Method for preparing anti-graffiti coating for rail train carriage

A rail train and anti-graffiti technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of anti-graffiti coatings that have not yet existed, and achieve excellent anti-graffiti performance, good corrosion resistance, and high hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

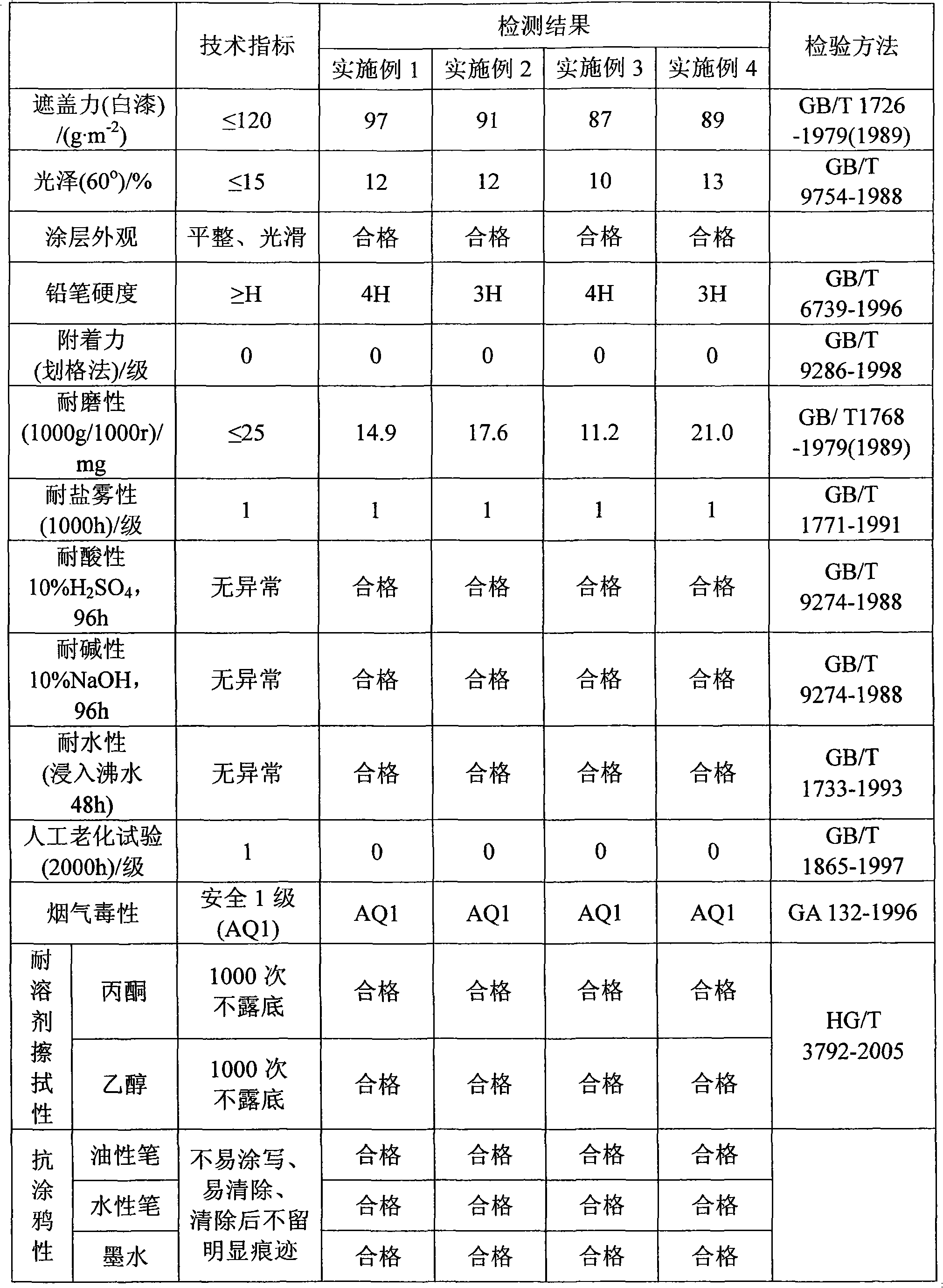

Examples

Embodiment 1

[0031] The anti-graffiti coating for rail train carriage of the present embodiment comprises following raw material:

[0032] Trifluoropropyl cyclotrisiloxane 10 parts

[0033] Octamethylcyclotetrasiloxane 6 parts

[0034] 12 parts of hydroxyl-terminated silicone resin

[0035] 15 parts of trifluoroethyl methacrylate

[0036] 8 parts ethyl methacrylate

[0037] 9 parts of hydroxyethyl methacrylate

[0038] Polyisocyanate prepolymer 26 parts

[0039] Catalyst 0.3 parts

[0040] Initiator 0.2 parts

[0041] 31 parts of pigments and fillers

[0042] Auxiliary 6 parts

[0043] 30 parts of organic solvent

[0044] The preparation method of the anti-graffiti coating for rail train carriage of the present embodiment, its steps are as follows:

[0045] Add octamethylcyclotetrasiloxane, trifluoropropylcyclotrisiloxane, hydroxyl-terminated silicone resin, and catalyst into reactor 1 by weight ratio, stir evenly, and heat to keep the system temperature at 80-100°C , vacuumize,...

Embodiment 2

[0048] Trifluoropropyl cyclotrisiloxane 12 parts

[0049] Octamethylcyclotetrasiloxane 8 parts

[0050] 8 parts of hydroxyl-terminated silicone resin

[0051] 12 parts of hexafluorobutyl methacrylate

[0052] 8 parts ethyl methacrylate

[0053] 12 parts of hydroxyethyl methacrylate

[0054] Polyisocyanate prepolymer 28 parts

[0055] Catalyst 0.4 part

[0056] Initiator 0.2 part

[0057] 28 parts of pigments and fillers

[0058] Auxiliary 6 parts

[0059] 37 parts of organic solvent

[0060] The preparation method of the anti-graffiti coating for rail train carriage of the present embodiment, its steps are the same as embodiment 1.

Embodiment 3

[0062] Trifluoropropyl cyclotrisiloxane 15 parts

[0063] Octamethylcyclotetrasiloxane 8 parts

[0064] 10 parts of hydroxyl-terminated silicone resin

[0065] Dodecafluoroheptyl methacrylate 12 parts

[0066] Methyl methacrylate 12 parts

[0067] 10 parts of hydroxypropyl methacrylate

[0068] Polyisocyanate prepolymer 27 parts

[0069] Catalyst 0.45 parts

[0070] Initiator 0.2 parts

[0071] 32 parts of pigments and fillers

[0072] Auxiliary 9 parts

[0073] 33 parts of organic solvent

[0074] The preparation method of the anti-graffiti coating for rail train carriage of the present embodiment, its steps are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com