Method for preparing impact modifier of polyvinyl chloride in new type nuclear shell structure

An impact modifier, the technology of polyvinyl chloride, applied in the field of new core-shell structure polyvinyl chloride impact modifier and its preparation, can solve the problem of poor weather resistance and impact toughness of polyvinyl chloride resin, high production cost, Difficulty in granulation and other problems, to achieve the effect of increasing interfacial bonding force, good dissipation of impact energy, and high toughening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

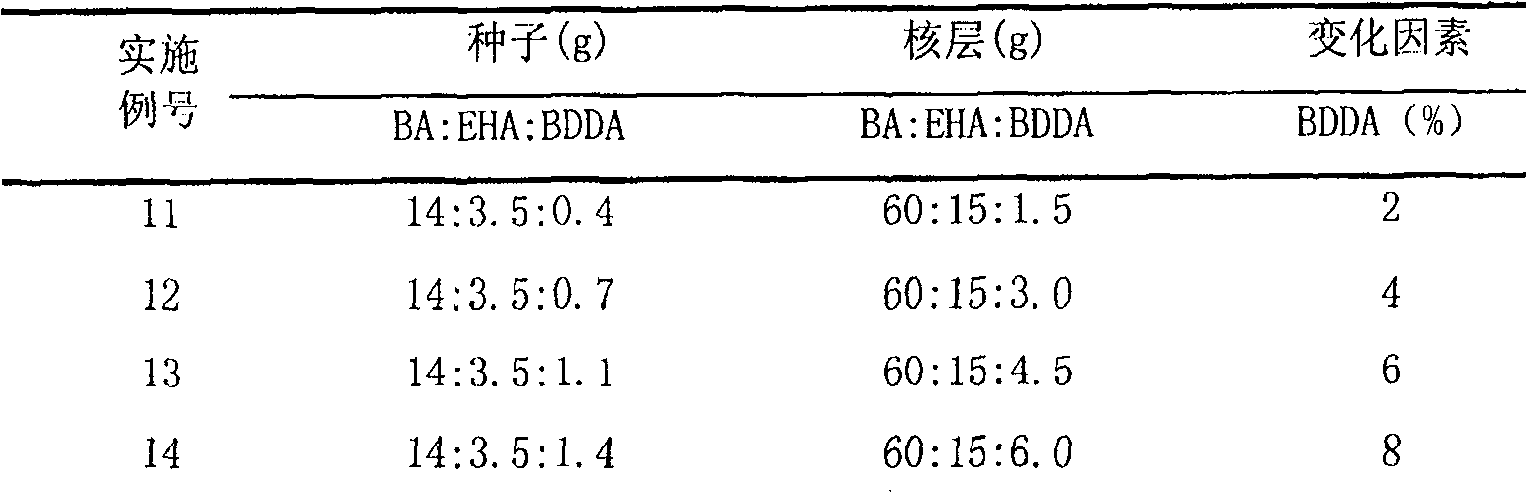

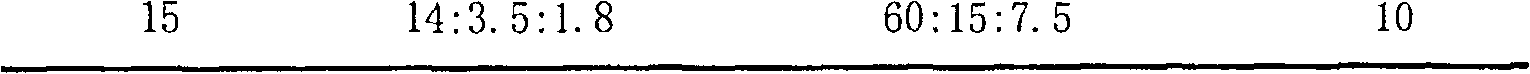

Embodiment 1

[0061] (1) Preparation of polyacrylate composite latex

[0062] Add 200ml of deionized water, 0.50g of emulsifier sodium dodecyl sulfate (SDS) and a mixture of seed comonomer and crosslinking agent (14g BA, 3.5 g EHA, 0.2g BDDA), stir at room temperature and blow nitrogen gas to make it fully emulsified. Then start the water bath to heat up, and at the same time pass cooling water to the reflux condenser. When the system temperature reaches 64℃, start adding 0.2g of the initiator potassium persulfate (K 2 S 2 O 8 ), at the beginning of the reaction, the system exotherms and heats up. When the temperature of the reaction solution is constant to 75°C, the reaction is kept for 1 hour. Complete the synthesis of seed emulsion.

[0063] After the heat preservation reaction, add 0.5g SDS of the emulsifier required for the core layer to the system at one time, and add or dropwise add 0.4g K of the initiator for the core layer formula to the system after 15-20 minutes. 2 S 2 O 8 At the sam...

Embodiment 2

[0074] In the preparation process of the composite latex (1), the crosslinking agent was changed to allyl methacrylate (ALMA), and the rest of the formula and operation were the same as in Example 1.

Embodiment 3

[0076] In the preparation process of the composite latex (1), the crosslinking agent was changed to dicyclopentenyl acrylate (DCPA), and the rest of the formula and operation were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com