Preparation method of enteric capsule coating material polyacrylic resin II and method for preparing enteric capsule by using enteric capsule coating material polyacrylic resin II

A technology of polyacrylic acid resin and coating materials, which is applied in the direction of capsule delivery, medical preparations of non-active ingredients, pharmaceutical formulas, etc. It can solve problems such as uneven distribution, large molecular weight, and unqualified capsule friability, and achieve technological The effect of stability, uniform molecular weight distribution, and simple coating formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

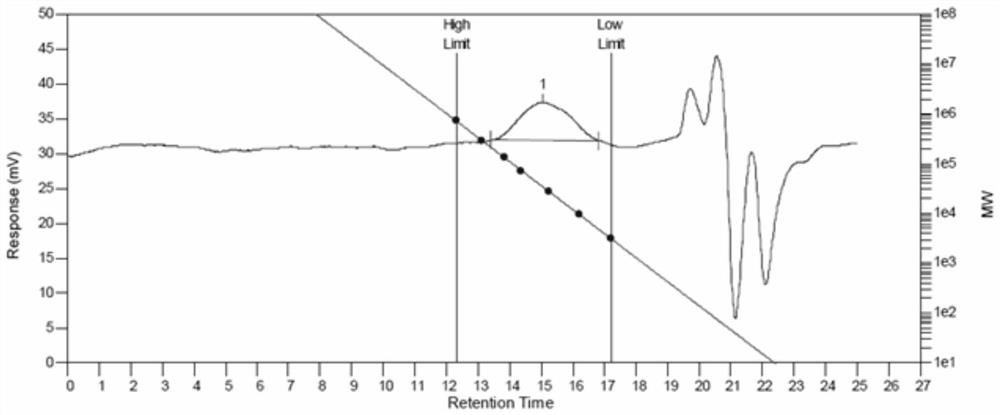

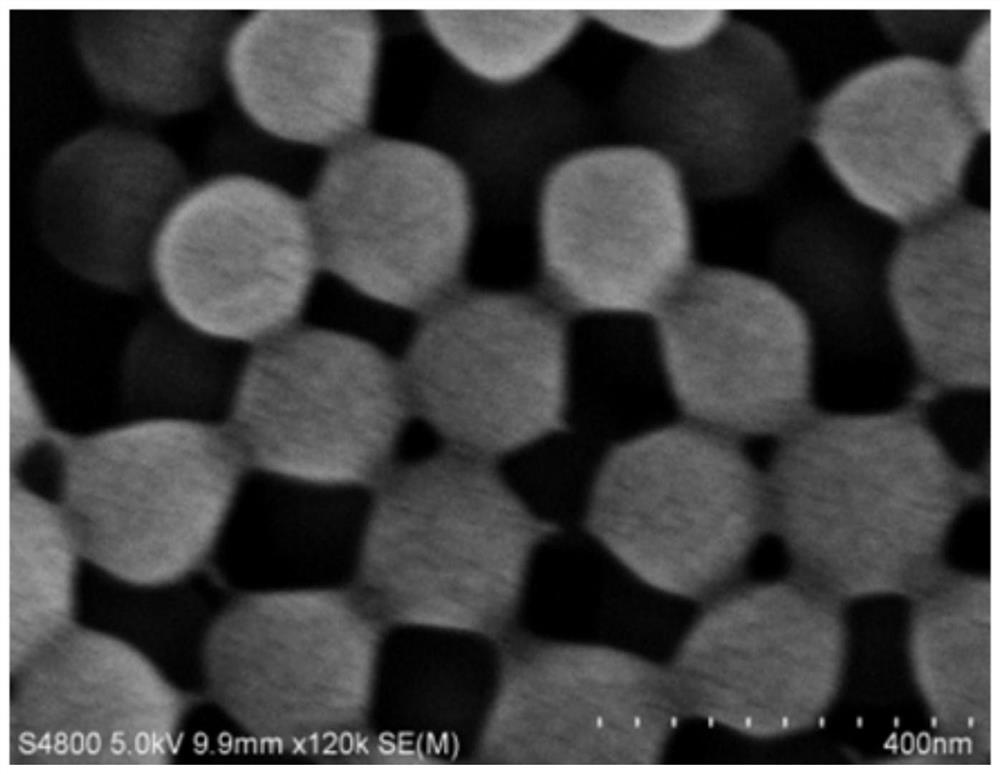

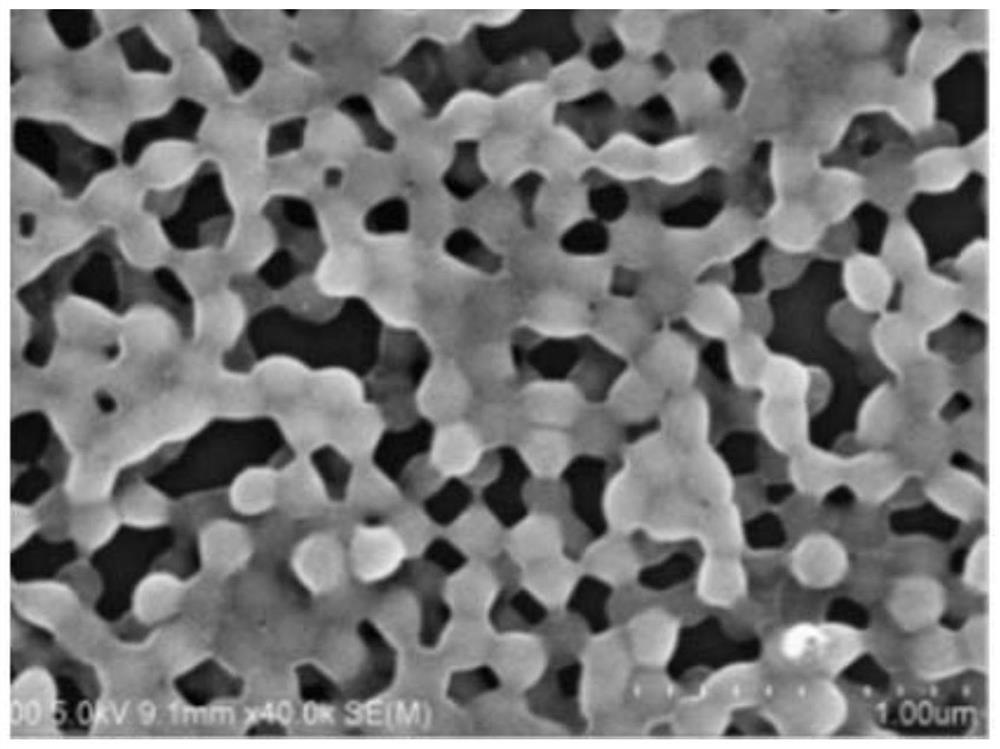

Image

Examples

Embodiment 1

[0043] A preparation method of enteric capsule coating material polyacrylic acid resin II, comprising the following steps:

[0044] (1) SDS 0.2795g, NaHCO 3 Add 0.1380g, 0.8115g of OP-10 into 180mL of deionized water, sonicate until completely dissolved, then add 0.2750g of potassium persulfate until completely dissolved to obtain reaction solution 1;

[0045] (2) Mix 35mL of MAA, 37.5mL of MMA, and 0.5mL of α-methylstyrene linear dimer, and sonicate until the mixture is uniform to obtain reaction solution 2, which is then heated to 70°C;

[0046] (3) Under the protection of nitrogen, add the reaction solution 1 dropwise to the reaction solution 2, the dropping time is controlled at 2.0h, and after the dropping is completed, keep the temperature at 70°C for 2.5h;

[0047] (4) Obtain a uniform white milky solution after the heat preservation finishes, then place it in a blast drying oven at 60° C. for drying, and then ball mill and pulverize to prepare the white powder of pol...

