Patents

Literature

45results about How to "Improve toughening efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nucleocapsid structure polyvinyl chloride impact modifier, and its preparing method and use

InactiveCN1743371AImprove toughening efficiencyImprove the interface binding forceElastomerCross-link

Owner:HEBEI UNIV OF TECH

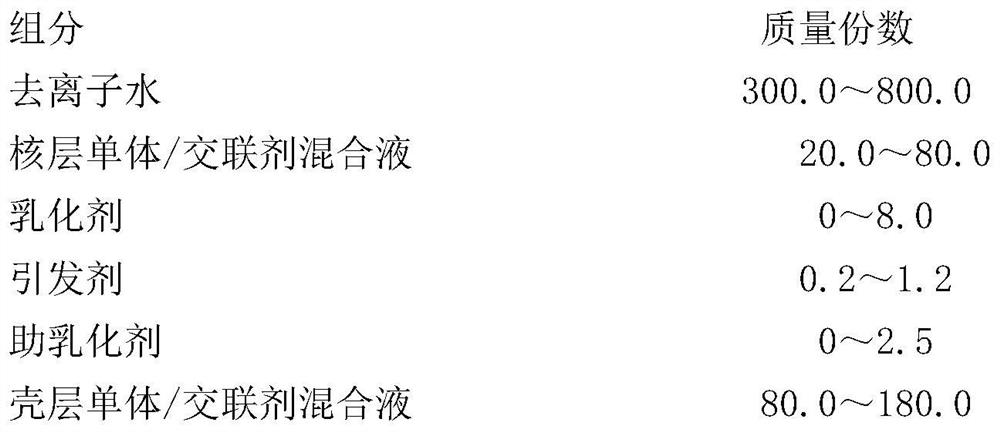

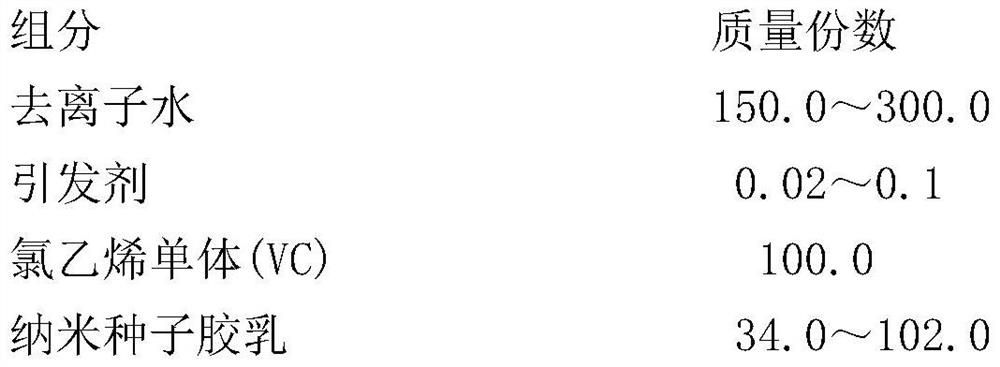

Method for preparing impact modifier of polyvinyl chloride in new type structure of hud

InactiveCN1916046AImprove toughening efficiencyImprove the interface binding forceElastomerResin matrix

This invention relates to a method for preparing polyvinyl chloride impact modifier with core / shell structure. The method comprises: utilizing acrylate monomer as the raw material, performing seed emulsion polymerization by semi-continuous adding the raw material to obtain crosslinked polymer latex with elastomer core / transition layer structure, adding vinyl chloride monomer and other monomers into the high-pressure kettle, and performing emulsion polymerization to obtain polyvinyl chloride impact modifier with core / shell structure. The impact modifier has polyvinyl chloride as the shell, thus can improve the compatibility with polyvinyl chloride resin matrix when blending, and effectively exert the functions of polyacrylate elastomer core and functional groups. The impact modifier can improve the impact property, weathering resistance and heat stability of polyvinyl chloride materials. Besides, the cost of the impact modifier is lower than that of polyacrylate impact modifier, thus can increase the added value of polyvinyl chloride resin and broaden the applications of polyvinyl chloride resin.

Owner:HEBEI UNIV OF TECH

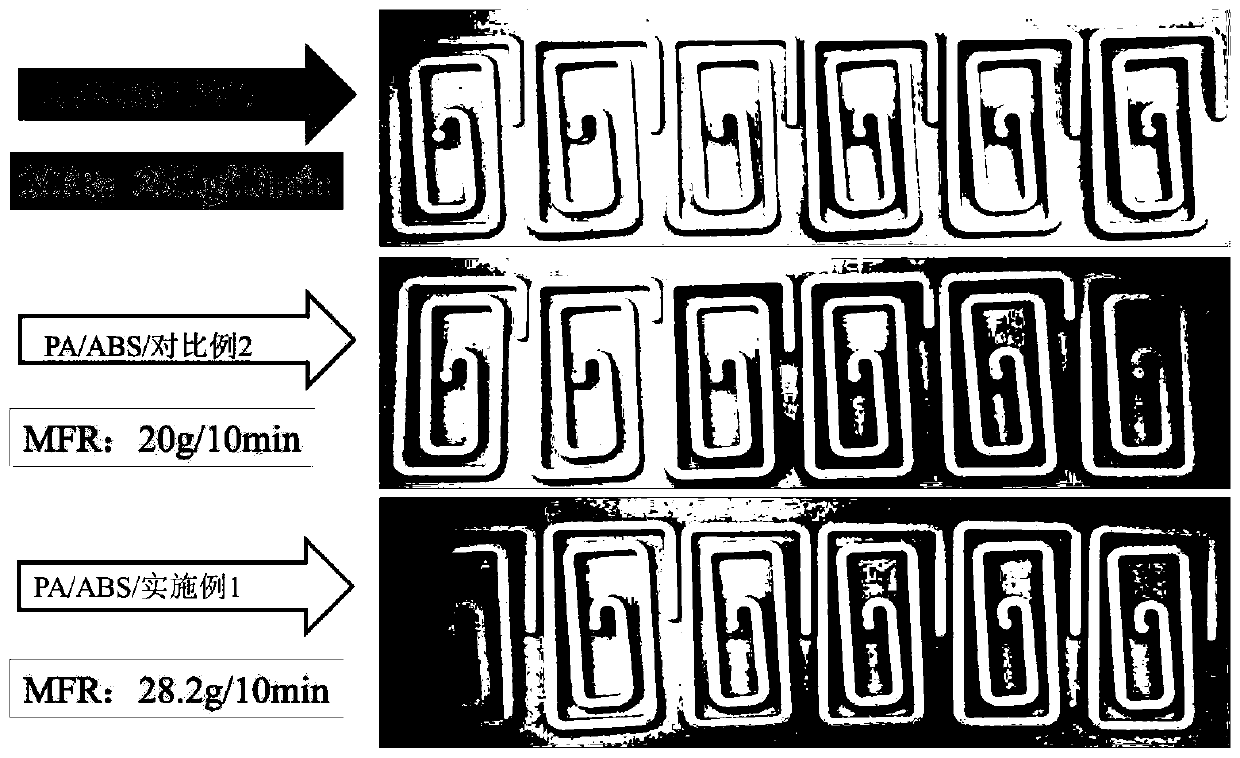

ABS extrusion board material for automobiles and preparation method thereof

The invention relates to an ABS extrusion board material for automobiles and a preparation method thereof. The board material comprises the following components in percentage by weight: 20 to 50 percent of ABS, 20 to 60 percent of SAN, 5 to 40 percent of TPEE, 1 to 5 percent of compatilizer, 0.1 to 3 percent of lubricant and 0.1 to 1 percent of antioxidant. The preparation method comprises the following steps of: adding 0 to 0.3 weight percent of white oil into the mixture, putting the mixture into a high mixer and mixing the mixture for 2 to 5 minutes, then discharging the mixture, and extruding and granulating the discharged mixture through a double-screw extruder to obtain the board material, wherein the cylinder temperature of the double-screw extruder is between 190 and 250 DEG C, and the rotational speed of screws is between 180 and 600rpm. Compared with the prior art, the board material has the advantages of predominant super toughness, ultrahigh rigidity, molding property, chemical resistance and the like.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

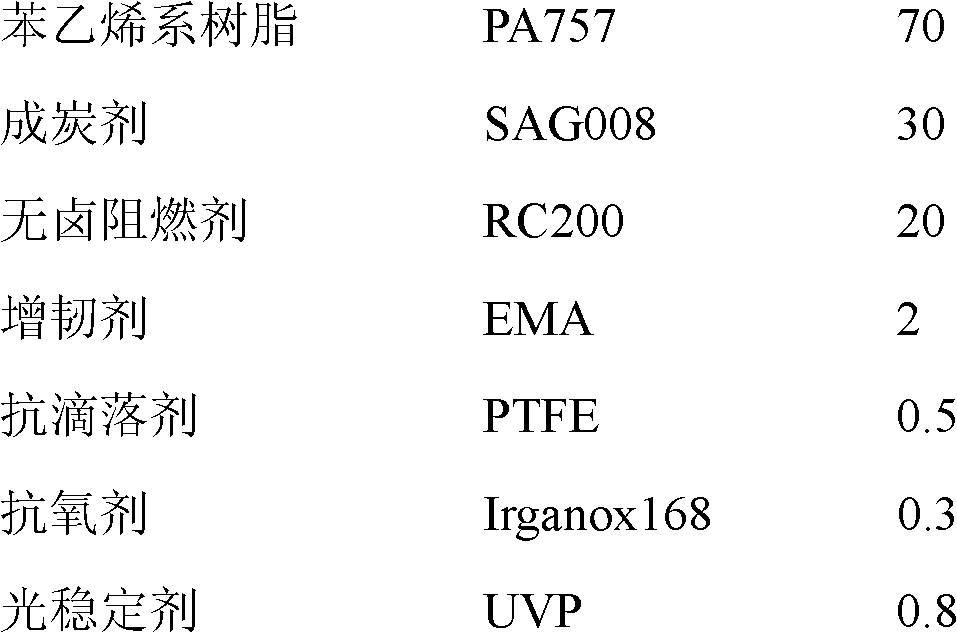

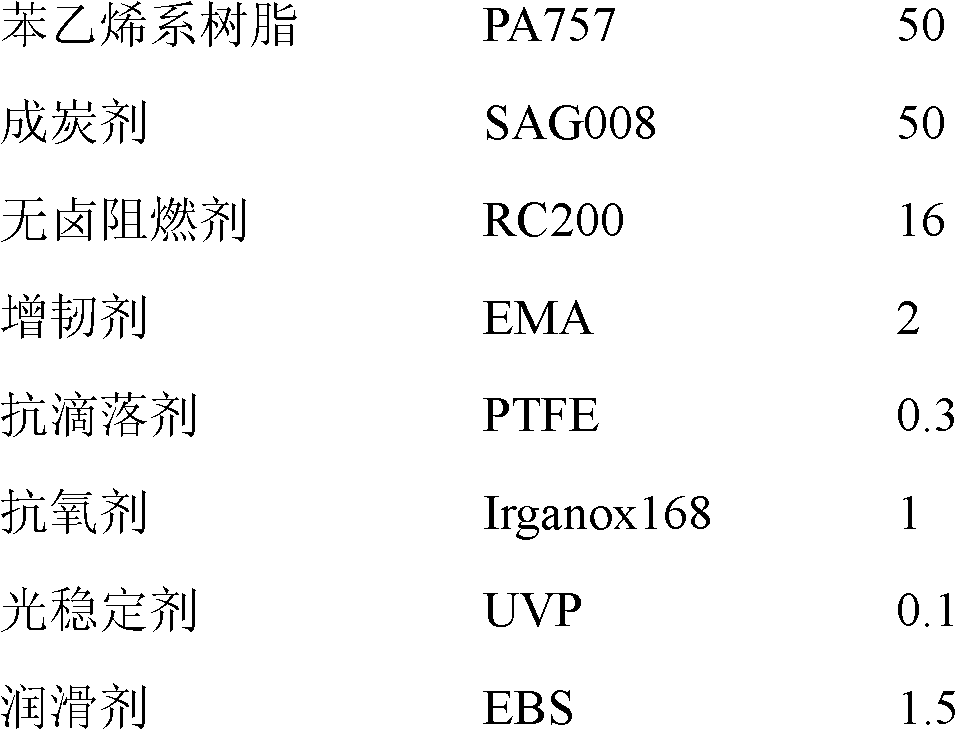

Halogen-free flame-retardant styrene-series resin composition and preparation method thereof

The invention relates to a halogen-free flame-retardant styrene-series resin compound and a preparation method thereof. The resin composition comprises the following components in parts by weight: 40-80 parts of styrene system resin, 20-60 parts of a char forming agent, 0-5 parts of a compound char forming agent, 5-25 parts of a halogen-free flame retardant, 0.5-10 parts of a toughening agent, 0.1-0.5 part of an anti-falling agent, 0.1-1 part of an antioxidant and 0.2-2 parts of a lubricating agent. The preparation method comprises the following steps of: premixing the raw materials through a high mixer; performing melt extruding through a dual-screw extruder; and cooling and granulating to obtain a product. The obtained product is accordant with the requirements of halogen freeness and environmental friendliness, has superior flame retardance and mechanical performance, and can be used for office equipment such as copiers, printers, fax machines and the like, and household electrical appliance products such as displays, cameras, air conditioners, refrigerators and the like with requirements of halogen freeness and environmental friendliness.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

