High-impact wear-resistant transparent polystyrene composition as well as preparation method and application thereof

A technology of transparent polystyrene and high impact resistance, applied in the field of engineering plastics, can solve the problems of low economic value and feasibility of large-scale production, ineffective improvement of GPPS toughness, insignificant improvement in wear resistance of materials, etc., to achieve increased Dispersion residence time, reduction of adverse effects, fine dispersion particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

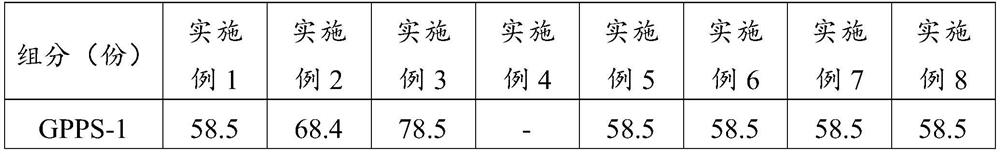

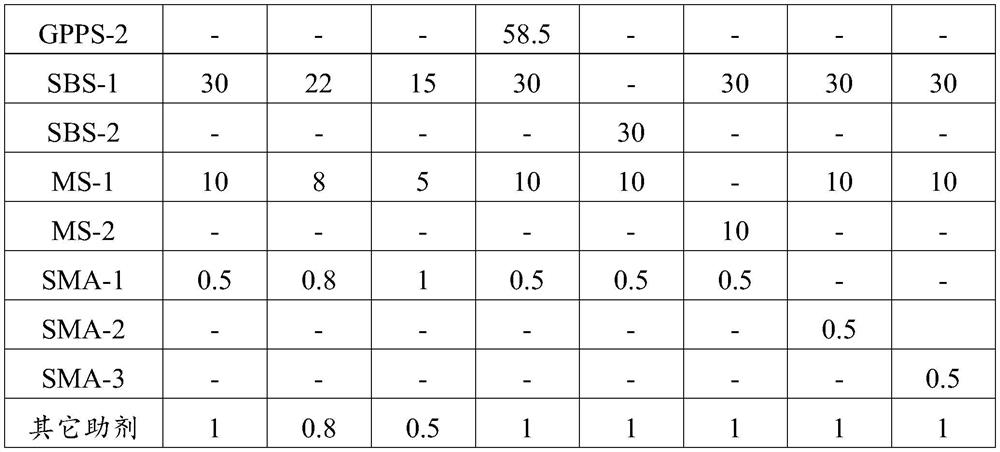

[0038] Examples 1 to 8 provide a high-impact and wear-resistant transparent polystyrene composition, and its composition in parts by weight is shown in Table 1. The preparation method is as follows: Weigh each raw material component according to the formula, put all the components into the mixer, mix at a speed of 1000rpm for 5 minutes, take it out, and then plasticize the mixed raw material through a twin-screw extruder, extrude and pelletize , to obtain a high-impact wear-resistant transparent polystyrene composition. Wherein, the temperature of each section of the twin-screw extruder is 180-190° C., and the screw speed is 350-400 rpm.

[0039] Comparative Examples 1-5 provide a polystyrene composition, the formula of which is shown in Table 1 in parts by weight, and the preparation method refers to the preparation method of Examples 1-8. Wherein, the temperature control and the screw speed of the twin-screw extruder of Comparative Examples 1-5 are the same as that of Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com