Chip-level underfill adhesive and preparation method thereof

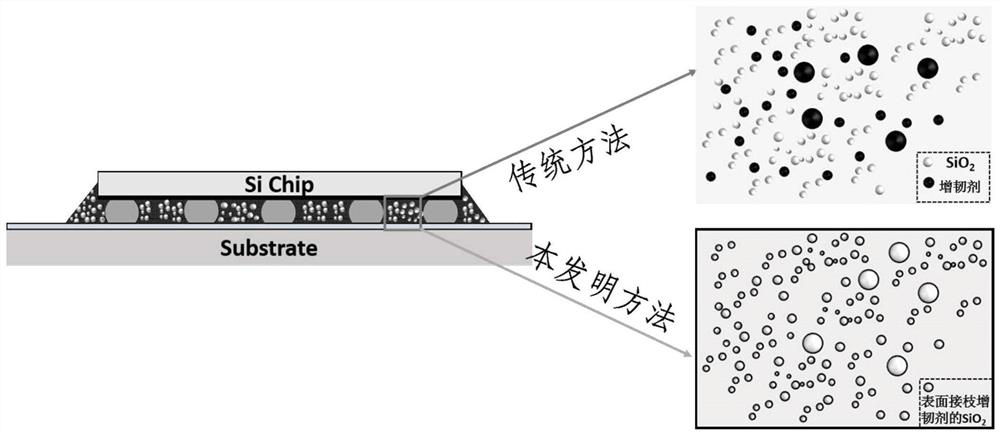

An underfill and chip-level technology, applied in the direction of adhesives, epoxy resin glue, non-polymer adhesive additives, etc., can solve the problems of uneven dispersion of tougheners and large phase separation scales, and achieve toughening efficiency High, small phase split size, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