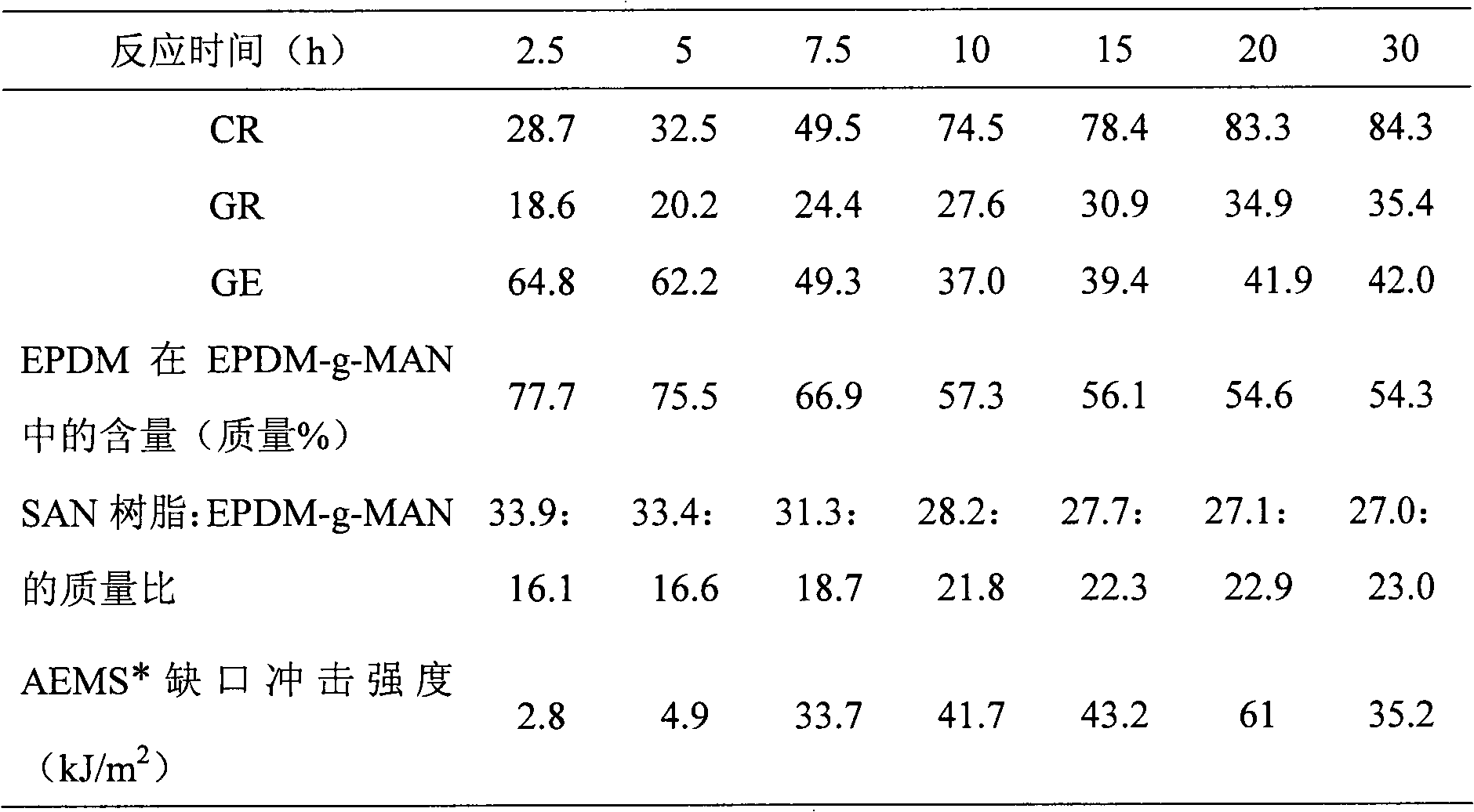

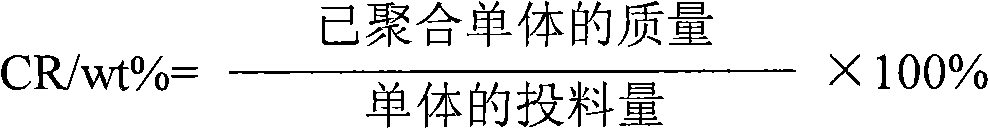

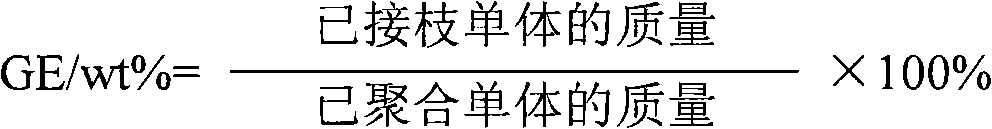

Method of preparing ethylene propylene diene monomer graft polymer through solution grafting copolymerization and application thereof

The invention discloses a method of preparing ethylene propylene diene monomer (EPDM) graft polymer through solution grafting copolymerization and an application thereof in the preparation of engineering plastics. The method optimizes and improves the preparation method on the basis of the solution grafting copolymerization preparation of EPDM-g-SAN, introduces polar monomer MMA, synthesizes EPDM-g-MAN or EPDM-g-MAS which has less content of AN unit of the graft chain, on the condition of low AN dosage; in addition, the highest monomer conversion rate of the method can reach 70-95% by adjusting the monomer proportioning so as to increase the grafting rate and grafting efficiency of the grafting copolymerization system and significantly improve the compatibility between EPDM graft polymer and SAN resin and the toughening efficiency of EPDM graft polymer to SAN resin. By mixing the EPDM graft polymer prepared in the invention and SAN resin, impact resistance engineering plastics with excellent weather resistance, aging resistance and yellowing resistance and high glossiness can be prepared.

Owner:KINGFA SCI & TECH CO LTD +1

Core-shell particle toughened PBT/PC alloy and preparation method

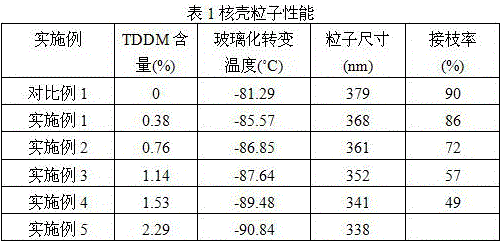

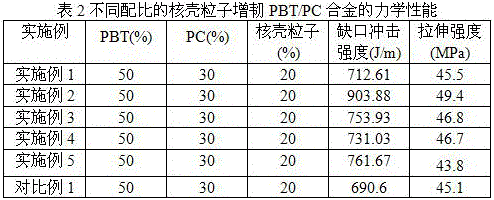

The invention discloses core-shell particle toughened PBT / PC alloy which is composed of 50% of PBT, 30% of PC and 20% of PBg-MSG core-shell particles. The PB-g-MSG core-shell particles are adopted as a modifier, core-shell particles PB-g-MSG taking polybutadiene as a core and methyl methacrylate-styrene-glycidyl methacrylate copolymer as a shell are used to toughen PBT / PC, and vitrification temperature and grafting degree of polybutadiene in the core-shell particles are regulated by changing molecular weight to adjust using amount of TDDM, so that effective toughening of PBT / PC is realized by PB-g-MSG. As content of TDDM is increased, glass-transition temperature of polybutadiene is lowered, and toughening ability of the core-shell particles is improved. At the same time, content of rigid and free methyl methacrylate-styrene-glycidyl methacrylate copolymer (f-MSG) in the system is increased, and PBT and the f-MSG copolymer react, so that strength of a mixture is improved. Notch impact strength of the mixture reaches 904J / m, tensile strength is 49.4MPa, and high strength and high tenacity are realized.

Owner:CHANGCHUN UNIV OF TECH

Micro-foaming PA/ASA (polyamide/acrylonitrile styrene acrylate) material and preparation method thereof

The invention discloses a micro-foaming PA / ASA (polyamide / acrylonitrile styrene acrylate) material and a preparation method thereof. The micro-foaming PA / ASA material is prepared from PA resin, ASA resin, a toughening agent, a lubricating agent, a compatilizer, an antioxidant and a foaming agent in parts by weight by virtue of two-step method fusion and extrusion as well as injection molding. The toughness of the material is improved, and the material has excellent mechanical properties of both PA and ASA, and is stable in size, good in fluidity and excellent in weathering resistance; and meanwhile, the problems of poor fluidity and shrinkage marks during injection molding of a PA / ASA product are solved, so that the micro-foaming PA / ASA material can be widely applied to the fields of automobiles, electronic appliances, electric tools and the like.

Owner:ORINKO NEW MATERIAL CO LTD

Low-temperature-resistant PC alloy material and preparation method thereof

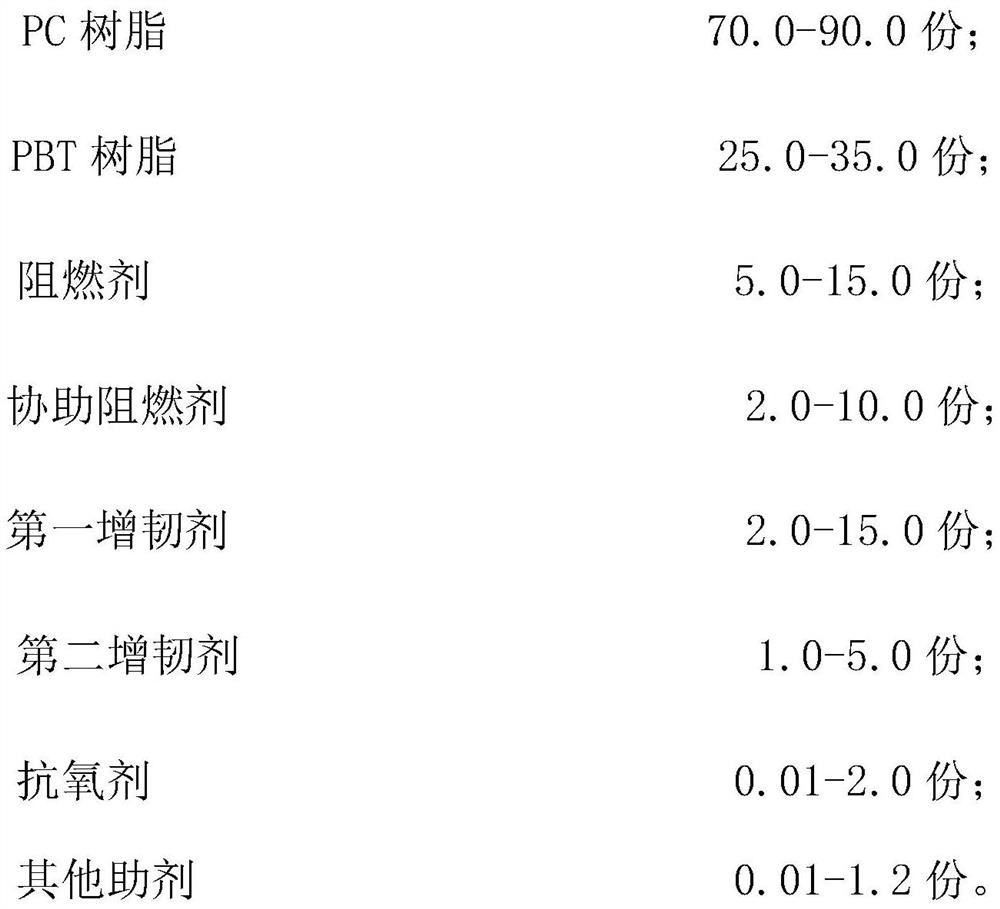

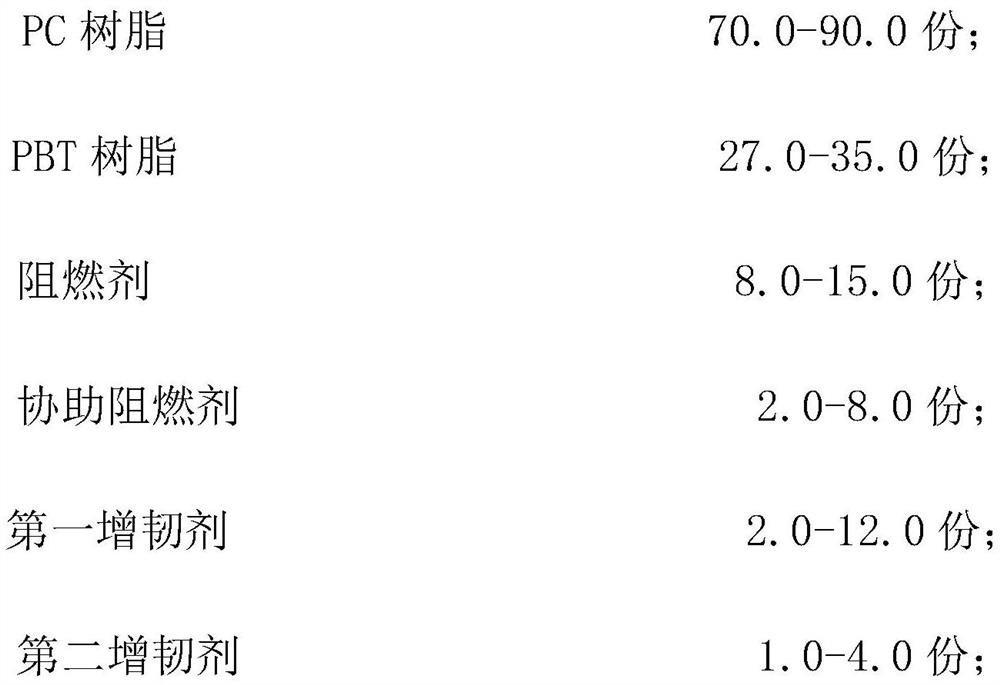

The invention provides a low-temperature-resistant PC alloy material and a preparation method thereof. The low-temperature-resistant PC alloy material comprises the following components in parts by weight: 70.0-90.0 parts of PC resin, 25.0-35.0 parts of a PBT resin, 5.0-15.0 part of a flame retardant, 2.0-10.0 parts of an auxiliary flame retardant, 2.0-15.0 parts of a first toughening agent, 1.0-5.0 parts of a second toughening agent, 0.01-2.0 parts of an antioxidant, and 0.01-1.2 parts of other auxiliary agents. The low-temperature-resistant PC alloy material provided by the invention has excellent low-temperature resistance, and is especially suitable for occasions with relatively high requirements on use environments, especially in the fields of household appliances, industrial machinesand the like which are in contact with oil stains and solvents and have requirements on low-temperature toughness.

