Patents

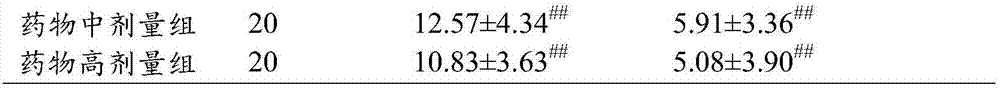

Literature

49 results about "Middle molecular weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The middle molecule (MM) hypothesis states that molecules in the molecular weight range of 500 to 2000 daltons/molecule accumulate in uremia and are one cause of peripheral neuropathy.

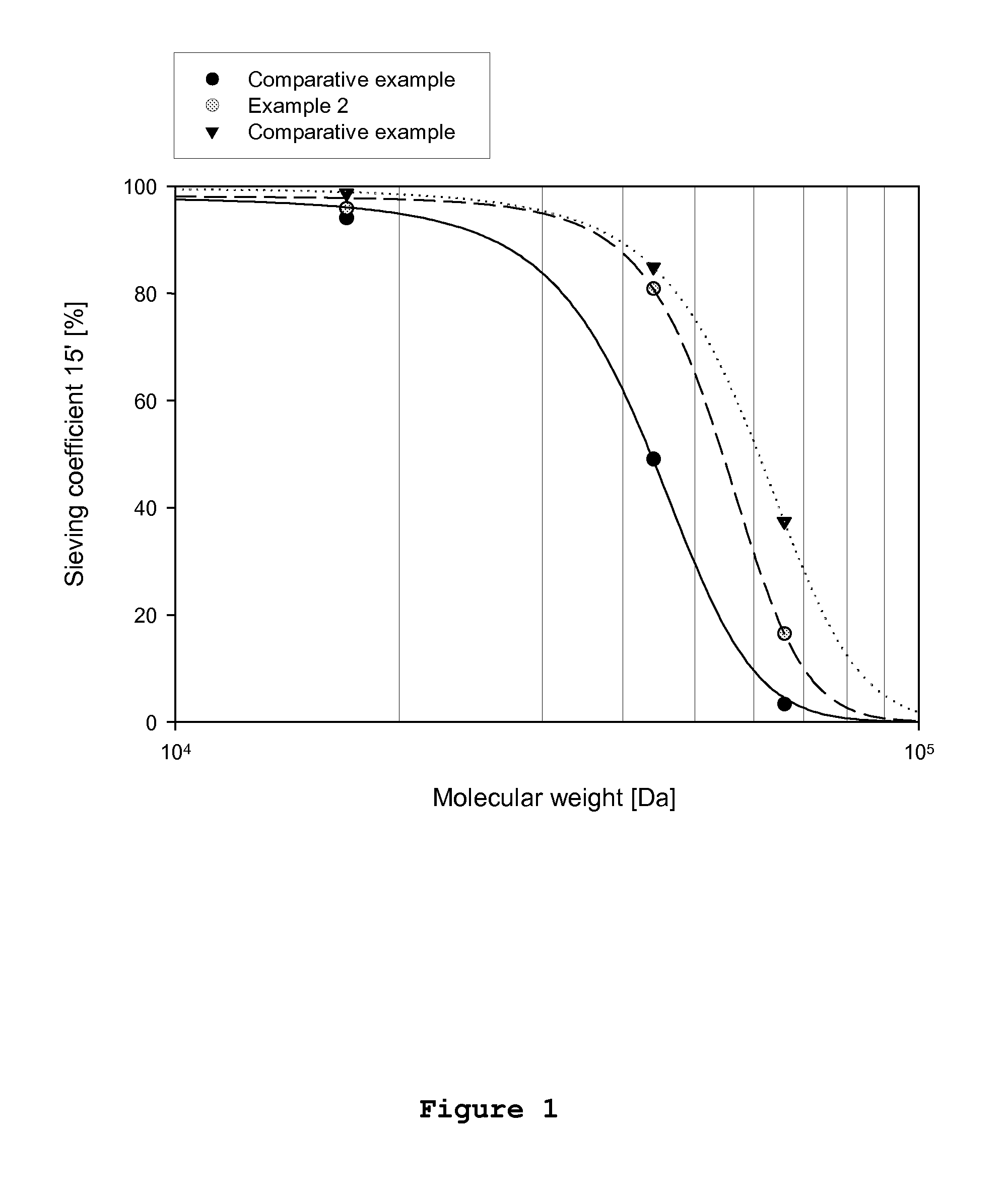

Membranes having improved performance

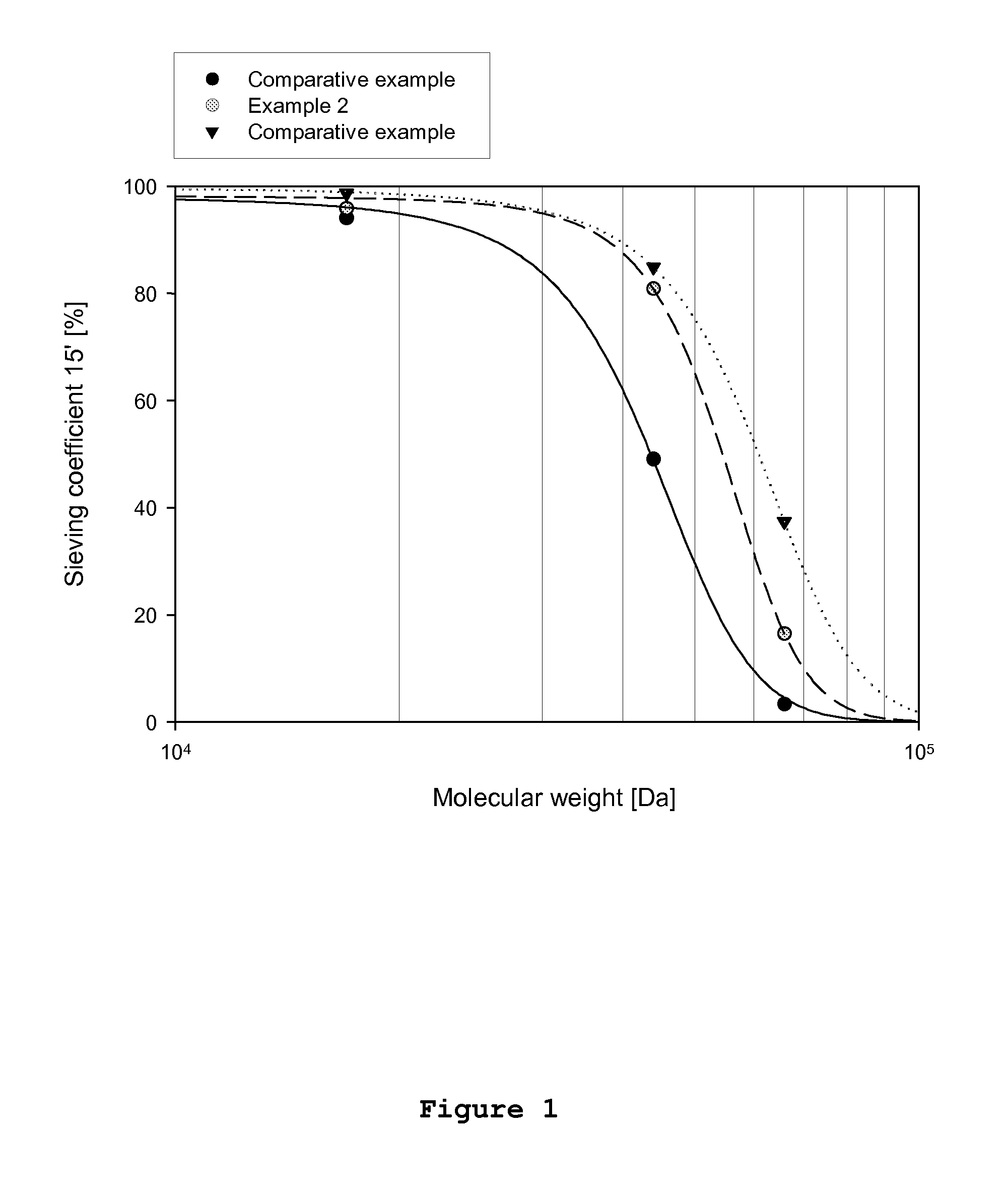

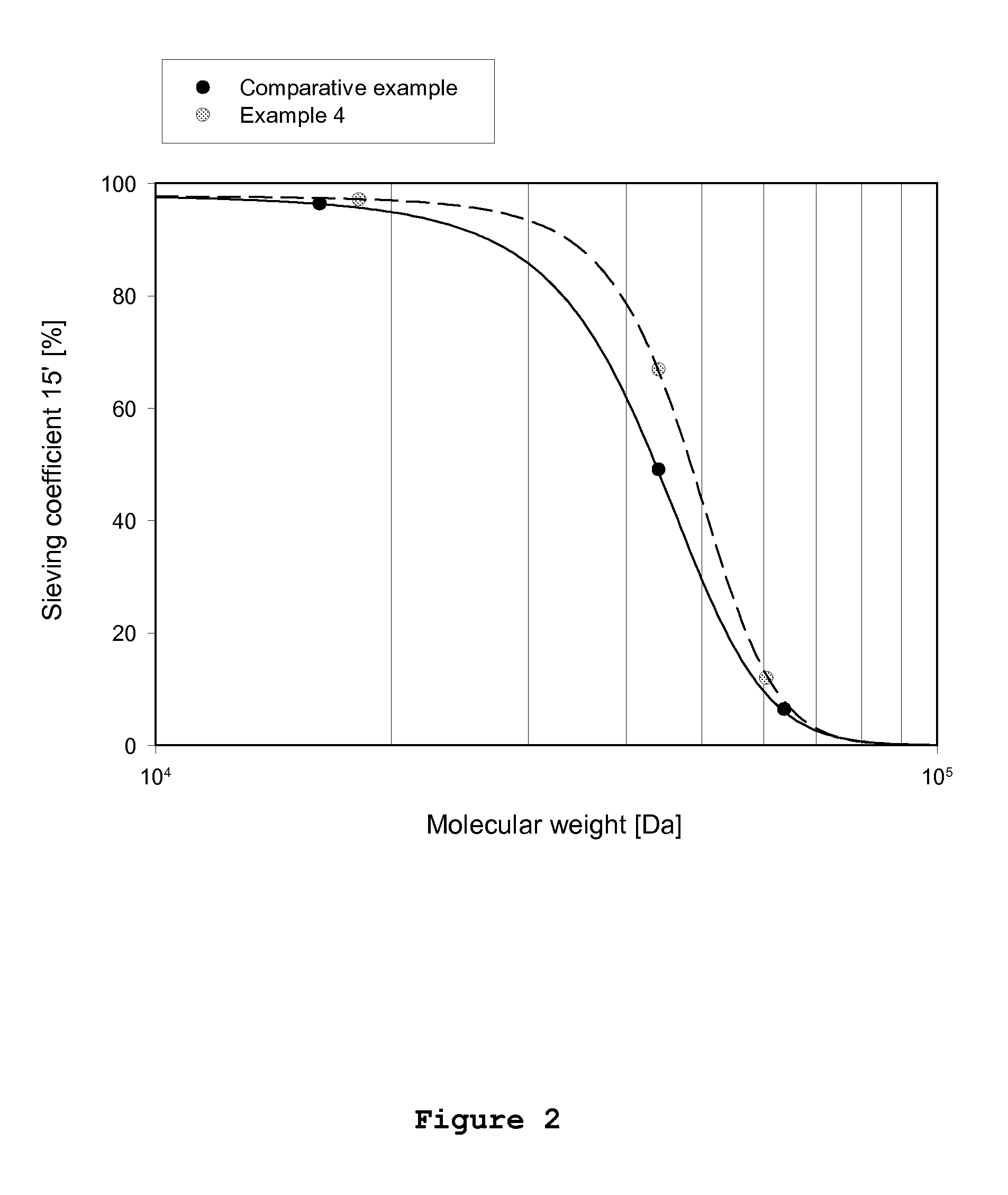

