Method for preparing catalyst and dihydroxyl-terminated polyether polyol

A catalyst and polyol technology, applied in the field of polyether polyol synthesis, can solve problems such as irritating odor and abnormal chromaticity of polyether polyol, and achieve suppression of side reactions, simple polymerization method and system, and good molecular weight and molecular weight distribution. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~31

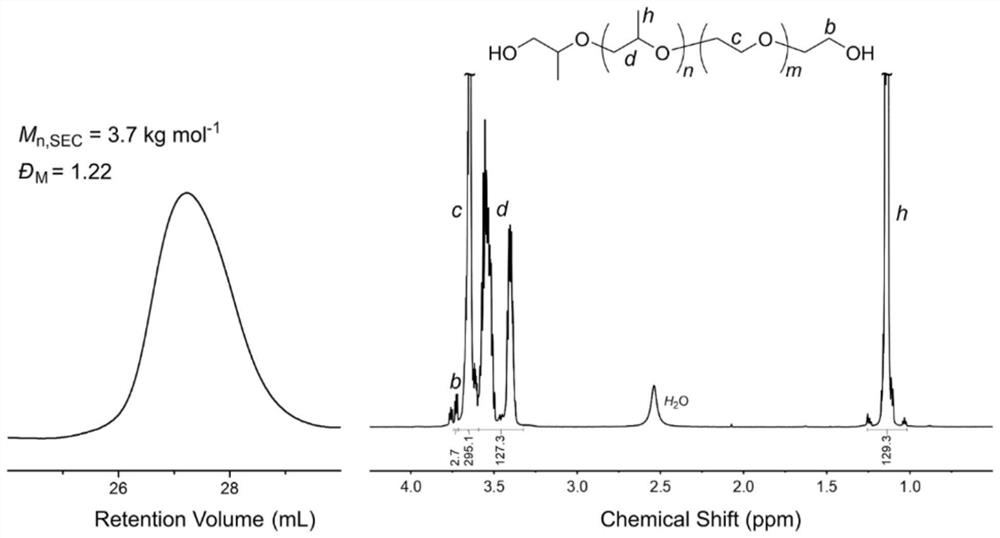

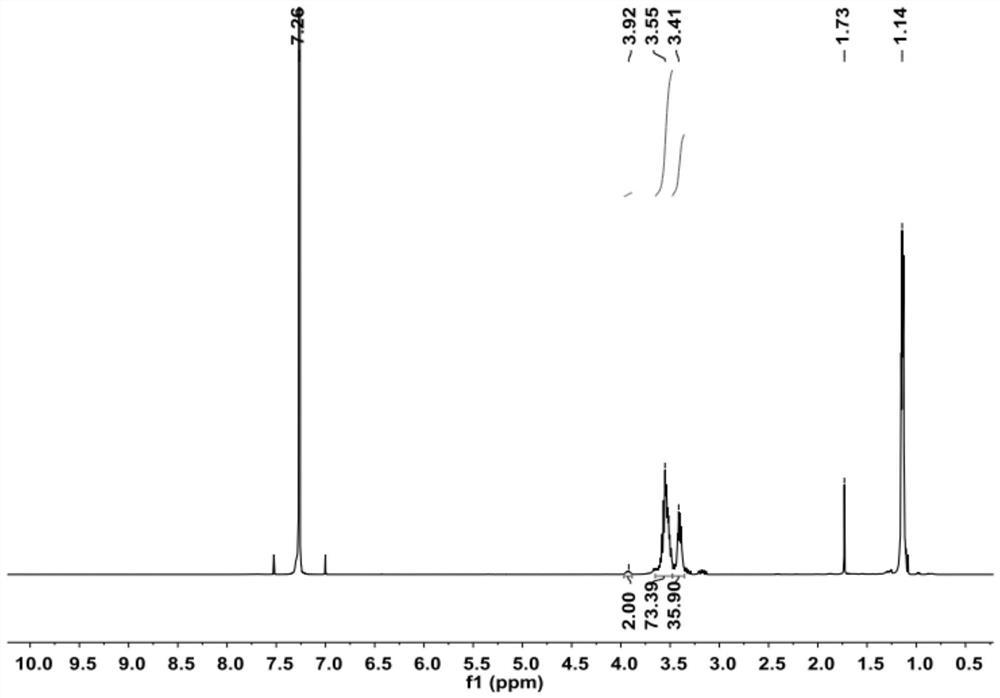

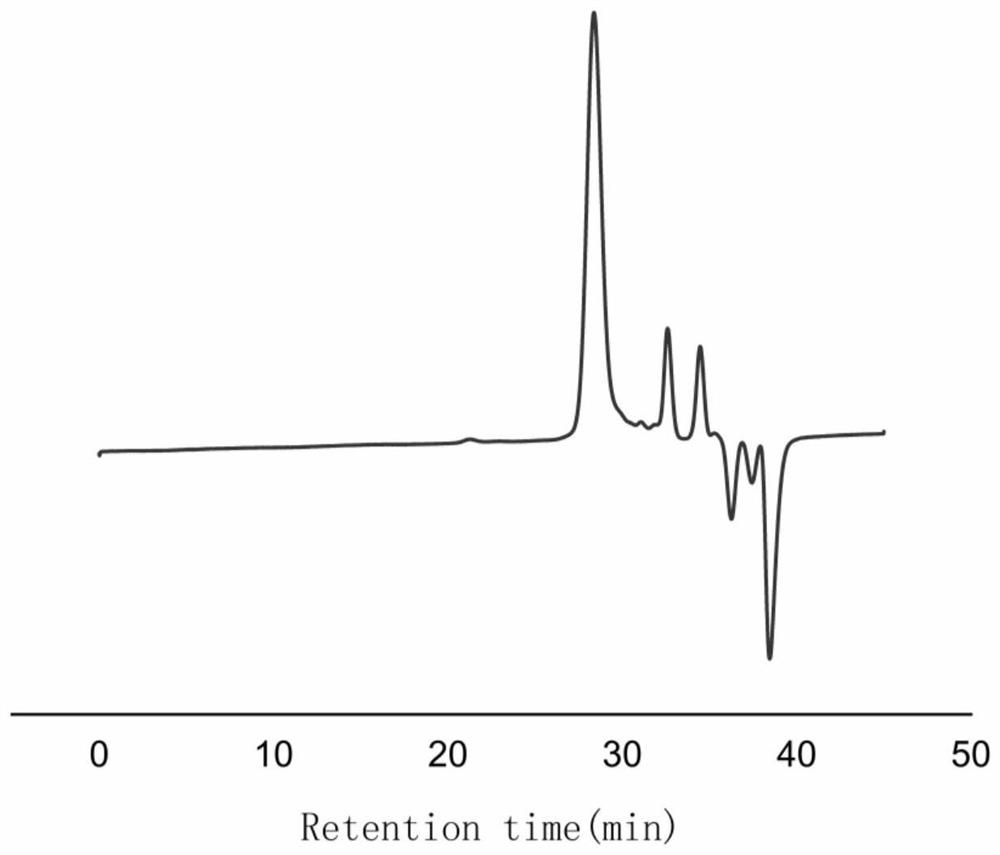

[0050] Examples 1-31 Ring-opening polymerization of propylene oxide

[0051] Set in a glove box, weigh the initiator, sodium hydride, phosphorus salt, propylene oxide, and weigh into a 10 mL pressure-resistant bottle vial equipped with a magnetic stirrer that has been flame-dried in advance. Seal the vial and take out the heating reaction. Set -20~45℃ as the reaction temperature, the molar ratio of propylene oxide, initiator, phosphorus salt and sodium is 10000:1:0.1:0.1-100:1:0.01:0.01, and the reaction time is controlled at 0.3~72h. The specific operations of Examples 1 to 31 are as follows, and the key data are arranged in Table 1.

Embodiment 1

[0053] In a 100mL pressure bottle, add H 2 O (0.1 mmol, 1.8 μL, 1 equiv), sodium hydride (10 μmol, 0.24 mg, 0.1 equiv), phosphorus salt (10 μmol, 5.9 mg, 0.1 equiv), followed by propylene oxide (1 mol, 67.6 mL, 10000 equiv) , the reaction mixture was stirred for 48h, the reaction temperature was 0°C, the number-average molecular weight Mn measured by GPC was 390,000 g / mol, and the molecular weight distribution is 1.12.

Embodiment 2

[0055] In a 100mL pressure bottle, add H 2 O (0.1 mmol, 1.8 μL, 1 equiv), sodium hydride (10 μmol, 0.24 mg, 0.1 equiv), phosphorus salt (10 μmol, 5.9 mg, 0.1 equiv), followed by propylene oxide (0.5 mol, 33.8 mL, 5000 equiv) ), the reaction mixture was stirred for 24 h, the reaction temperature was 0 °C, the number-average molecular weight Mn measured by GPC was 189000 g / mol, and the molecular weight distribution is 1.13.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com