Owner:TIANJIN KINGFA NEW MATERIAL

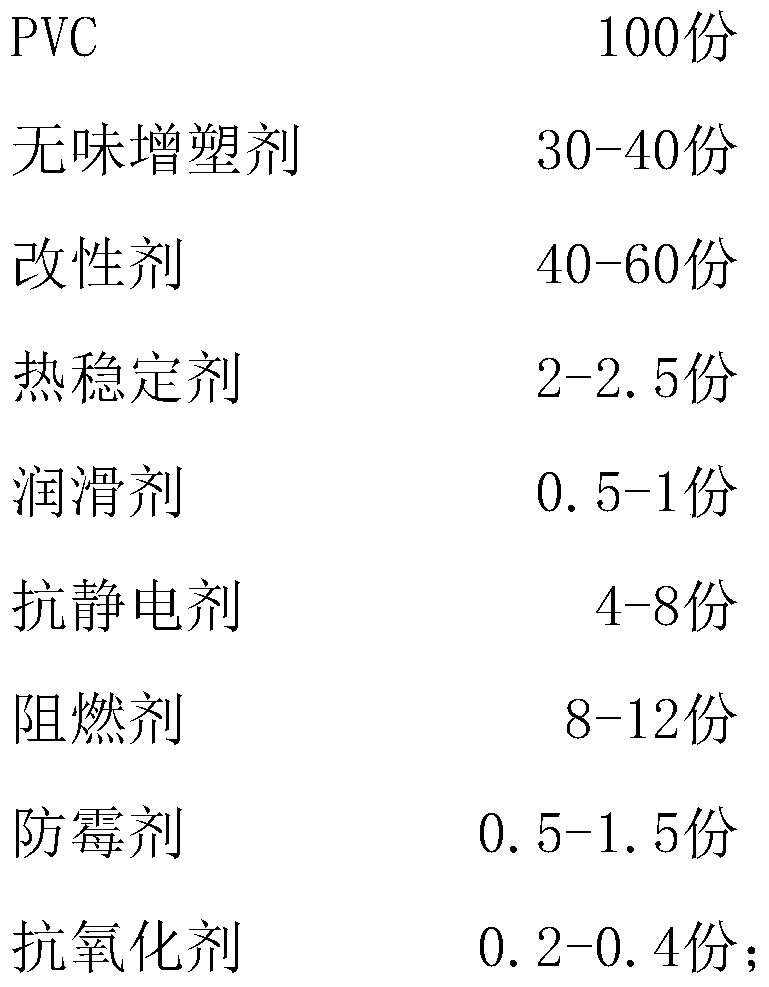

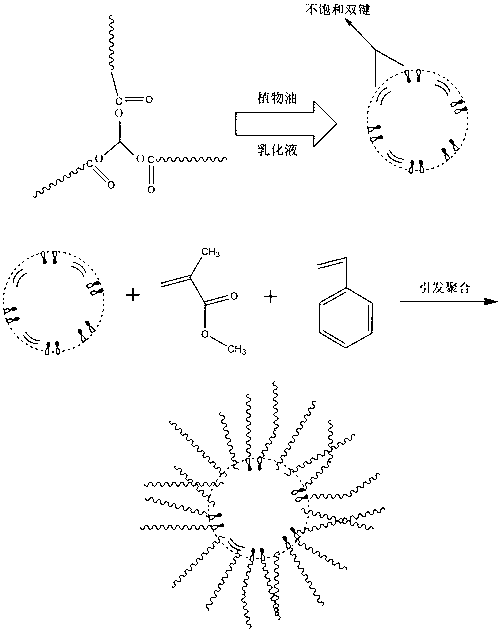

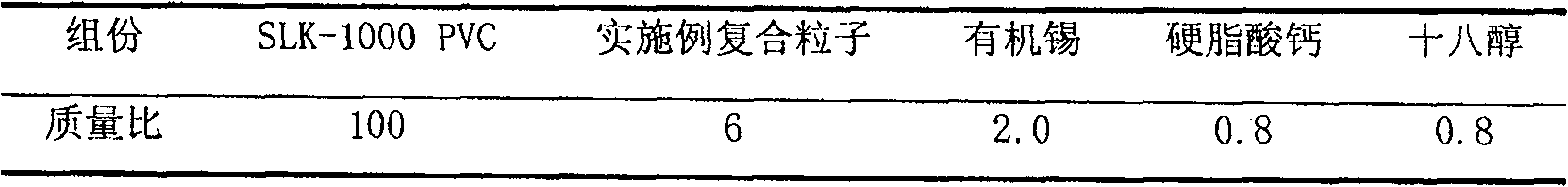

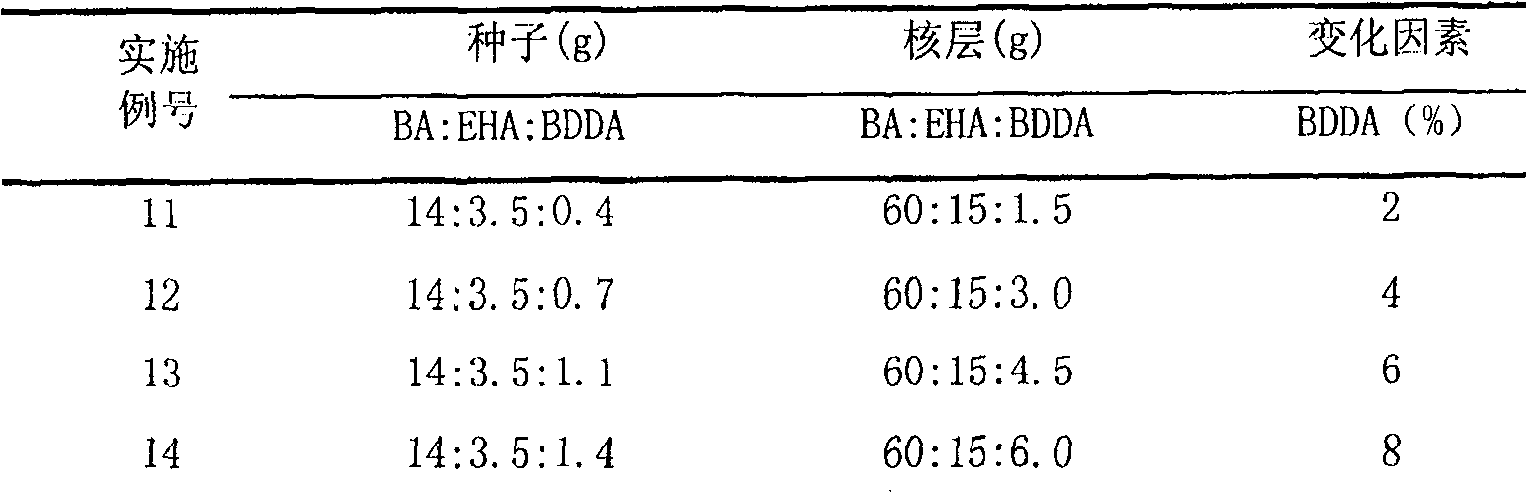

Odorless antistatic PVC composite material and preparation method thereof

The invention relates to the technical field of nylon, in particular to an odorless antistatic PVC composite material and a preparation method thereof, and the odorless antistatic PVC composite material comprises the following raw materials by weight: PVC, an odorless plasticizer, a modifier, a heat stabilizer, a lubricant, an antistatic agent, a flame retardant, a mildew inhibitor and an antioxidant. A core-shell particle modifier with nano silicon dioxide as a core, polymethyl methacrylate as a middle layer and polystyrene as an outer layer shell is prepared by an emulsion polymerization method; the dispersion problem of the nano silicon dioxide is effectively solved; meanwhile, by utilizing the characteristic that all layers of the core-shell particles are different in performance, whenthe core-shell particles are impacted, all the layers are prone to deformation to different degrees to form cavities, and compared with MBS of a core-shell structure, the toughening efficiency is higher, the inorganic rigid particles serve as cores, and the rigidity performance of PVC is well improved.

Owner:广东祺龙科技有限公司

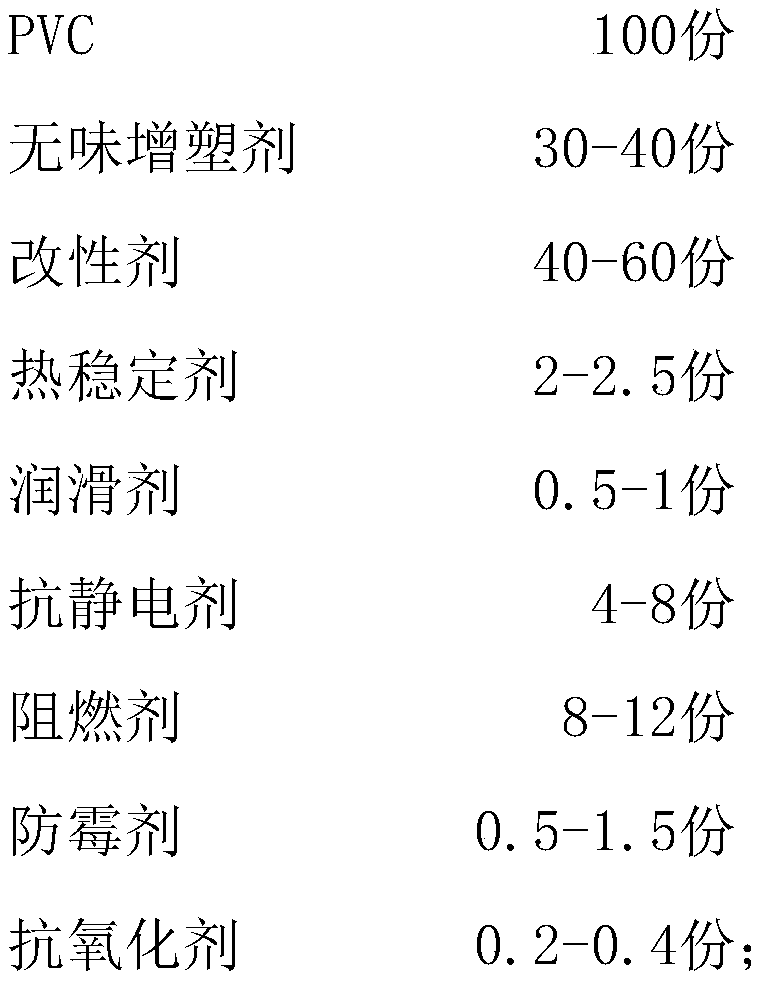

Method for preparing plant oil-based core-shell structural flexibilizer

The invention discloses a method for preparing a plant oil-based core-shell structural flexibilizer. The method is characterized in that liquid plant oil serves as a core, and the core is adopted to properly crosslink so as to obtain a relatively stable plant oil core structure; and then, a layer of hard polymer shell with high fluidity and solubility parameters similar to polyvinyl chloride (PVC) is polymerized on the external surface of the plant oil core structure through grafting free radical polymerization. The plant oil-based core-shell structural flexibilizer which is suitable for PVC is obtained through designing different core-shell structures. Compared with a conventional flexibilizer (such as acrylate copolymer ACR and chlorinated ppolyethylene CPE), the plant oil-based core-shell structural flexibilizer has the advantages of low price, high toughening efficiency, green, environment friendliness and the like; and the plant oil-based core-shell structural flexibilizer can be widely applied to the fields such as PVC building door and window sections, pipes, pipe fitting, electric wires and cables, conduits, small household appliances and the like.

Owner:YUNNAN UNIV

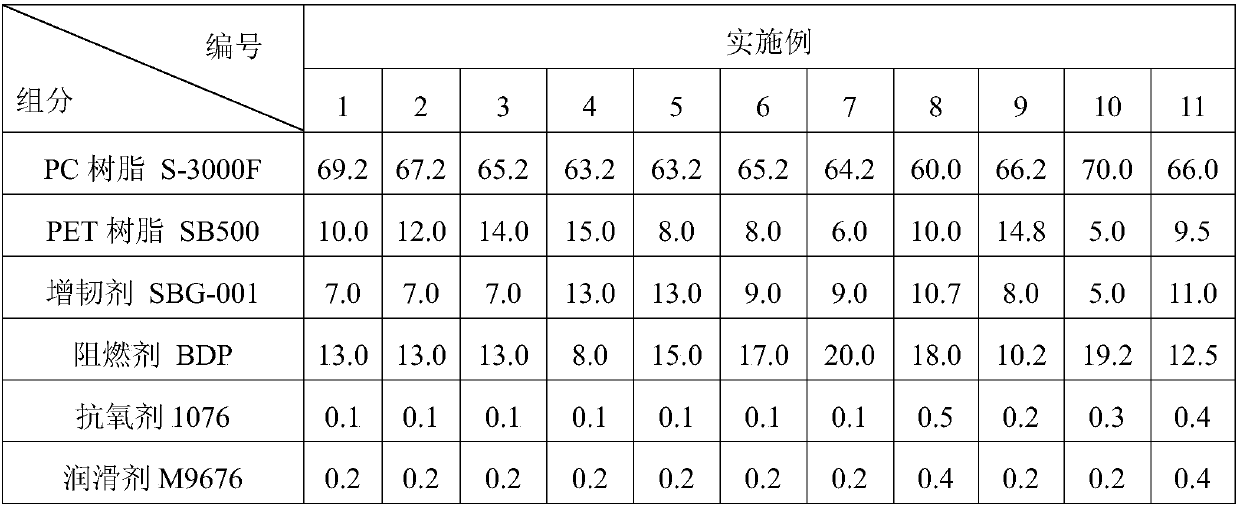

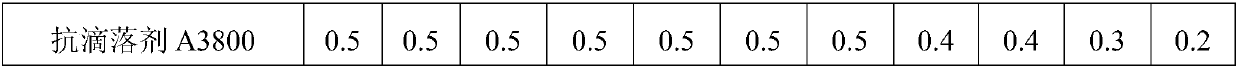

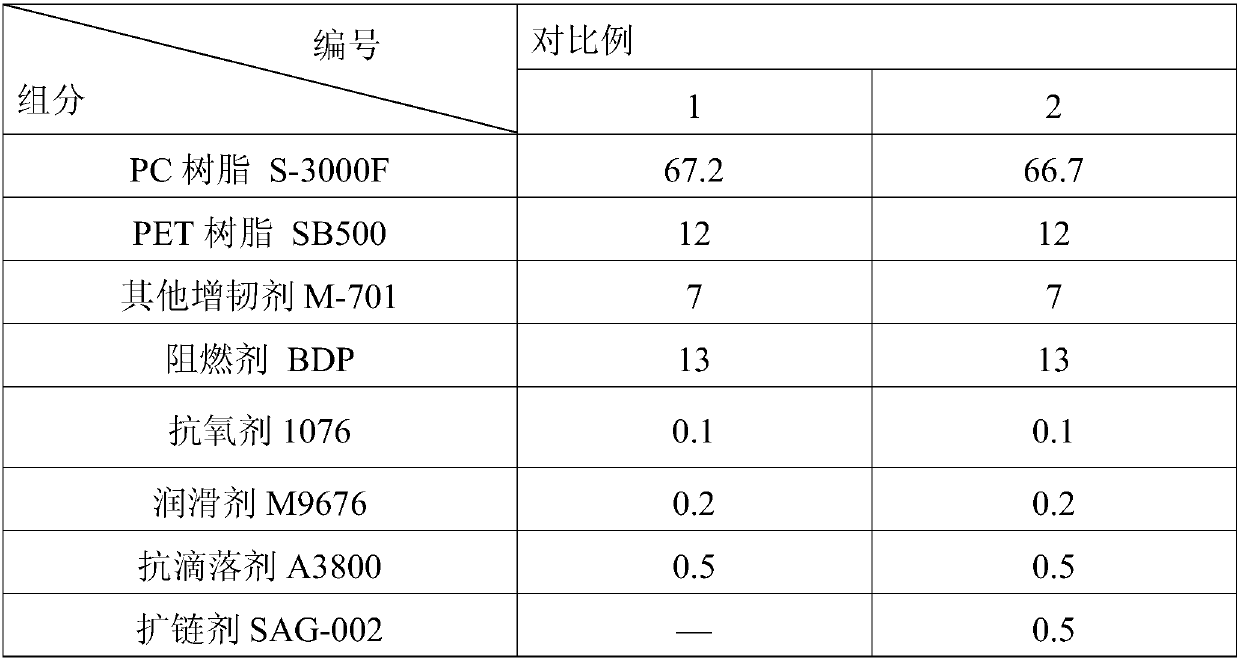

High-flowability and high-toughness PC/PET (polycarbonate/polyethylene terephthalate) composite and preparation method thereof