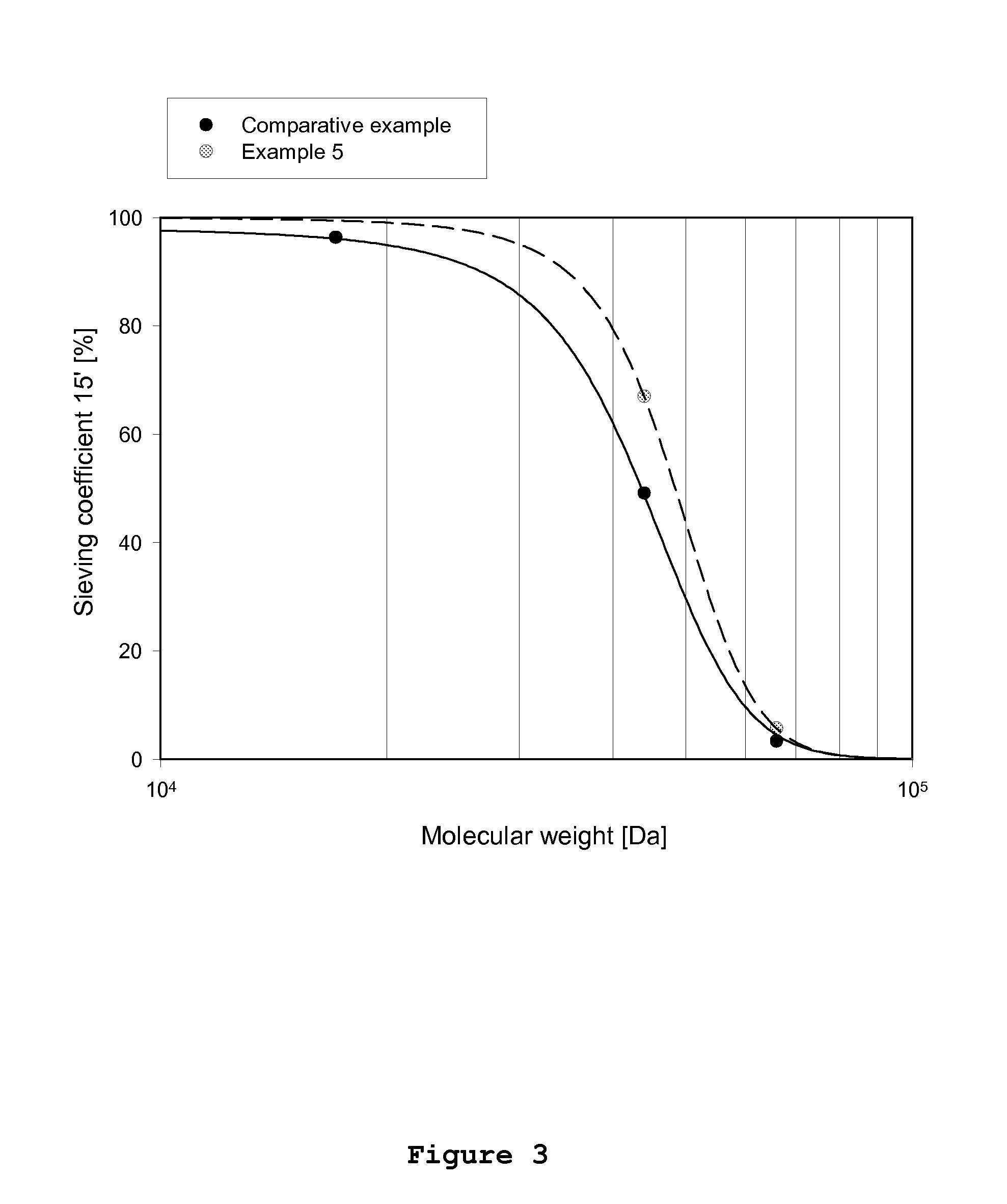

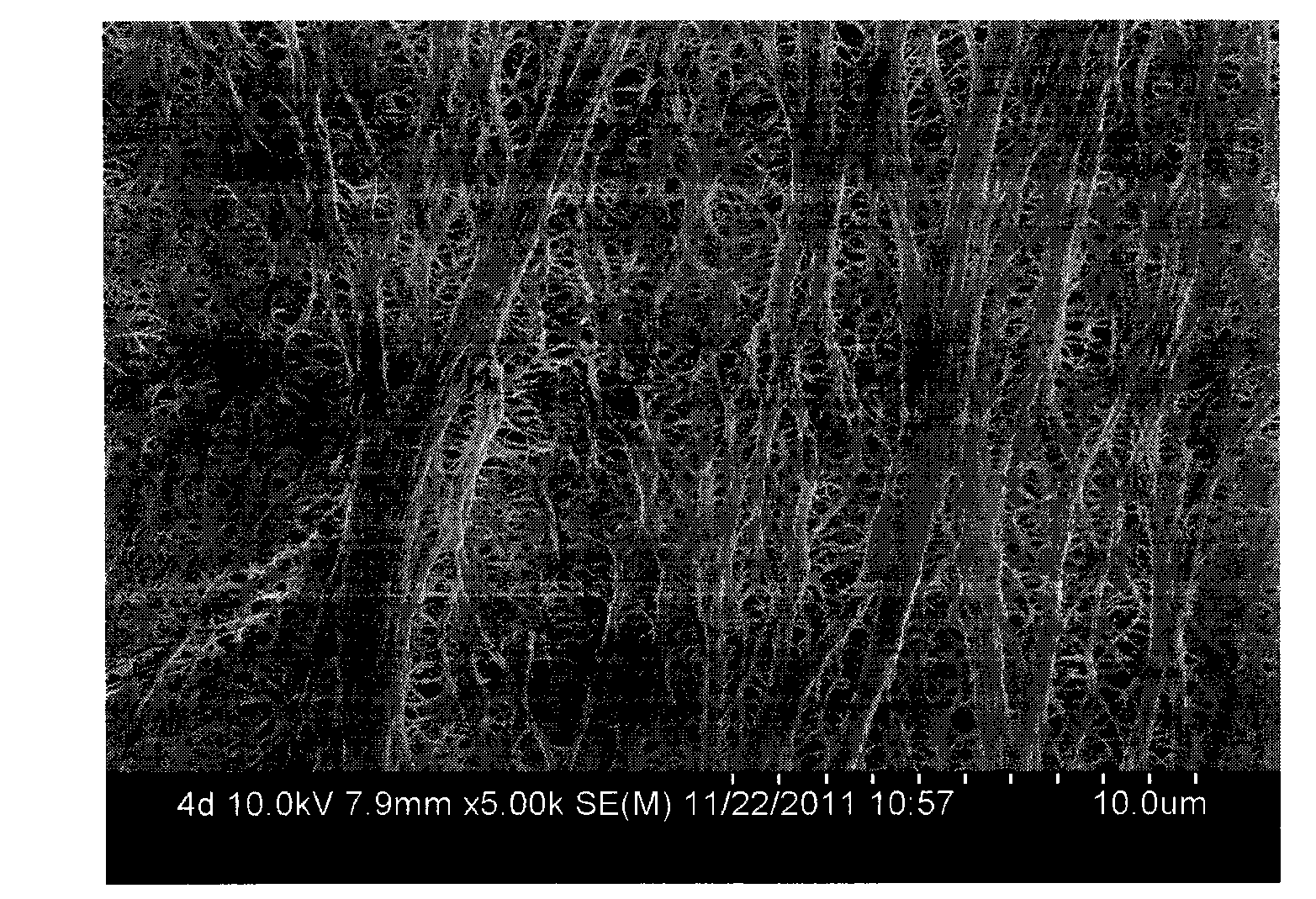

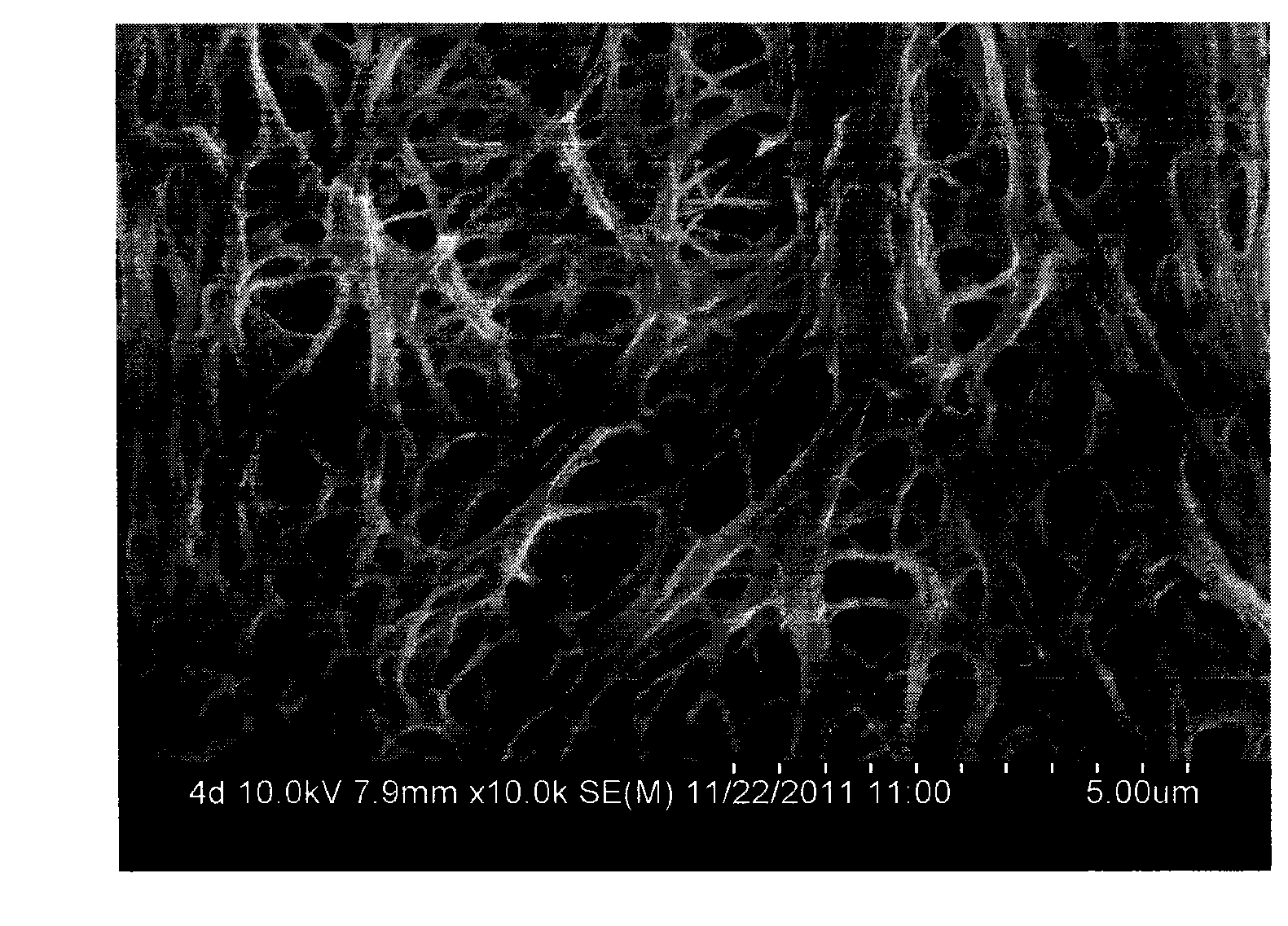

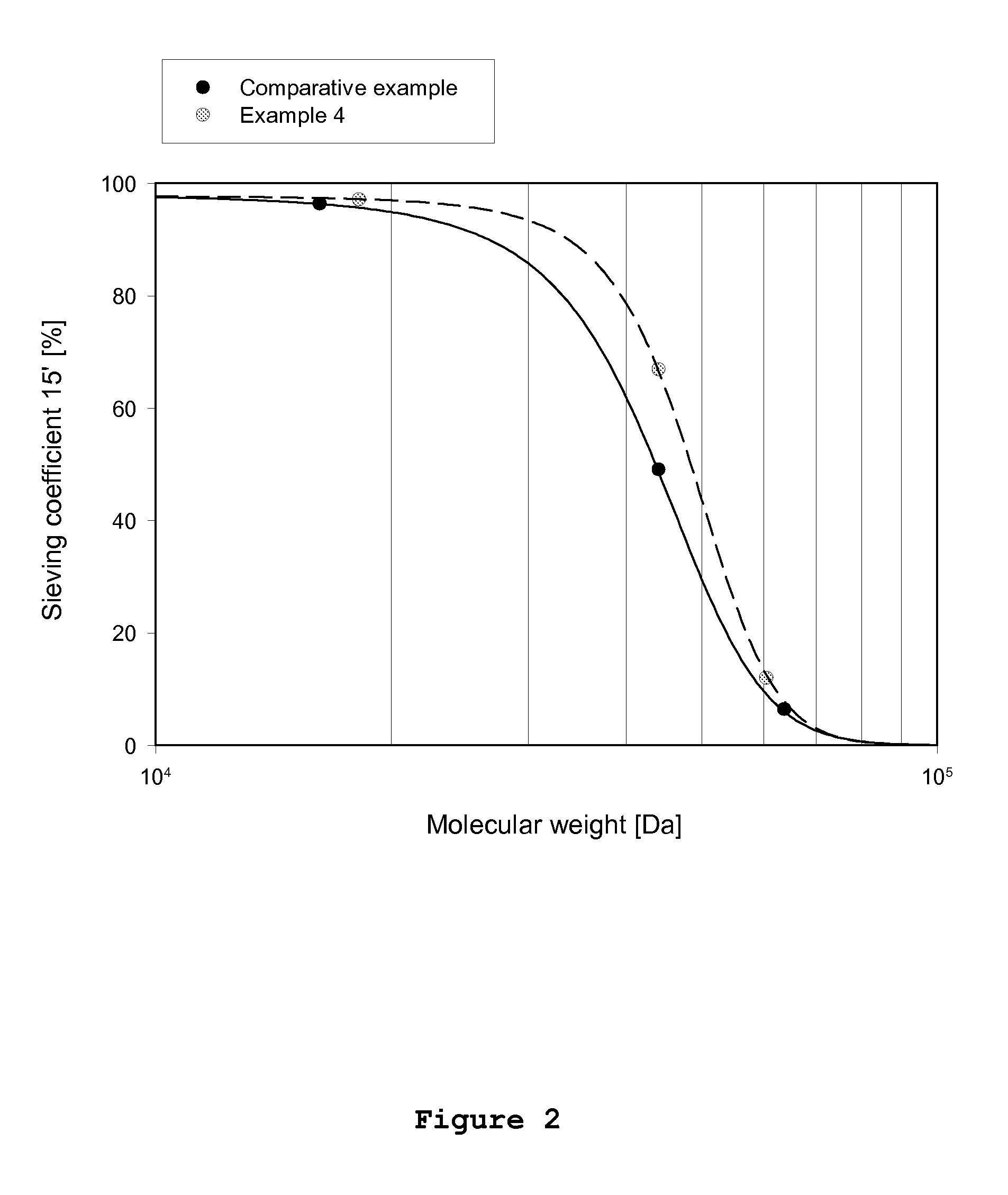

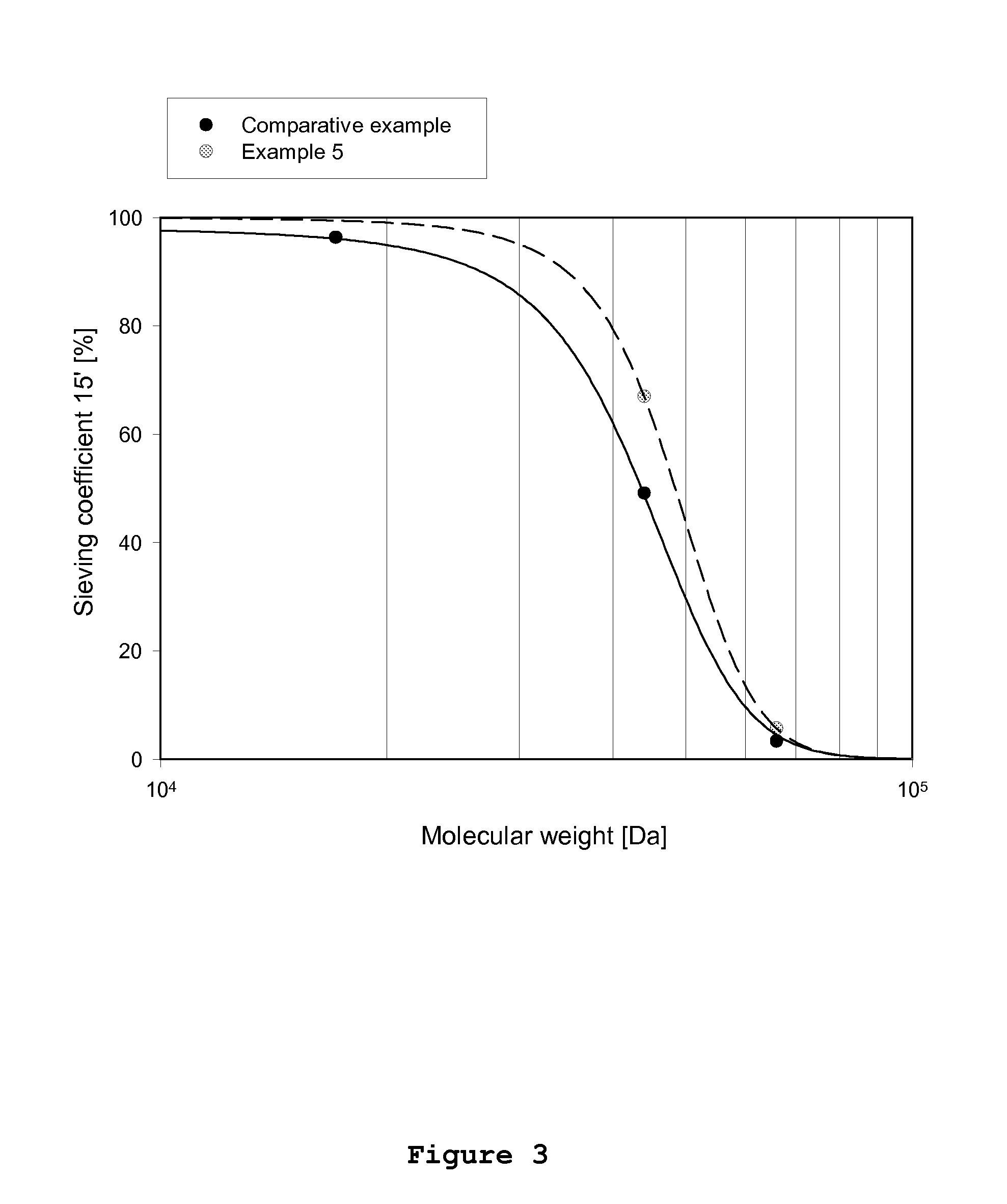

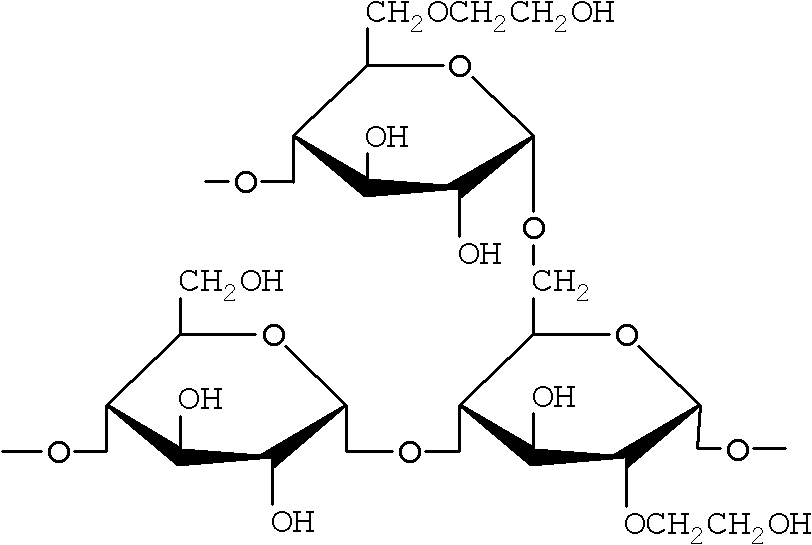

ActiveUS20120074063A1Improve performanceInflammatory mediatorSolvent extractionDialysisPhosphoryl cholineProtein solution

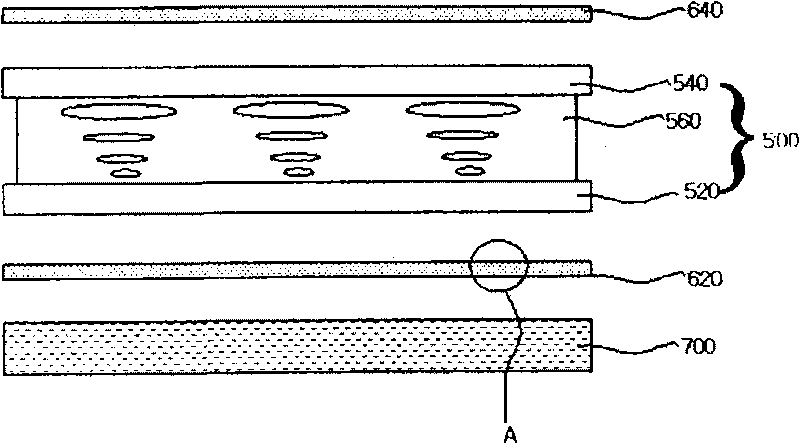

