PEB-g-MAN toughening agent, preparation method thereof and engineering plastic ABMS

A toughening agent, peb-g-man technology, applied in the field of high-impact engineering plastics ABMS, can solve the problems of large amount of solvent, high production cost, large investment in equipment, etc., to achieve easy heat transfer, improve compatibility, The effect of polymerization process stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

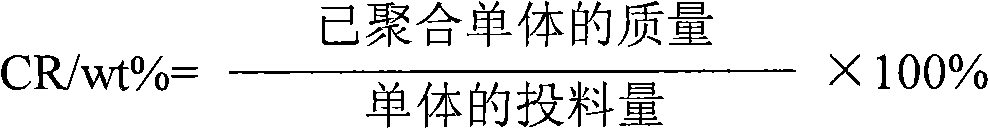

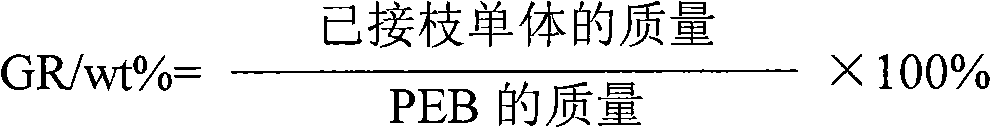

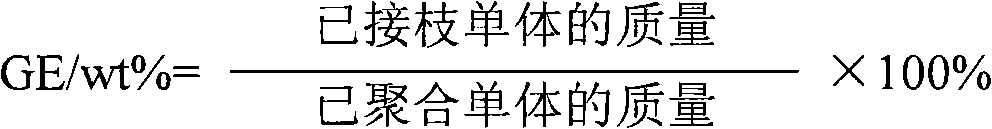

[0030] The basic formula and implementation formula of embodiment 1 are as shown in table 1. The synthetic operation process of PEB-g-MAN when the mass ratio of AN / MMA is 5 / 95 is as follows:

[0031]A 1000mL four-neck flask was used as the reactor, equipped with a stirrer, an automatic temperature control oil bath heating device, a reflux pipe, a nitrogen pipe and a material thermometer. Add 80g of toluene and 55.00g of PEB into a four-necked flask, and dissolve at 65°C for 4-6 hours to make the system into a uniform glue. Add the mixed monomer of 2.25g AN and 42.75g MMA into the glue solution, stir for 30-70 minutes to make the system a uniform solution. Add 1.0 g of BPO and 0.126 g of SDS into the flask, and stir for 30 minutes to make them evenly mixed. Begin to drop 63g of 2wt% PVA aqueous solution into the PEB / MMA-AN solution system, and the PVA aqueous solution will be added dropwise within 20 to 30 minutes, during which the stirring speed will be slowly increased to 8...

Embodiment 2

[0055] Table 2 (b) The relationship between the PEB / MMA-AN mass ratio of Example 2 and the CR, GR, GE and ABMS notched impact strength of the graft system

[0056]

[0057]

[0058] *PEB content of ABMS is 25wt% of ABMS.

Embodiment 3

[0061] Table 3 (b) The relationship between the amount of BPO in Example 3 and the CR, GR, GE and ABMS notched impact strength of the graft system

[0062]

[0063]

[0064] *PEB content of ABMS is 25wt% of ABMS.

[0065] Table 4 (a) embodiment 4 formula and reaction condition

[0066]

[0067] Table 4 (b) the relationship between the amount of solvent in Example 4 and the CR, GR, GE and ABMS notched impact strength of the graft system

[0068]

[0069]

[0070] *PEB content of ABMS is 25wt% of ABMS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com