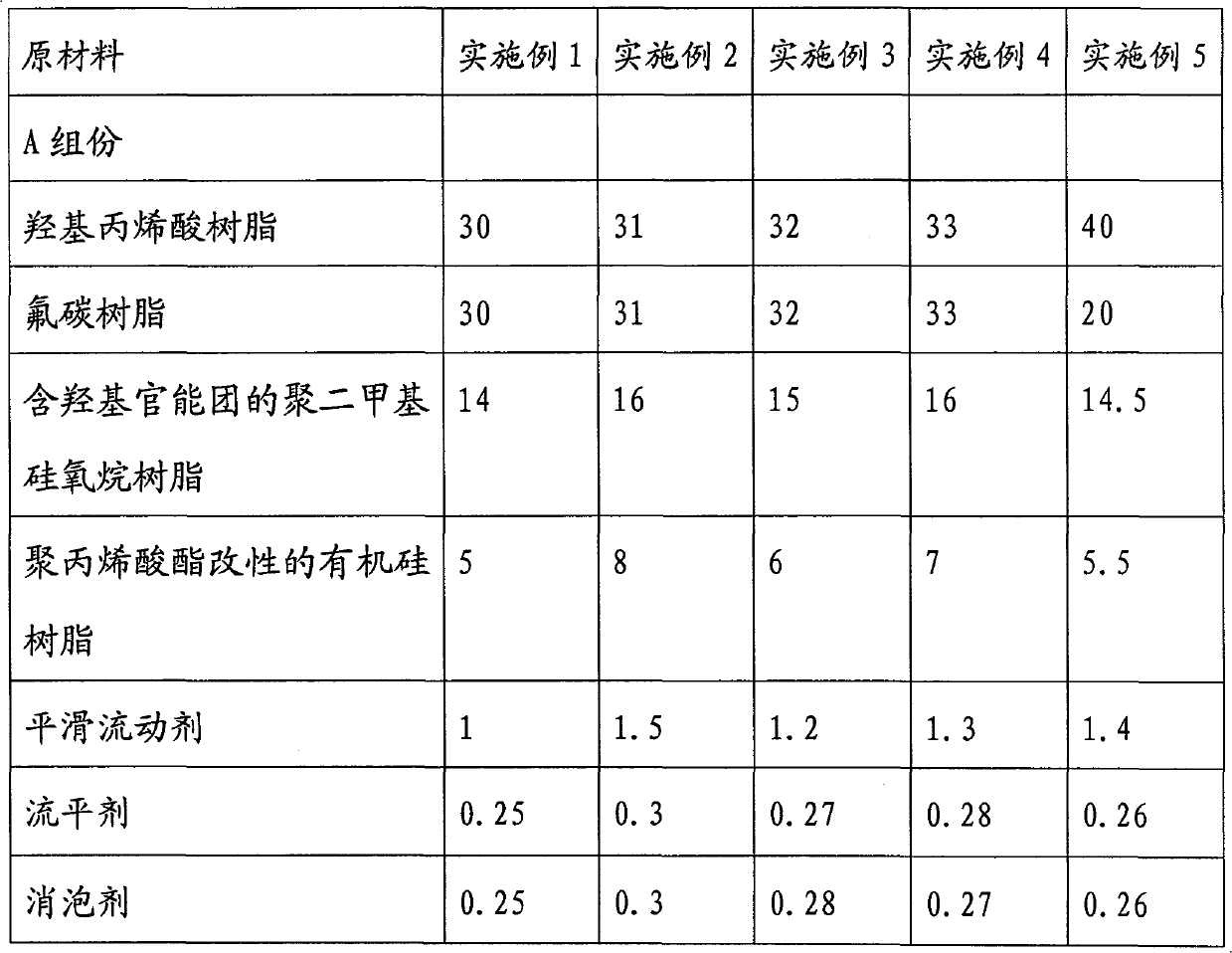

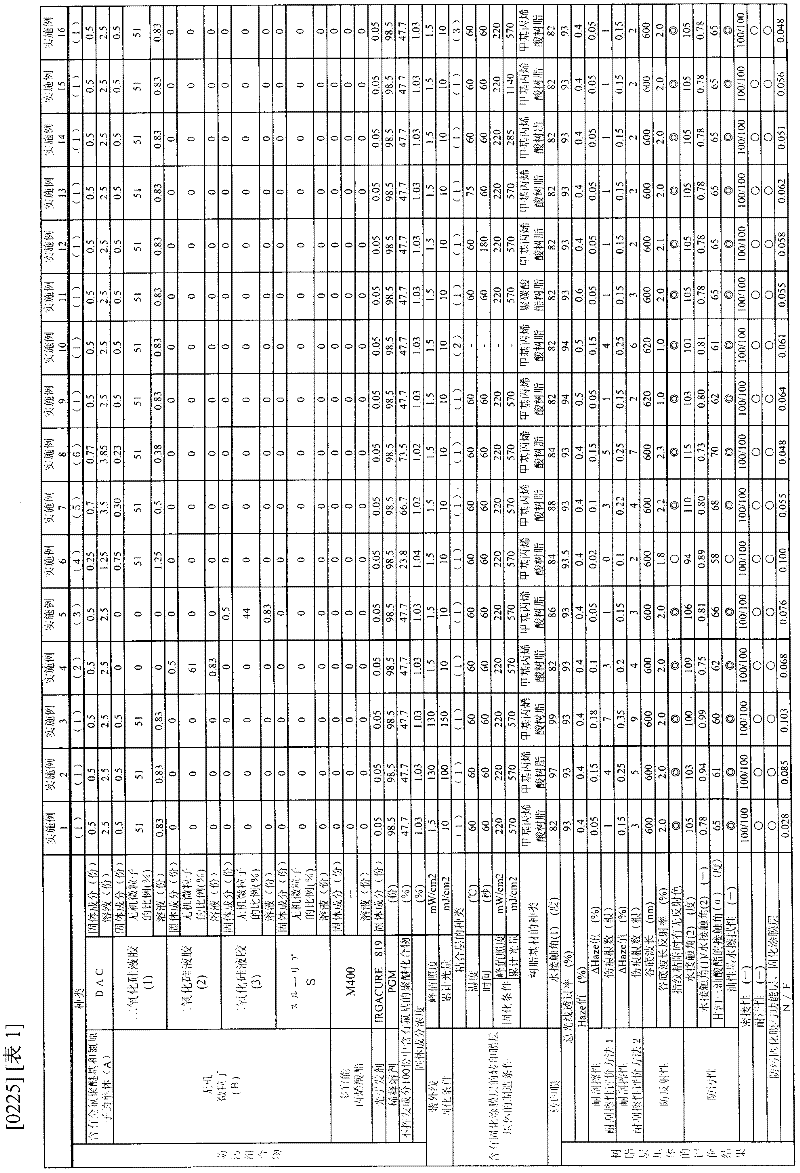

Oil-based anti-graffiti adhesion resistant paint and preparation method thereof

ActiveCN101585995AHigh hardnessImprove self-cleaningPolyurea/polyurethane coatingsAcrylic resinPolydimethyl siloxane

The invention discloses oil-based anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. Components A of the paint comprise hydroxy acrylic resin, fluorocarbon resin, modified polydimethyl siloxane resin, polyacrylate modified organic silicon resin, smooth flow agent, flatting agent, antifoaming agent, drier, dibutyl tin laurate, butyl acetate and dimethyl benzene; components B comprise hexamethylene diisocyanate, butyl acetate and ethylene glycol monoethyl ether acetate; and the mixture ratio of the components A to the components B is 3:1. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easy cleaning, and quick and convenient construction, has limited harmful substances, and achieves national requirement.

Owner:LANZHOU XUNMEI PAINT IND TECH

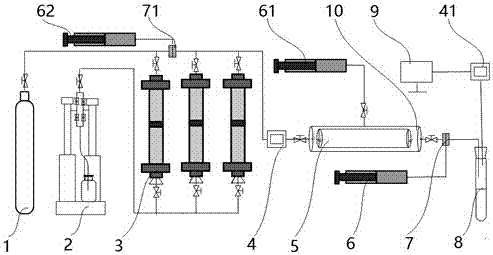

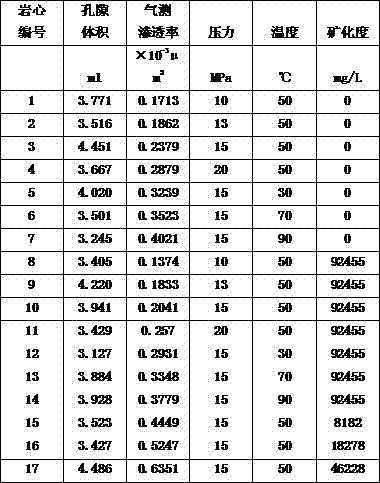

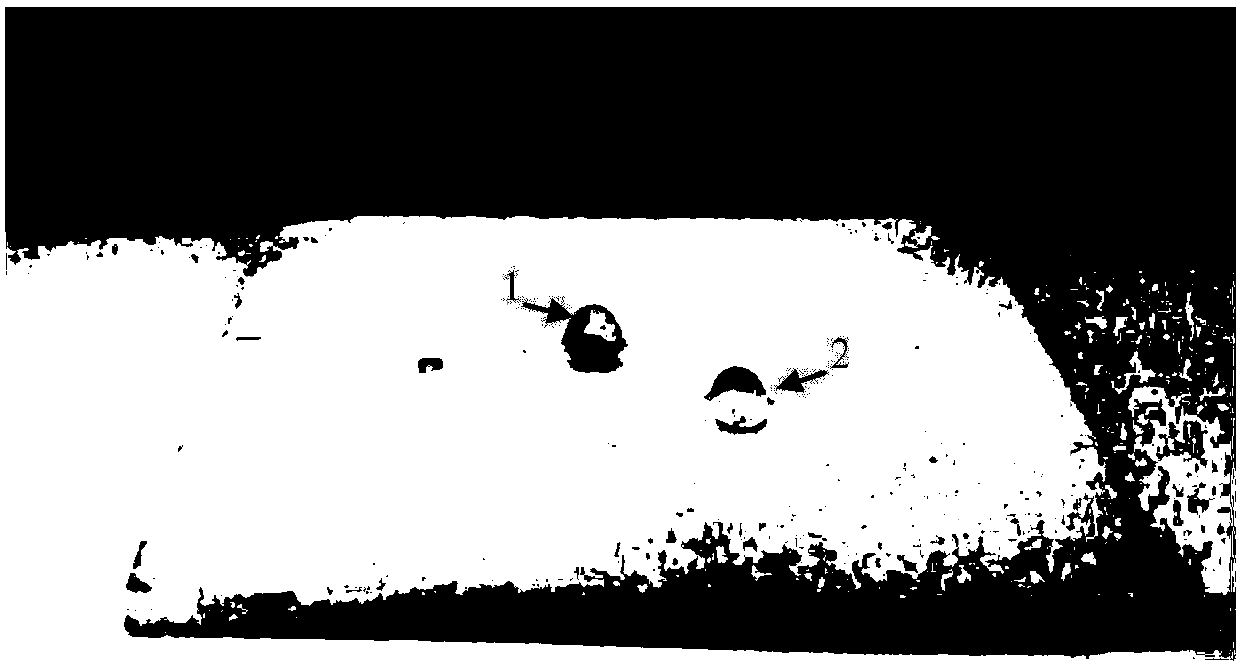

Experimental device researching influence of formation water with high degree of mineralization on CO2 flooding

InactiveCN106908579AImprove securityAvoid corrosionEarth material testingFluid removalPorosityGas cylinder

The invention provides an experimental device researching influence of formation water with a high degree of mineralization on CO2 flooding. The experiment device comprises a gas cylinder, a core holding unit and a gas-liquid separating device. The gas cylinder is connected to a piston container, the top of the piston container is connected to a back-pressure valve and a pressure gage, the bottom of the piston container is connected to an ISCO pump, the pressure gage is connected to the core holding unit, the outlet end of the core holding unit is connected to the gas-liquid separating device, and the gas-liquid separating device is connected to an upper computer through a gas flowmeter. The back-pressure valve is connected to the back-pressure valve, the side face of the core holding unit is connected to a circular pressing pump and the suction lift is high, the outlet of the core holding unit is connected to the back-pressure valve, and the back-pressure valve is connected to a back-pressure pump. The designed device can compare changes of core permeability after and before CO2 flooding, porosity, pore structures, contents of core minerals, surface shapes of the cores, masses of the core and the recovery rates and research influence of CO2 flooding on reservoir physical property and development parameters.

Owner:ZHEJIANG OCEAN UNIV

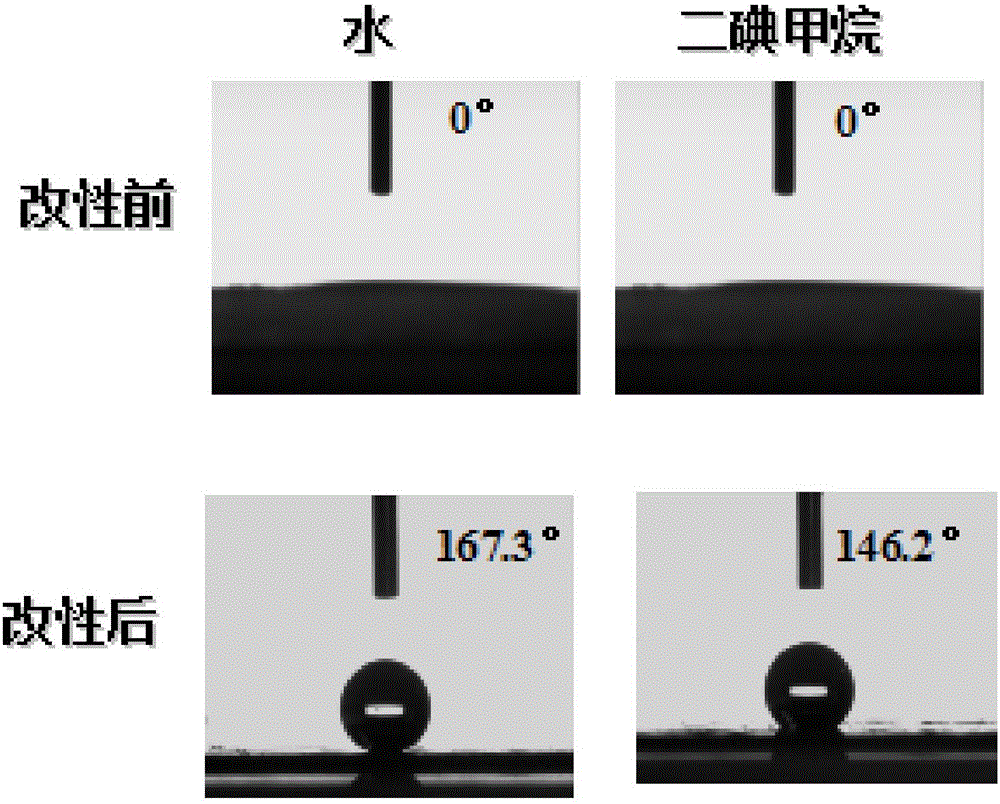

Superhydrophobic oleophobic modification method of porous membrane

ActiveCN106390764AImprove stabilityImprove wear resistanceSemi-permeable membranesDiiodomethaneFiltration

The invention relates to a superhydrophobic oleophobic modification method of a porous membrane, and belongs to the technical field of separation membrane. According to the present invention, based on the self-cleaning bionic principle, fluorosilane-modified SiO2 nanoparticles having low surface energy are dispersed in an organic solution to prepare a uniform dispersion liquid, and a porous membrane is subjected to superhydrophobic oleophobic modification by using a dynamic filtration method to prepare the amphiphobic composite membrane having good stability, wherein the water contact angle of the amphiphobic composite membrane surface can achieve 167.3+ / -1 DEG C, the contact angle of diiodomethane can achieve 145.9+ / -1 DEG C, and the good amphiphobic property is presented; and method has characteristics of no requirement of complex equipment, simple and easy-performing process and short preparation period, and the prepared membrane has characteristics of high flux and good pollution resistance.