Permselective asymmetric membranes suitable e.g. for hemodialysis, hemodiafiltration and hemofiltration of blood, and having improved sieving characteristics providing enhanced removal of middle molecular weight substances, e.g. inflammatory mediators having a molecular weight between 20 and 40 kDa. The membranes comprise polyethersulfone and polyvinylpyrrolidone and are coated with hyaluronic acid or copolymers of 2-methacryloyloxyethyl phosphoryl choline and other vinyl polymerizable monomers. Processes for the preparation of these membranes, devices comprising these membranes, and the use of these membranes in hemodialysis, hemodiafiltration and hemofiltration of blood, as well as in bioprocessing, plasma fractionation and the preparation of protein solutions.

Owner:GAMBRO LUNDIA AB

Flexible gel particle and flexible gel particle plugging agent prepared from the same

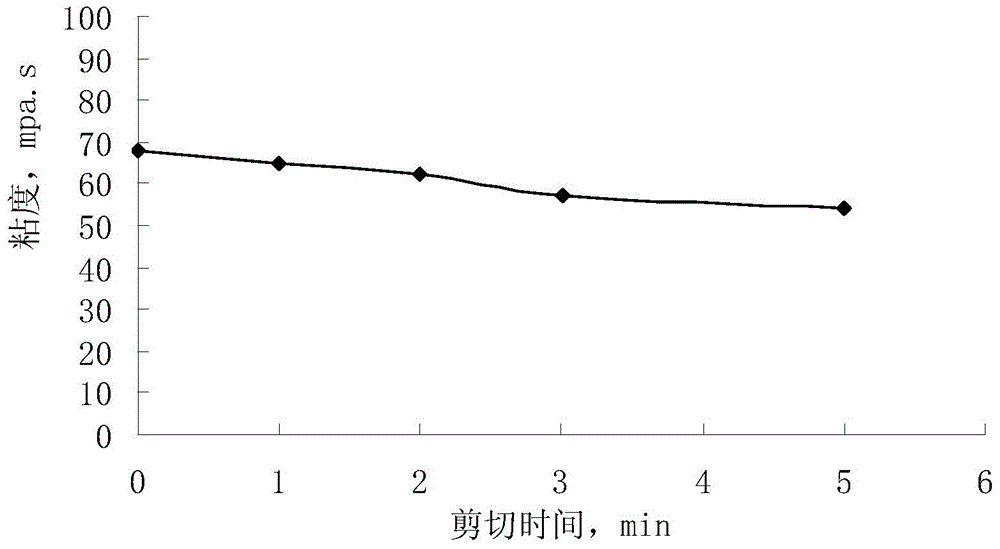

ActiveCN104910882ALow costSimple preparation processDrilling compositionPlasticizerMiddle molecular weight