ActiveCN107556724AImprove liquidityLittle impact on liquidityGlycidyl methacrylatePolyethylene terephthalate glycol

The invention discloses a high-flowability and high-toughness PC / PET (polycarbonate / polyethylene terephthalate) composite. The high-flowability and high-toughness PC / PET composite is prepared from PCresin, PET resin, a toughening agent, a flame retardant, an antioxidant and other aids, wherein the toughening agent is a styrene-butadiene-glycidyl methacrylate terpolymer and contains 30wt.%-40wt.%of styrene, 55wt.%-65wt.% of butadiene and 0.1wt.%-1.0wt.% of glycidyl methacrylate and has the mass average molecular weight being 18,000-25,000. On the premise that no compatibilizer or chain extender is used in the composite, the toughening agent with the special structure is selected, has very high toughening efficiency and has very small influence on the flowability of the composite, the thermal stability of the composite is improved, and the mechanical property of the composite is guaranteed. The flowability, toughness and thermal stability of the composite are greatly optimized, and thecomposite is particularly applicable to occasions with higher requirements for the flowability and the use environments.

Owner:SHANGHAI KINGFA SCI & TECH +1

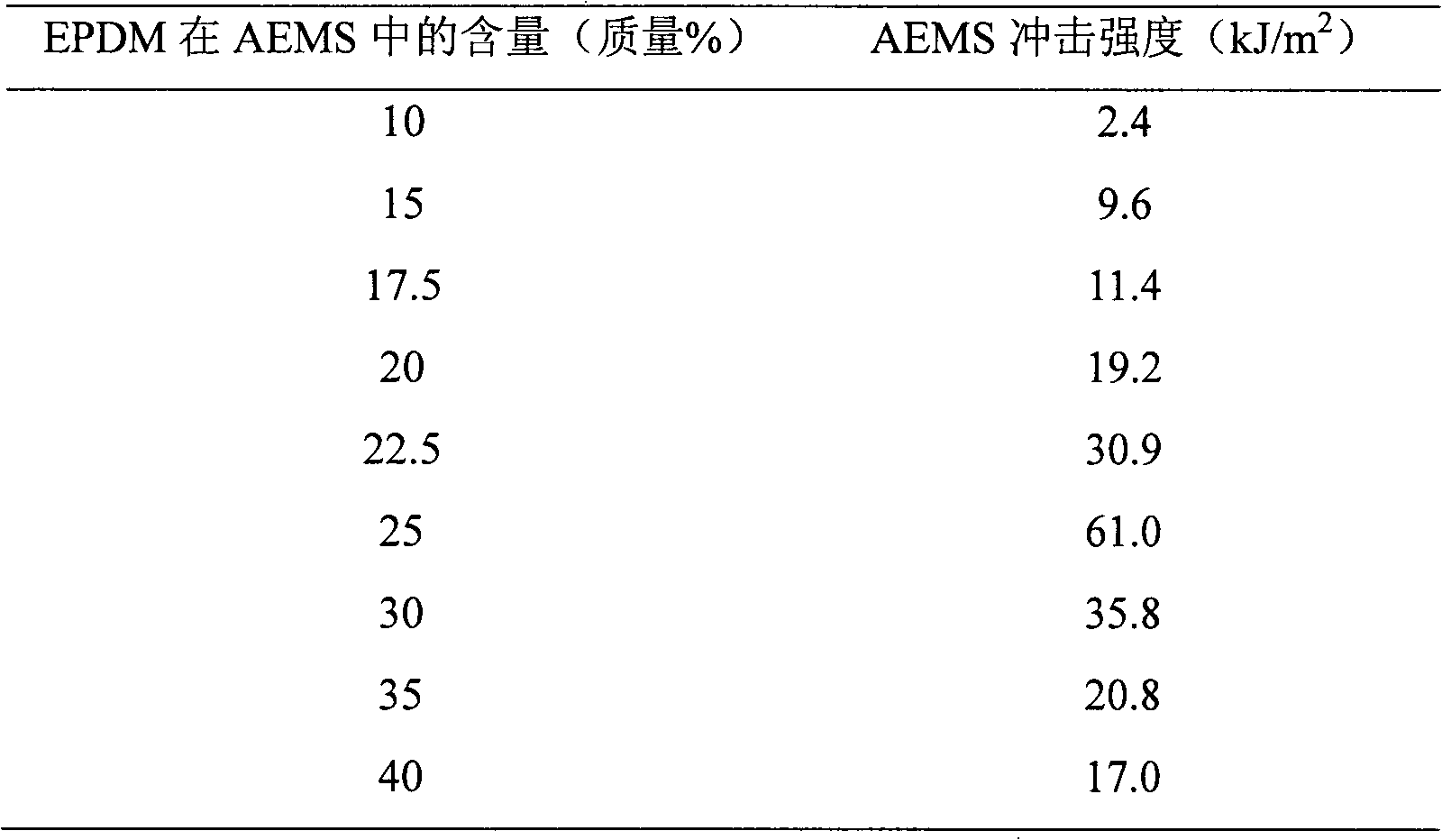

EPM-g-MAN toughener and preparation method thereof as well as engineering plastics AEMS

The invention discloses an EPM-g-MAN toughener and a preparation method thereof as well as engineering plastics AEMS. In the preparation method, ethylene propylene rubber and methyl methacrylate as well as acrylonitrile serve as raw material to synthesize graft copolymer EPM-g-MAN by a suspension graft copolymerization method. In the method, EPM is dissolved in organic solvent, and the mixed solution is added with MMA-AN mixed monomer, evocating agent and assistant dispersant to be stirred at low temperature to be evenly mixed; then, the mixture is dripped with dispersant water solution under the high speed agitation and the needed de-ionized water for reaction when the mixed solution is heated up under the nitrogen protection. The product is filtered, washed and dried after the reaction, so that granular toughener EPM-g-MAN with the EPM content of 47.5-68.7% can be obtained. The monomer conversion rate of an EPM / MMA-AN suspension graft copolymerization system is 85-94.82%, and the grafting percent reaches as high as 40%. The synthesized EPM-g-MAN can be mixed with SAN resin to prepare the high-impact engineering plastics AEMS with excellent weather aging yellowing resistant property, and the notch impact strength of the AEMS is 17-59.3kJ / m.

Owner:KINGFA SCI & TECH CO LTD +1

Thin-wall lightweight meter cable for oil-gas engineering

InactiveCN107805351AGood compatibilityAvoid breakingRubber insulatorsFlexible cablesFiberCarbon fibers

The invention discloses a thin-wall lightweight meter cable for oil-gas engineering. The thin-wall lightweight meter cable comprises a cable core and a sheath layer coating the outer side of the cablecore, wherein the sheath layer is prepared from the raw materials in parts by weight: 60-80 parts of ethylene propylene terpolymer rubber, 40-50 parts of polyurethane rubber, 50-60 parts of nitrile silicone rubber, 6-10 parts of vulcanizer, 40-50 parts of vermiculite powder, 20-30 parts of precipitated barium sulfate, 60-70 parts of channel carbon black, 4-8 parts of octyl phenolic aldehyde tackifying resin, 40-50 parts of carbon fibers, 4-8 parts of propylene glycol polysebacate, 2-4 parts of modified soybean oil and 3-5 parts of anti-aging agent.

Owner:安徽蓝德仪表有限公司

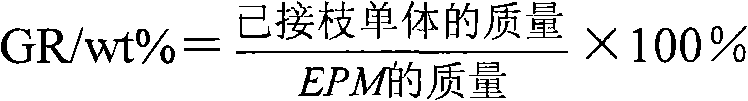

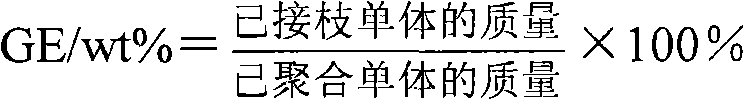

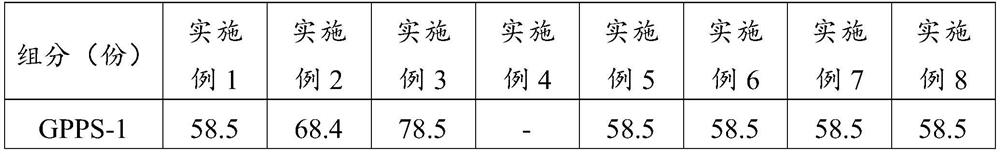

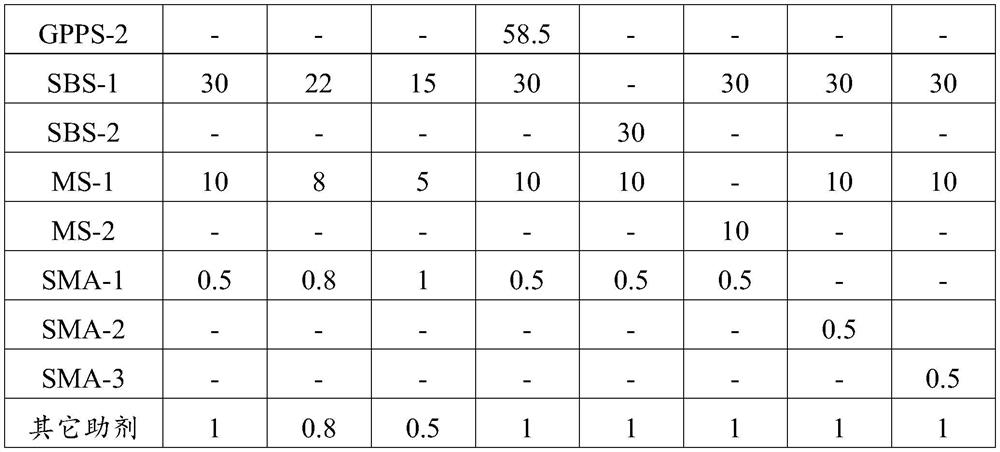

High-impact wear-resistant transparent polystyrene composition as well as preparation method and application thereof

ActiveCN114479297AEnsure transparencyImprove impact performancePolymer scienceStyrene-methylmethacrylate copolymer

The invention discloses a high-impact wear-resistant transparent polystyrene composition as well as a preparation method and application thereof, and belongs to the technical field of engineering plastics. The transparent polystyrene composition is prepared from the following components in parts by weight: 58.5 to 78.5 parts of GPPS, 15 to 30 parts of a styrene-butadiene block copolymer, 5 to 10 parts of a styrene-methyl methacrylate copolymer and 0.5 to 1 part of a styrene-maleic anhydride copolymer, the melt flow rate of GPPS under the test conditions of 200 DEG C and 5kg is greater than or equal to 6g / 10min. The impact resistance and wear resistance of the GPPS are improved while the transparency of the GPPS is maintained, and the transparent material with high impact resistance and wear resistance is obtained.