Owner:BEIJING UNIV OF TECH

Bottom surface-integrated wear-resistant fluorosilicone-based super-amphiphobic coating, and preparation method and application thereof

The invention discloses a bottom surface-integrated wear-resistant fluorosilicone-based super-amphiphobic coating, and a preparation method and application thereof. The preparation method comprises the following steps: 1) performing synergistic modification treatment on two or more nanoparticles to obtain modified blended particles; 2) adding the blended modified particles into a dispersing solvent, performing ultrasonic dispersion for 1 to 2 hours and then mechanically stirring; 3) adding a certain amount of tert-butyl acetate into fluoro-siloxane resin and performing shearing dispersion to obtain substrate material emulsion; 4) mixing the blended modified particle turbid liquid in the step 2 and the substrate material emulsion in the step 3, adding a coupling agent, heating, stirring anddispersing, and performing dispersion by a high-speed shearing dispersing machine to obtain super-amphiphobic coating; and 5) stirring the super-amphiphobic coating uniformly, spray-coating the surface of an object with the super-amphiphobic coating and drying at room temperature for 10 to 30 minutes to successfully prepare the wear-resistant integrated super-amphiphobic coating. The wear-resistant super-amphiphobic organic-inorganic hybrid coating is obtained by connecting a fluorine-silicon substrate and the blended modified particles through chemical grafting copolymerization reaction.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

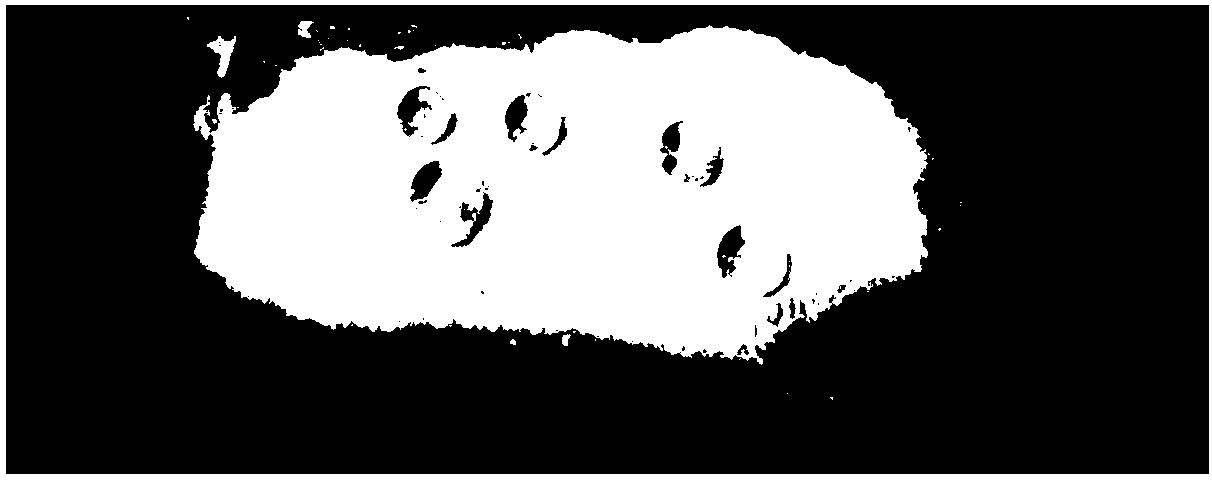

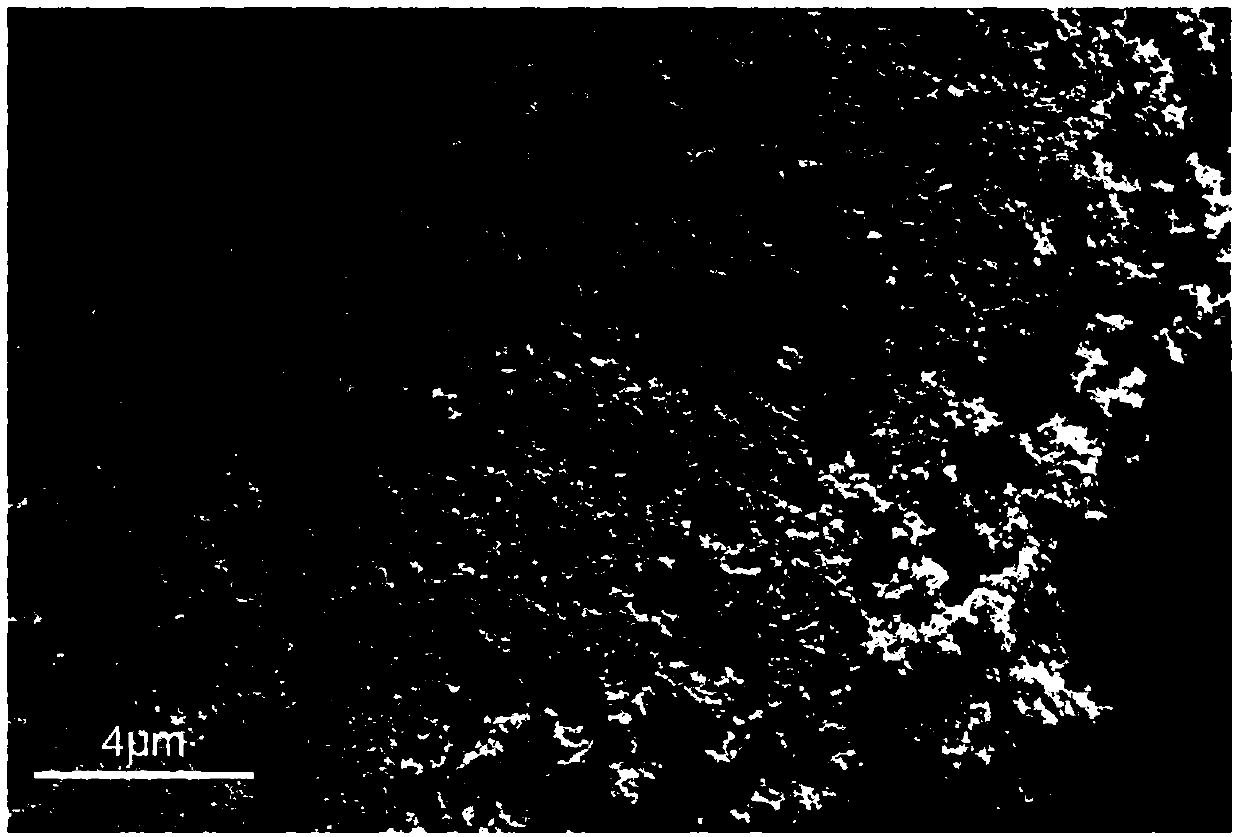

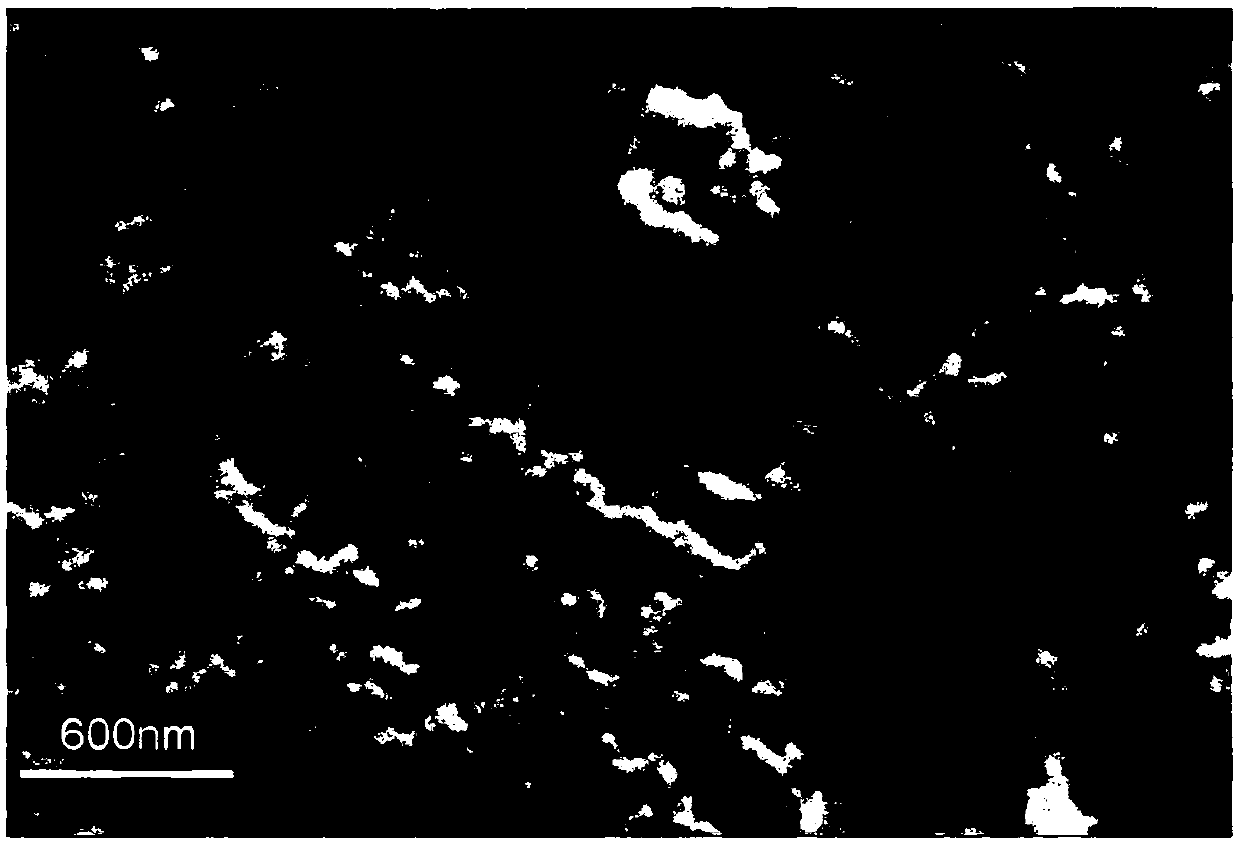

Magnetic bacterial cellulose membrane with lyophobic performance and its preparation method

InactiveCN102336920AGrowth inhibitionAvoid inhalationCellulosic plastic layered productsFerroso-ferric oxidesSurface roughnessSelf-assembly

The invention belongs to the functional material field, relates to a magnetic bacterial cellulose membrane with lyophobic performance and its preparation method; especially relates to a magnetic bacterial cellulose membrane with 130-160 DEG of apparent contact angle and lyophobic performance; concretely relates to a magnetic bacterial cellulose membrane with lyophobic performance and the surface roughness of the bacterial cellulose membrane microfiber increased by the ferroferric oxide nano particles and its preparation method. The method comprises the following steps: attaching the ferroferric oxide nano particles to the bacterial cellulose membrane through an in-situ composite method; then generating a lyophobic monolayer membrane through a lyophobic reagent by a self-assembly technology to reach the lyophobic effect. Therefore, the bacterial cellulose membrane with lyophobic performance and permanent magnetism can be prepared by the method.

Owner:DONGHUA UNIV

Silicone polymer topical eye compositions and methods of use

InactiveUS20050288197A1Easily disperseImprove resistanceSenses disorderPharmaceutical delivery mechanismCentistokesSilicone polymer

The present invention is an eye preparation comprising a hydrophobic composition adapted for use on a patient's eye and having a viscosity of 1 to 15,000 centistokes. The composition includes a silicone polymer, fluorinated silicone polymer, fluorocarbon polymer, fluorinated alcohol, or perfluorinated polyether composition, singly or blended, adapted to coat at least a portion of a patient's eye. Silicone polymers for use in the invention include dimethicone, cyclomethicone, and silicone gums.

Owner:OCULARIS PHARMA

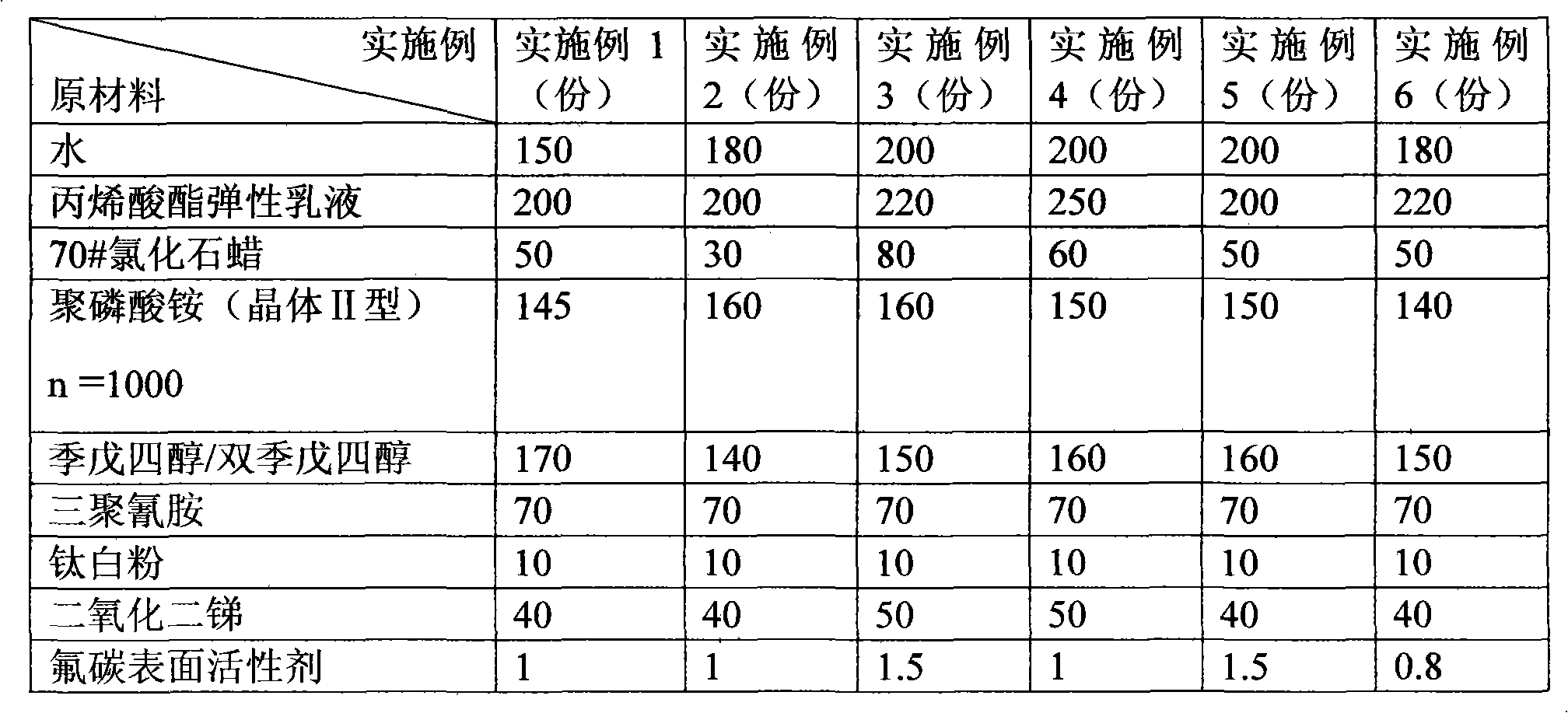

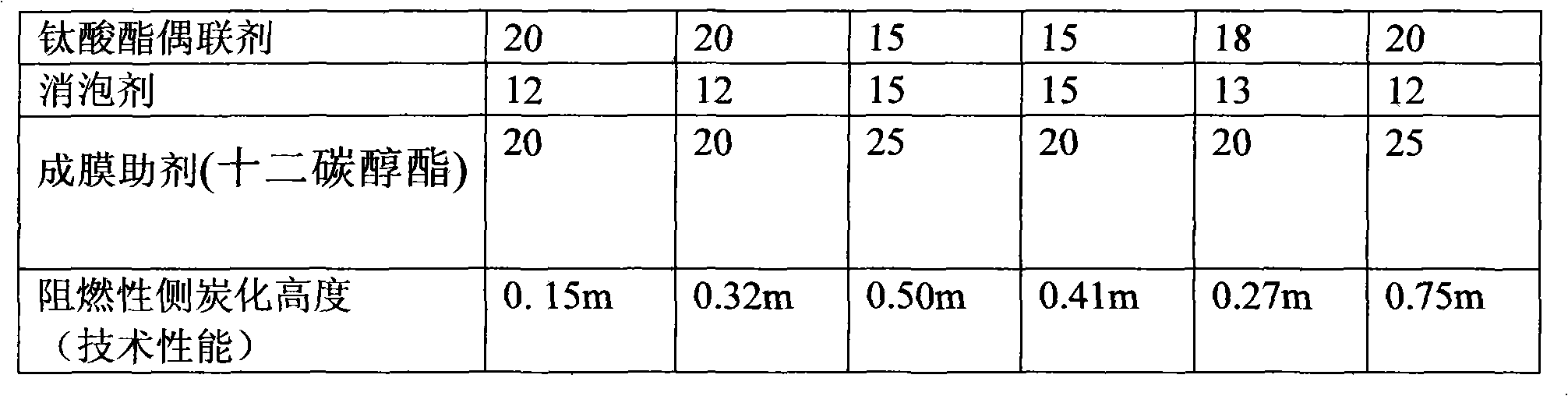

High weather resistance environment-friendly cable fire-refractory coating and preparation process thereof

InactiveCN101597454AGood film forming effectGood water resistanceFireproof paintsSolventAmmonium polyphosphate

The invention discloses high weather resistance environment-friendly cable fire-refractory coating and a preparation process thereof, belonging to the technical field of coating. The process adopts a base material, namely acrylic ester elastic emulsion, as a main film-forming substance, dopes high polymerization degree ammonium polyphosphate into the base material, has good film-forming effect and water resistance. The method particularly selects Number 70 chlorcosane and diantimony trioxide as synergistic flame-retardant to greatly improve the fire retardant performance, has low proportion of pigment and the base material, optimizes compatibility of a fire retardant system; the coating has weather resistance and has oil resistance for selecting fluorocarbon surfactant. The process improves water resistance and weather resistance of the coating, and adopts titanate coupling agent to improve the combining firmness of the pigment, the base material and cable base materials, and the weather resistance of the coating is further improved. Green and environment-friendly water is used as solvent to reduce cost, and as the solvent is removed in preparation or construction, the coating does not pollute the environment and not hurt the health of operators.