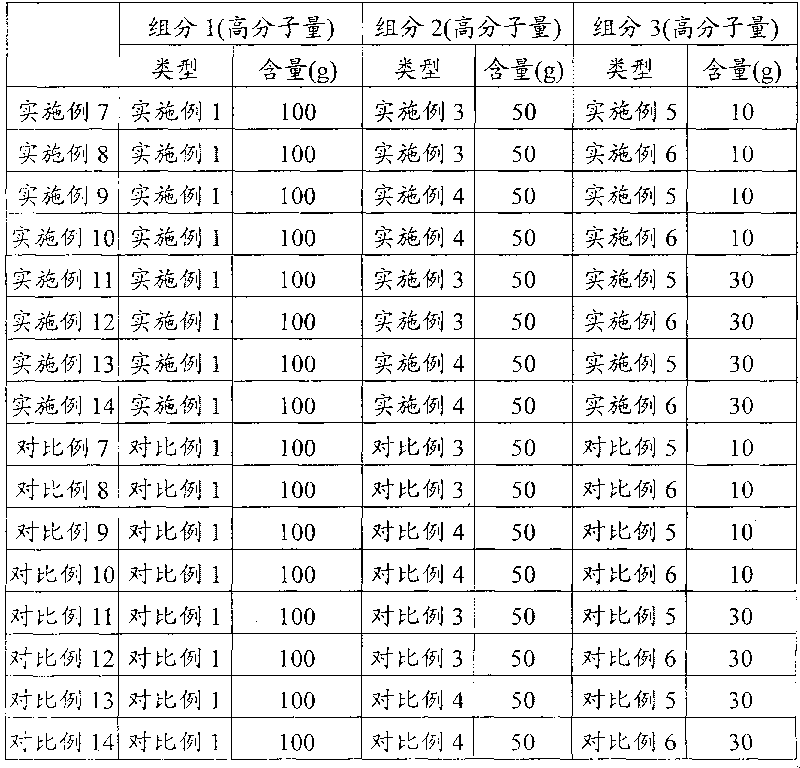

The present invention provides a flexible gel particle and a flexible gel particle plugging agent prepared from the same. The raw materials for preparing the gel particle comprise, by weight, 6-12wt% of acrylamide, 3-12wt% of temperature tolerant monomer, 5-15wt% of alkali and salt resistant monomer, 0.2-1wt% of partially hydrolyzed polyacrylamide with high and middle molecular weight, 0.02-0.08wt% of an initiator, 0.04-0.1wt% of a crosslinking agent, 0.01-0.1wt% of a retarder, 1-8wt% if a plasticizer and the balance of water. The temperature tolerant monomer includes Si-O bond monomer; the alkali and salt resistant monomer includes acrylate monomer; and the partially hydrolyzed polyacrylamide with high and middle molecular weight has number-average molecular weight of 8-16 million. The flexible gel particle is prepared into a suspension with certain concentration by water or polyacrylamide solution, so as to prepare the flexible gel particle plugging agent. The flexible gel particle plugging agent provided by the invention has the advantages of environment-friendliness, low cost, little pollution to the stratum, no toxicity, and simple preparation process.

Owner:PETROCHINA CO LTD

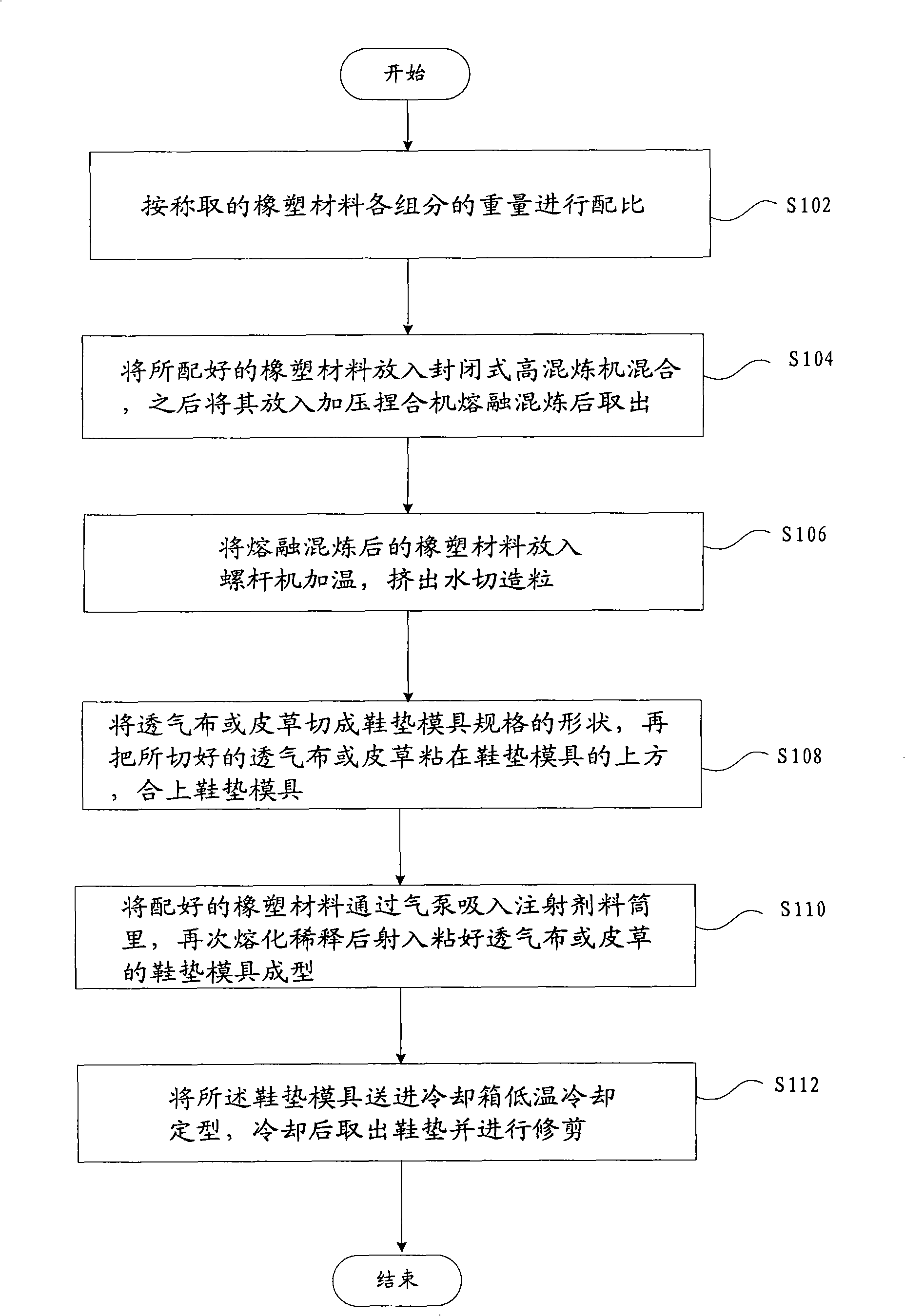

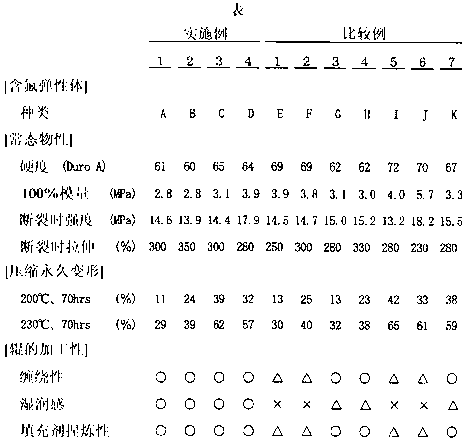

Rubber plastic material for producing shoe pad, shoe pad and manufacturing method thereof

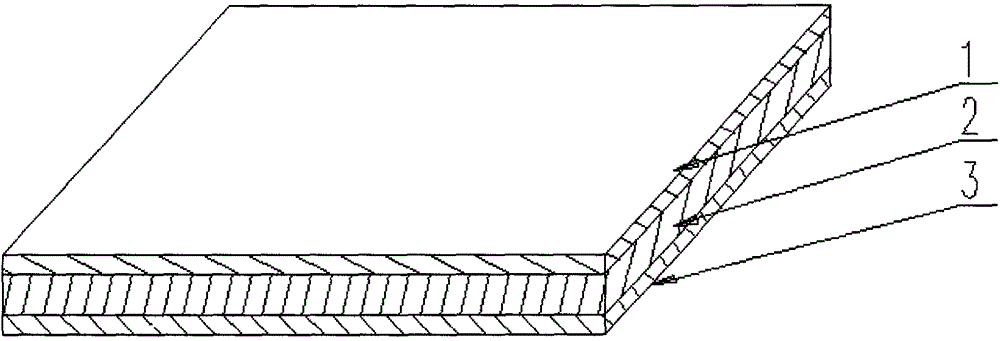

The invention provides a rubber and plastic material used for manufacturing insoles, which comprises copolymer A type SEBS composed of high molecular weight styrene (S)-ethylene (E) and butylene (B)-styrene (S), copolymer B type SEBS composed of middle molecular weight styrene (S)-ethylene (E) and butylene (B)-styrene (S), plasticizer, polyurethane, compatilizer, chemical inhibitor, and inorganic minerals. The invention also provides insoles, which comprises two layers which are an upper layer and a lower layer; wherein, the upper layer is a breathable cloth layer or a fur layer, and the lower layer is a rubber and plastic layer made of rubber and plastic materials. The invention manufactures the insoles by adopting the rubber and plastic materials, can obtain ideal mechanical property and fluidity, and overcomes the problem that the existing insoles loss the elasticity after being used for a period of time to give rise to the reduction of anti-seismic performance, and simultaneously the bottom of the insoles becomes smoothness after being squeezed and deformed to bring about inconvenience for users.