Owner:SHANGHAI KINGFA SCI & TECH +1

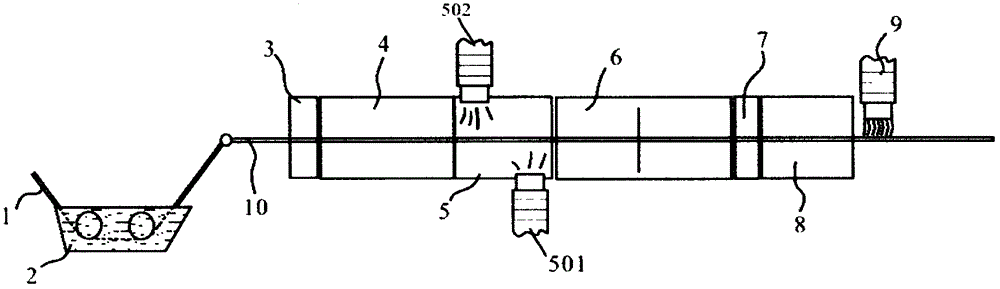

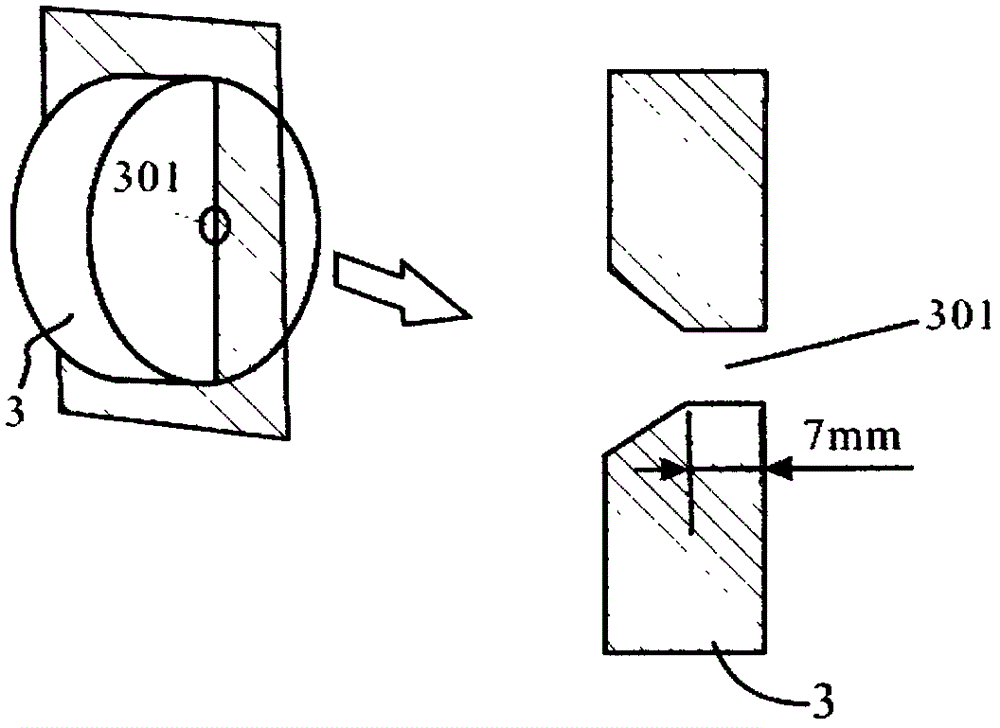

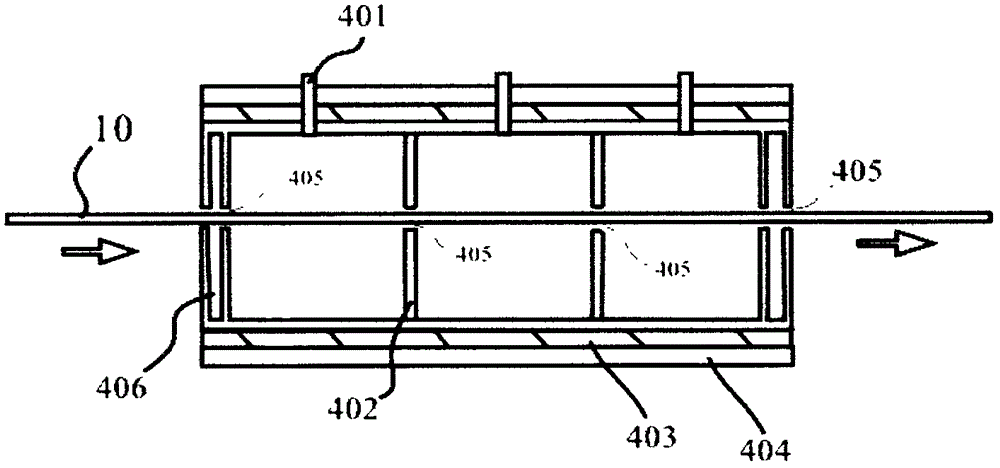

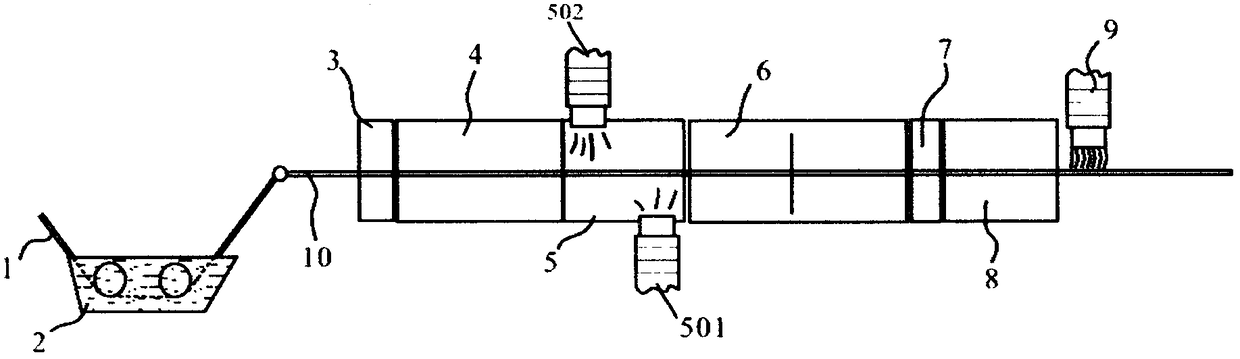

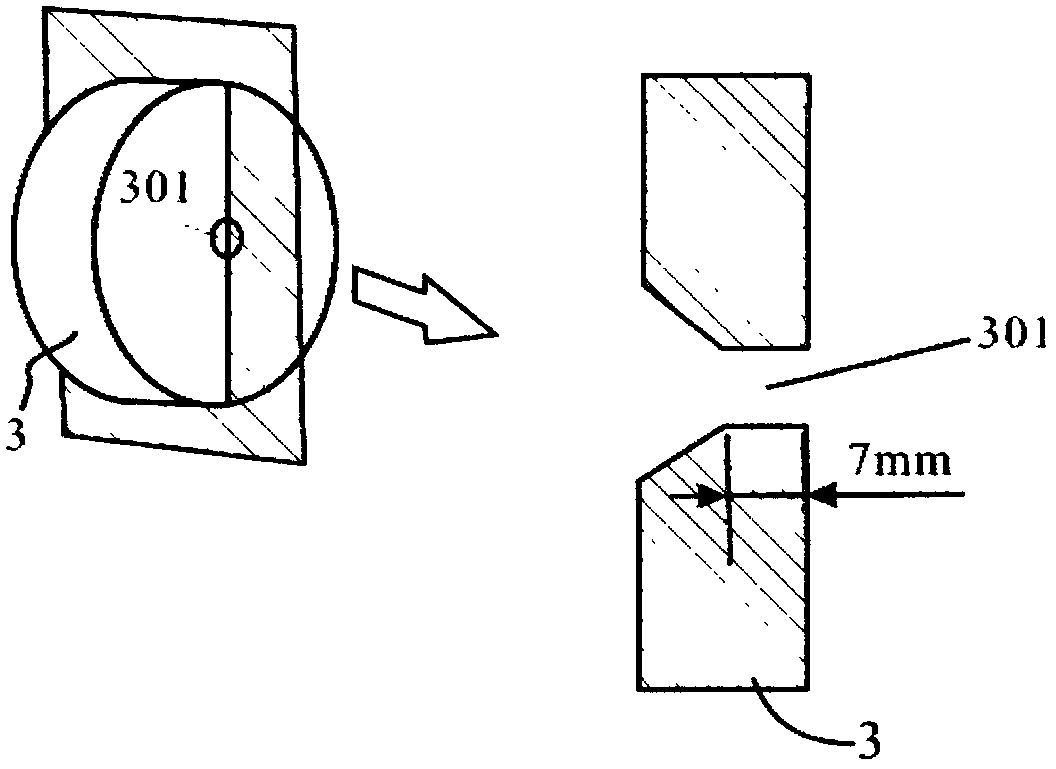

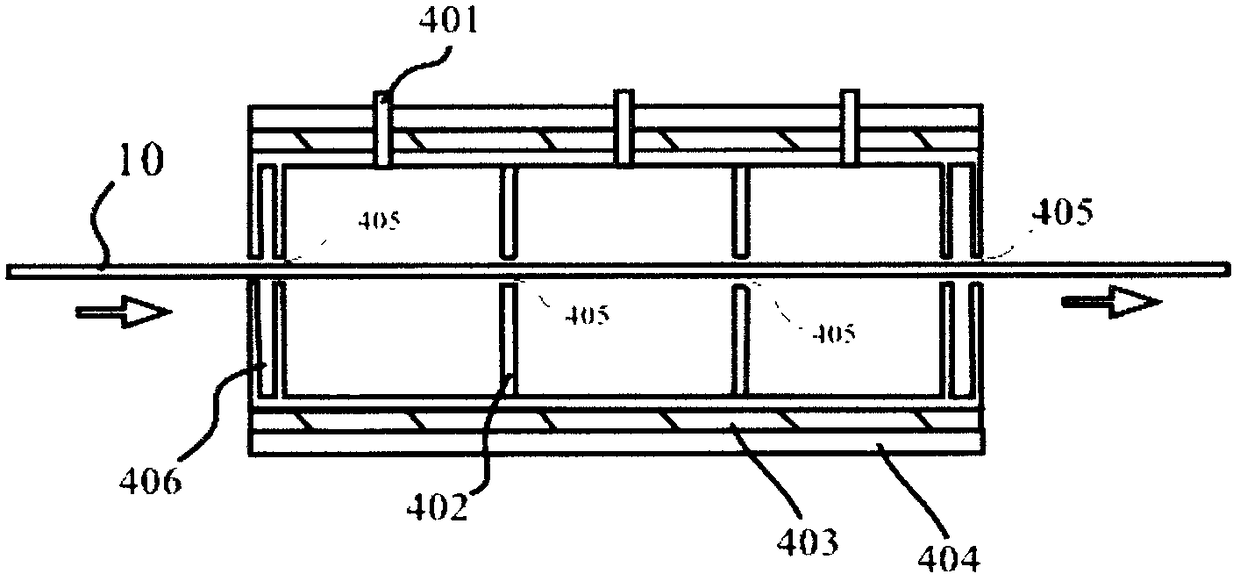

Coating method of composite toughened slender rod

The invention relates to a coating method of a composite toughened slender rod, and belongs to the technical field of composite surface modification. The coating method comprises the following steps that firstly, fiber bundles soaked in resin penetrate through a small hole primary forming mold, and the circular section shape is formed; secondly, the fiber bundles penetrate through a coating chamber with carbon fiber powder coating stored inside; thirdly, the slender rod passes through a dust collection device which does not make direct contact with the slender rod, and carbon fiber powder which bonded to the surface infirmly are removed; fourthly, the slender rod passes through a preheating device and a heating device for preheating and gelling; fifthly, the slender rod passes through a shaping mold for shaping; sixthly, the slender rod is solidified through the heating device; and finally, the slender rod passes through a dust collector with fine bristle brushes, and fiber powder bonded to the surface of the slender rod infirmly is removed. The coating method can be achieved in the production process of the slender rod, the fiber powder is used as the coating, the bonding performance of coated composites is used, chemical residues are avoided, a separated coating procedure is omitted, the method is simple, and the efficiency is high.

Owner:江苏德晴新材股份有限公司

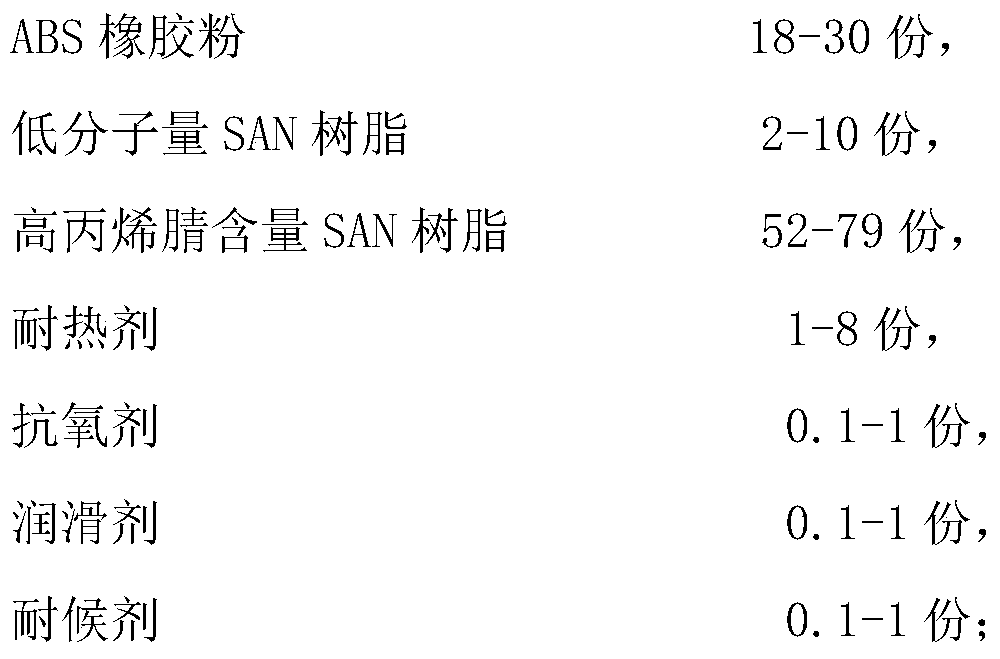

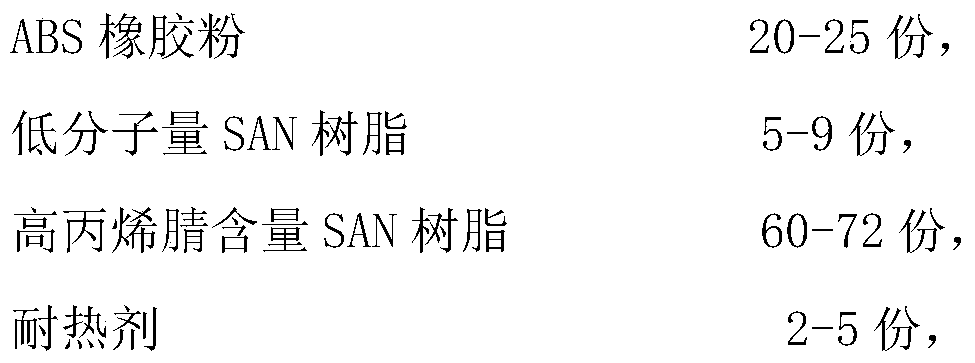

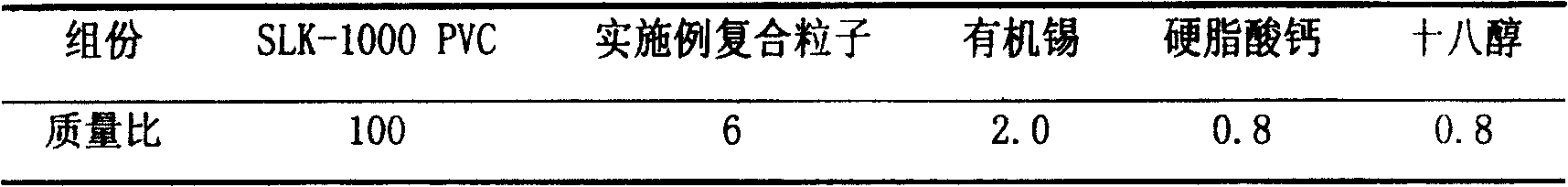

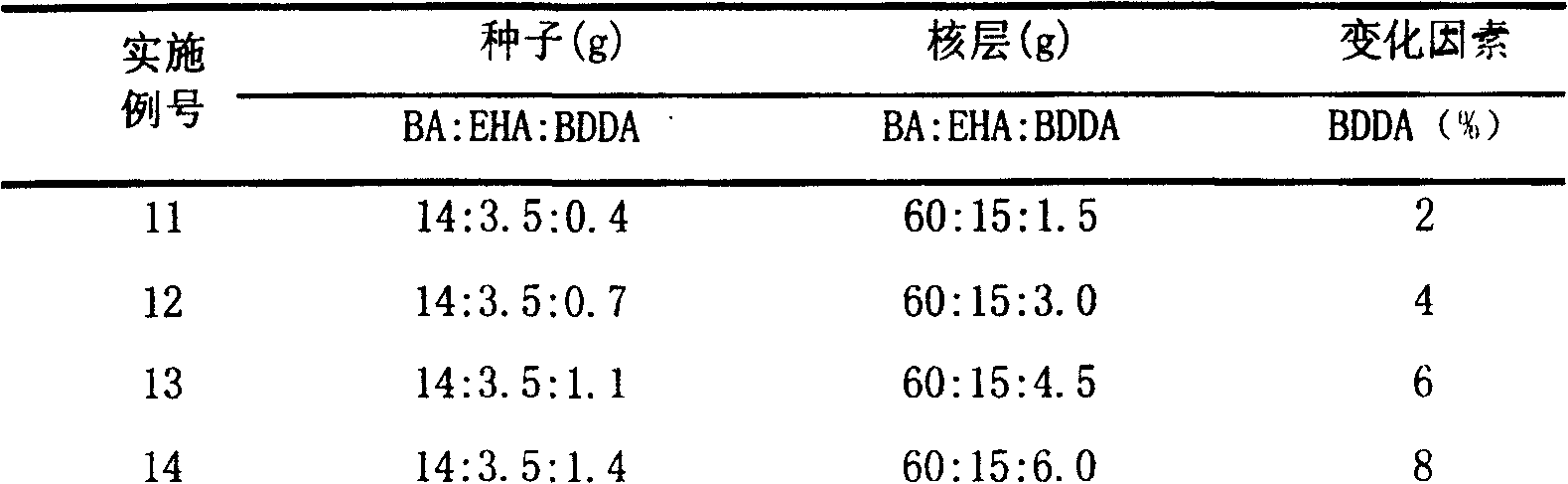

A kind of low internal stress heat-resistant ABS resin and preparation method thereof