Owner:ZHEJIANG TIANHUA FIREPROOF MATERIAL

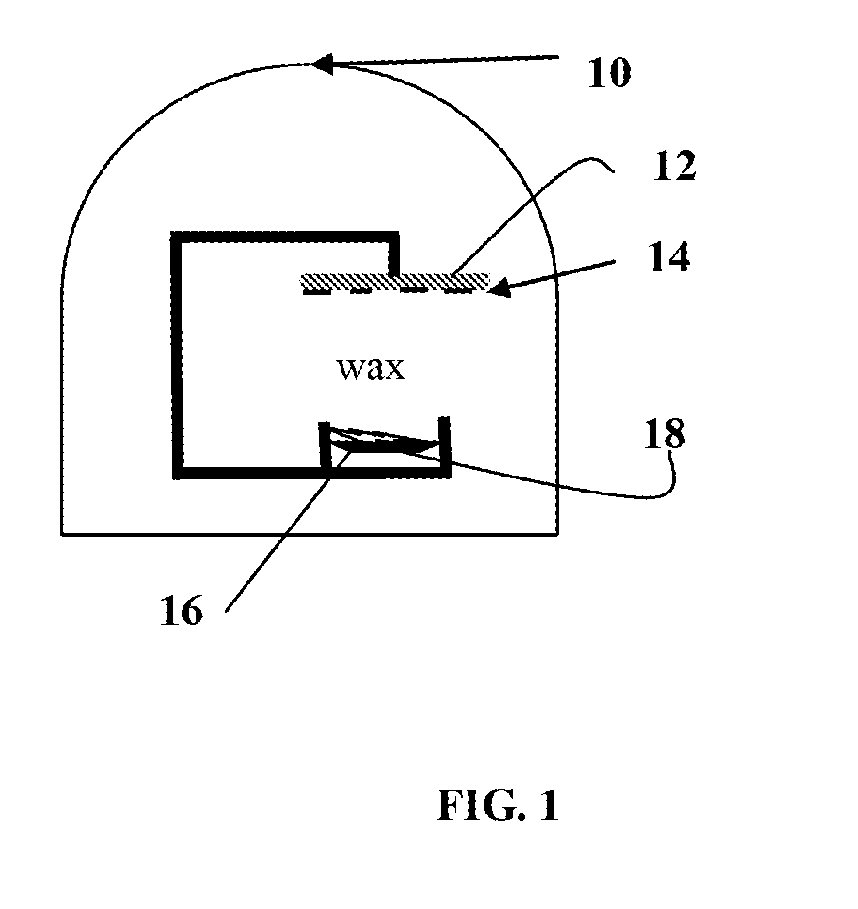

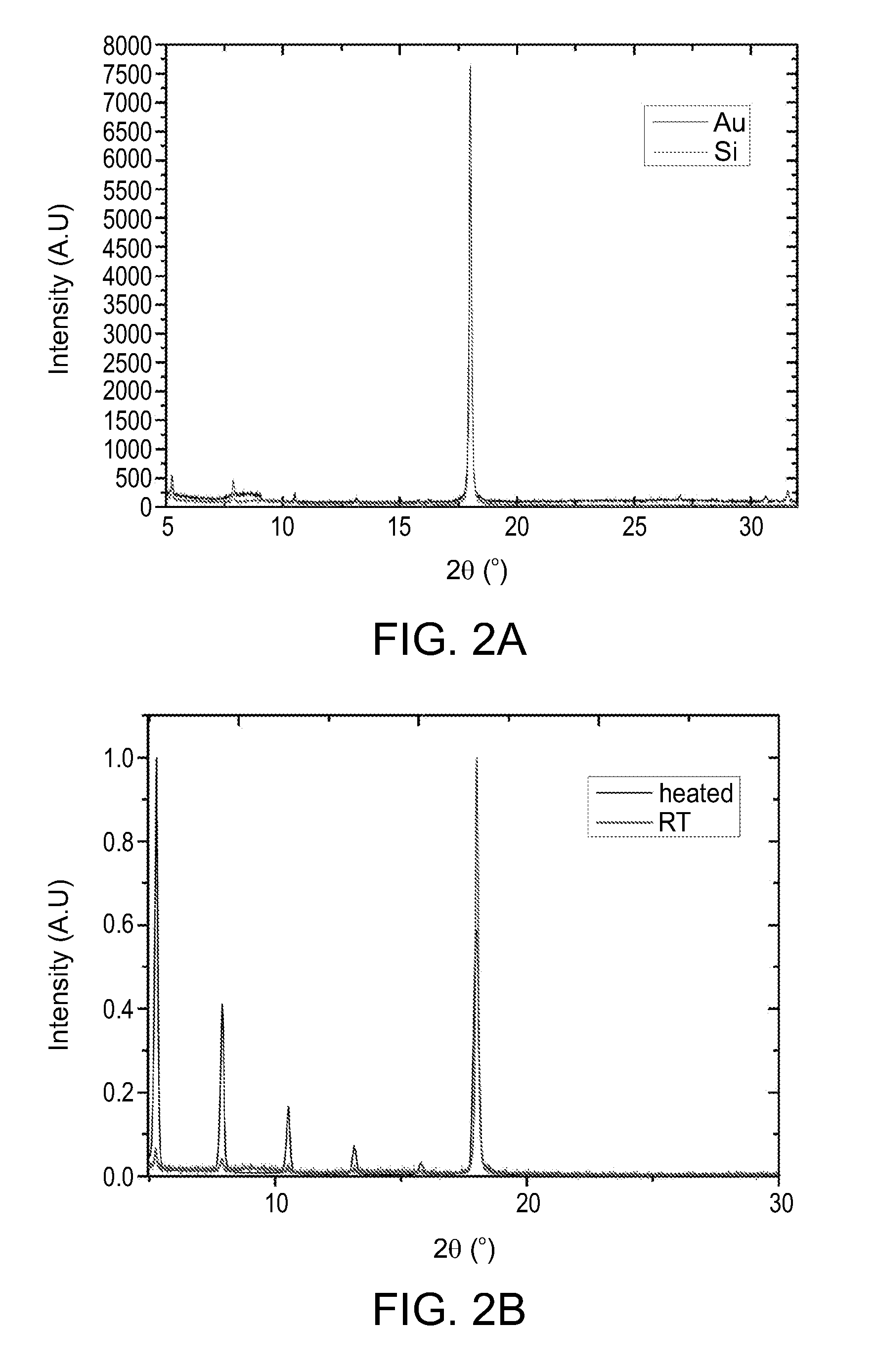

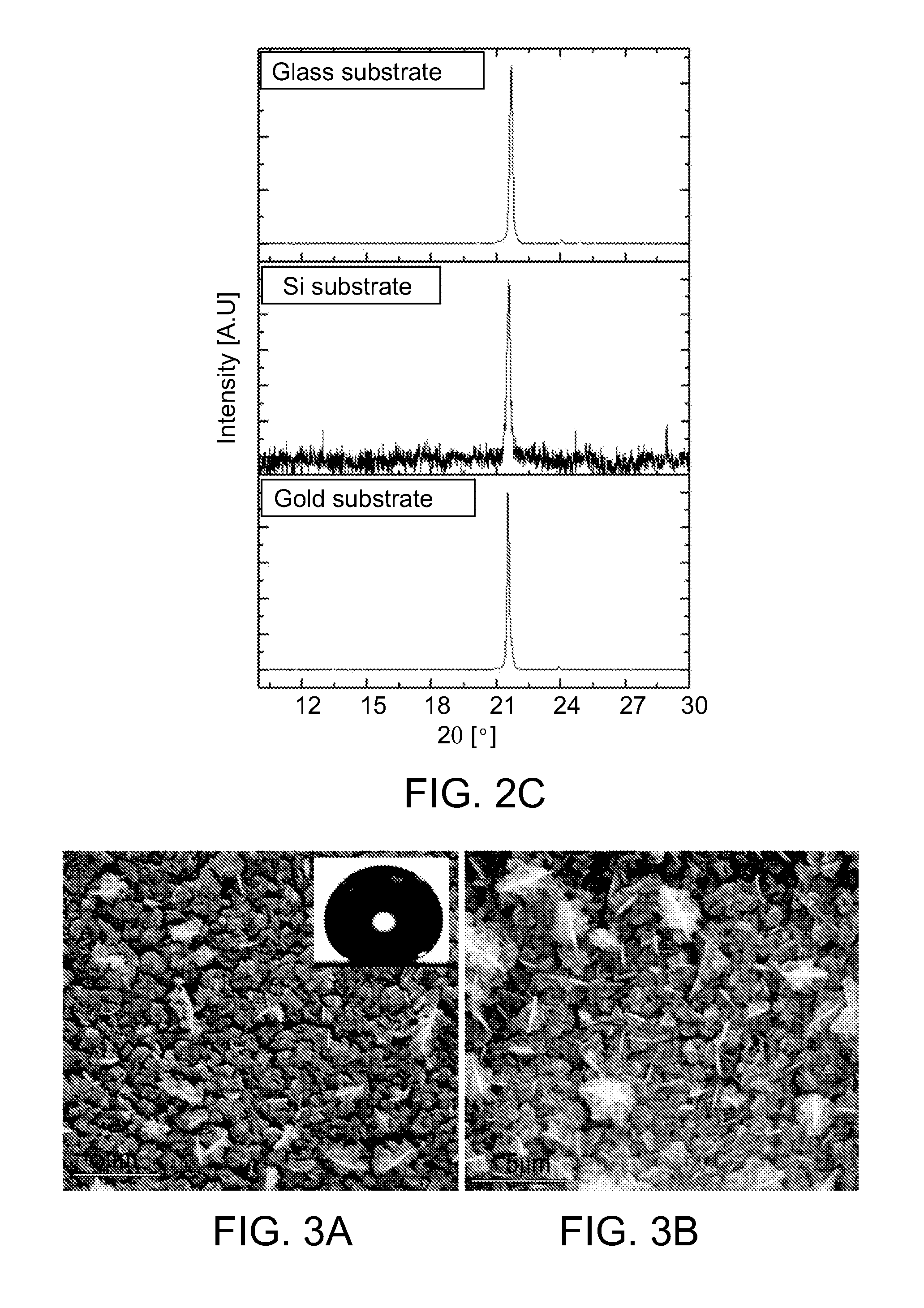

Hydrophobic and oleophobic surfaces and uses thereof

A methodology is provided for generating hydrophobic superhydrophobic, oleophobic and / or superoleophobic surfaces. Compositions of matter made of a substrate having deposited on a surface thereof (e.g., by thermal evaporation) hydrocarbon waxes, including fluorinated waxes, are disclosed. Process of preparing such compositions of matter and articles of manufacturing incorporating such compositions are also disclosed. Further disclosed are articles of manufacturing and methods which are useful in inhibiting, reducing and / or retarding biofilm formation, and which include applying waxes (e.g., by thermal evaporation) on a surface of the articles.

Owner:STATE OF ISRAEL MINIST OF AGRI & RURAL DEV AGRI RES ORG (A R O) (VOLCANI CENT) +1

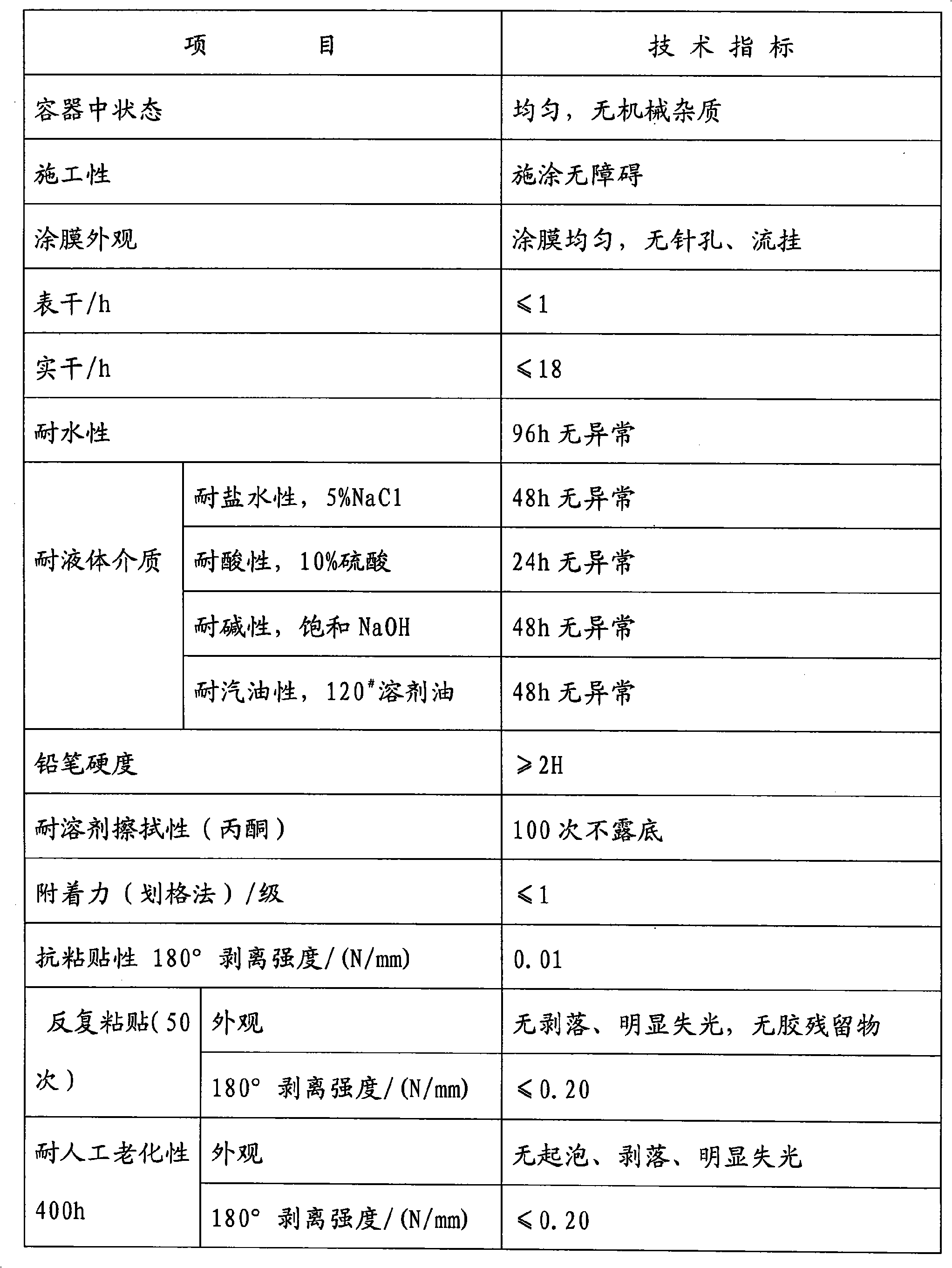

Method for preparing anti-graffiti coating for rail train carriage

InactiveCN101613563AImprove hydrophobicityGood oleophobic effectPolyurea/polyurethane coatingsAcrylic resinLacquer

The invention discloses a method for preparing an anti-graffiti coating for a rail train carriage, wherein the coating is prepared by mixing a component A and a component B. The component A comprises the following components: 21 to 65 portions of hydroxy-fluoro-silicon modified acrylic resin, 15 to 40 portions of pigments and fillers, 1 to 10 portions of auxiliary agent, and 16 to 42 portions of organic solvent; and the component B comprises 20 to 36 portions of polyisocyanate prepolymer. When in use, the components A and B are mixed and stirred evenly according to a mass ratio of 2-7:1, and then the mixture is adjusted to proper viscosity for construction by using a spraying method. The surface of a lacquer film formed by the coating has the advantages of low tensile force, compact structure, high hardness, excellent anti-graffiti performance, abrasion resistance, scrub resistance, corrosion resistance and long service life.

Owner:SOUTHEAST UNIV

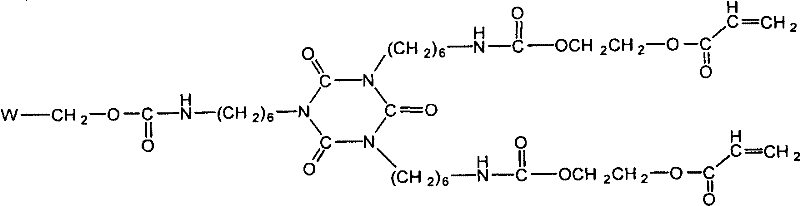

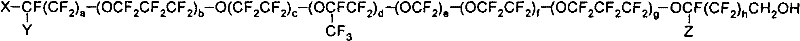

Perfluoropolyether group-containing silane compound, preparation method thereof, surface treatment agent and article

ActiveCN109071793AImprove hydrophobicityGood oleophobic effectAntifouling/underwater paintsPaints with biocidesSurface finishingWear resistant

The invention relates to a perfluoropolyether group-containing silane compound represented by a formula (1): Rf-X1-X2-NQkT2-k(1), and a preparation method therefor. The invention also relates to a perfluoropolyether group-containing silane compound shown in the description, and a preparation method therefor. The invention also relates to a perfluoropolyether group-containing silane compound represented by a formula (3) shown in the description, and a preparation method therefor. The perfluoropolyether group-containing silane compound can be used for a surface treatment agent so that the glassand other base materials processed by the surface treatment agent are excellent in anti-pollution, anti-fingerprint, scrape-resistant and wear-resistant performances, and the preparation methods for the compounds are simple in process, and are easy to operate and implement.

Owner:GUANGZHOU UR MATERIALS TECH CO LTD

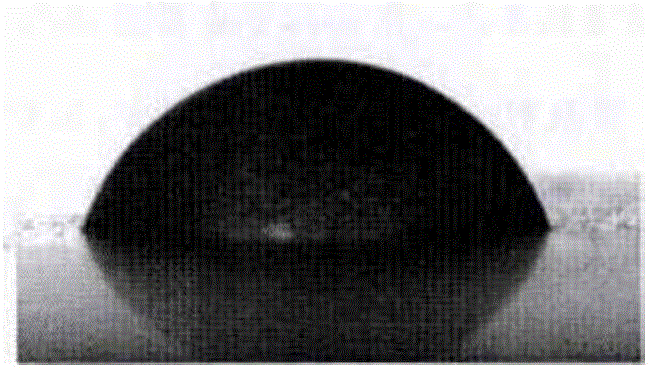

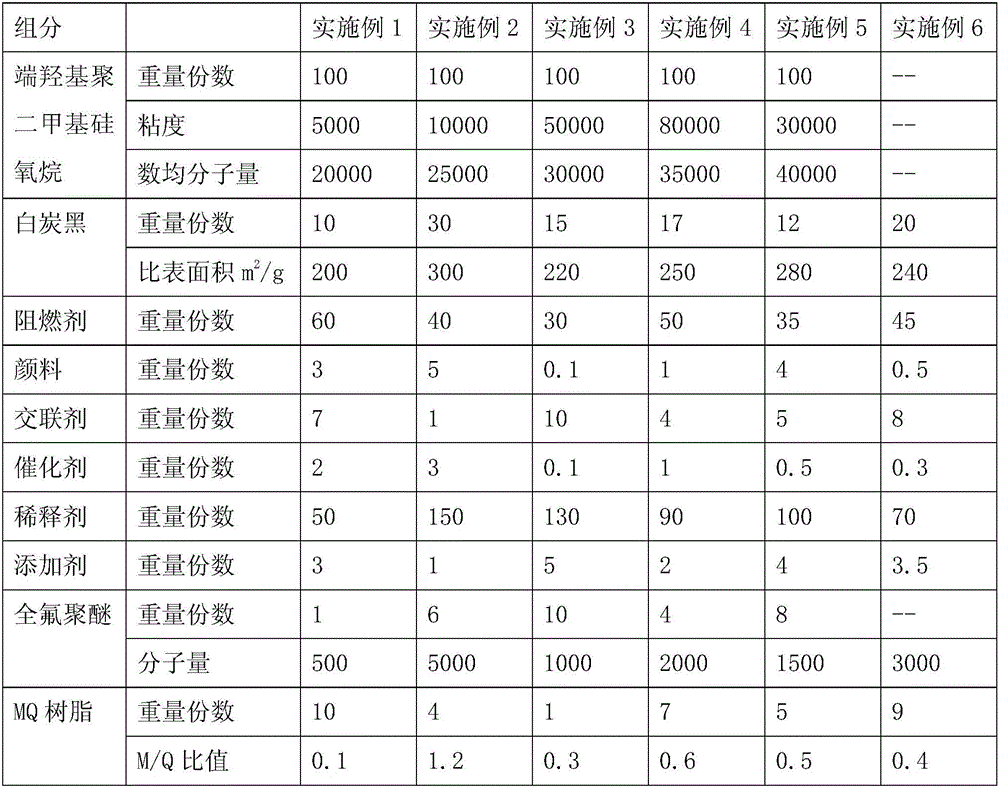

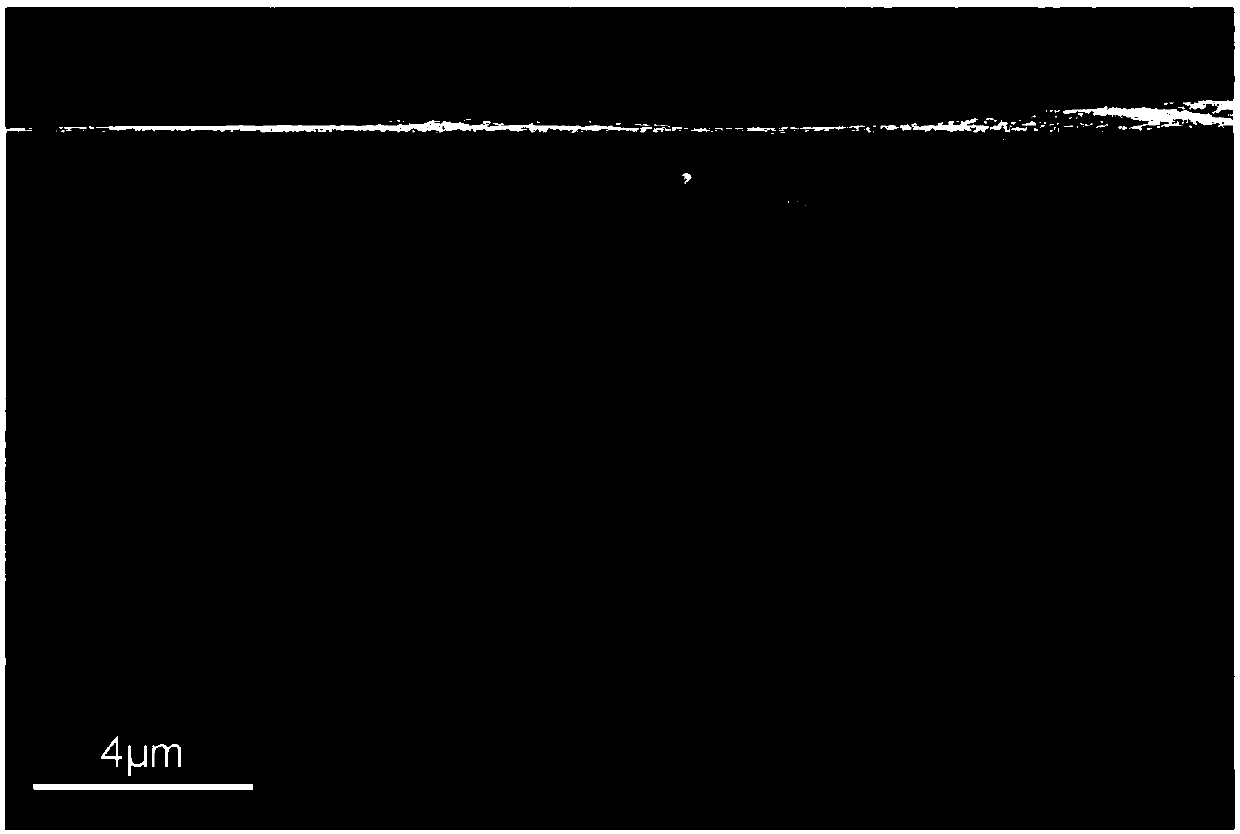

Anti-haze and anti-pollution-flashover coating as well as preparation method and application thereof

