Room temperature crosslinked polyacrylate elastomer and preparation method thereof

A technology of polyacrylate and acrylate, which is applied in the field of cross-linkable polyacrylate elastomer at room temperature and its preparation, can solve the problems of low glass transition temperature, hardness and heat resistance, fluidity and processing performance, etc. Achieve low viscosity, excellent processability, controllable structure and molecular weight

Inactive Publication Date: 2019-01-22

CHANGZHOU UNIV

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, since its hard segment is polymethyl methacrylate, its glass transition temperature is low, which affects its hardness and heat resistance.

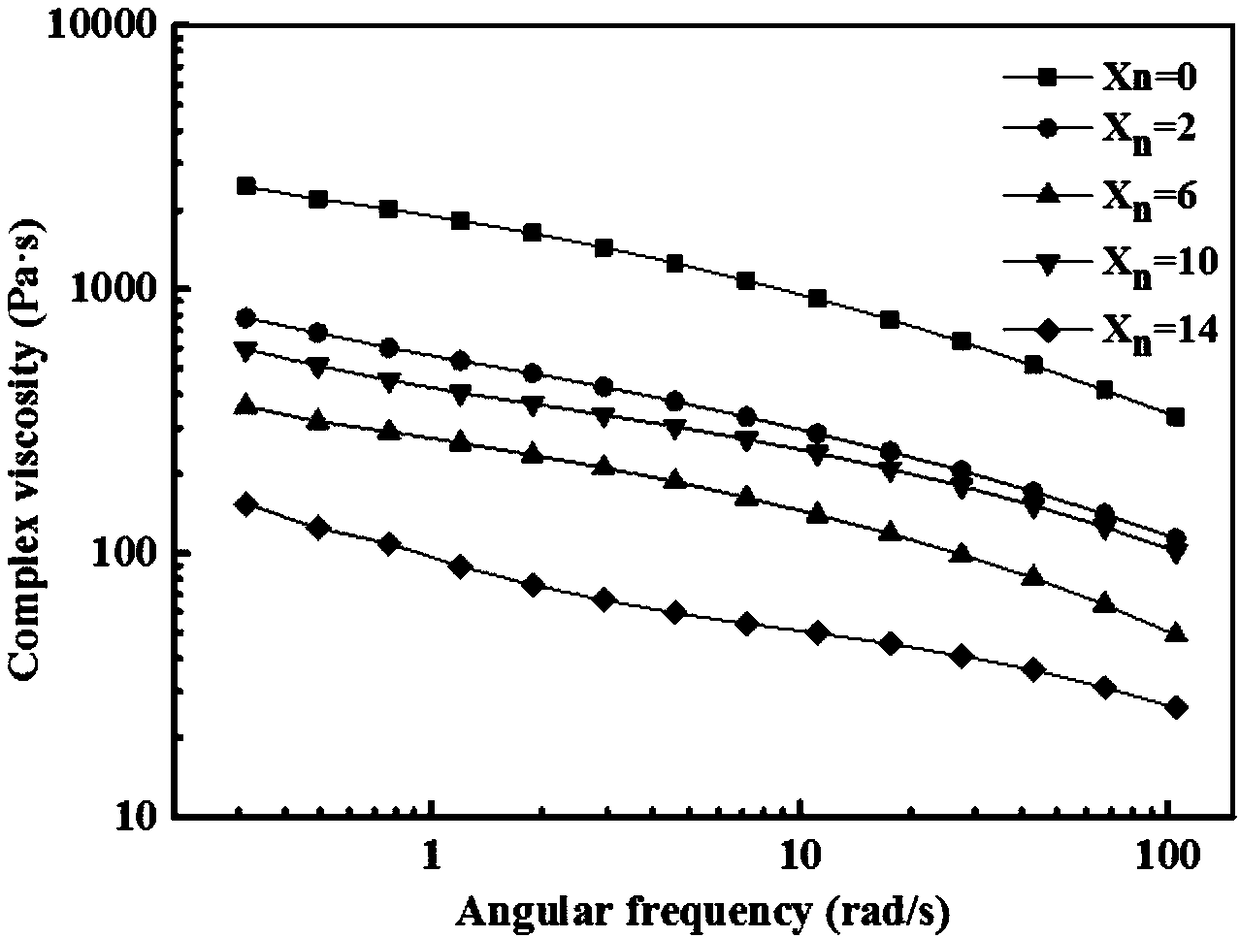

On the other hand, to make polyacrylate elastomer have excellent performance, its molecular weight must be large enough, but this will affect its fluidity and processing performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0029] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