Owner:晋江市蓝牙高分子科技开发有限公司

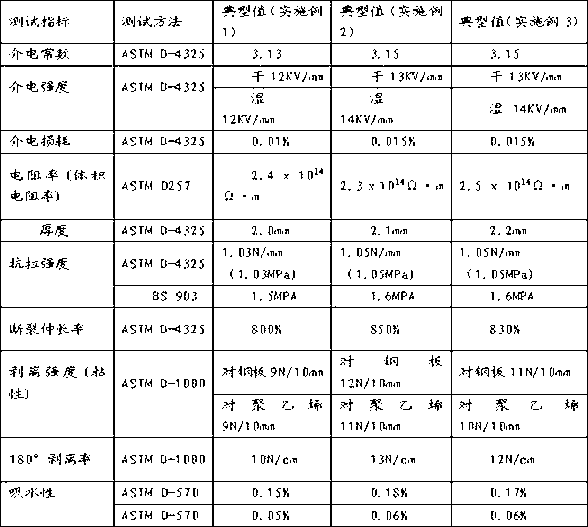

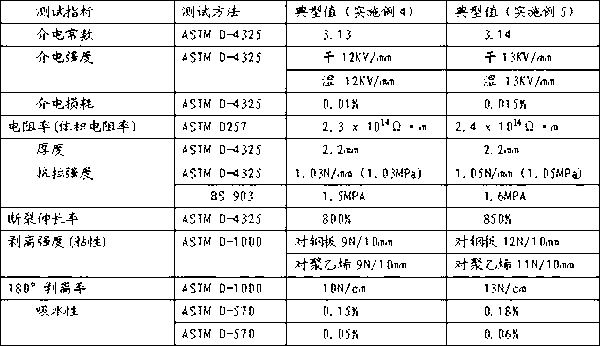

Butyl rubber sealing tape used for automobile and preparing method thereof

InactiveCN105505240AImprove air tightnessImprove mechanical propertiesMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesMiddle molecular weightPerformance index

The invention provides butyl rubber sealing tape used for an automobile. The butyl rubber sealing tape is prepared from, by weight, 15-20 parts of butyl rubber, 6-10 parts of nanoscale calcium carbonate, 30-40 parts of light calcium carbonate, 2-5 parts of acticel, 10-20 parts of low-molecular-weight polyisobutene, 4-10 parts of middle-molecular-weight polyisobutene, 4-10 parts of high-molecular-weight polyisobutene, 6-10 parts of pigment and 8-15 parts of petroleum resin. One face of the provided butyl rubber sealing tape used for the automobile is bonded with an automobile steel plate, and the other face is bonded with a plastic moisture-proof film to have the waterproof effect. Experiment results show that performance indexes of the butyl rubber sealing tape used for the automobile reach or exceed those of existing similar products, the butyl rubber sealing tape used for the automobile has the advantages that airtightness is good, the sealing tape is resistant to high temperature and does not flow, and the bonding strength is not lowered at low temperature.

Owner:BAODING JINYUEMEI IND & TRADE CO LTD

Double-sided all-purpose adhesive tape

InactiveCN102965047AGood weather resistanceImprove aging resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesWeather resistanceMiddle molecular weight

The invention discloses a double-sided all-purpose adhesive tape. The adhesive tape is prepared by taking a fiber fabric as a base material, and respectively coating an adhesive layer on the upper and lower sides of the base material. The adhesive layer comprises the following materials in parts by weight: 30-50 parts of butyl rubber, 10-25 parts of polyisobutylene (middle molecular weight), 5-15 parts of polyisobutylene (low molecular weight), 0-10 parts of operating oil, 10-20 parts of modified terpene resin, 0.3-0.5 part of a colorant, 0-0.5 part of an antioxidant, and 0-15 parts of a filler. When the double-sided all-purpose adhesive tape is applied to construction, an adhesive is not required to be daubed on the scene, the double-sided all-purpose adhesive tape can be directly used just through uncovering release paper, and therefore, the adhesive tape is simple and convenient; the adhesive tape is good in weather resistance, aging resistance, water repellency, anti-skidding property, adsorbability, shock-absorbing property, explosion-proof property and heat insulation property, longer in application time and wider in application range; and the adhesive tape has an excellent bonding capacity to various sheet metals, plastic sheets, plastic films and various pipes, therefore, the adhesive tape is extensive in use.

Owner:吴孟怀

Polyvinyl composite microporous membrane with thermocompression bonding characteristic

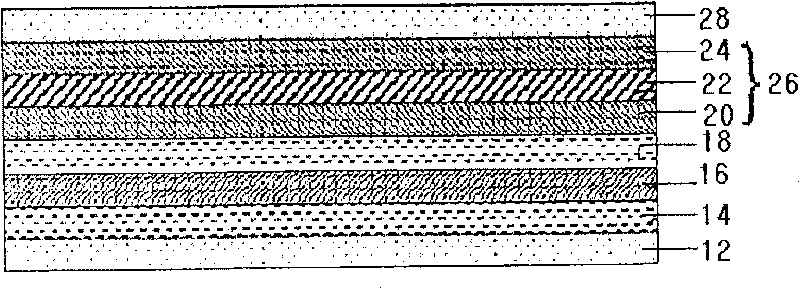

InactiveCN103184013AInhibit heat shrinkageImprove securitySemi-permeable membranesNon-macromolecular adhesive additivesMiddle molecular weightCrystallinity

The present invention relates to polyvinyl composite microporous membrane with thermocompression bonding characteristics. High-crystallinity and high-density polyethylene is modified by using ethylene-propylene methylene copolymer of the middle molecular weight and polyisobutylene rubber. The membrane with thermocompression bonding characteristics is obtained by using aliphatic dibasic acid ester with a flash point above 210 DEG C as a craft solvent and a pore forming agent. The membrane is hot pressed to bond integrally with a positive electrode sheet. The thermal shrinkage of the membrane is suppressed. The composite membrane has the characteristics of high strength and high temperature resistence, and can be used for lithium-ion batteries with high security and long cycle life.

Owner:TIANJIN DG MEMBRANE

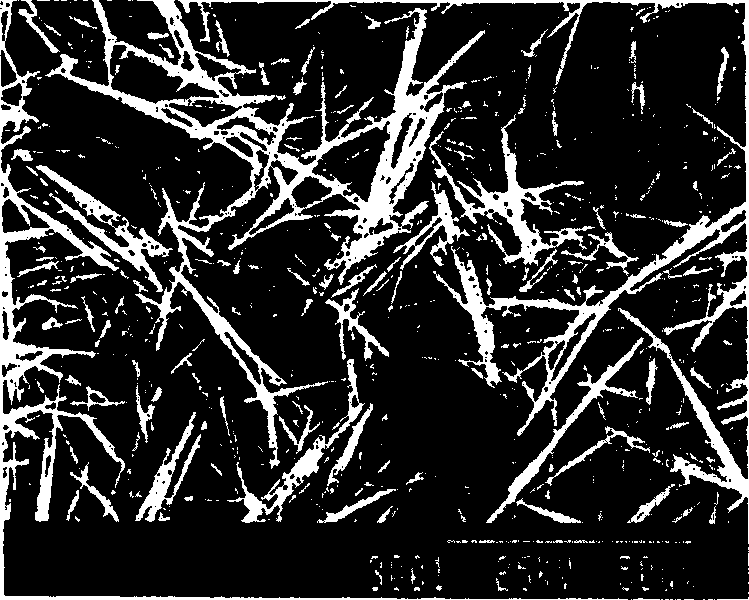

Inorganic whisper reinforced polyolefin composite material in-situ filled polymerization preparing method

The invention relates to a kind of insitu filling polymerization-manufacturing method of inorganic whisker intensification polyolefin composite material. Load olefinic polymerization catalyst in the surface of inorganic whisker with preliminary stirring-dispersing treatment, and then take alkene monomer polymerization in its surface in order to get polyolefin / whisker composite material. The composite material is composed with 3-80% inorganic mineral whisker and 20-97% polyolefin polymer. The manufacturing method in the invention is convenient. The composite material manufactured by the method has high filling extent of whisker, retentive slenderness ratio of whisker, and also the whisker has well distribution in matrix polymer and fine adhesion with matrix interface, so that it can give full play to intensification characteristic of whisker, in order to get polyolefin / inorganic whisker composite material with the advantages such as easiness to formation and processing, fine cleanliness of product, and excellent mechanical property. Plastics matrix can be manufactured into polyolefin from low molecular weight, middle molecular weight, and high molecular weight to superhigh molecular weight, such as polypropylene or polythene. The material acquired can be used not only as structural material by direct injection formation, but also as masterbatch after having crossblend with commercial polyolefine.