ActiveCN106085219AImprove hydrophobicityGood oleophobic effectFireproof paintsAntifouling/underwater paintsParticulatesVulcanization

The invention discloses an anti-haze and anti-pollution-flashover coating as well as a preparation method and an application thereof and belongs to the technical field of chemical coatings. White carbon black and MQ resin are taken as reinforcing materials of the anti-haze and anti-pollution-flashover coating. Compared with the traditional RTV (room temperature vulcanization) silicone coatings, the anti-haze and anti-pollution-flashover coating has double-phobic technological advantages including hydrophobic and oleophobic, has a self-cleaning function on dust particulate matters, can prevent adhesion of organic fouling, resists weather and salt-spray corrosion, thereby having the anti-haze performance..

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +1

Multifunctional super-amphiphobic fabric and preparation method thereof and application thereof

ActiveCN109610161AImprove mechanical propertiesGood chemical resistanceStain/soil resistant fibresLiquid repellent fibresDouble bondTetrahydrofuran

The invention discloses a multifunctional super-amphiphobic fabric and a preparation method thereof and application thereof. The preparation method of the multifunctional super-amphiphobic fabric comprises the steps of firstly, washing the fabric by using deionized water and ethanol, preparing an ethanol mixed solution of thiol siloxane and tetraethoxysilane, and putting a clean woven fabric intothe mixed solution to be soaked; and secondly, enabling the fabric to react for 5-120 min in the atmosphere containing ammonia, and putting the dried fabric into a tetrahydrofuran solution containinga photoinitiator and a fluorine-containing double-bond compound to perform click reaction. The preparation method of the multifunctional super-amphiphobic fabric, disclosed by the invention, has the advantages of short reaction time, low raw material consumption and simple operation; and the obtained fabric also has a self-cleaning function, an anti-fouling function and a function of separating oil and water of light and heavy oil.

Owner:SOUTH CHINA UNIV OF TECH

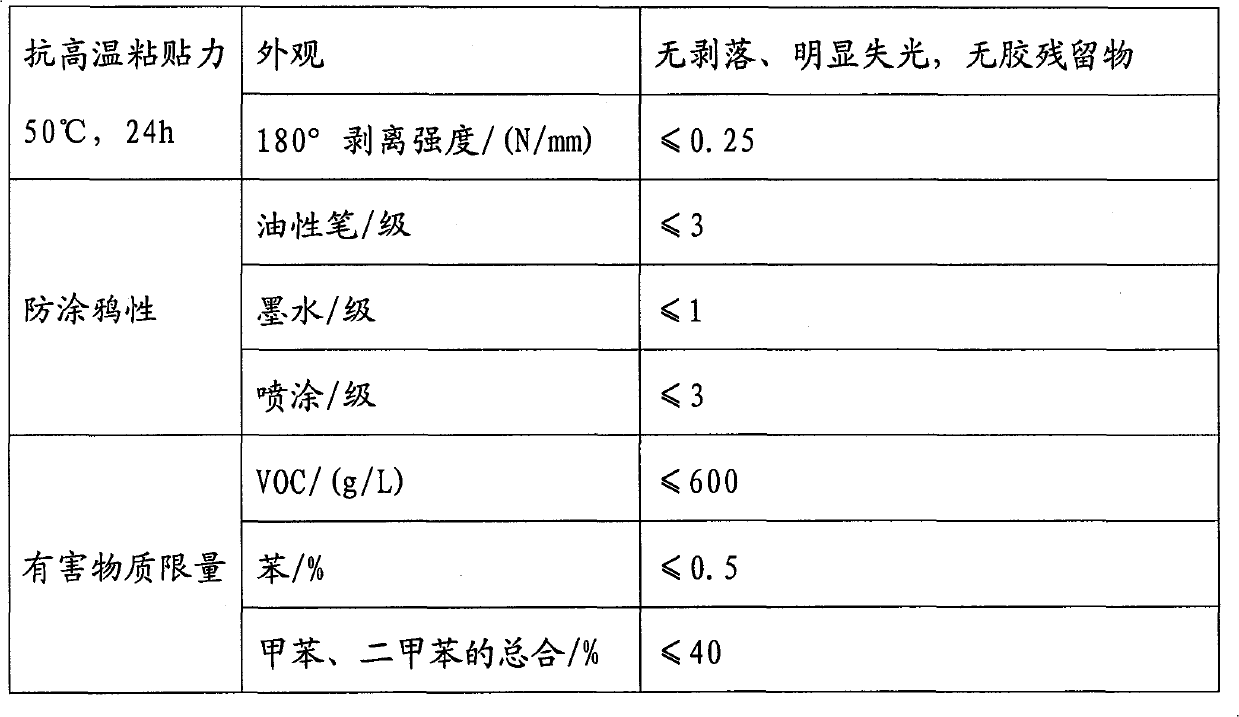

Anti-doodling, anti-fouling, anti-sticking and high weather-resistant coating and preparation method thereof

InactiveCN104946110AReduce penetrationDifficult to growAntifouling/underwater paintsPaints with biocidesAcrylic resinAcrylate ester

The invention relates to the field of coatings, in particular to an anti-doodling, anti-fouling, anti-sticking and high weather-resistant coating and a preparation method thereof. The anti-doodling, anti-fouling, anti-sticking and high weather-resistant coating comprises an A component and a B component, wherein the A component comprises the following components in parts by weight: 20-50 parts of modified hydroxy acrylic resin, 10-40 parts of FEVE fluorocarbon resin, 1-5 parts of organopolysiloxane and 2-10 parts of organosilicone modified acrylate; and the B component comprises the following components in parts by weight: 70-80 parts of curing agent and 20-30 parts of solvent. The anti-doodling, anti-fouling, anti-sticking and high weather-resistant coating has very excellent hydrophobic and oleophobic properties and anti-doodling and anti-sticking functions, reduces water percolation, and can prolong the service life of a paint film; and mould growth is not easy.

Owner:恒昌涂料(惠阳)有限公司

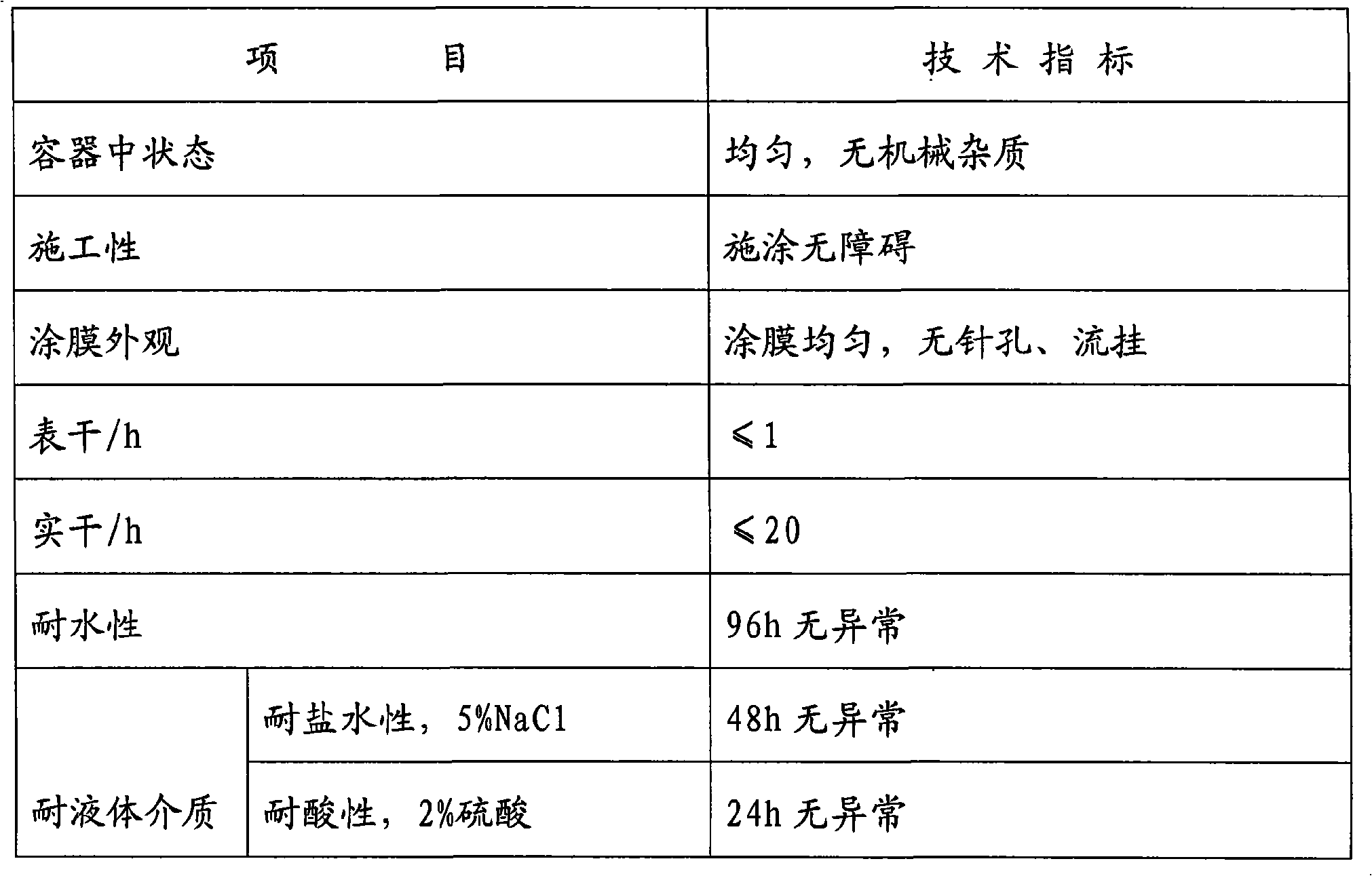

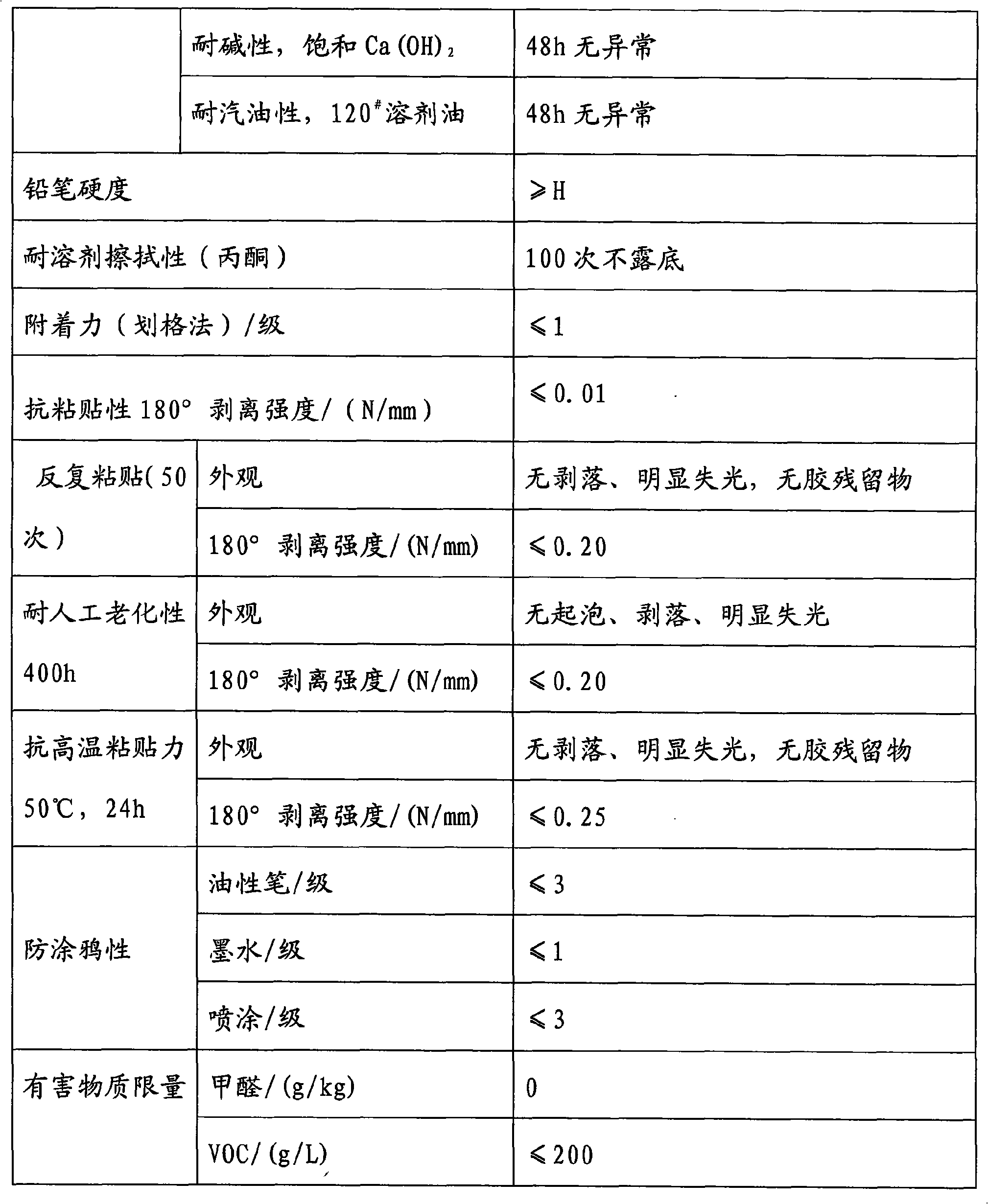

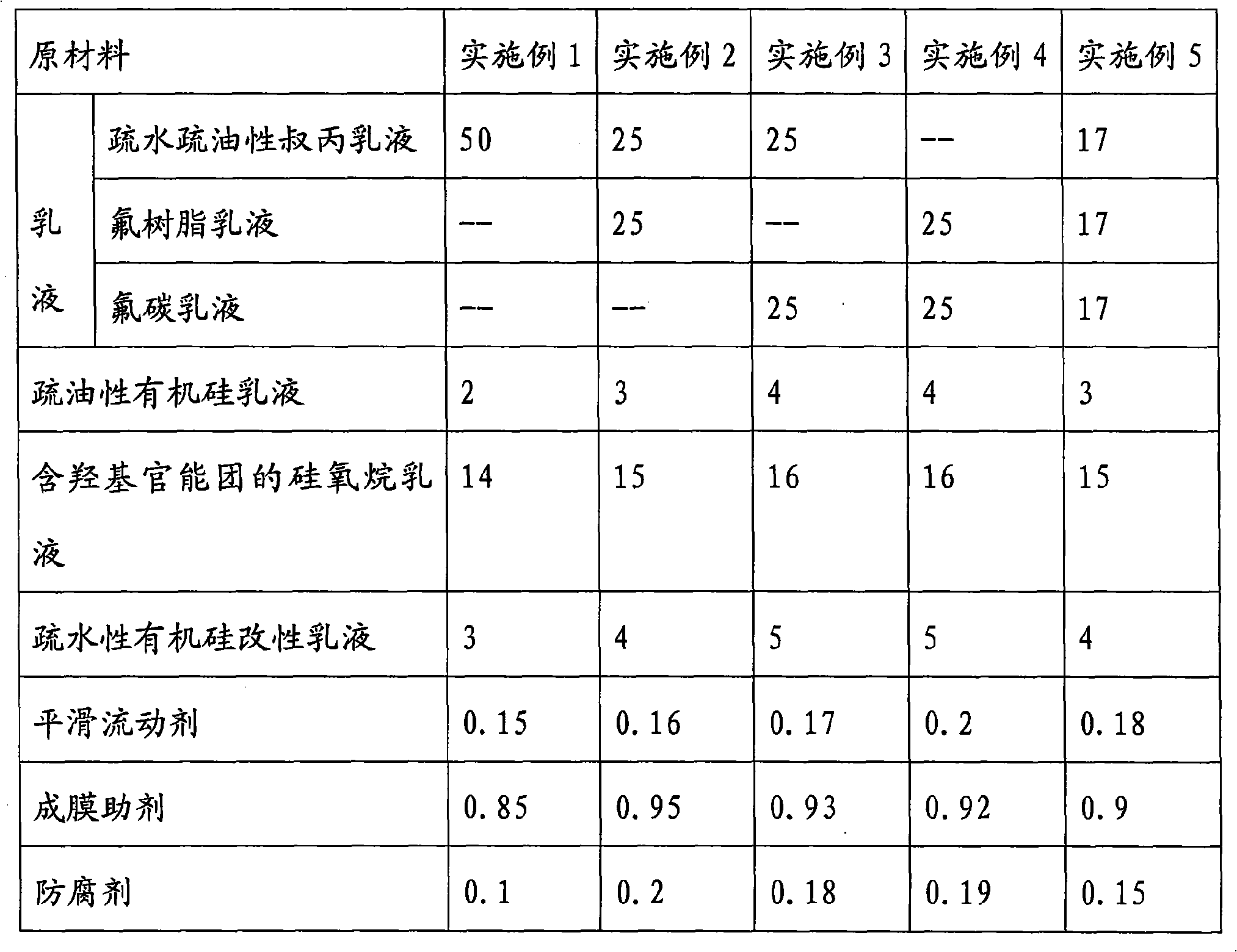

Aqueous anti-graffiti adhesion resistant paint and preparation method thereof

InactiveCN101585990AIncrease elasticityGood resistance to acid, alkali and saltCoatingsEmulsionPreservative

The invention discloses aqueous anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. The paint consists of the following components by weight portion: 50 to 55 portions of emulsion, 2 to 4 portions of organic silicon emulsion, 14 to 16 portions of siloxane emulsion containing hydroxy functional group, 3 to 5 portions of hydrophobic organic silicon modified emulsion, 0.15 to 0.2 portion of smooth flow agent, 0.85 to 0.95 portion of film forming assistant, 0.1 to 0.2 portion of preservative, 0.1 to 0.2 portion of mildew preventive, 0.8 to 1 portion of ethylene glycol, 5 to 7 portions of hydrophobic agent, 0.1 to 0.2 portion of thickening agent, and 23 to 25 portions of deionized water. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easy cleaning, and quick and convenient construction, has zero formaldehyde, benzene and heavy metals, has low VOC, and is typical environment-friendly paint.

