Preparation method of PVC nanometer alloy resin with high fluidity and low temperature toughness

A nano-alloy, low-temperature toughness technology, which is applied in the field of polymer copolymer resin manufacturing to achieve the effects of improving stability, toughening efficiency and dispersion degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

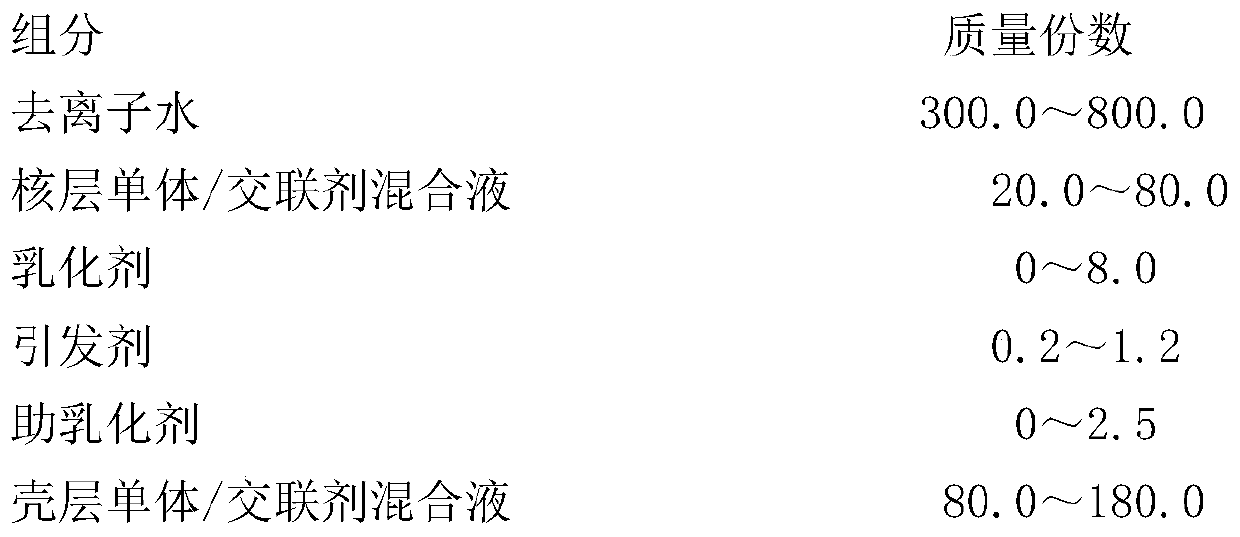

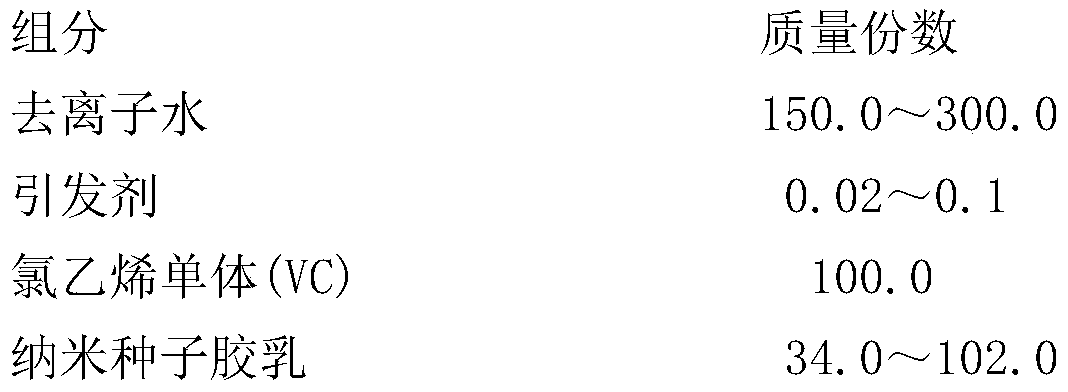

[0032] (1) Preparation of nano seed emulsion

[0033] Add 300ml of deionized water and 0.70g of emulsifier SDS to a small autoclave equipped with mechanical stirring, thermometer and nitrogen inlet, and stir for 20min, then add the mixture of core layer monomer and crosslinking agent (20gBA, 0.20gBDDA) and 0.12 g of potassium persulfate initiator in the nuclear layer stage. Vacuumize nitrogen at room temperature and repeat twice and stir for 20 minutes, then seal the autoclave, and when the temperature of the reaction solution is constant to 75°C, heat-preserve and mature for 1 hour to complete the synthesis of the core layer emulsion.

[0034]Add 0.48 g of shell initiator potassium persulfate and 0.70 g of emulsifier SDS. Evacuate the reactor to -0.09MPa, add a mixture of shell monomer 80g BD and cross-linking agent 0.80g BDDA at one time, continue to react for 2 hours, and end the reaction. The temperature is lowered and the discharge is pumped out to obtain nano-latex wit...

Embodiment 2

[0048] (1) Preparation of nano seed emulsion

[0049] Add the mixed solution (80g BA , 1gBDDA), blow nitrogen at room temperature and stir for 20min. Close the autoclave again, pump and reduce the pressure, feed 20g of BD comonomer, and then start to heat up in a water bath. When the temperature of the reaction solution was constant to 75°C, the reaction was kept for 1 hour, and the reaction was terminated. The temperature is lowered and the discharge is pumped out to obtain the nano-seed latex.

[0050] (2) the preparation step of nano-alloy PVC resin is the same as embodiment 1 step (2)

Embodiment 3

[0052] Change the mixed solution BA and BDDA of the core layer monomer and the crosslinking agent in the embodiment 1 step (1) into BD and BDDA, and change the mixed solution BD and BDDA of the shell monomer and the crosslinking agent into BA and BDDA, All the other formulas and operations are the same as in Example 1.

[0053] Different feeding order in the embodiment of table 2 is to the performance of nano-alloy PVC resin

[0054]

[0055] It can be seen from Table 2 that when polybutadiene is the core, the resin has the highest impact strength and the best low temperature toughness. When polybutadiene is the shell, the plasticizing time of the resin is the shortest. When the two are copolymerized, the overall performance of the resin is uniform and stable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com