Anti-doodling, anti-fouling, anti-sticking and high weather-resistant coating and preparation method thereof

An anti-graffiti and coating technology, applied in anti-fouling/underwater coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc. Water penetration, good solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

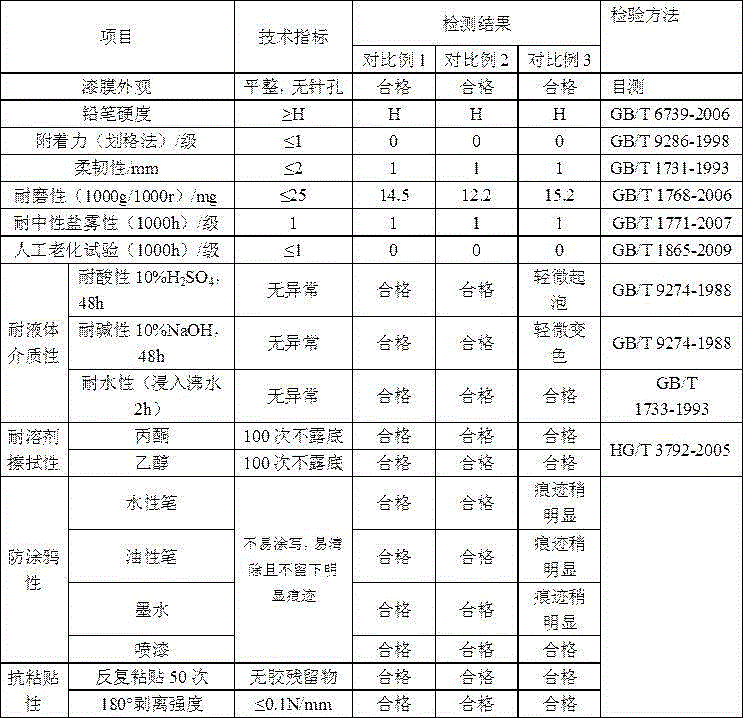

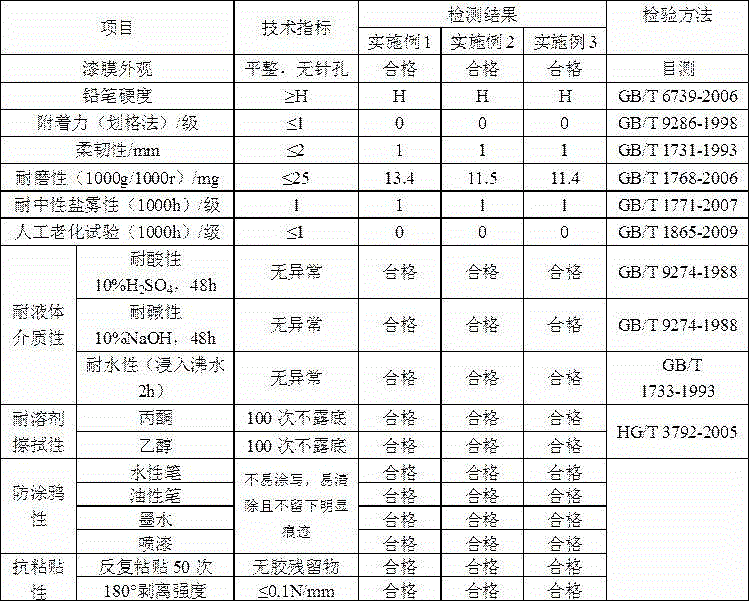

Examples

preparation example Construction

[0041] The preparation method of the A component comprises the following steps:

[0042] Add the modified hydroxy acrylic resin and FEVE low surface energy fluororesin into the mixing tank, stir with the agitator at a speed of 600-700 rpm, then add polyorganosiloxane, and continue stirring at 800-850 rpm for at least 10 Minutes, then add solvent, functional additives and silicone modified acrylate, continue to stir at 500-600 rpm for at least 10 minutes, adjust the viscosity with the remaining part of the solvent, filter and pack after passing the inspection;

[0043] The preparation method of the B component comprises the following steps:

[0044] First add the solvent into the mixing tank, then add the curing agent, stir at 500-600 rpm under an inert atmosphere, and then filter and pack.

[0045] When using, fully mix A and B components according to a certain weight ratio and stir evenly, adjust to a suitable viscosity and then apply to obtain a cured paint film.

Embodiment 1

[0048] An anti-graffiti, anti-fouling, anti-sticking and high weather resistance coating, comprising two components A and B, wherein component A includes the following parts by weight:

[0049] 50 parts of modified hydroxyl acrylic resin, 25 parts of FEVE low surface energy fluororesin, 1 part of polyorganosiloxane, 3 parts of silicone modified acrylate, 0.2 part of defoamer, 0.3 part of leveling agent, 0.2 part of drier 1.6 parts, 1.6 parts of anti-aging agent, 12 parts of butyl acetate, 6.7 parts of propylene glycol methyl ether acetate.

[0050] Component B includes the following materials in parts by weight:

[0051] 75 parts of hexamethylene diisocyanate, 15 parts of butyl acetate, and 10 parts of propylene glycol methyl ether acetate.

Embodiment 2

[0053] An anti-graffiti, anti-fouling, anti-sticking and high weather resistance coating, comprising two components A and B, wherein component A includes the following parts by weight:

[0054] 50 parts of modified hydroxyl acrylic resin, 25 parts of FEVE low surface energy fluororesin, 5 parts of polyorganosiloxane, 3 parts of silicone modified acrylate, 0.2 part of defoamer, 0.3 part of leveling agent, 0.2 part of drier 1.6 parts, 1.6 parts of anti-aging agent, 12 parts of butyl acetate, 2.7 parts of propylene glycol methyl ether acetate.

[0055]Component B includes the following materials in parts by weight:

[0056] 75 parts of hexamethylene diisocyanate, 15 parts of butyl acetate, and 10 parts of propylene glycol methyl ether acetate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com