Owner:LANZHOU XUNMEI PAINT IND TECH

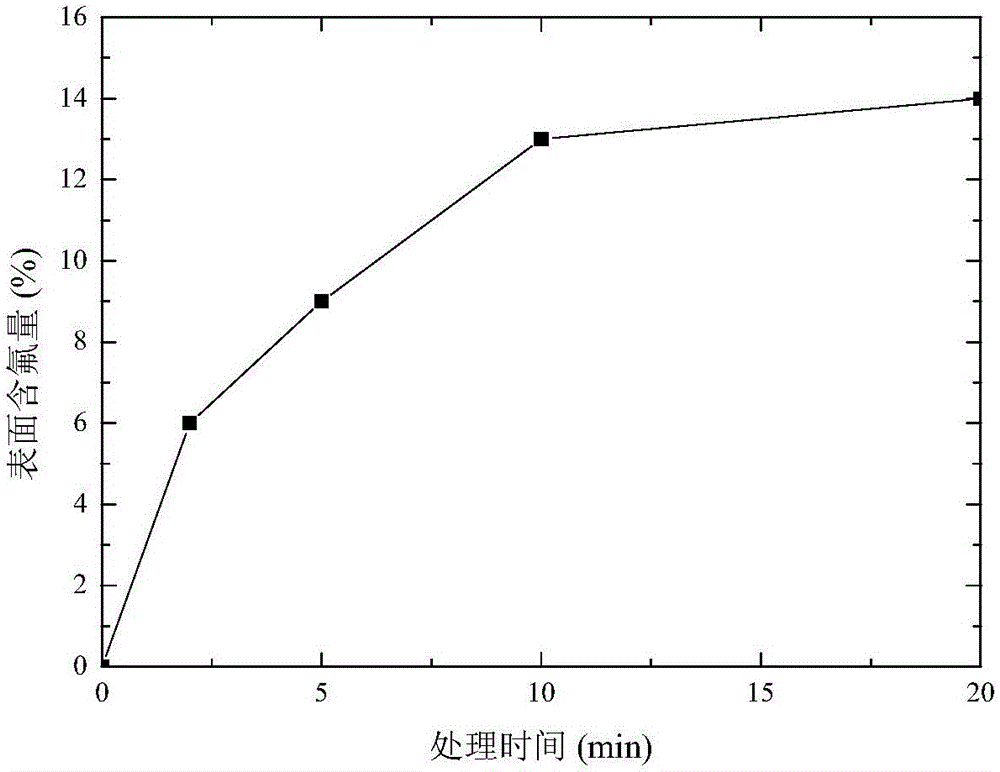

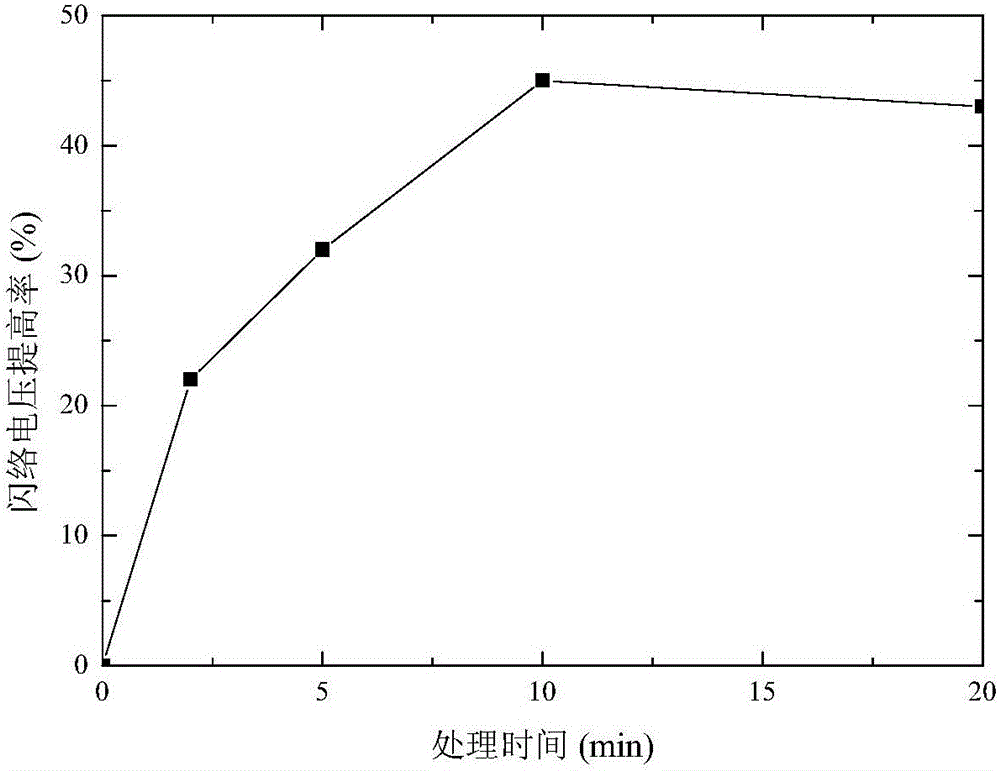

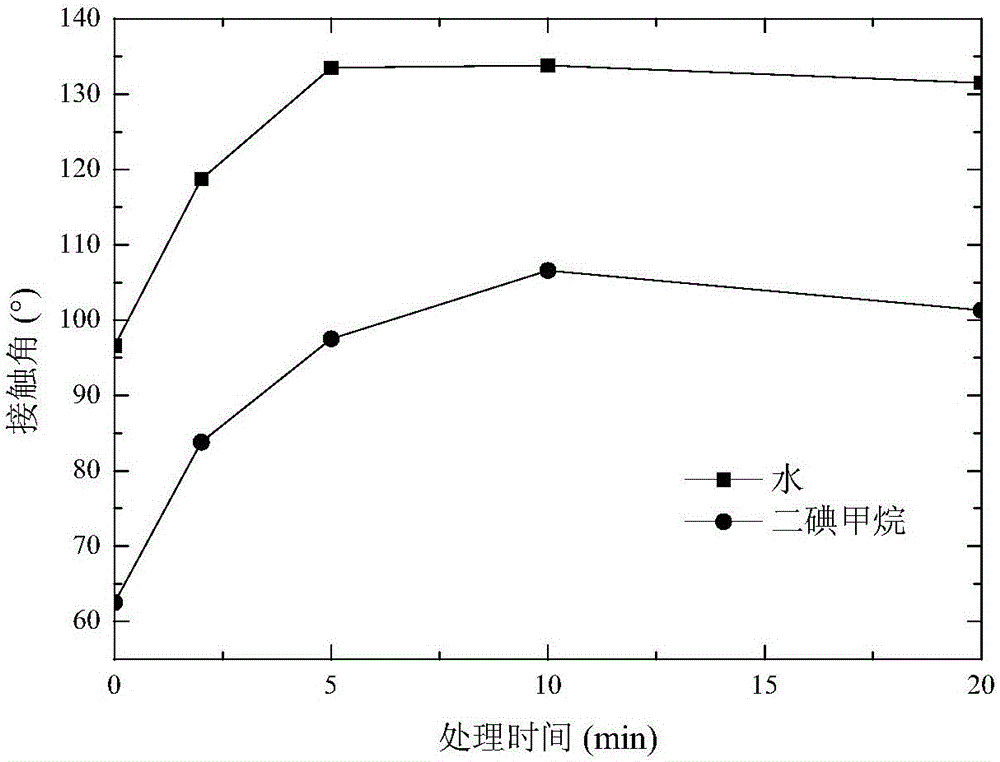

Method for fluorinating insulator through use of CF4 plasma

The invention belongs to the technical field of high voltage and insulation, and specifically relates to a method for fluorinating an insulator through use of a CF4 plasma. According to the method, an insulator is put in a reaction cavity, a mixture of CF4 and an inert gas is fed into the reaction cavity, the insulator is processed by a discharge plasma for 2-30min at room temperature and at low pressure of 0.01-0.1atm, so CF4 and the surface of the insulator are reacted with each other to generate a fluorinated layer. The method has the characteristic that the surface of a insulator is fluorinated through plasma processing in CF4, the surface flashover characteristic of insulators is improved, the electric strength of insulators is improved, the flashover voltage can be improved by about 50% to the maximum, the hydrophobic and oleophobic properties of the surfaces of insulators are improved, and the capability of insulators to prevent wet flashover and pollution flashover is improved.

Owner:XI AN JIAOTONG UNIV

High-performance wind-power generating facility coating prepared by taking organic fluorinated silicone modified elastic polyurethane-urea resin as substrate

InactiveCN101665655AHigh tensile strengthHigh resistivityPolyurea/polyurethane coatingsUreaWeather resistance

The invention discloses high-performance wind-power generating facility coating prepared by taking organic fluorinated silicone modified elastic polyurethane-urea resin as substrate. The high-performance wind-power generating facility coating is prepared from component A and component B according to proportion. The wind-power generating facility coating has toughness, attrition resistance, high elasticity, excellent mechanical property, yellowing resistance, good colour retention, high ultraviolet resistance, high weather resistance, favorable and excellent electrical insulation, chemical stability, moisture resistance and freeze resistance. In addition, the wind-power generating facility coating has high performance and moderate cost and can strongly protect the wind-power generating facility, reduce the maintenance frequency and lower the purchasing cost of the wind-power generating facility, thereby having extremely high implementation value and social and economic benefit.

Owner:西北永新涂料有限公司 +1

Hydrophobic and oleophobic coating composition and preparation method thereof

InactiveCN112210293AHydrophobicImprove oleophobic propertiesAntifouling/underwater paintsPaints with biocidesPolymer scienceOrganosolv

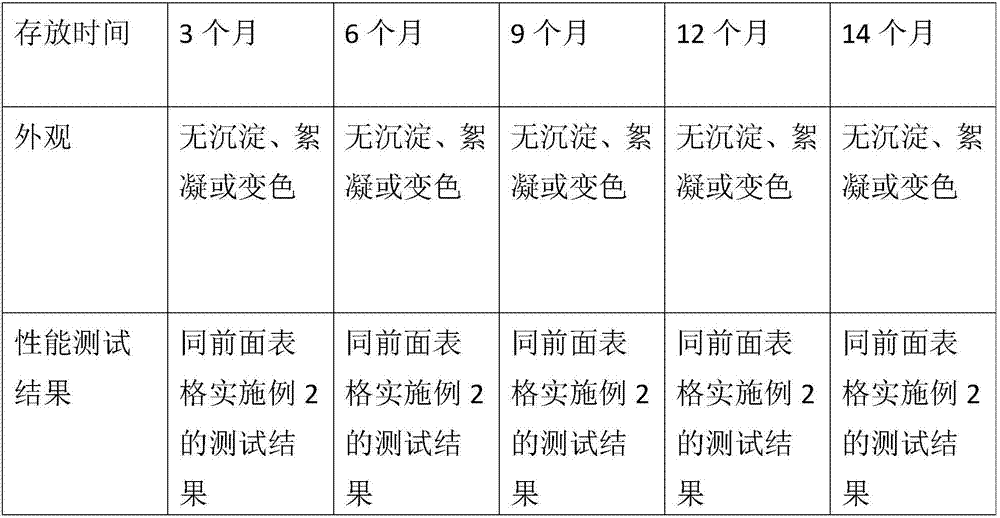

The invention relates to the technical field of hydrophobic and oleophobic coatings, and particularly discloses a hydrophobic and oleophobic coating composition and a preparation method thereof. The hydrophobic and oleophobic coating composition comprises the following components in parts by weight: 10-25 parts of methyl hydrogen-containing silicone oil; 5-15 parts by weight of hydroxyl-terminatedsilicone oil; 2-8 parts by weight of amino silicone oil; 0.1 to 2 parts by weight of perfluorosilicone oil; 3-10 parts by weight of organic solvent type silica sol; and 40-80 parts by weight of organic solvent. According to the invention, methyl hydrogen-containing silicone oil, hydroxyl-terminated polydimethylsiloxane and amino silicone oil undergo a condensation reaction to form a three-dimensional network structure, and perfluorosilicone oil is combined to further improve the oleophobic effect of the system; and by adding the solvent type silica sol, inorganic silicon oxide particles in the silica sol and organopolysiloxane are hybridized, and a uniform system is formed, so that the formed coating has excellent hydrophobic and oleophobic effects and good wear resistance, the product islow in production cost, long in shelf life, simple in preparation method and suitable for industrial production, and industrial production and wide application are facilitated.