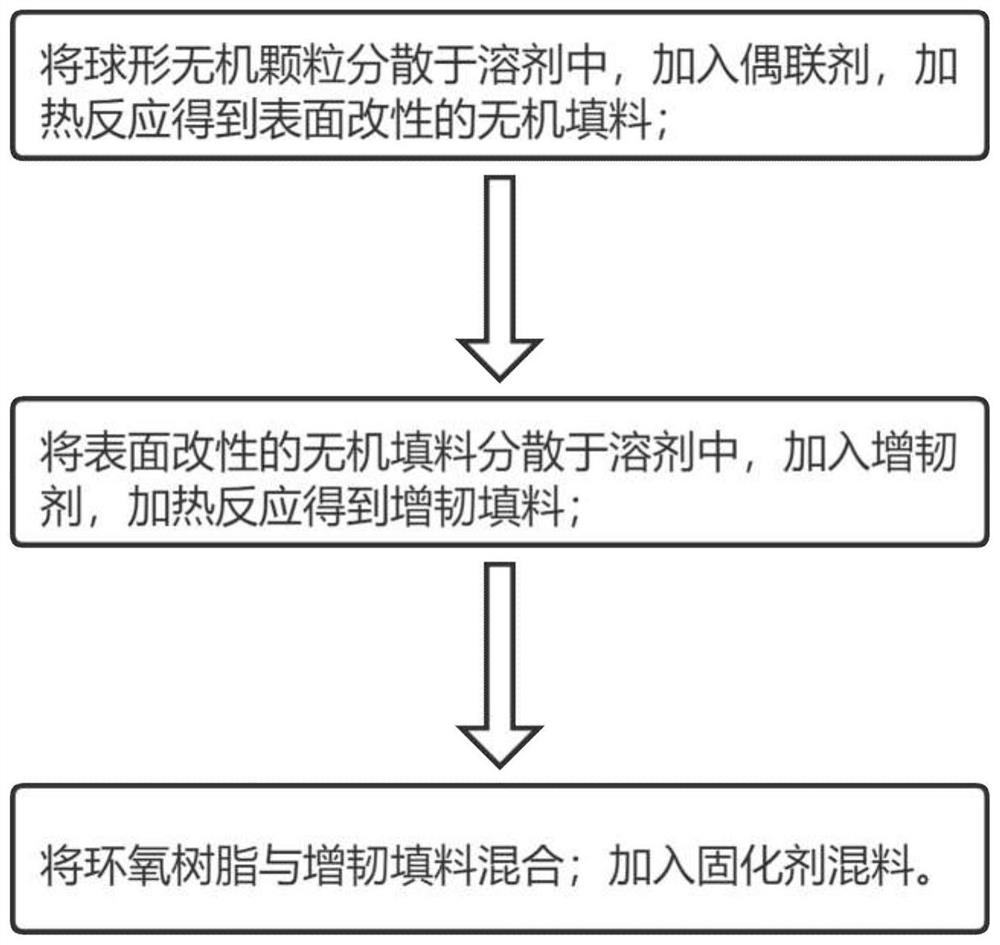

[0102] For the preparation of the chip-level underfill in this embodiment, see figure 2 ,Specific steps are as follows:

[0103] Step 1: Disperse 120 g of spherical silica (component D2, average particle size 15 μm) prepared by the melting method in 500 mL of a mixed solvent of ethanol and water (ethanol:water volume ratio 90:10), and add 1 g of 3- Aminopropyltrimethoxysilane, stirred and refluxed at 80°C for 12h, cooled and centrifuged to remove the ungrafted silane coupling agent on the surface, and dried at 100°C for 4h to obtain surface-modified amino-functionalized silica powder; Disperse 60 g of the obtained amino-functionalized silica powder in 500 mL of methyl ethyl ketone solvent, add 1 g of carboxyl-terminated acrylic rubber copolymer LA2250 (toughener C1), react at 80 ° C for 5 h, and then centrifuge and dry to obtain toughened Filler D1;

[0104] Step 2: Weigh 30g of bisphenol A epoxy resin (component A1), and mix at a high speed of 1000rpm / min for 2min;

[010...

Embodiment 2

[0109] For the preparation of the chip-level underfill in this embodiment, see figure 2 ,Specific steps are as follows:

[0110] Step 1: Disperse 240 g of spherical silica (component D4, average particle size 2 μm) prepared by deflagration method in 500 mL of a mixed solvent of ethanol and water (volume ratio of ethanol:water 80:20), and add 0.5 g of 3-Aminopropyltriethoxysilane, stirred and refluxed at 60°C for 24h, cooled and centrifuged to remove ungrafted silane coupling agent on the surface, and dried at 120°C for 6h to obtain surface-modified amino-functionalized silica Powder: Disperse 60g of the obtained amino-functionalized silica powder in 1000mL butanone solvent, add 1g of carboxy-terminated acrylic rubber copolymer LA2230 (toughener C2), react at 60°C for 2h, then centrifuge, wash and dry , to obtain the toughening filler D3;

[0111] Step 2: Weigh 27.38g of bisphenol F epoxy resin (component A2), and mix at a high speed of 1500rpm / min for 1min;

[0112] Step 3...

Embodiment 3

[0116] For the preparation of the chip-level underfill in this embodiment, see figure 2 ,Specific steps are as follows:

[0117] Step 1: Disperse 360g of spherical silica (component D6, average particle size 0.5μm) prepared by deflagration method in 500mL of mixed solvent of ethanol and water (volume ratio of ethanol:water 60:40), and add 2g of 3- (Triethoxysilyl) propyl succinic anhydride, stirred and refluxed at 70°C for 12h, cooled and centrifuged to wash, remove the ungrafted silane coupling agent on the surface, and dry at 140°C for 2h; the obtained surface-modified silica Disperse 120g of powder in 500mL of acetone solvent, add 2g of epoxy-modified silicone oil X22-343 (toughener C3), react at 60°C for 2h, then centrifuge, wash and dry to obtain toughening filler D5;

[0118] Step 2: Weigh 18.28g of naphthalene ring epoxy resin (component A3), and mix at a high speed of 1500rpm / min for 1min;

[0119] Step 3: Weigh 61g of the toughening filler (component D5) obtained i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com