Embodiment 2

[0053] Others are the same as in Example 1, only changing the temperature in steps (2) and (3) to be 55°C, 60°C, 65°C, 75°C, 80°C, 85°C, 90°C respectively, the polyacrylic resin II prepared finally Productive rate is respectively 41%, 58%, 65%, 68%, 68%, 60%, 55%; The curve figure of reaction temperature and productive rate is as Figure 5 As shown, it can be seen from the figure that the yield of the reaction is higher when the reaction temperature is 70°C, and the yield will decrease if the temperature is lower than or higher than this interval. Considering factors such as energy saving and economy, this paper The optimal reaction temperature for application is 70°C.

Embodiment 3

[0055] Others are the same as Example 1, but the heat preservation time is respectively 0h, 0.5h, 1.0h, 1.5h, 2.0h, 3.0h, 3.5h in the change step (3), and the productive rate of the polyacrylic acid resin II prepared finally is respectively 30 %, 48%, 61%, 64%, 68%, 70%, 70%, the curves of holding time and yield are as follows Figure 6 As shown, it can be seen from the figure that with the increase of the holding time, the yield increases continuously, but the increasing trend decreases to the maximum value and then tends to be stable. This shows that the holding time in the early stage has a great influence on the yield of the product, and the later stage The heat preservation time has less influence on the product yield, and the heat preservation time can be selected to be 2 to 2.5 hours, preferably 2.5 hours, in consideration of economical factors during production.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com