Superhydrophobic oleophobic modification method of porous membrane

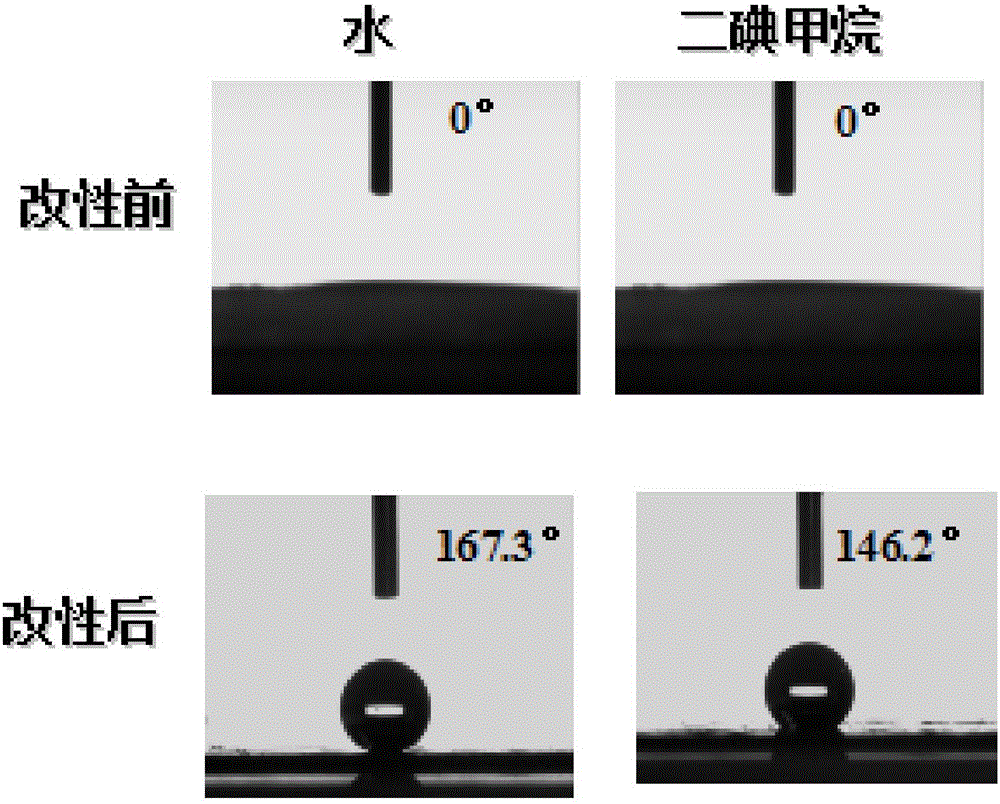

A super-hydrophobic and oleophobic, porous membrane technology, applied in the field of separation membranes, can solve the problems of weak super-amphiphobic surface, weak adhesion, weak friction and washing resistance, etc. Hydrophilization, good hydrophobicity, good stability and good abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Put 0.5g SiO 2 The nanoparticles were added to a beaker containing 60 ml of cyclohexane, and ultrasonically oscillated for 15 min to obtain a uniform dispersion; then 0.5 ml of trichloro(1H, 1H, 2H, 2H perfluorooctyl) silane was added dropwise, and at the same time Stir on a heated magnetic stirrer for 4 hours to control the temperature of the dispersion at 50°C; then centrifuge the dispersion at 1000 rpm for 10 minutes, and dry and grind the obtained precipitate for later use, which is the modified silica particles .

[0033] The above-mentioned modified nano-SiO 2 The particles can be used for amphiphobic modification on the surface of polyvinylidene chloride (PVDF) porous membranes to prepare amphiphobic composite membranes, including the following steps:

[0034] (a) 0.3 g of modified SiO 2 The nanoparticles were added to a beaker containing 40 ml of ethanol, and stirred at room temperature for 3 h on a magnetic stirrer. A homogeneous dispersion was obtained....

Embodiment 2

[0038] 1. Put 0.3g SiO 2 The nanoparticles were added to a beaker containing 60ml of n-hexane, and ultrasonically oscillated for 20min to obtain a uniform dispersion; then 0.5ml of trichloro(1H, 1H, 2H, 2H perfluorooctyl) silane was added dropwise, while heating Stir on a magnetic stirrer for 6 hours to control the temperature of the dispersion at 60°C; then centrifuge the dispersion at 800 rpm for 10 minutes, and dry and grind the obtained precipitate for later use, which is the modified silica particles.

[0039] 2. 0.5g of modified SiO 2The nanoparticles were added to a beaker containing 50 ml of ethanol, and stirred at room temperature for 3 h on a magnetic stirrer. At the same time, 0.5 ml of trichloro(1H, 1H, 2H, 2H perfluorooctyl)silane was added dropwise, and stirring was continued for 4 h to obtain Homogeneous dispersion.

[0040] 3. Cut a certain size of PVDF porous membrane and place it in the ultrafiltration cup, pour the above-prepared dispersion liquid into the...

Embodiment 3

[0042] 1. Put 0.5g SiO 2 The nanoparticles were added to a beaker containing 60ml of n-hexane, and ultrasonically oscillated for 15min to obtain a uniform dispersion; then 0.5ml of trichloro(1H, 1H, 2H, 2H perfluorooctyl) silane was added dropwise, while heating Stir on a magnetic stirrer for 5 hours, so that the temperature of the dispersion liquid is controlled at 60 ° C; then the dispersion liquid is centrifuged at 1000 rpm for 10 min, and the obtained precipitate is dried and ground for later use, that is, modified silica particles.

[0043] The above-mentioned modified nano-SiO 2 The particles can be used for amphiphobic modification on the surface of a polytetrafluoroethylene (PTFE) porous membrane to prepare an amphiphobic composite membrane, including the following steps:

[0044] a. 0.5g of modified SiO 2 The nanoparticles were added to a beaker containing 60 ml of cyclohexane, and stirred on a magnetic stirrer at room temperature for 2 h, while 0.3 ml of trichloro(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com