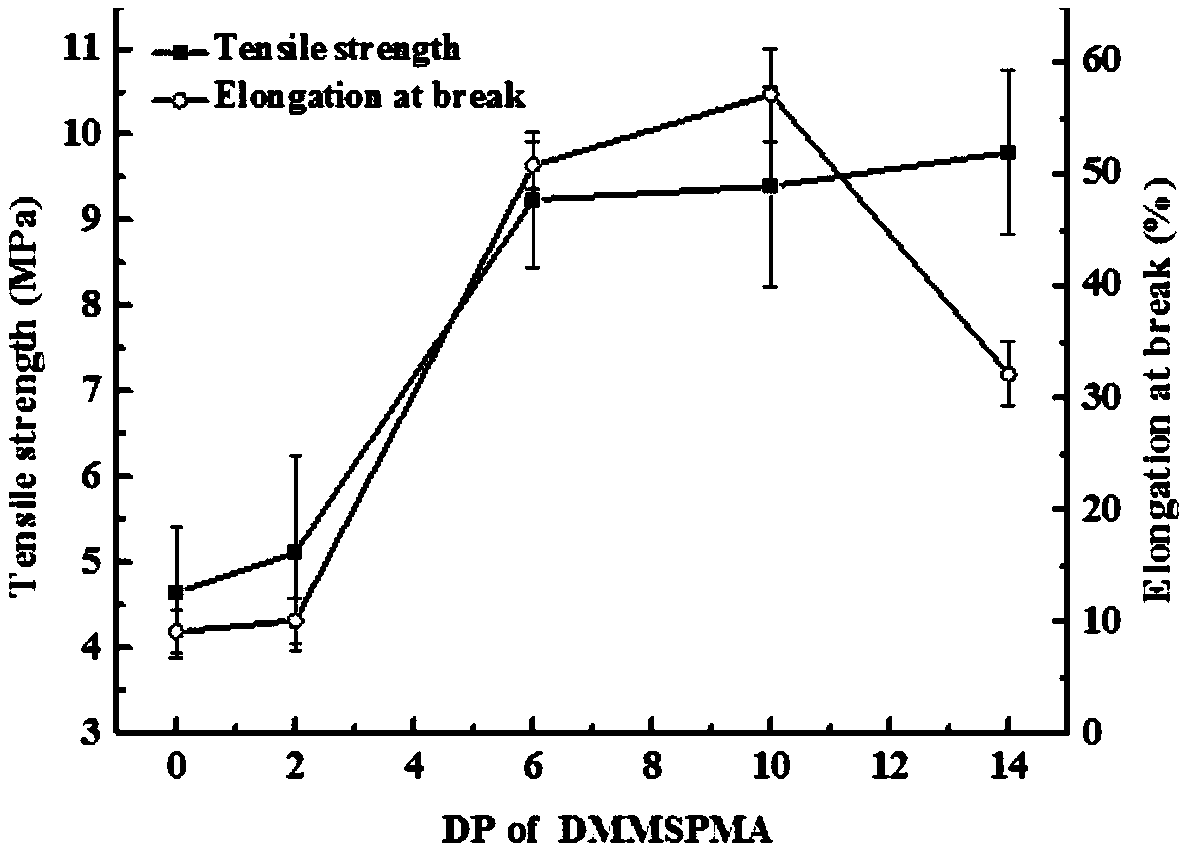

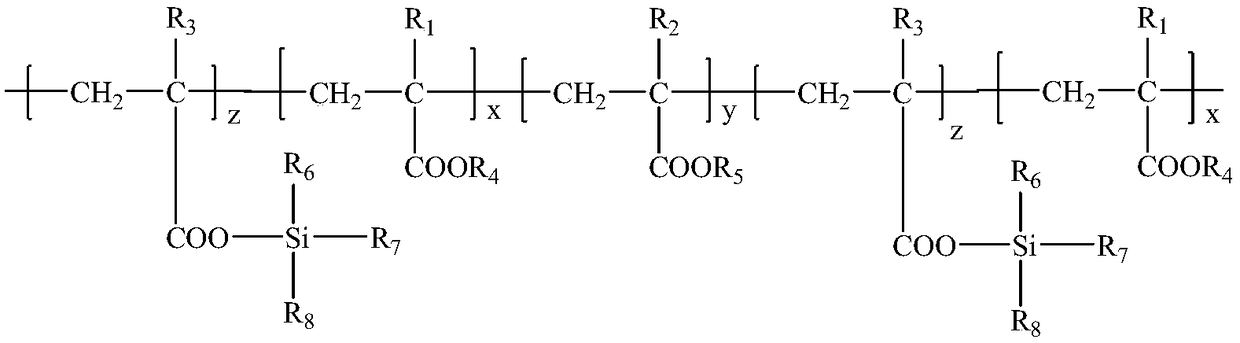

The invention relates to a room temperature crosslinked polyacrylate elastomer and a preparation method thereof. Firstly, a bifunctional polyacrylate macroinitiator is synthesized; and then, the macroinitiator reacts with an allyl monomer or a silane monomer to obtain the room temperature crosslinked polyacrylate elastomer. The invention has the following beneficial effect: the polyacrylate elastomer prepared by the method contains siloxane groups and can be cured at room temperature; the obtained polyacrylate elastomer has the advantages of low viscosity, controllable structure and molecularweight, excellent processability, high strength after curing, good aging resistance, etc.

Description

technical field [0001] The invention relates to the fields of adhesives, coatings, elastomers and the like, in particular to a normal-temperature crosslinkable polyacrylate elastomer and a preparation method thereof. Background technique [0002] Styrene is the most widely used traditional thermoplastic elastomer, such as styrene-isoprene-styrene (SIS) copolymer, styrene-butadiene-styrene (SBS) copolymer and their hydrogenation Objects SEPS, SEBS, etc. Due to their two-phase structure, polystyrene hard segments form physical crosslinks that increase the cohesion and hardness of the elastomer. The poly(iso)butadiene segment acts as a soft segment, endowing the elastomer with excellent elasticity. However, due to the presence of double bonds in the poly(iso)butadiene segment, its oxidation resistance, aging resistance and transparency are affected. Polyacrylate elastomers generally use polymethyl methacrylate as the hard segment and polybutyl acrylate as the soft segment bl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F293/00

CPCC08F293/005

Inventor 李坚吴婷徐慧任强汪称意

Owner CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com