The invention provides low-internal-stress heat-resistant ABS resin and a preparation method and application thereof and belongs to the technical field of modified resin. The low-internal-stress heat-resistant ABS resin is prepared from, by weight, 20-40 parts of ABS rubber powder, 2-10 parts of low-molecular-weight SAN resin, 42-77 parts of high-acrylonitrile-content SAN resin, 1-8 parts of a heat resistant agent, 0.1-1 part of an antioxidant, 0.1-1 part of a lubricant and 0.1-1 part of a weather resistance agent according to a formula. Compared with the prior art, the prepared low-internal-stress heat-resistant ABS resin greatly improves the liquidity of a material on the basis that heat resistance and impact are guaranteed, can obviously reduces the internal gravity in the injection molding process and can be applied to interior decorative parts and exterior decorative painted parts of automobiles.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

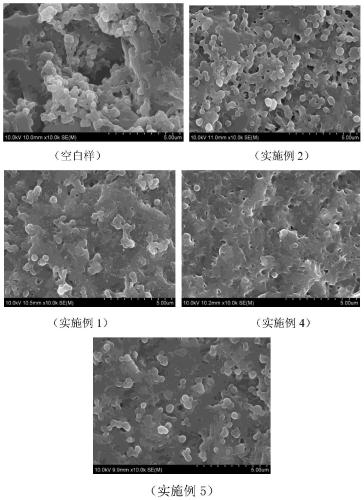

Nucleocapsid structure polyvinyl chloride impact modifier, and its preparing method and use

InactiveCN100457818CImprove toughening efficiencyImprove the interface binding forceElastomerCross-link

This invention relates to a PVC impact modifier with new-type nucleocapsid structure and its preparing method and application.It comprises: using acrylic monomer as main material, making cross-linked polymer latex with pure nucleus or nucleocapsid structure by semi-continuously charging mode of seed emulsion polymerization, then in the presence of said latex, adding chloroethene monomer to autoclave to emulsion polymerization, so as to obtain polyacrylate / PVC composite particle modifier with nucleocapsid structure.Because said modifier uses directly PVC as shell, it improves greatly compatibility between modifier and PVC resin matrix at crossblending, increasing two-phase bonding force, effectively giving play to characteristics of polyacrylate elastomer kernel so as to increase PVC material notch impact property, weathering-heating resistance and thermal stability, making general resin have high performance and functionization. It has low production cost, high added value of PVC resin, and widens PVC resin application.

Owner:HEBEI UNIV OF TECH

Method for preparing impact modifier of polyvinyl chloride in new type nuclear shell structure

InactiveCN100545187CImprove toughening efficiencyImprove the interface binding forceElastomerPolymer science

The invention relates to a preparation method of a polyvinyl chloride impact modifier with a core-shell structure. The method adopts acrylate monomer as the main raw material, and prepares a cross-linked polymer latex with an elastomer core-transition layer structure through seed emulsion polymerization in a semi-continuous feeding mode, and then, in the presence of the above-mentioned latex, adds Vinyl chloride monomer and its blend with other monomers are emulsion polymerized to prepare a core-shell structure polyvinyl chloride impact modifier with a transition layer structure. The modifier prepared by this method uses polyvinyl chloride as a thin shell, which greatly improves the compatibility between the modifier and the PVC resin matrix during blending, and effectively utilizes the polyacrylate elastomer core and functional functional groups. The characteristics of polyvinyl chloride can improve the notched impact resistance, weather resistance, and heat resistance stability of polyvinyl chloride materials, and the production cost of this method is lower than that of pure polyacrylate modifiers, which improves the added value of PVC resin and broadens the scope of polyvinyl chloride. Application field and application area of vinyl chloride resin.

Owner:HEBEI UNIV OF TECH

Process for preparing high shock-resistance polyacrylic ester composite particle grafted vinyl chloride emulsion resin

InactiveCN1181116CImprove toughening efficiencyImprove notched impact strengthEmulsionVinyl chloride

The present invention adopts acrylic ester monomer as main raw material, utilizes the processes of seed emulsion polymerization by adopting semi-continuous changing mode, agglomeration or organic agglomerating agent and addition of nano-grade inorganic particles to obtain composite particle latex; in the pressure of the above-mentioned latex it is grafted with polyethylene to obtain the invented composite polyvinyl chloride emulsion resin with high notch impact strength, weatherability and good low-temp. impact property at normal temp. It can be extensively used in the fields of indoor decoration material, electric equipmkent and meter, tog and others.

Owner:HEBEI UNIV OF TECH

High-strength heat-resistant flame-retardant ABS alloy material

The invention discloses a high-strength heat-resistant flame-retardant ABS alloy material. The material is prepared from, by weight, 100 parts of high-heat-resistant ABS particles, 11-53 parts of polyphenylene ether, 13-21 parts of PET, 5-10 parts of resorcinol diphenyl diphosphate, 0.5-2 parts of MAH-g-SEBS, 1.5-4.3 parts of SAN-g-GMA, 3-5 parts of dispersant, 5-15 parts of glass fiber, 0.1-1 part of antioxidant, 0.1-1 part of light stabilizer, 0.5-5 parts of processing aid and 2-11 parts of flame retardant. The high-strength heat-resistant flame-retardant ABS alloy material has extremely high heat resistance and impact resistance, a high flame-retardant effect and high stability, the glossiness of ABS alloy is guranateed, the excellent physical and mechanical properties of original ABS are maintained, and the alloy material can be widely used in the fields of household appliances, electronic telecommunication devices and automobile spare parts with a high requirement for the heat resistance of materials.

Owner:阜南县鲲鹏塑业科技有限公司

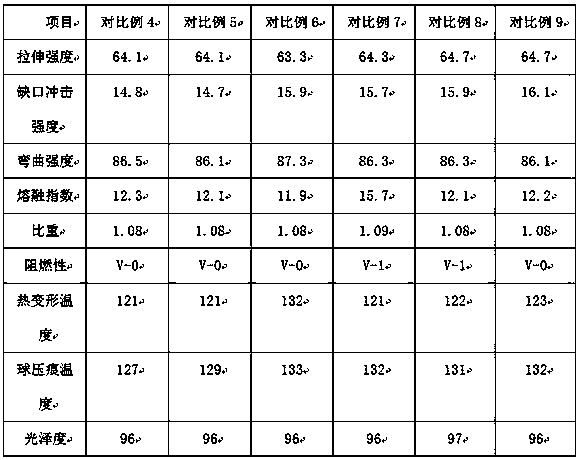

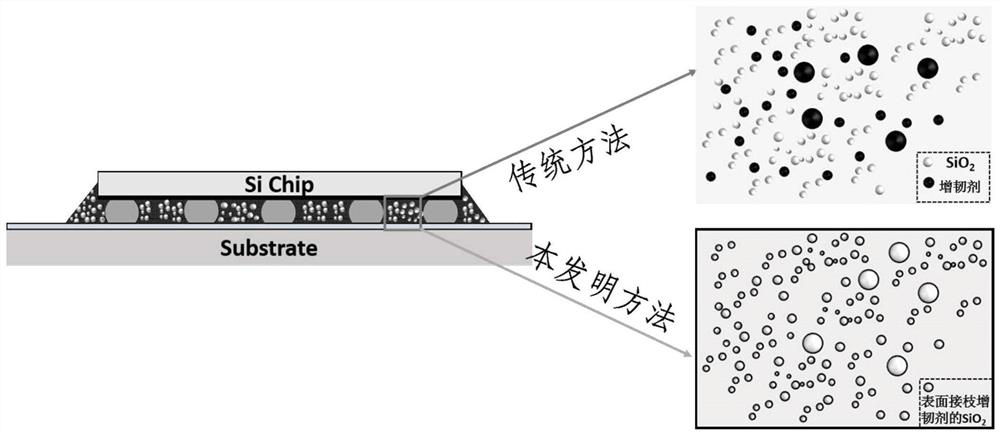

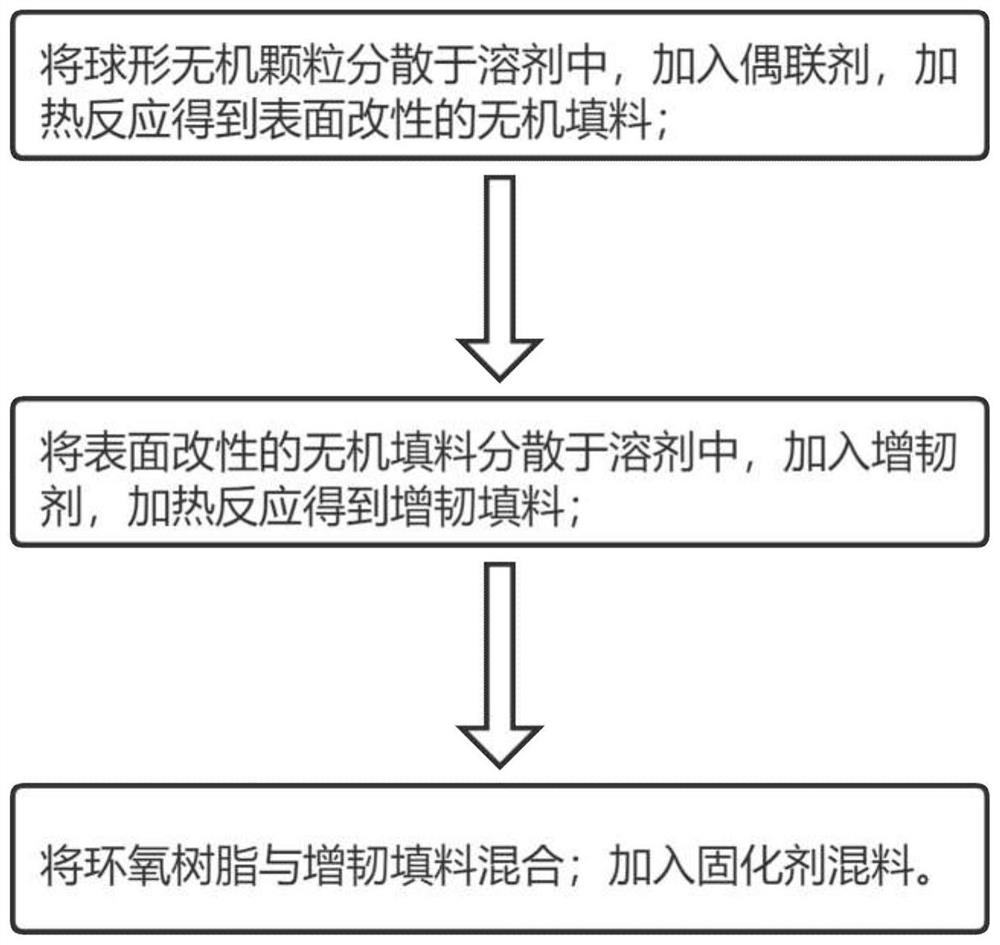

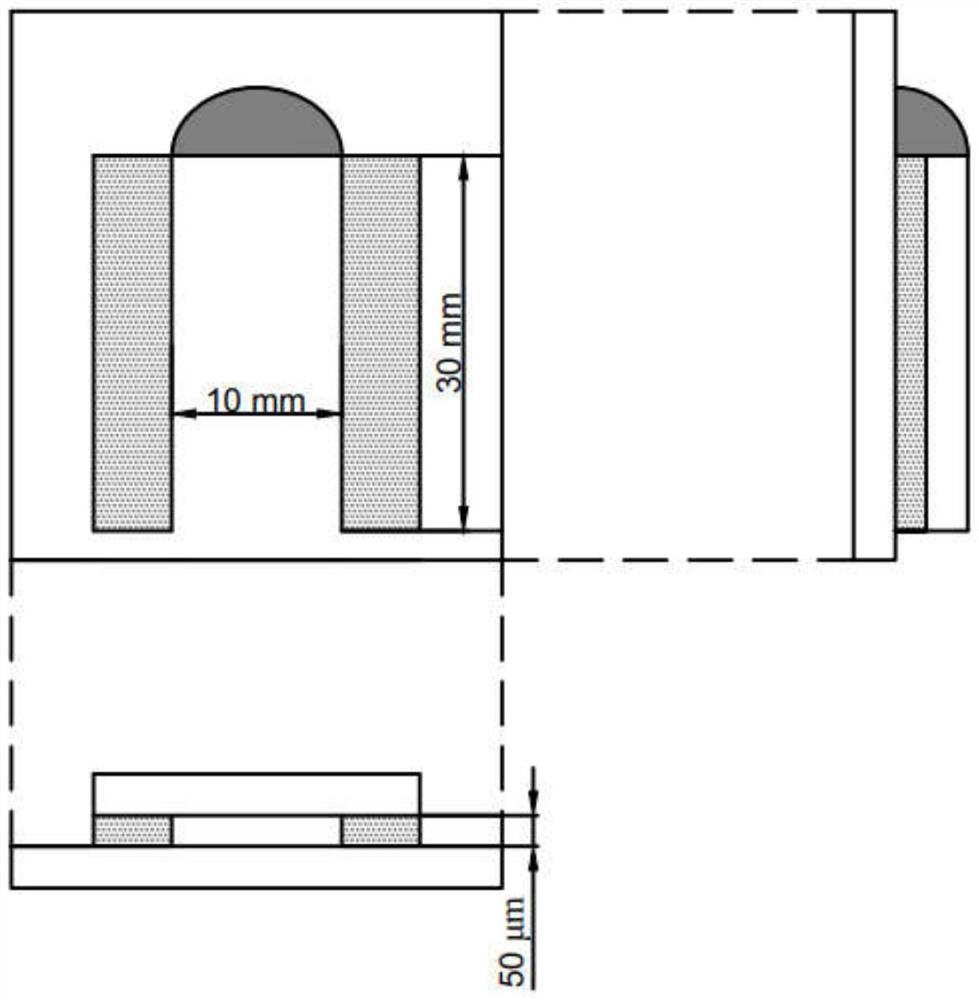

Chip-level underfill adhesive and preparation method thereof

PendingCN114479733AEvenly dispersedImprove reliabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceHigh fracture

