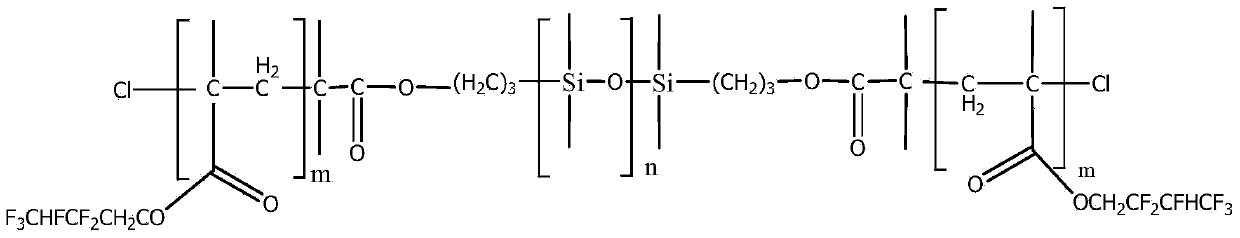

Hydrophobic/oleophobic fluorosilicone triblock polymer and preparation method thereof

A polymer and tri-block technology, applied in biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve high curing temperature, poor substrate adhesion, and poor film-forming properties of silicone resins and other problems, to achieve the effect of mild reaction conditions, low requirements, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Preparation of chlorine atom-terminated polydimethylsiloxane chain initiator

[0025] 20.0g (0.01mol) double-terminated hydroxyl-polydimethylsiloxane with an average molecular weight of 2000, 4.42g (0.028mol) α-chloroisobutyl chloride, 4.86g (0.048mol) triethylamine, 100mL Add tetrahydrofuran into a 250mL three-neck flask, under nitrogen protection, stir and react at -10°C for 8 hours, filter after the reaction is completed, distill the filtrate under reduced pressure to remove tetrahydrofuran, dissolve it in dichloroethane, and wash it three times with a saturated aqueous solution of sodium bicarbonate , standing for stratification, after liquid separation, add anhydrous sodium sulfate to the organic phase to dry and remove water, and then filter, and the filtered filtrate is distilled off under reduced pressure to remove dichloroethane to obtain oily yellow chlorine atom-capped polydimethylsiloxane Oxyalkylene chain initiators.