Owner:INST OF CHEM CHINESE ACAD OF SCI

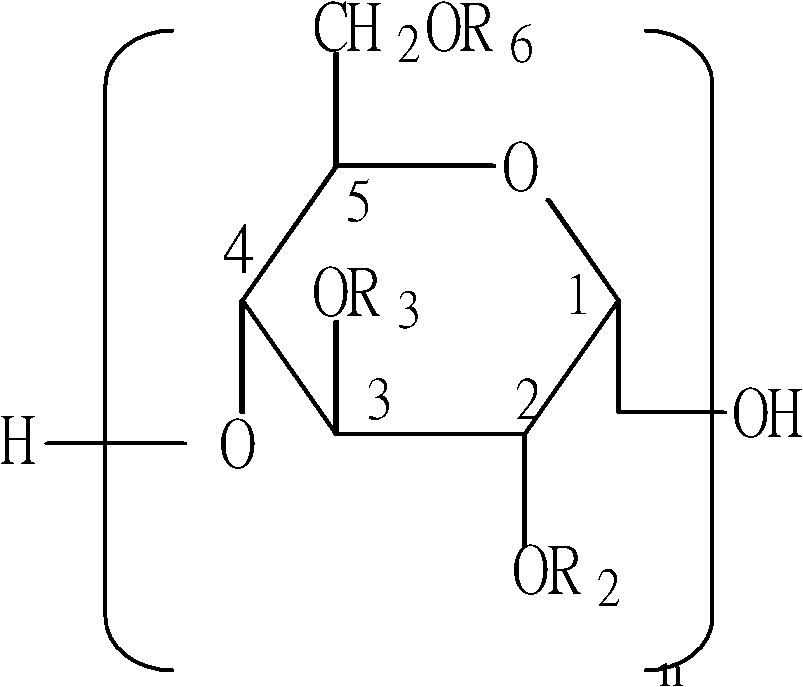

Synthesis method of middle-molecular-weight hydroxyethyl starch

The invention provides a synthesis method of middle-molecular-weight hydroxyethyl starch. The synthesis method comprises the following steps: carrying out hydroxyethyl substitution reaction on waxy corn starch hydrolyzate and a hydroxyethyl substituting agent under the conditions that water is used as a solvent and sodium hydroxide is taken as a catalyst; and carrying out ultrafiltration interception membrane separation and activated carbon decoloration, filtering, and carrying out spray drying on filtrate so as to obtain the white powdery middle-molecular-weight hydroxyethyl starch product. According to the invention, an adopted aqueous phase synthesis method has the advantages that an ideal molar degree of substitution (MS) of hydroxyethyl and an ideal substitution position ratio (C2:C6) are conveniently controlled in the reaction, and the byproducts of the reaction are easy to separate; and under the condition of the aqueous phase synthesis method, the reaction is a room temperature reaction, reactants and the catalyst are completely dissolved in the reaction system, the substitution positions are uniformly distributed in the product, the reaction byproducts such as sodium chloride, chlorohydrin, cyclochloroethane, glycol and the like can be easily removed once through a membrane separation technology, the obtained product has proper MS and a ratio of C2:C6, and the obtained product quality can reach or be superior to the existing national drug standard.

Owner:WUHAN HUST LIFE SCI & TECH

Power cable repairing adhesive tape and preparation method of the same

InactiveCN103131340AUnique cold flow characteristicsEasy curingNon-macromolecular adhesive additivesFilm/foil adhesivesPower cableMiddle molecular weight

The invention provides power cable repairing adhesive tape and a preparation method of the power cable repairing adhesive tape. The power cable repairing adhesive tape and the preparation method of the power cable repairing adhesive tape comprise, by weight ratio, 5-10% of butyl rubber, 5-10% of high molecular weight polyisobutene, 25-30% of middle molecular weight polyisobutene, 10-15% of low molecular weight polyisobutene, 40-50% of inorganic reinforcing powder, 0.5-1% of antioxidant 1010 and 0.5-1% of pigment. The repairing adhesive tape adopted by the power cable repairing adhesive tape is polymer which can never be solidified, wherein the repairing adhesive tape not only has ordinary adhesive performance, but also has unique cold flow characteristics, and can realize automatically repairing functions in the anti-erosion and repairing process to achieve the best sealing and anti-erosion effect.

Owner:CYG CHANGTONG NEW MATERIAL

Method for preparing carbon fiber reinforced polylactic acid/hydroxy apatite composite material

The present invention discloses a method for preparing carbon-fibre reinforced polylactic acid / hydroxyapatite composite material. It is made up by using (by wt%) 75-85% of lactide, 22-14% of hydroxyapatite and 1-3% of carbon fibre as raw material, using stannous octoate as catalyst through a certain preparation process.

Owner:ZHEJIANG UNIV +1

Blend of fluorine-containing elastomers

ActiveCN103180380AEasy to processLow hardnessOther chemical processesMiddle molecular weightFluorine containing

Provided is a blend of fluorine-containing elastomers comprising 5-60 wt% of a high-molecular-weight fluorine-containing elastomer having a number average molecular weight Mn (liquid chromatography, a tetrahydrofuran developing solvent, a polymer concentration of 0.5 wt%, a measurement temperature of 35 DEG C) of 3,000,000 or more, 20-80 wt% of a middle-molecular-weight fluorine-containing elastomer having an Mn of 100,000-1,000,000, and 10-50 wt% of a low-molecular-weight fluorine-containing elastomer having a Mn of 7,000-13,000. The blend of fluorine-containing elastomers achieves low hardness and low modulus, as well as an improved rolling processability.