Owner:FOSHAN SITECH CHEM TECH

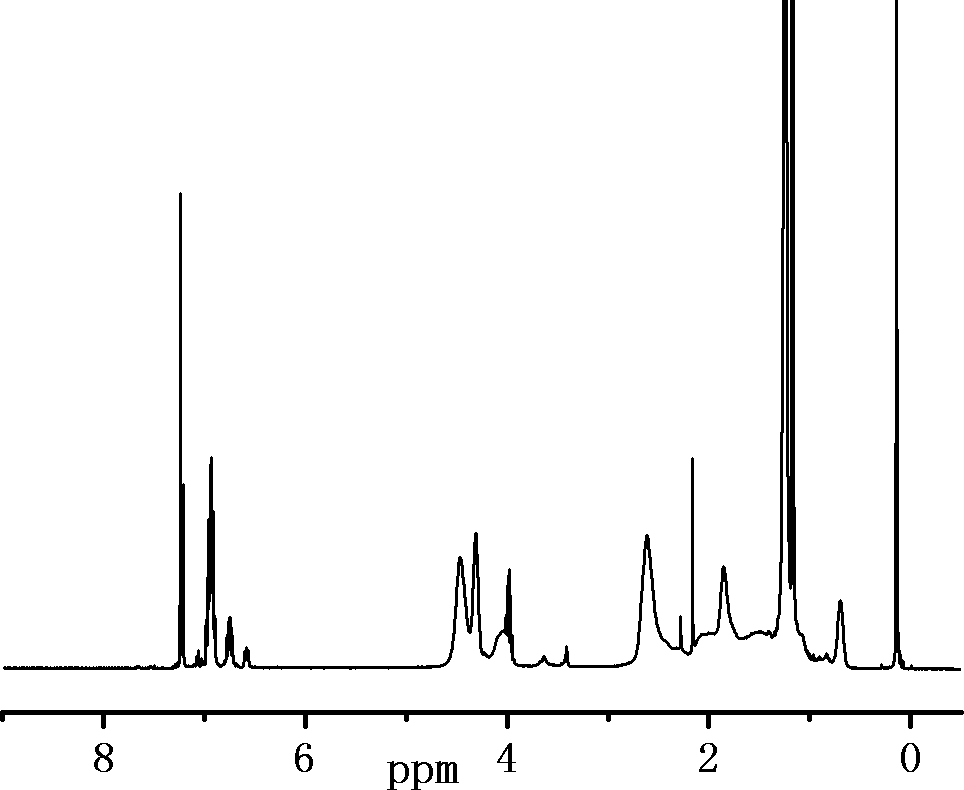

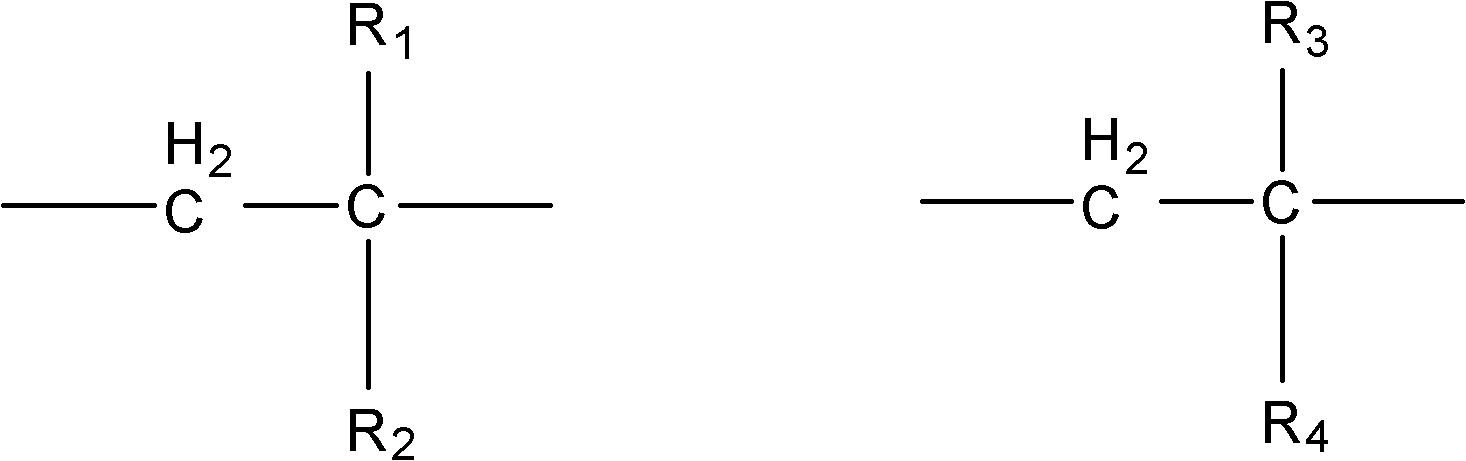

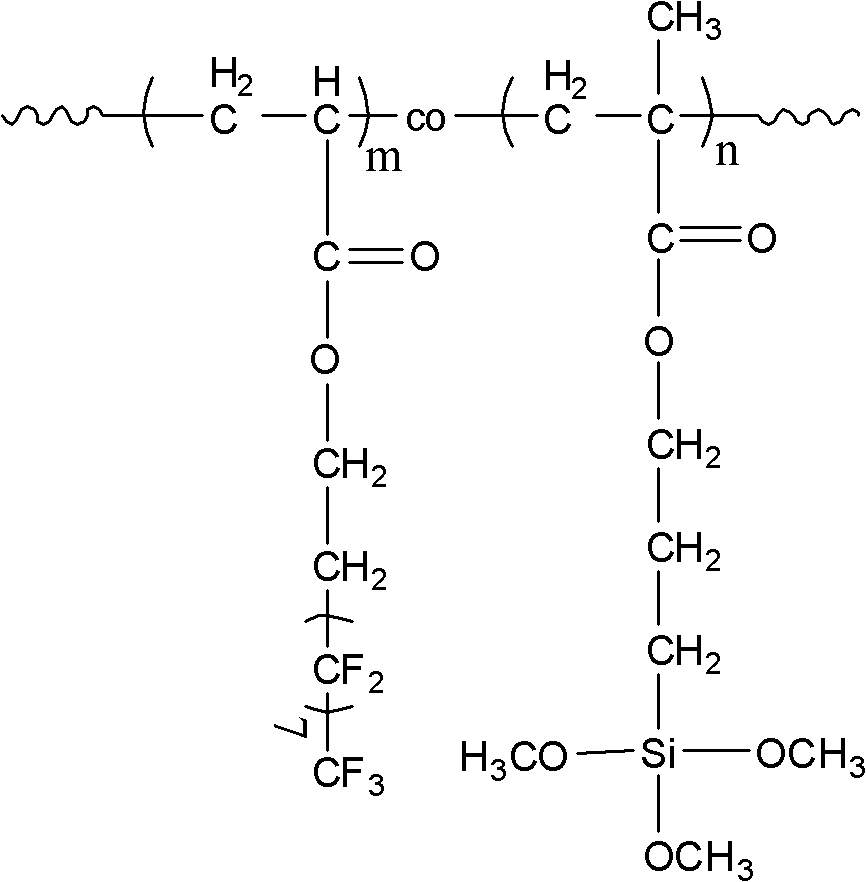

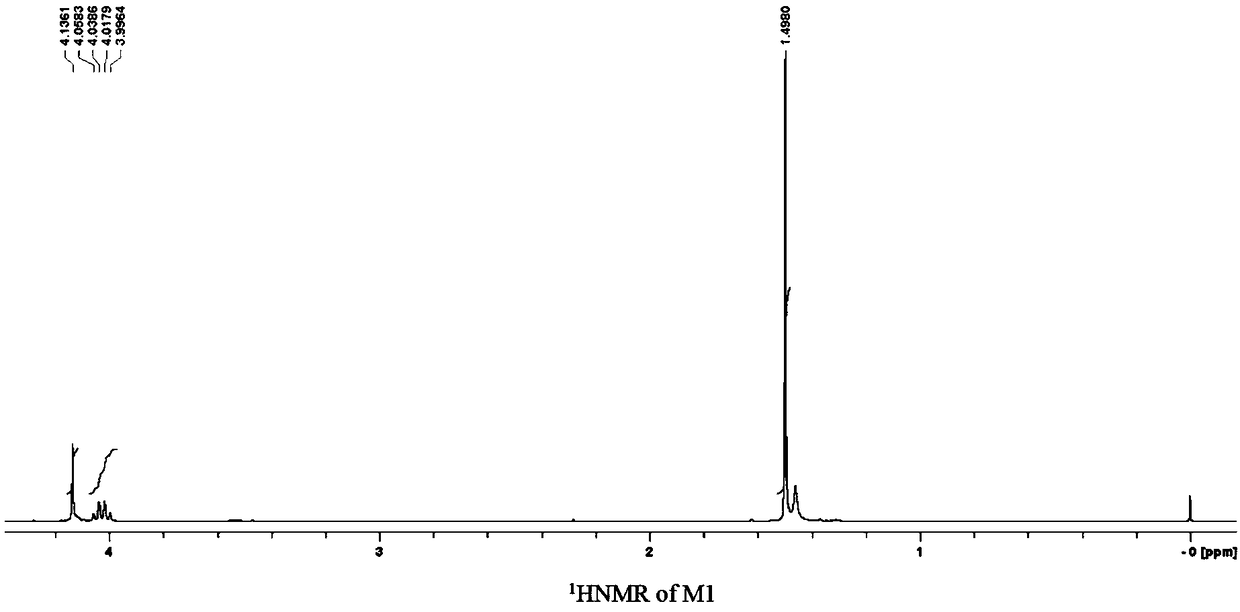

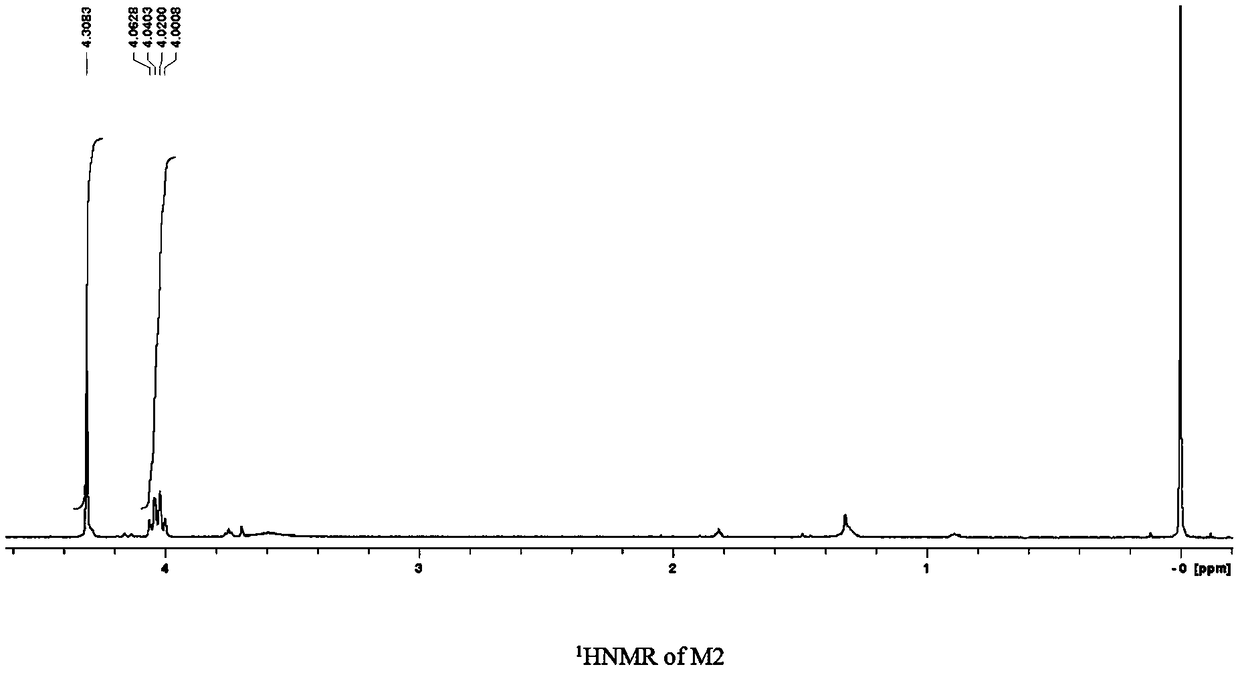

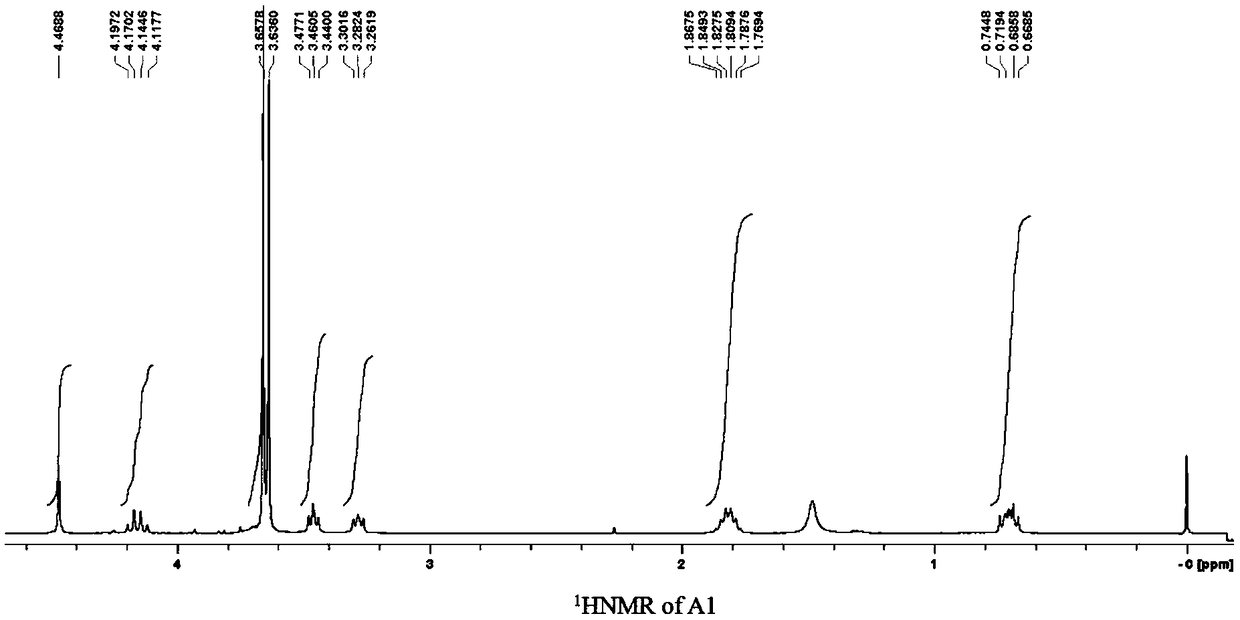

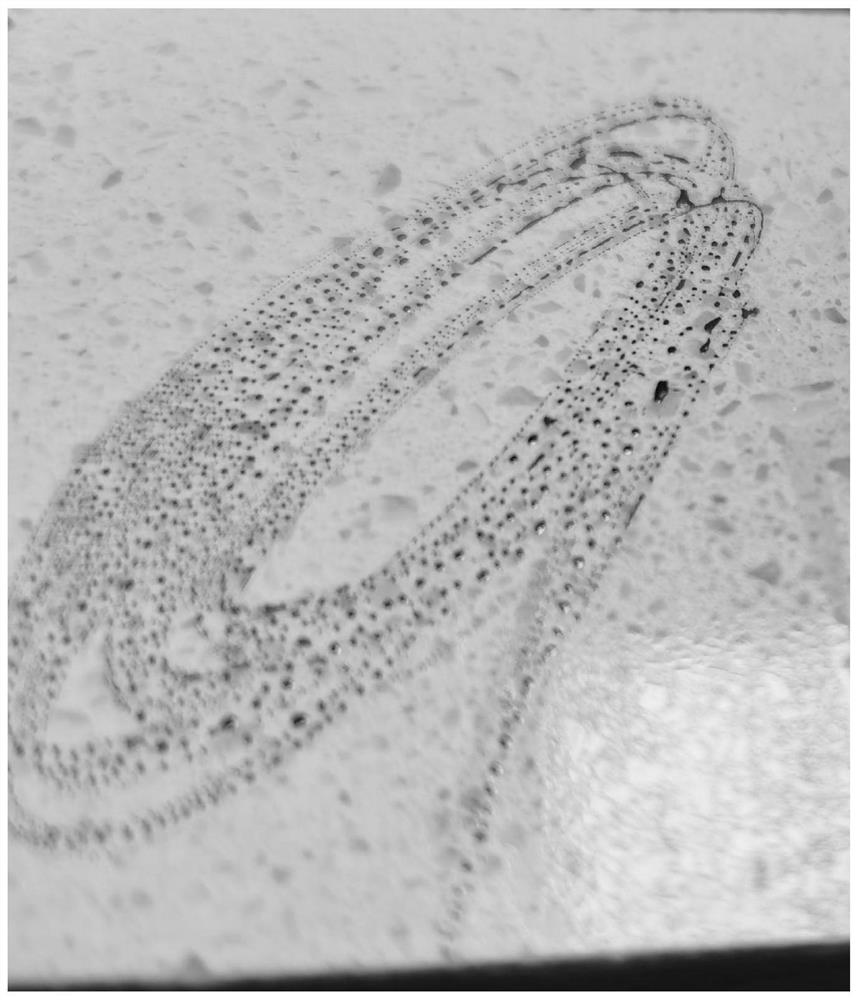

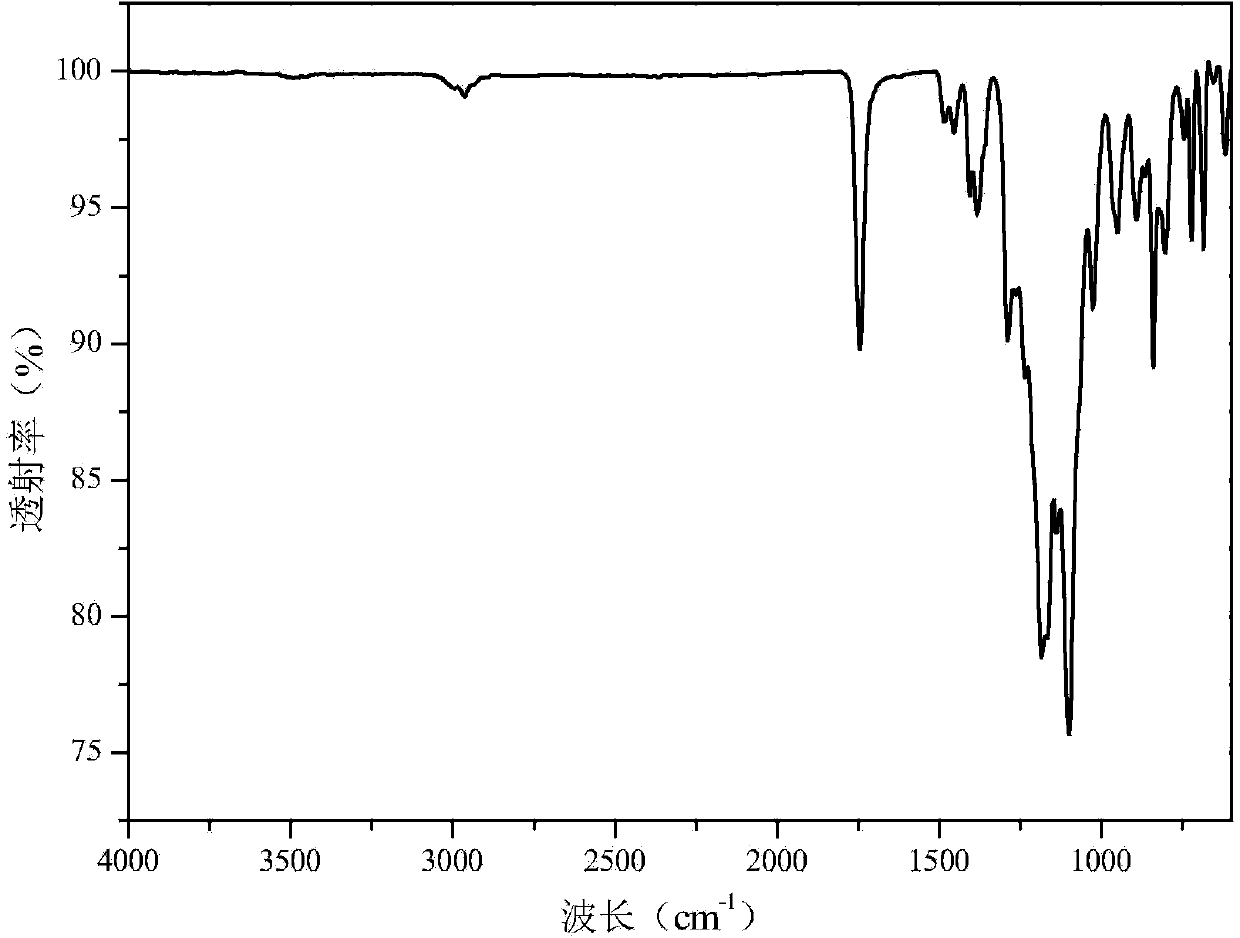

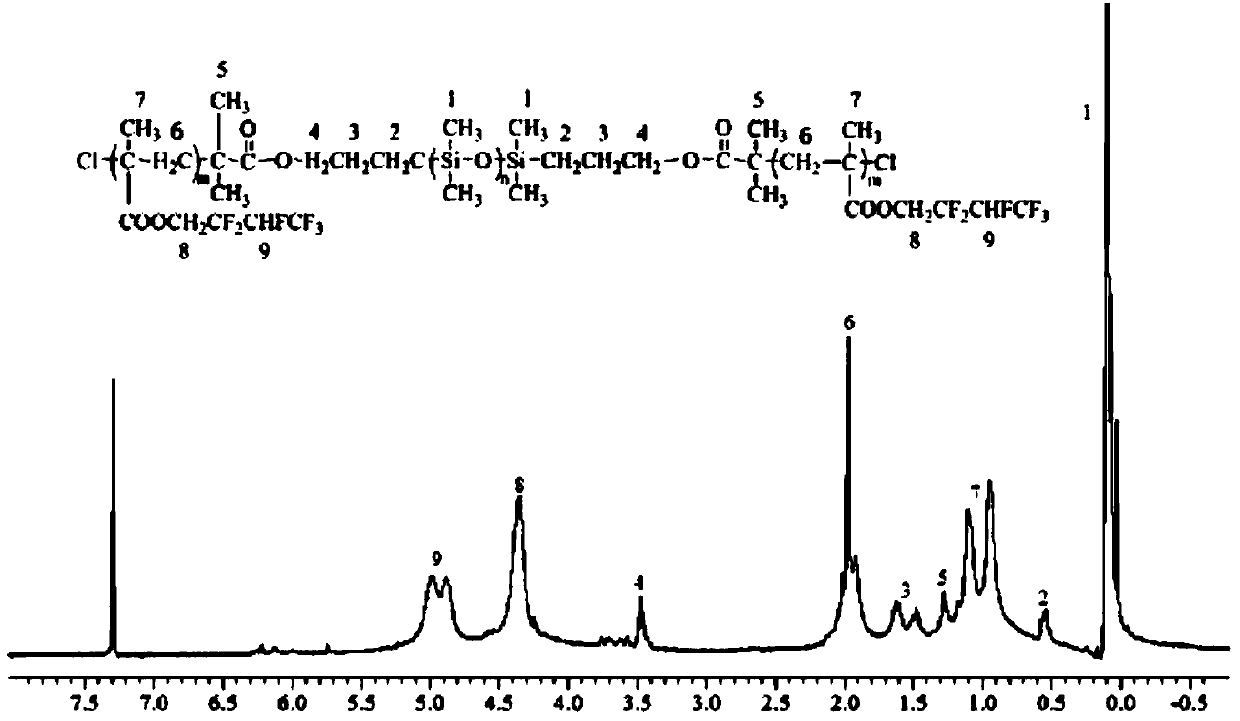

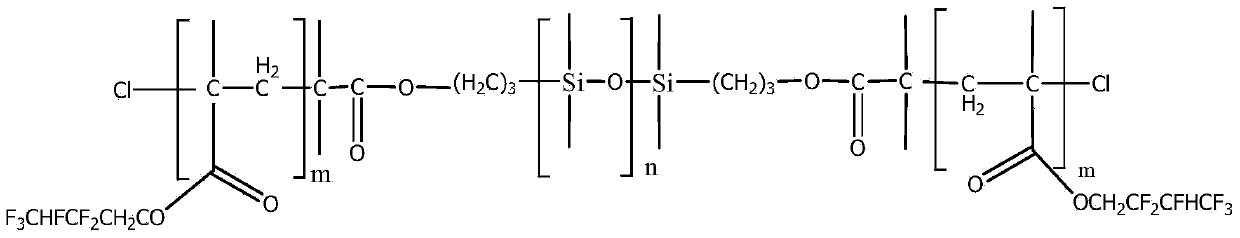

Hydrophobic/oleophobic fluorosilicone triblock polymer and preparation method thereof