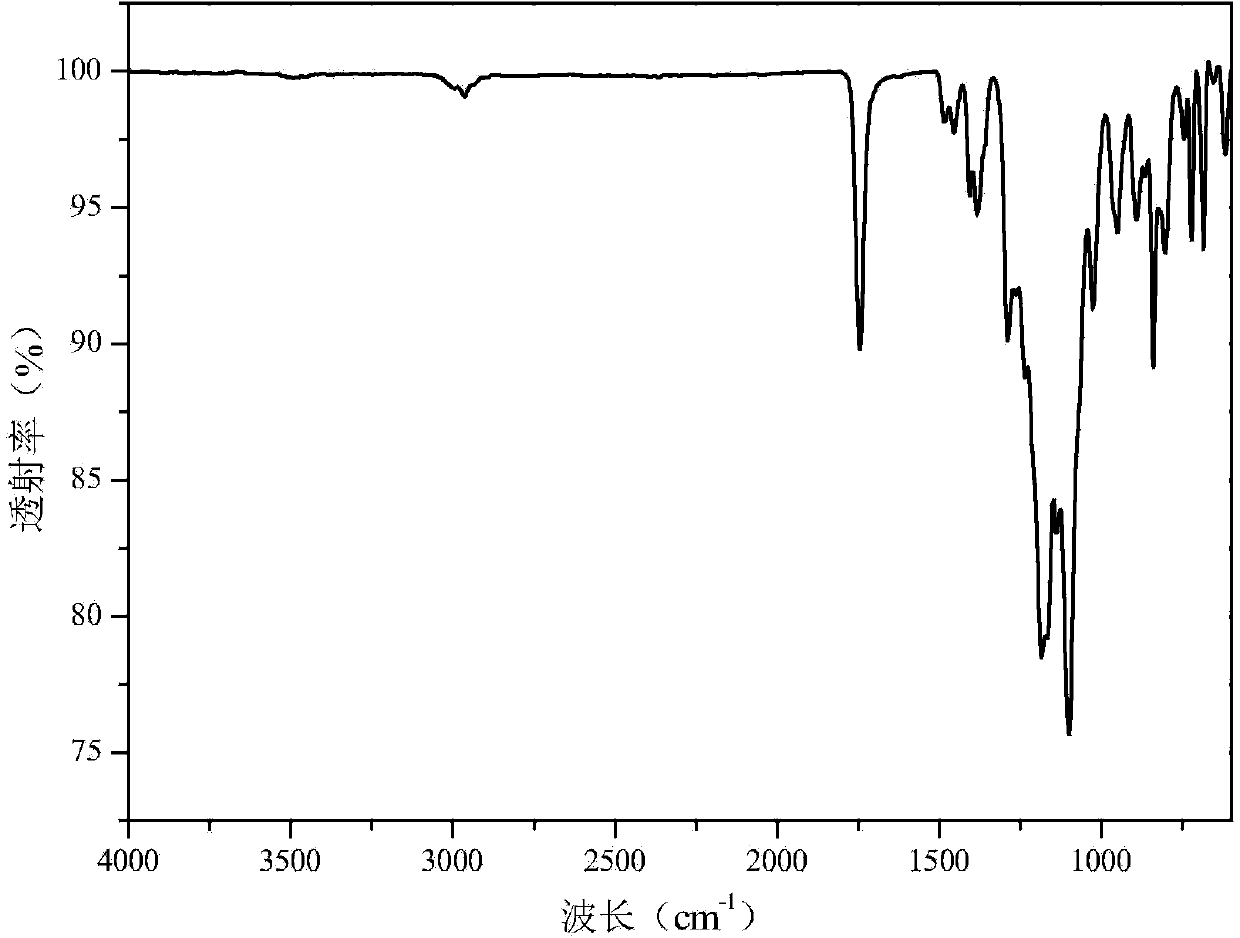

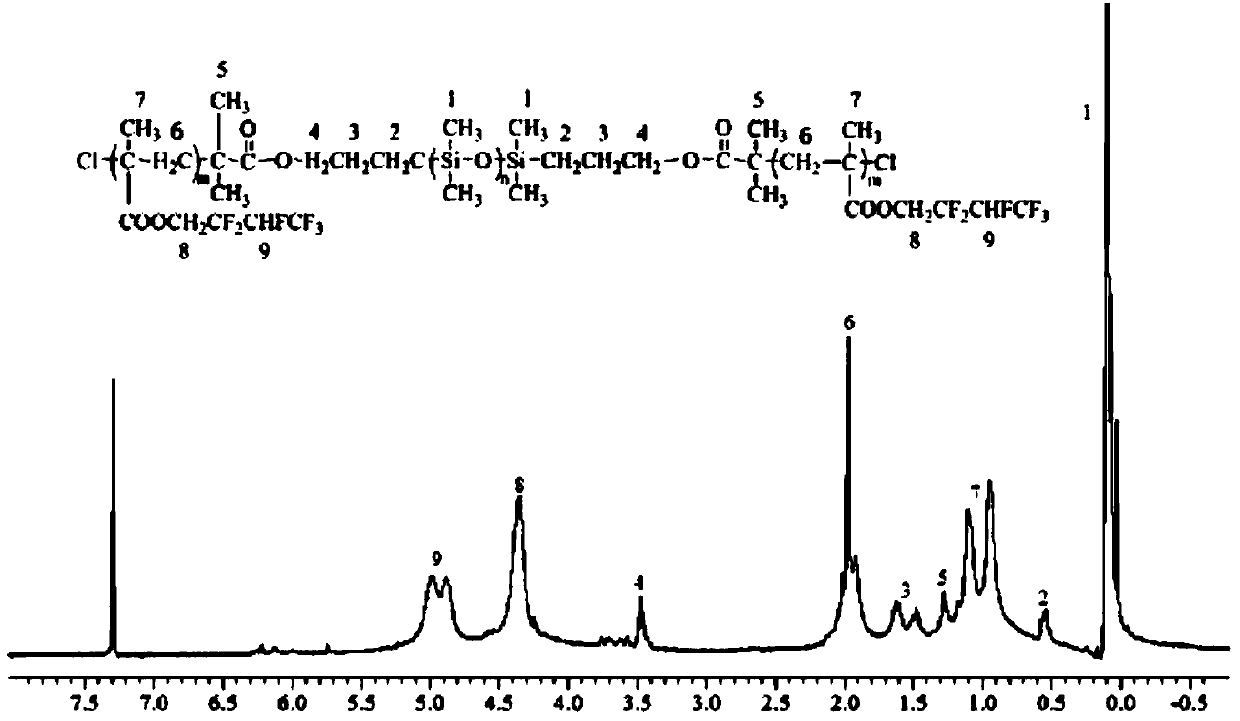

[0026] 2. Preparation of hydrophob...

Embodiment 2

[0031] 1. Preparation of chlorine atom-terminated polydimethylsiloxane chain initiator

[0032] 20.0g (0.01mol) of double-terminated hydroxyl-polydimethylsiloxane with an average molecular weight of 2000, 5.06g (0.032mol) of α-chloroisobutyl chloride, 5.27g (0.052mol) of triethylamine, 100mL Tetrahydrofuran was added into a 250 mL three-necked flask, and stirred and reacted at -10° C. for 10 hours under nitrogen protection. Other steps in this step were the same as in Example 1 to obtain an oily yellow polydimethylsiloxane chain initiator terminated by chlorine atoms.

[0033] 2. Preparation of hydrophobic / oleophobic fluorosilicone triblock polymer

[0034] 2.24g (0.001mol) of chlorine atom-terminated polydimethylsiloxane chain initiator prepared in step 1, 12.5g (0.05mol) hexafluorobutyl methacrylate, 0.0099g (0.001mol) cuprous chloride , 0.094g (0.0006mol) 2,2'-bipyridine, 0.089g (0.0006mol) N-(2-pyridylmethylene)-1-propylamine, 100mL toluene were added to a 250mL three-nec...

Embodiment 3

[0038] 1. Preparation of chlorine atom-terminated polydimethylsiloxane chain initiator

[0039] 30.0g (0.01mol) of double-terminated hydroxyl-polydimethylsiloxane with an average molecular weight of 3000, 4.42g (0.028mol) of α-chloroisobutyl chloride, 4.86g (0.048mol) of triethylamine, 100mL Tetrahydrofuran was added into a 250 mL three-necked flask, and stirred and reacted at 10° C. for 10 hours under nitrogen protection. Other steps in this step were the same as in Example 1 to obtain an oily yellow polydimethylsiloxane chain initiator terminated by chlorine atoms.

[0040] 2. Preparation of hydrophobic / oleophobic fluorosilicone triblock polymer

[0041]With 3.24g (0.001mol) the polydimethylsiloxane chain initiator that the chlorine atom termination of step 1 prepares, 15.0g (0.06mol) hexafluorobutyl methacrylate, 0.0099g (0.001mol) cuprous chloride , 0.139g (0.0012mol) tetramethylethylenediamine, and 100mL toluene were added to a 250mL three-necked flask, and under nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com