The invention discloses a chip-level underfill adhesive and a preparation method thereof, and the chip-level underfill adhesive comprises the following components in parts by mass: 10-30 parts of epoxy resin; 5-25 parts of a curing agent; 45 to 75 parts of toughening filler; wherein the toughening filler is a composite particle which takes a spherical inorganic particle as a core and is grafted with a toughening agent after the surface of the spherical inorganic particle is modified by a silane coupling agent; preferably, the silane coupling agent is selected from one or more of compounds as shown in a formula (1). The spherical inorganic particles are used as a carrier to realize uniform dispersion of the filler and the flexibilizer in an epoxy resin matrix, the inorganic particles are used as a stress bearing framework to induce and transfer stress, the stress is dispersed through the surface grafted flexibilizer, the fracture toughness is remarkably improved while the strength is not lost, and the service life of the filler and the flexibilizer is prolonged. And meanwhile, the flexibilizer is inhibited from separating out split phases at the underfill. After a chip is filled with the filling adhesive provided by the invention, no crack is generated in 1000 times of cold and hot cycles at the temperature of-45 to 125 DEG C, and the filling adhesive has relatively high reliability.

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS

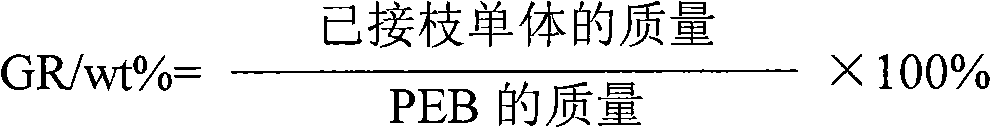

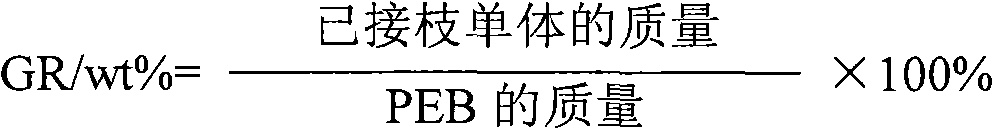

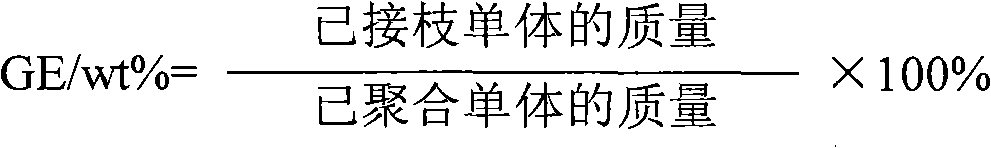

PEB-g-MAN toughening agent, preparation method thereof and engineering plastic ABMS

ActiveCN101684169BExcellent resistance to weathering and yellowingHigh glossPolymer scienceOrganic solvent

The invention discloses a PEB-g-MAN toughening agent, a preparation method thereof and an engineering plastic ABMS. The invention discloses a method for preparing a PEB-g-MAN toughening agent by usinga suspension grafting copolymerization method. The method comprises that: an ethylene-1-butylene copolymer is used as a grafting matrix, methyl methacrylate and vinyl cyanide are used as grafting monomers, and a PEB-g-MAN grafting copolymer of which PEB content is between 52.8 and 71.8 percent by weight is prepared by using suspension grafting copolymerization technology in the presence of an organic solvent. The monomer transformation rate of a grafting copolymer system reaches 80 to 95 percent. The synthesized PEB-g-MAN and SAN resin are mixed together to prepare the engineering plastic ABMS with excellent weather resistance, ageing resistance and yellowing resistance and high impact resistance, wherein the gap impact strength of the ABMS is between 10.5 and 63.1 kJ / m<2>.

Owner:KINGFA SCI & TECH CO LTD +1

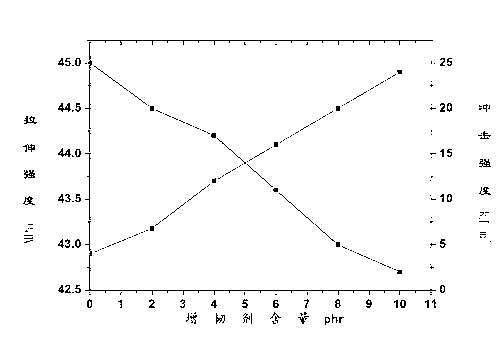

Composite modified hard PVC sheet with high calcium carbonate content and preparation method thereof

PendingCN112724553AIncrease the amount addedImprove toughening efficiencyCalcium carbonatePlasticizer

The invention discloses a composite modified hard PVC sheet with high calcium carbonate content and a preparation method thereof. The composite modified hard PVC sheet comprises the following components in parts by weight: 80-100 parts of PVC resin, 30-80 parts of calcium carbonate, 3.5-10 parts of a composite modifier, 1-3 parts of a heat stabilizer, 1-2 parts of a plasticizer and 0.1-0.6 part of fatty acid ester; wherein the composite modifier is composed of an acrylate core-shell polymer and a binuclear coupling agent according to a certain weight ratio. Through compounding of AIM and FT-16, toughening is achieved with less AIM, and meanwhile, the addition amount of calcium carbonate in the hard PVC sheet is increased through FT-16, so that the hard PVC sheet is easy to form. According to the invention, the hard PVC sheet provided by the invention has good toughness, weather resistance, processability and mechanical properties, solves the problems of great processing difficulty and influence on the mechanical properties of the material when the existing hard PVC sheet is modified and the addition amount of calcium is higher than 30%, and has good practical and economic values.

Owner:SUZHOU OCAN POLYMER MATERIAL CO LTD

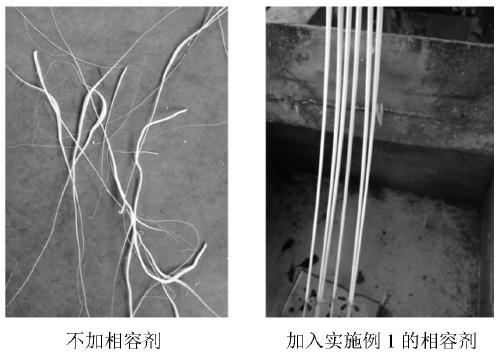

Compatilizer and preparation method and application thereof

ActiveCN110372822AAdd lessFacilitate control of residence time distribution widthElastomerFunctional monomer

The invention relates to a compatilizer and a preparation method and application thereof. The compatilizer is prepared from the following components in parts by weight: 50-90 parts of styrene resin, 10-40 parts of vinyl elastomer, 0.1-3 parts of an initiator, 0.1-3 parts of an antioxidant, 0.1-3 parts of a lubricant and 0.5-5 parts of a functional monomer. According to the compatilizer and the preparation method and application, the initiator is fed by using a side feeding method, and the free radical deactivation post-treatment is carried out at the rear stage of the reaction to stop the residual free radicals, and the product stability is improved. Compared with the prior art, a reactive compatilizer with active functional groups and a core-shell structure is prepared, the compatibilityof the styrene resin with the polyamide resin is effectively improved through the reaction of the functional groups, the core-shell structure can effectively improve the processability and toughness of an alloy, a reaction extrusion process is adopted, the processing is convenient, the input cost is low, and the environment is not polluted.

Owner:FINE BLEND COMPATILIZER JIANGSU CO LTD

Preparation method of pvc nano alloy resin with high fluidity and low temperature toughness

The invention is a preparation method of PVC nano-alloy resin with high fluidity and low-temperature toughness. The method includes (1) preparation of nano-seed latex and (2) preparation of PVC nano-alloy resin; by grafting and copolymerizing (BD-ACR) nano-alloy latex through high-temperature suspension to prepare a low-temperature, high-toughness, Nano-alloy PVC resin with good fluidity. The invention not only improves the dispersion degree of the inner core of the elastomer, but also improves the toughening efficiency of the rubber phase. The copolymerized resin can be applied to injection-molded PVC products with high fluidity requirements, and overcomes that the current high-impact PVC alloy resin is not suitable for PVC Insufficient injection molding raw materials.