ActiveCN104193923AControllable Molecular WeightControllable distributionAntifouling/underwater paintsPaints with biocidesMethacrylatePolymer science

The invention discloses a hydrophobic / oleophobic fluorosilicone triblock polymer and a preparation method thereof. The structural formula of the polymer is as shown in the specification, in the structural formula, m is an integer from 10 to 50, n is an integer from 20 to 50, and a target polymer, namely, hexafluorobutyl methacrylate-b-polydimethylsiloxane-b-polyhexafluorobutyl methacrylate is synthesized by taking chloro-polydimethylsiloxane as a chain initiator under the co-catalysis of a catalyst CuCl and catalyst ligands 2,2'-dipyridyl and N-(2-pyridine methylene)-1-propylamine or tetramethylethylenediamine by using an atom transfer radical polymerization method. According to the hydrophobic / oleophobic fluorosilicone triblock polymer, microwave radiation heating is adopted, the operation is simple and convenient, the reaction condition is gentle, the molecular weight and the distribution of a reaction product can be controlled, and the synthesized hydrophobic / oleophobic fluorosilicone triblock polymer is excellent in hydrophobic and oleophobic property and is wide in application prospect in anti-flouring coating.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

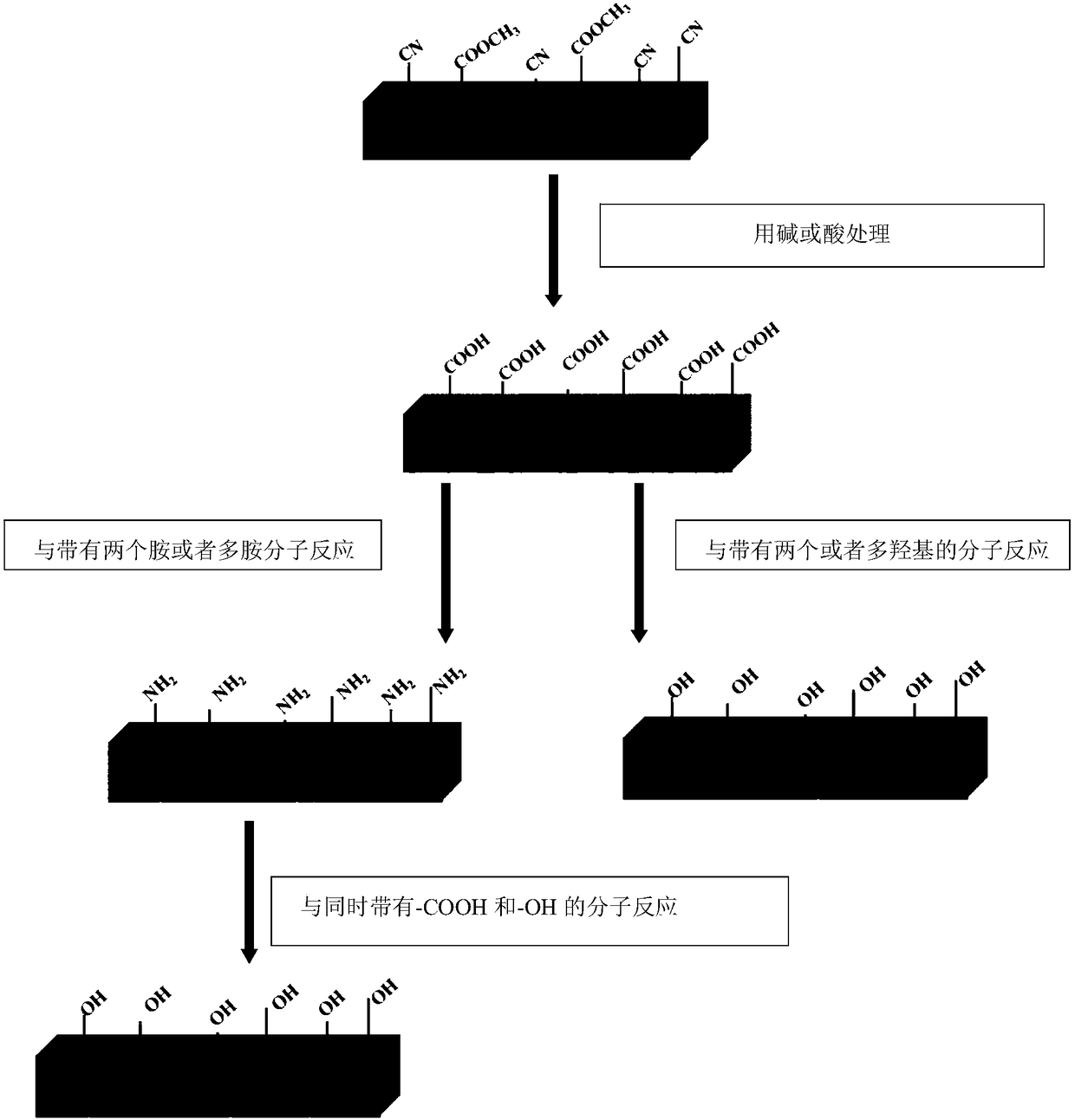

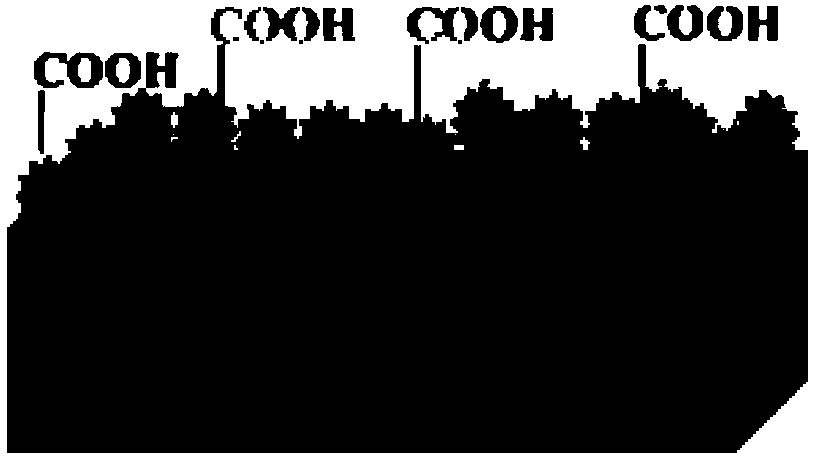

Preparation method of superhydrophilic and underwater-superoleophobic polyacrylonitrile-based oil-water separating membrane

ActiveCN108246112ALow costUniform pore size distributionMembranesSemi-permeable membranesPorosityNano structuring

The invention provides a preparation method of a superhydrophilic and underwater-superoleophobic polyacrylonitrile-based oil-water separating membrane. The preparation method comprises the following steps of: adopting acrylonitrile monomer as a main-body raw material, and adopting an aqueous-phase precipitated polymerization method to synthesize a polyacrylonitrile-based copolymer; selecting a crystalline diluting agent, combining with a thermally-induced phase separation method to construct a polyacrylonitrile-based microporous membrane with a micro / nano structure and high flux on the surface, and preparing the superhydrophilic and underwater-superoleophobic microporous membrane by simple modification and grafting, wherein the use of an organic solvent is avoided in synthesis and modification of the process. The oil-water separating membrane prepared by the preparation method has the advantages of high porosity, good pressure resistance, permanent hydrophilia and excellent underwateroleophobic property; in addition, the adhesion to oil drops is very low, the pollution resistance is good, long-time and stable operation can be achieved, and high-efficiency separation from an oil-water mixture to oil-in-water type oil-water emulsion can be realized only by means of gravity or lower pressure.

Owner:TIANJIN POLYTECHNIC UNIV

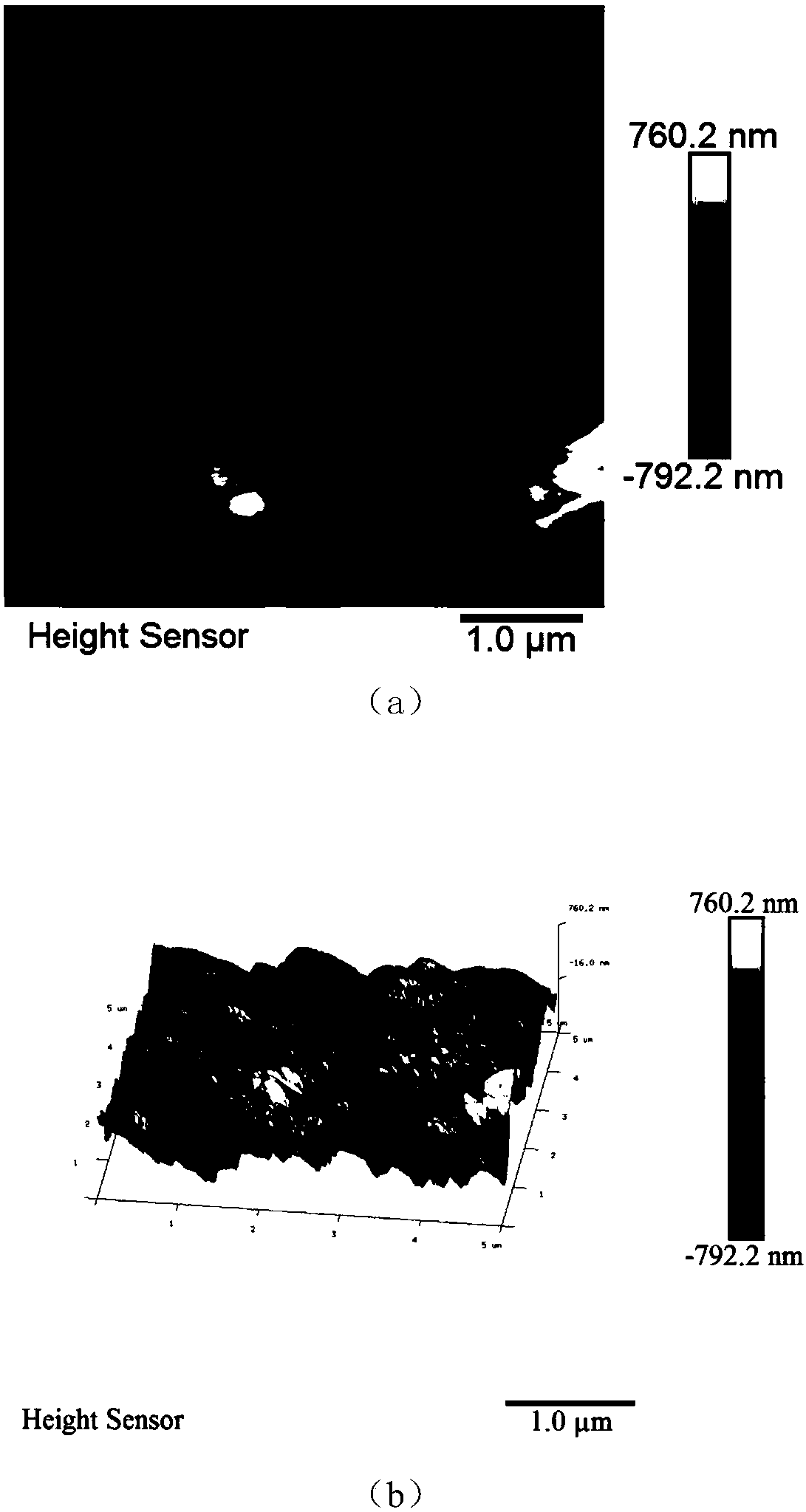

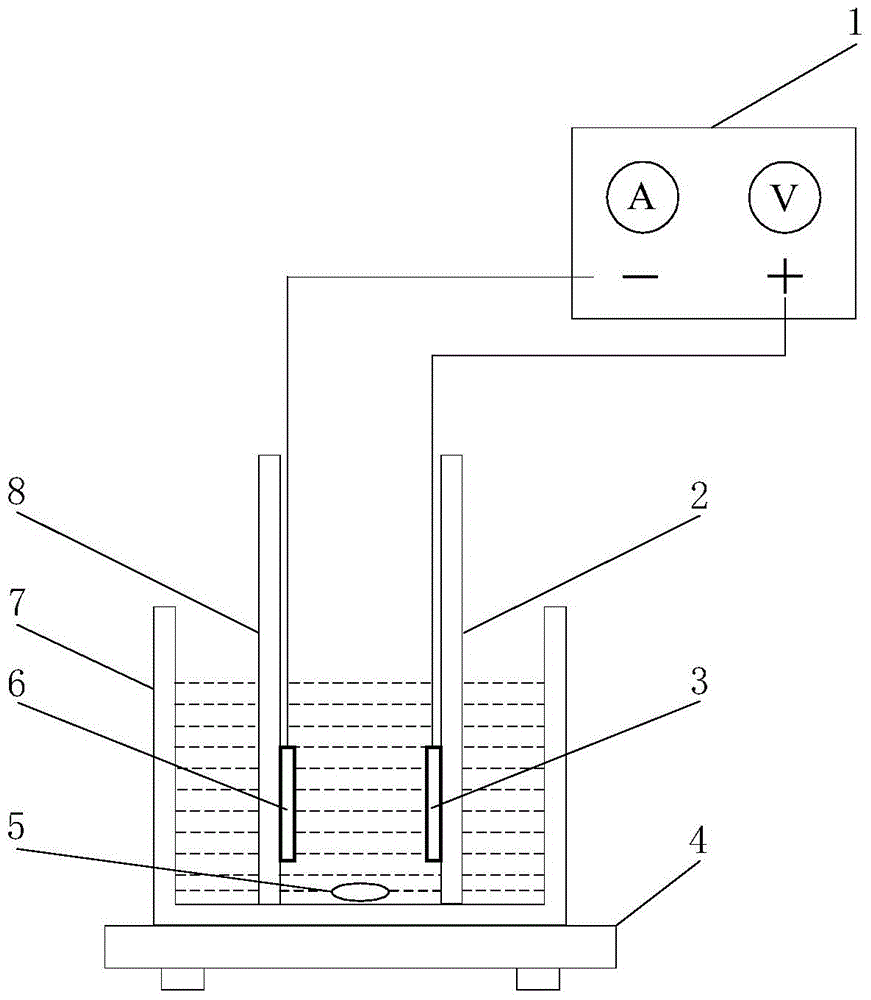

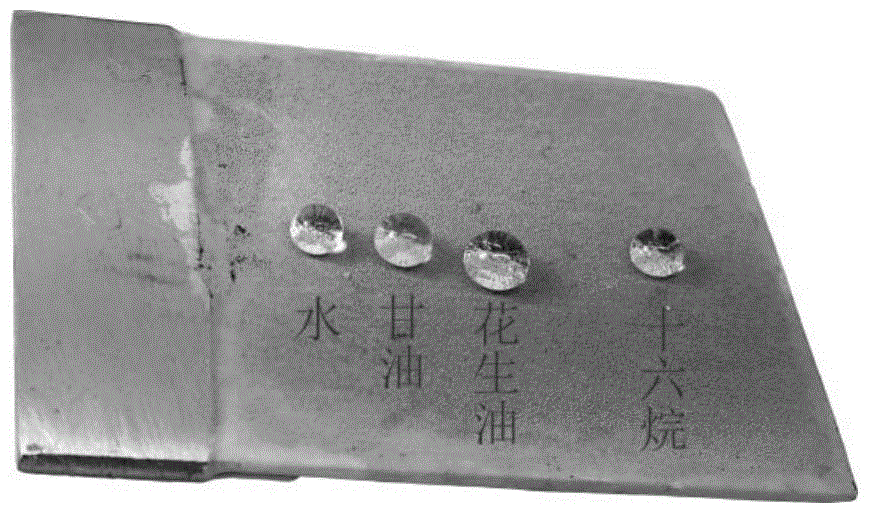

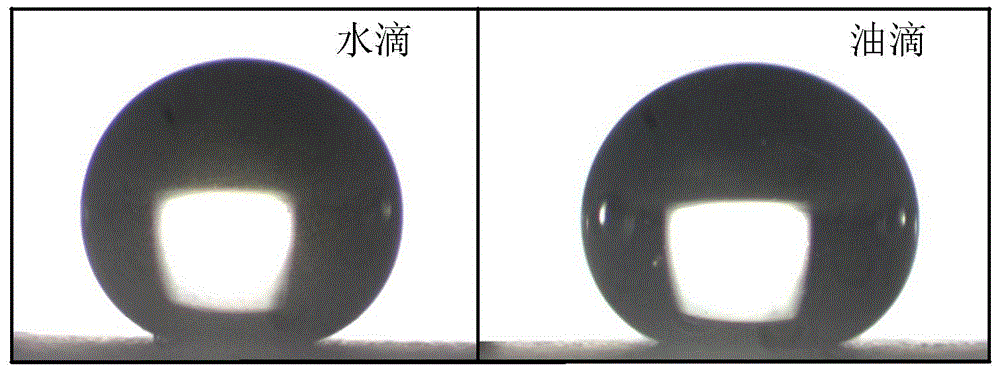

Process method for preparing super-amphiphobic zinc surface

InactiveCN104878430AImprove hydrophobicityGood oleophobic effectAnodisationMetallic material coating processesMicro nanoSurface oxidation

The invention provides a process method for preparing a super-amphiphobic zinc surface. According to the process method, electrochemical etching and low-surface-energy material modification are combined; a metal zinc plate is cleaned by virtue of an organic solvent to remove oil and is mechanically polished to remove a surface oxide layer, the cleaned zinc plate is fixed on a positive electrode clamp to serve as a positive electrode, and a graphite plate with same area size with the zinc plate is fixed on a negative electrode clamp to serve as a negative electrode; a used electrochemical etching solution is a neutral salt solution with a proper concentration, constant current is introduced into two ends of the positive electrode and the negative electrode, and by controlling the machining time and machining current in the electrochemical etching process, a proper binary micro-nano coarse structure is machined on the surface of the zinc plate; after the binary micro-nano coarse structure produced by virtue of electrochemical etching is modified by virtue of the low-surface-energy material, the super-amphiphobic zinc surface can be obtained. The process method has the advantages of simplicity in operation, high efficiency, good environmental friendliness, low cost and the like and is expected to be applied to large-scale industrial production.

Owner:DALIAN UNIV OF TECH

Compound PTFE/PAN (polytetrafluoroethylene/polyacrylonitrile) hydrophilic and oleophobic film and preparation method thereof

The invention discloses a compound PTFE / PAN (polytetrafluoroethylene / polyacrylonitrile) hydrophilic and oleophobic film and a preparation method thereof, belonging to the technical fields of film material preparation and modification. A casting film solution is prepared from the following substances in percentage by mass: 10 to 15 percent of high-molecular polymer, 10 to 25 percent of inorganic nano particle, 0 to 20 percent of additive and 70 to 90 percent of solvent. The thickness of the PTFE / PAN-SiNPs hydrophobic / oleophobic complex film is 0.4 to 0.6mm, the porosity is 30 to 50 percent, thepore size of the film is 0.1 to 1mu m, the water contact angle is less than 40 degrees, and the underwater oil contact angle is greater than 150 degrees. After alkaline leaching and modifying, the film thickness is 0.2 to 0.4mm, the porosity is 20 to 50 percent, the pore size of the film is 0.1 to 1mu m, the water contact angle is less than 20 degrees, and the underwater oil contact angle is greater than 160 degrees. According to the compound PTFE / PAN hydrophilic and oleophobic film and the preparation method thereof, the film forming technology is simple, the operation is convenient, and theindustrial production can be easily realized; the complex film has good antipollution performance, high chemical stability, good mechanical property, high interception efficiency and wide applicationprospect.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

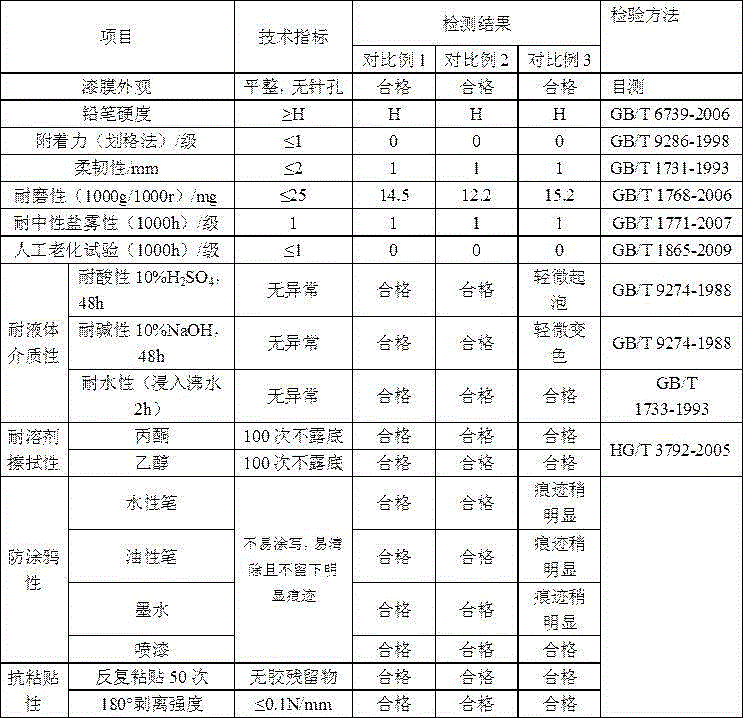

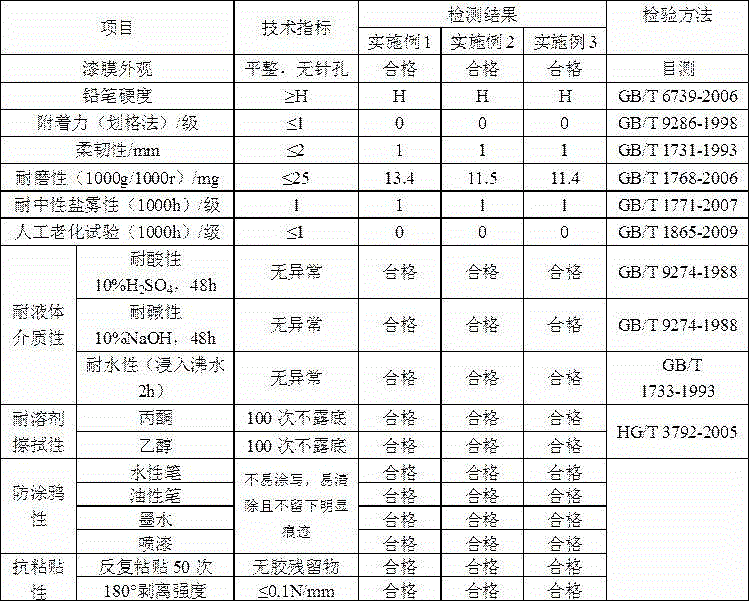

Oil-based anti-graffiti adhesion resistant paint and preparation method thereof

ActiveCN101585995BHigh hardnessImprove self-cleaningPolyurea/polyurethane coatingsAcrylic resinPolydimethyl siloxane

The invention discloses oil-based anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. Components A of the paint comprise hydroxy acrylic resin, fluorocarbon resin, polydimethyl siloxane resin containing hydroxyl functional group, polyacrylate modified organic silicon resin, smooth flow agent, flatting agent, antifoaming agent, drier, dibutyl tin laurate, butyl acetate and dimethyl benzene; components B comprise hexamethylene diisocyanate, butyl acetate and ethylene glycol monoethyl ether acetate; and the mixture ratio of the components A to the components B is 3:1. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easycleaning, and quick and convenient construction, has limited harmful substances, and achieves national requirement.

Owner:LANZHOU XUNMEI PAINT IND TECH

Super oleophobic coating preparation method

InactiveCN102925882AEasy to makeSufficient supply in the marketMetallic material coating processesSpecial surfacesAcetic acidSaline solutions

The invention discloses a super oleophobic coating preparation method which comprises the steps of dispersing perfluoro caprylic acid into water, dropwise adding acetic acid saline solution of 0.1 to 0.3 mol / L, stirring for 1 to 4 hours, obtaining perfluoro caprylate, dispersing 0.1 to 0.3g of perfluoro caprylate into 10-20mL ethanol, fully stirring to obtain perfluoro caprylate dispersion liquid, and using a spray method to obtain a perfluoro caprylate super oleophobic coating. The raw materials of the preparation method are simple to prepare, sufficient in market goods supply and low in cost. The preparation method is easy to achieve. The super oleophobic coating is good in stability and excellent in oleophobic effect. The prepared super oleophobic coating can be applied to the outer surfaces of metal, oil conveying pipelines, water transportation tools and the like.

Owner:镇江中孚复合材料有限公司

Transfer film, resin laminate, method for producing the transfer film, and method for producing the resin laminate

ActiveCN102648091AImprove hydrophobicityGood oleophobic effectSynthetic resin layered productsThin material handlingPerspirationHigh surface

Disclosed is a transfer film which uses a film having high surface tension and is provided with an antifouling layer by a wet process, and on which a functional layer such as an antireflection layer can be laminated. The transfer film is capable of providing a laminate that has excellent water repellency, oil repellency, transparency, abrasion resistance and perspiration resistance. Also disclosed is a method for producing the transfer film. Specifically disclosed is a transfer film which is obtained by laminating an antifouling cured film on the surface of a transparent base film. The transfer film is characterized in that the water contact angle (1) of a surface of the antifouling cured film, said surface being not in contact with the transparent base film, is 100 DEG or less, the water contact angle (2) of a surface of the antifouling cured film, said surface being in contact with the transparent base film, is 90 DEG or more, and the contact angle (a) thereof with triolein is 55 DEG or more.

Owner:MITSUBISHI CHEM CORP

Preparation method and application of oil-water separation net membrane

A preparation method and application of an oil-water separation net membrane are disclosed; the oil-water separation net membrane is prepared by ultrasonic cleaning of a 400 mesh red copper mesh in turn in acetone, absolute ethanol and deionized water, then immersion in hydrochloric acid to remove a surface oxide film, washing and drying by blowing with N2; immersion in a silver ammonia solution and drying. A micro-nano structure is formed on the surface of the copper mesh by impregnating the copper mesh with the oxide film removed in the silver ammonia solution, the water wettability of the surface of the structure is changed from hydrophobic to super-hydrophilic, and the oil wettability of the surface of the structure is changed from oleophobic to super-lipophilic, so that the oleophobicand hydrophilic function can be realized. Because of good oleophobicity and hydrophilicity, the oil-water separation net membrane can be successfully applied in oil-water separation. The oleophobic hydrophilic material has a very good application prospect in oil pollution prevention and oil sewage treatment.

Owner:XI AN JIAOTONG UNIV

Surface coating with both hydrophobicity and oleophobic property and touch control panel

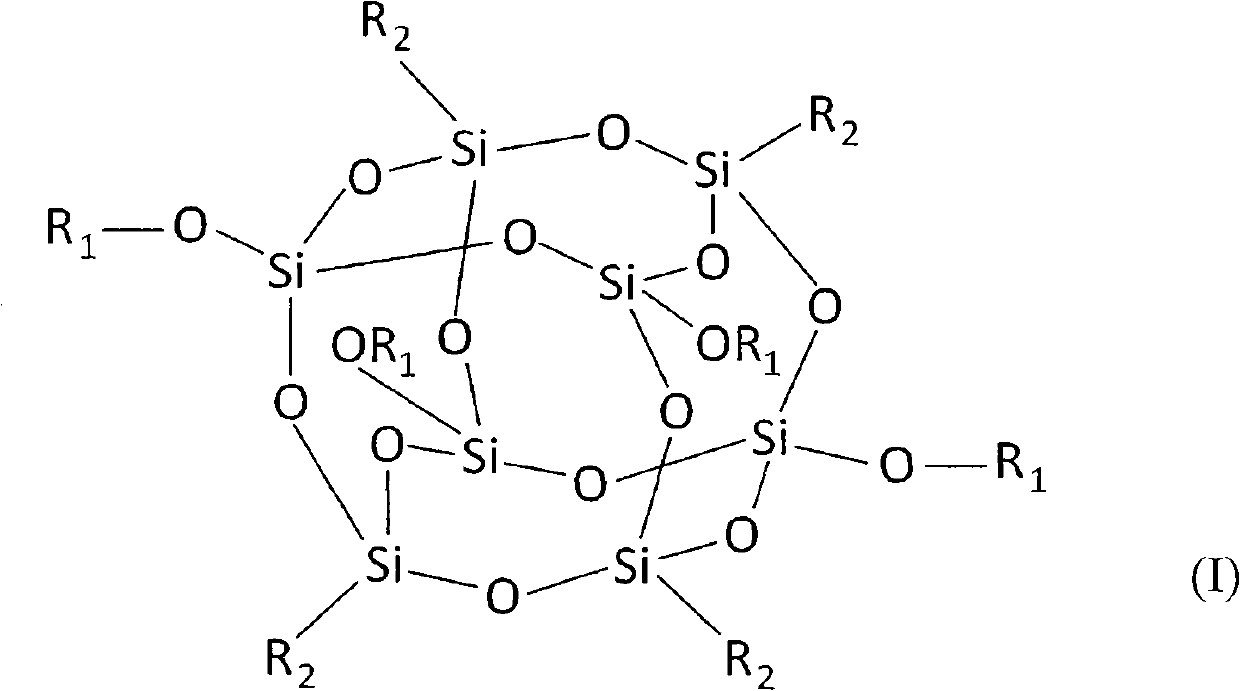

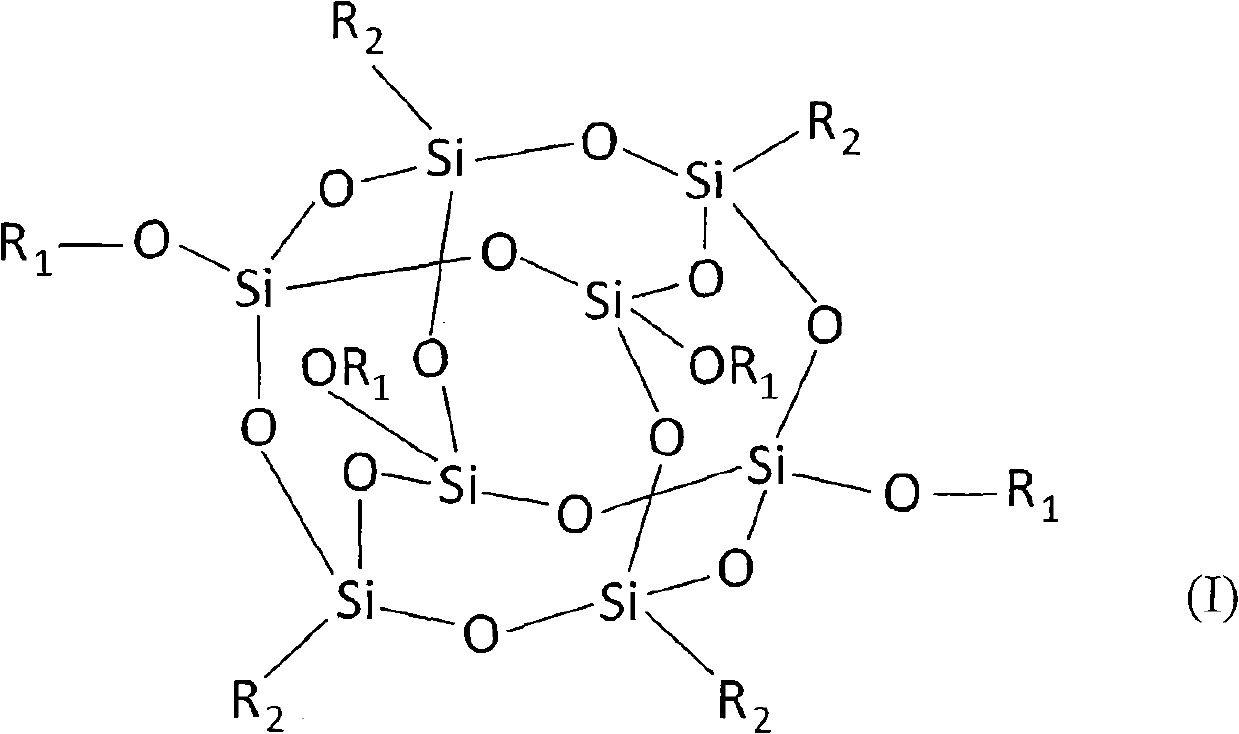

InactiveCN102558930AHydrophobicOleophobicCoatingsInput/output processes for data processingChemical structureAcyl group

The invention relates to a surface coating with both hydrophobicity and oleophobic property and a touch control panel coated by the surface coating. The surface coating comprises nano particles of chemical structures shown as formula (I): R1 may be halogen, hydrogen, alkyl, alkoxy, hydroxyl, alkenyl, alkyne, acyl, acryl, carboxyl, alkoxycarbonyl or aromatic oxycarbonyl, R2 may be a fluorine-containing group. The touch control panel comprises a conductive layer or an outer cover plate coated by the surface coating with both hydrophobicity and oleophobic property. When the surface coating is coated on the outer cover plate or the conductive layer of the touch control panel, the touch control panel is easy to clean, can resist greasy dirt, can prevent fingerprint generation, and has excellent anti-glare properties by virtue of the excellent hydrophobicity and oleophobic property of the surface coating.

Owner:高丰有限公司

Antifouling anti-scale nano easy-to-clean coating solution, and preparation method and application thereof

ActiveCN107245255AImprove hydrophobicityGood oleophobic effectAntifouling/underwater paintsPaints with biocidesAlcoholOrganic matter

The invention relates to a surface hydrophobing agent, particularly to an antifouling anti-scale nano easy-to-clean coating solution, and a preparation method and application thereof. The preparation method of the antifouling anti-scale nano easy-to-clean coating solution comprises the following steps: (1) dissolving a silane coupling agent or a titanate coupling agent and an active-group-containing perfluorinated organic matter in C2-C5 saturated monohydric alcohols, regulating the pH value to 2-4 by using an acidic catalyst, adding a curing agent, and performing a reaction at 40-60 DEG C to form a gel liquid; and (2) adding nano fumed silica into the transparent gel liquid obtained in the step (1), and performing uniform dispersion to obtain the antifouling anti-scale nano easy-to-clean coating solution. The antifouling anti-scale nano easy-to-clean coating solution provided by the invention is hydrophobic and oleophobic; low surface energy is achieved; the surface is easy to clean; and the coating solution is capable of resisting fouling and scales, is transparent and friction-resistant, and can be stored stably. The coating solution has the characteristics of favorable chemical stability and the like, and can be cured at normal temperature. The production technique is simple, and is suitable for large-scale production and application.

Owner:南通天驰环保科技有限公司

Polypropylene composite material with lotus effect on greasy dirt and preparation method for polypropylene composite material

The invention relates to a polypropylene composite material with a lotus effect on greasy dirt. The polypropylene composite material is prepared from the following components in percentage by mass: 60-80% of polypropylene, 5-8%of nitrile rubber, 2-5% of a compatilizer, 2-8% of fluoride, 10-15% of nano silicon dioxide polymer composite particles, 0.2-0.5% of a composite anti-oxidant and 0.1%-0.3% of a composite nucleating agent. The invention further relates to a preparation method for the polypropylene composite material. The polypropylene composite material surface has relatively strong greasy dirt resistance and easy cleaning performance, and can form the lotus effect on the greasy dirt.

Owner:鑫同吸塑(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com