Owner:HEBEI UNIV OF TECH

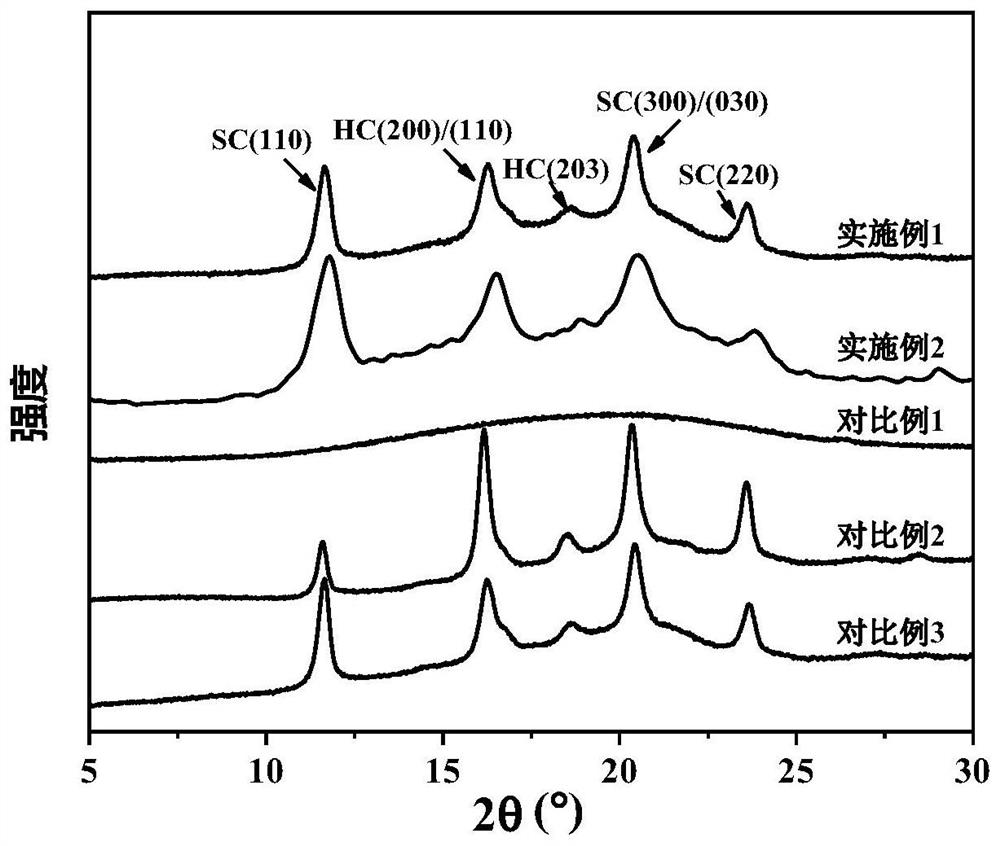

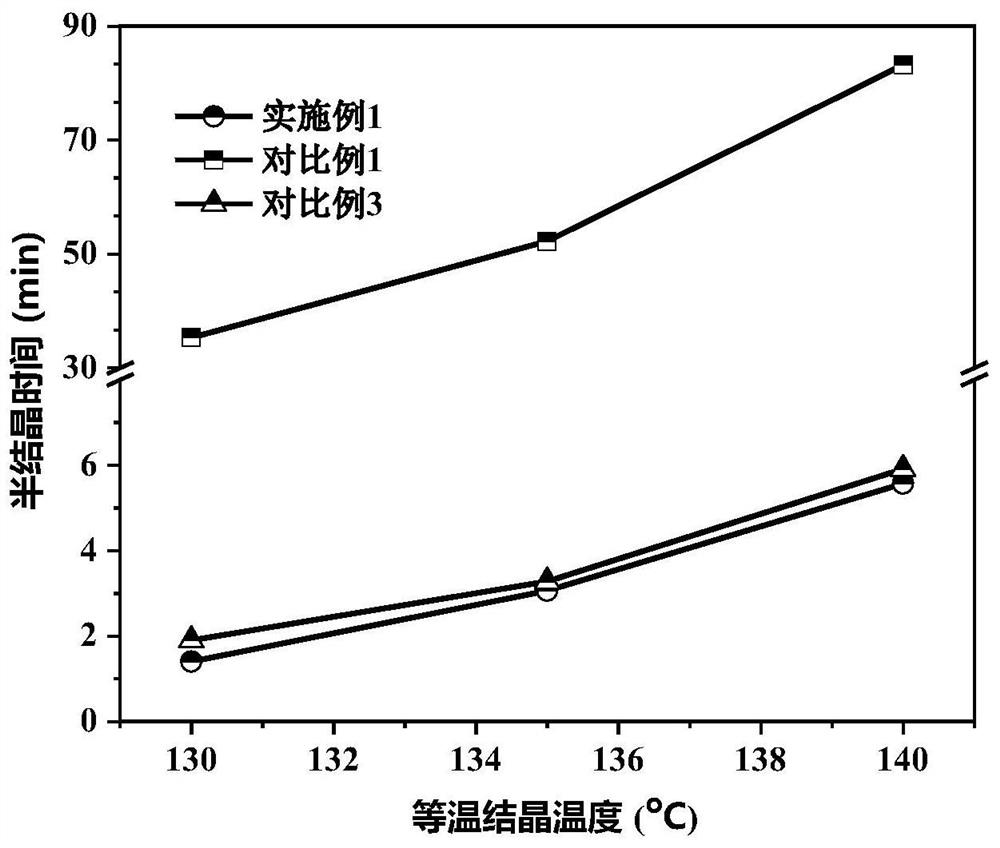

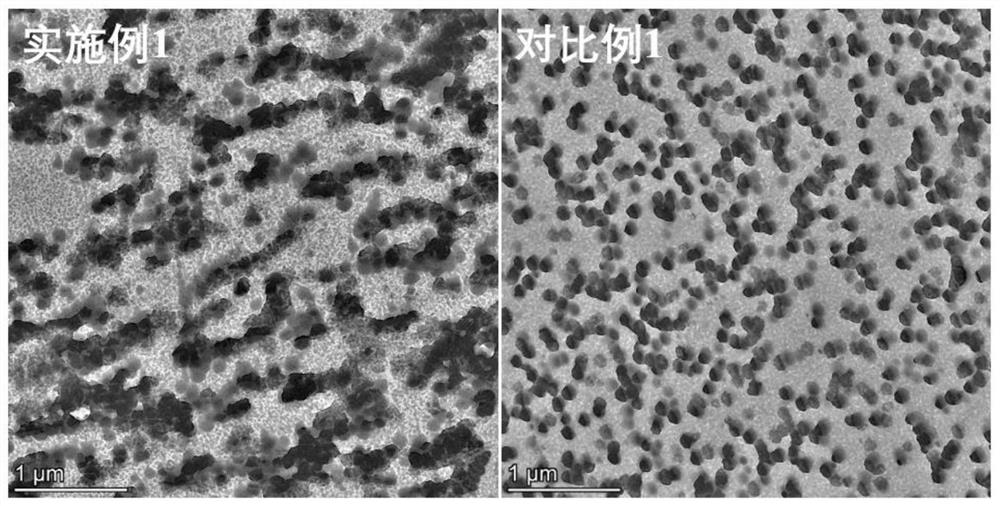

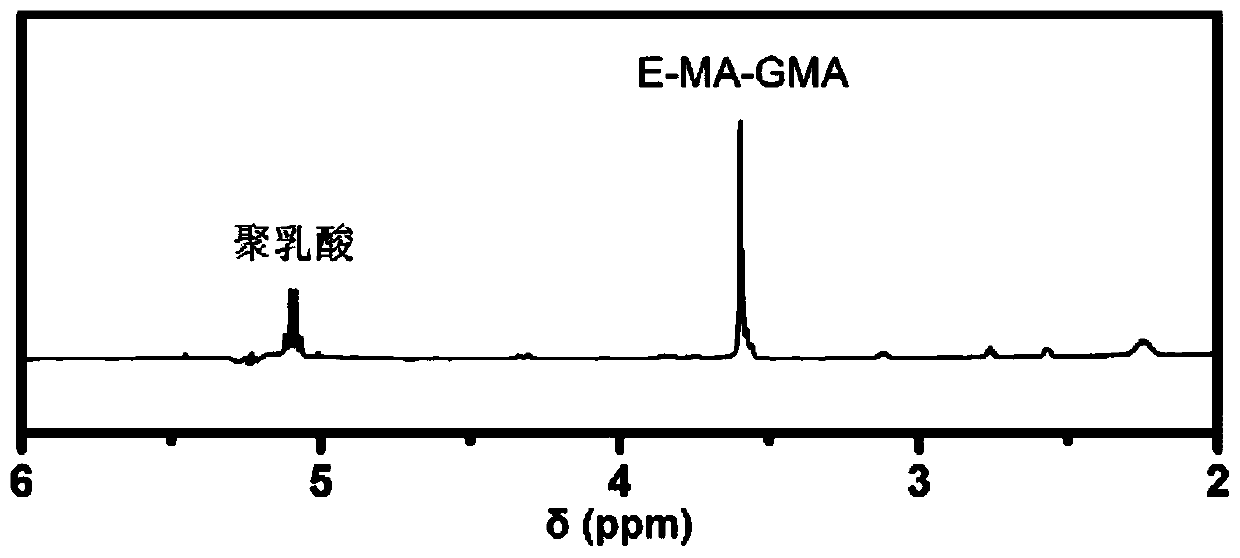

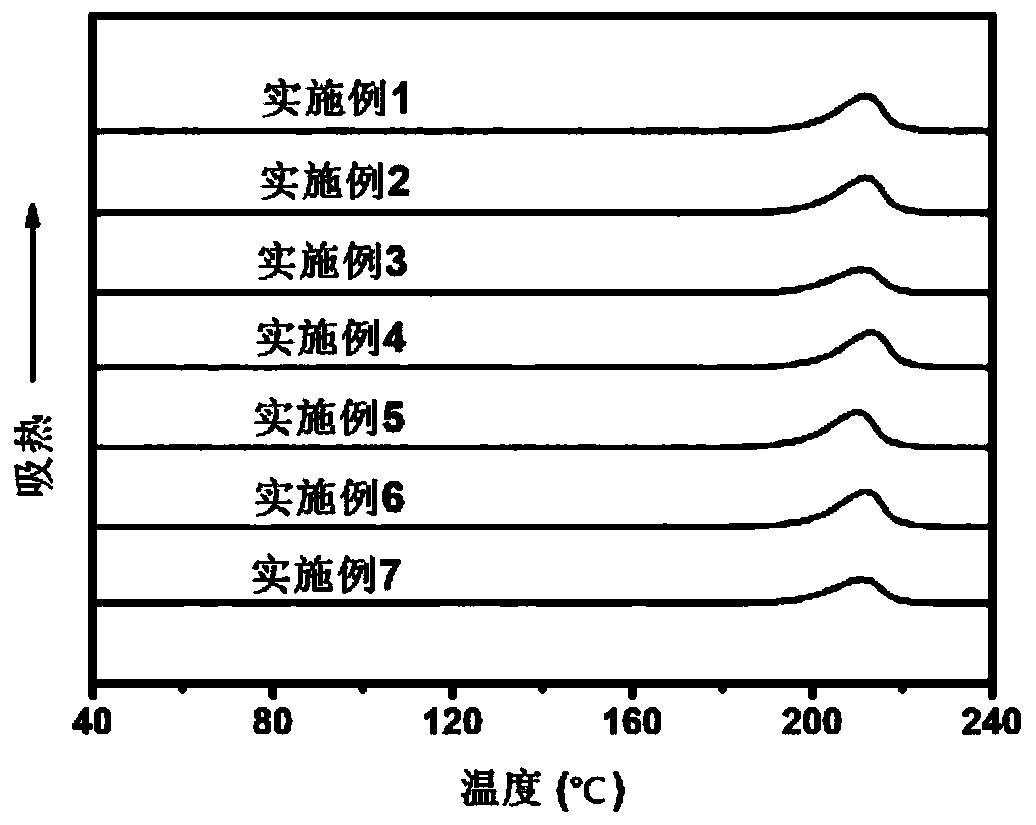

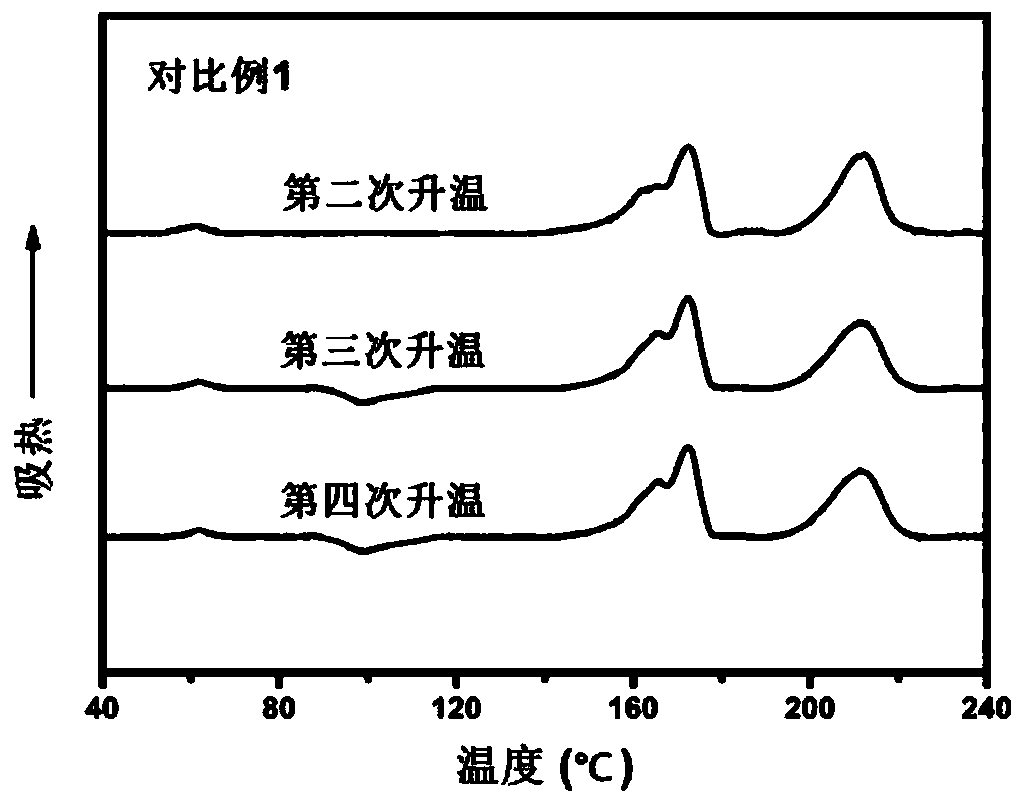

Super-tough heat-resistant polylactic acid/rubber alloy and preparation method thereof

ActiveCN113717510AImprove toughening efficiencyHigh crystallinityComposite materialPoly l lactic acid

The invention belongs to the technical field of polylactic acid materials and preparation thereof, and particularly relates to a super-tough heat-resistant polylactic acid / rubber alloy with a network-like structure and a preparation method thereof. The invention provides the preparation method of the super-tough heat-resistant polylactic acid / rubber alloy. The preparation method comprises the steps: preparing the polylactic acid / rubber alloy from poly-L-lactic acid, poly-D-lactic acid and rubber particles through a melt blending method, wherein at least one of the poly-L-lactic acid and the poly-D-lactic acid is multi-arm star-shaped polylactic acid, and the rubber particles are rubber particles with core-shell structures. According to the invention, when one of the selected poly-L-lactic acid and poly-D-lactic acid is selected from multi-arm star-shaped polylactic acid, the multi-arm star-shaped polylactic acid and the rubber particles are subjected to melt blending, so that the notch impact strength of the polylactic acid can be greatly improved; the super-tough heat-resistant polylactic acid / rubber alloy can be prepared; and in addition, the method is simple in process and easy to industrialize.

Owner:CHONGQING UNIV OF ARTS & SCI

Instrument signal cable for controlling computer

InactiveCN107828100AGood compatibilityAvoid breakingRubber insulatorsInsulated cablesFiberWater vapor

The invention discloses an instrument signal cable for controlling a computer. The instrument signal cable comprises a cable core and a jacket layer covering the outer side of the cable core; the jacket layer is prepared from the following raw materials in parts by weight: 100 to 110 parts of main materials, 1.5 to 2.5 parts of tert-butyl hydroperoxide, 2 to 4 parts of lauric acid, 1 to 2 parts oftetramethyl thiuram disulfide, 20 to 30 parts of heavy calcium carbonate, 15 to 25 parts of talcum powder, 45 to 55 parts of expanded perlite, 2 to 4 parts of melamine resin, 35 to 45 parts of cottonand linen fiber, 3 to 7 parts of plasticizer, 2 to 4 parts of antioxidant 1010, 1 to 2 parts of ultraviolet absorbent UVP-327, and 0.5 to 1.5 parts of light stabilizer GW-540. The instrument signal cable for controlling the computer is good in bend resistance and pulling resistance, high in tear strength, capable of preventing the direct contact between oxygen or vapour and a carbon chain, capable of effectively improving the hot oxygen stability and the aging resistance, and long in service life.

Owner:安徽蓝德仪表有限公司

PEB-g-SAN toughener and preparation method thereof as well as engineering plastics AEBS

ActiveCN101560282BImprove notched impact strengthImprove conversion rateOrganic solventEngineering plastic

The invention discloses a PEB-g-SAN toughener and a preparation method thereof as well as engineering plastics AEBS. In the invention, ethylene-butylene copolymer (PEB) serves as grafting substrate and styrene (St) and acrylonitrile (AN) serve as grafting monomers; under the condition of the existence of organic solvent, a suspension graft copolymerization technology can be used for preparing graft copolymer PEB-g-SAN with the PEB content of 40-60wt%. The monomer conversion rate of a graft copolymerization system is 85-95%. The synthesized PEB-g-SAN can be mixed with SAN resin to prepare the high-impact engineering plastics AEBS with excellent weather aging yellowing resistant property, and the notch impact strength of the AEBS is 2-52.5kJ / m<2>.

Owner:KINGFA SCI & TECH CO LTD +1

A coating method for composite toughened thin rods

Owner:江苏德晴新材股份有限公司

High-performance stereocomplex polylactic acid/elastomer alloy material or product and preparation method thereof

The invention discloses a preparation method for a high-performance steric composite type polylactic acid / elastomer alloy material or product. The preparation method comprises the following steps: completely dissolving a catalyst into absolute ethyl alcohol to obtain a mixture; uniformly mixing the mixture with elasatomer, L-polylactide and R-polylactide; and adding a material mixture into a melting mixer to co-mix and pelletize or re-melt and process, thereby obtaining the high-performance steric composite type polylactic acid / elastomer alloy material or product with excellent melting and stabilizing characteristics and heat resistance as well as high toughness. Though an efficient catalyst, part of a PLA molecular chain is grafted onto an elastomer molecular chain through coupling grafting reaction, so that compatibility with PLA is effectively improved, toughening efficiency is improved, and the obtained alloy material or product has excellent melting stabilizing characteristics, and therefore, multi-time melting processing can be performed. The preparation method is simple and efficient, and easily realizes large-scale industrial production.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com