Owner:UNIMATEC CO LTD

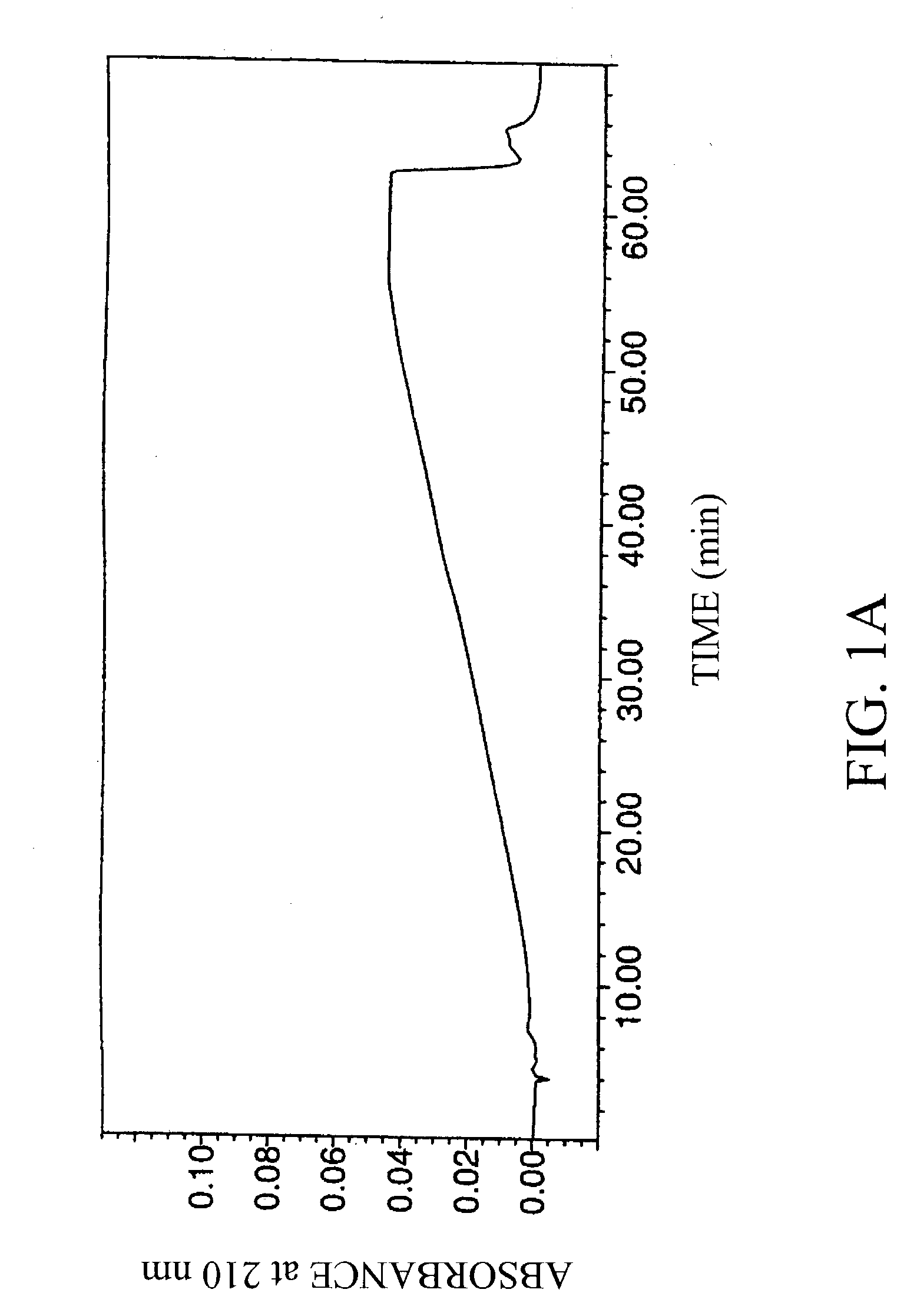

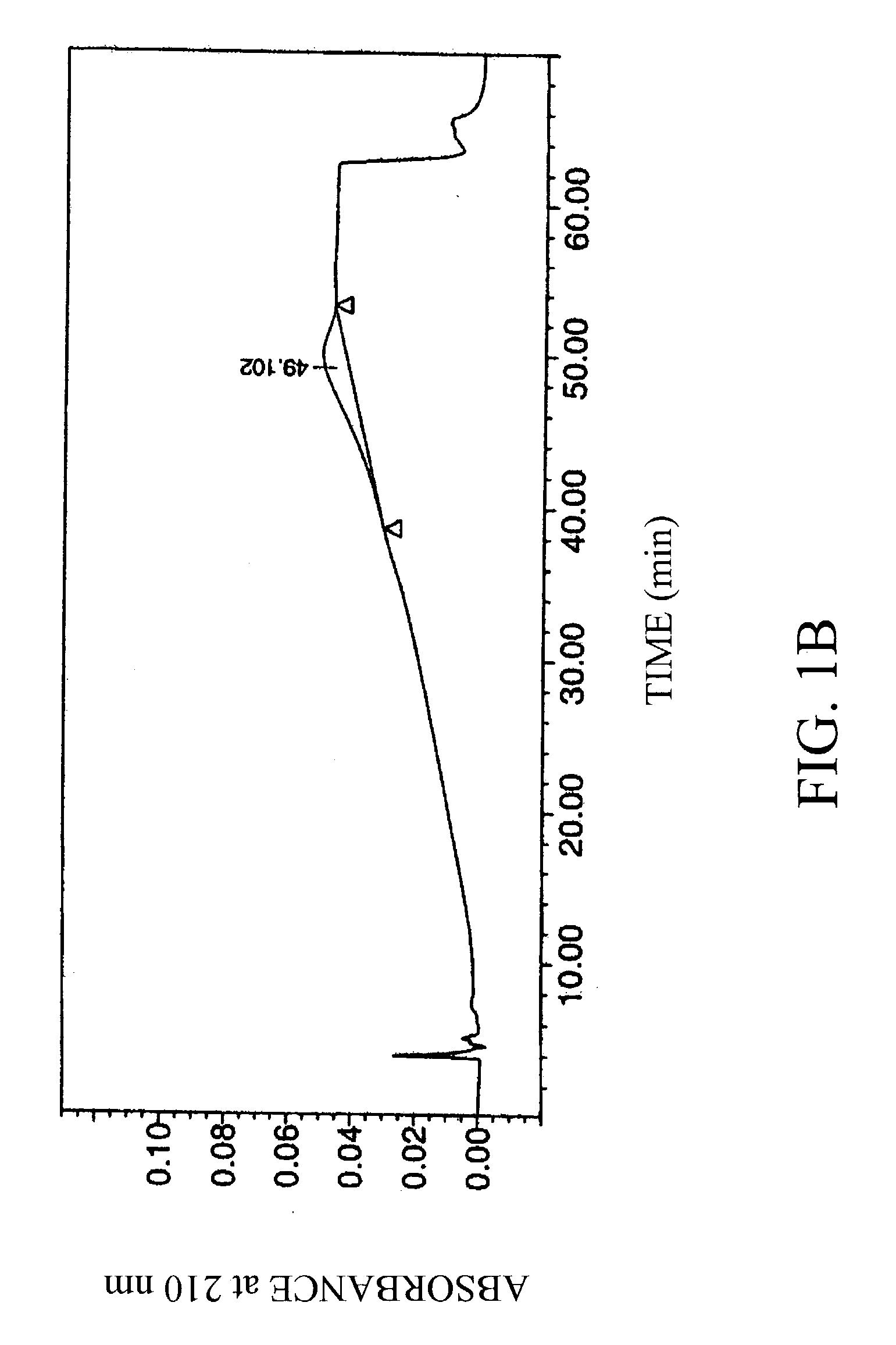

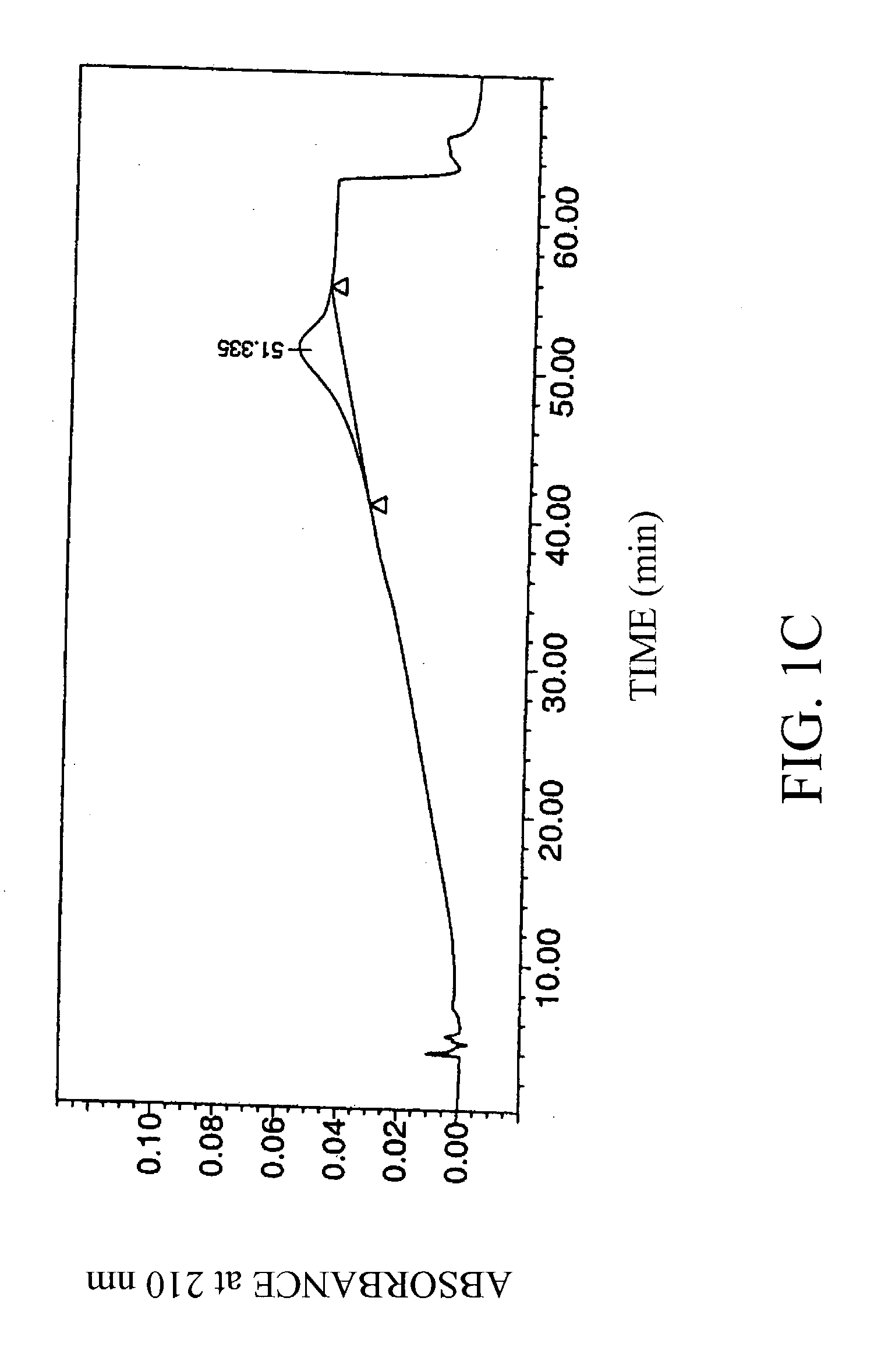

Chromatographic method

InactiveUS20030224346A1Easy to adaptComponent separationMicrobiological testing/measurementMiddle molecular weightAnion-exchange chromatography

Methods for determining the molecular weight distribution in a sample of an anionic polysaccharide is provided. The methods generally include: providing a sample of an anionic polysaccharide with an average molecular weight in the range of from 0.05 to 10 MDa; applying the sample to an anion-exchange chromatography column so as to immobilize the polysaccharide to the column; eluting the immobilized polysaccharide while recording a chromatogram of the amount of polysaccharide eluted as a function of time; and determining the molecular weight distribution in the polysaccharide sample through analysis of the chromatogram. Also provided is use of anion-exchange chromatography for the determination of molecular weight distribution in a sample of an anionic polysaccharide with an average molecular weight in the range of from 0.05 to 10 MDa.

Owner:BIOVITRUM AB (PUBL)

Hyaluronic acid flushing fluid for nasal cavity as well as preparation method and application of hyaluronic acid flushing fluid

InactiveCN105147771APromote healingAchieve healingRespiratory disorderPlant ingredientsPotassiumMiddle molecular weight

The invention relates to hyaluronic acid flushing fluid for the nasal cavity as well as a preparation method and an application of the hyaluronic acid flushing fluid. The hyaluronic acid flushing fluid is prepared from the following components in percentage by weight: 0.01-0.3% of middle-molecular-weight hyaluronic acid, 0.01-0.3% of small-molecular-weight hyaluronic acid, 0.9-5.0% of sodium chloride, 0.005-0.1% of mint extract, 0.01-0.07% of potassium chloride, 0.02-0.08% of calcium chloride, 0.01-0.1% of magnesium chloride, and the balance of distilled water. The hyaluronic acid flushing fluid for the nasal cavity has the efficacies of preserving moisture, repairing, diminishing inflammation, and flushing, and is suitable for daily care for the nasal cavity, the adjuvant therapy for acute and chronic rhinitis, and nasosinusitis, as well as the chemotherapy and postoperative care for the nasal cavity.

Owner:NANJING TZONE BIOLOGICAL SCI & TECH

Composition of ginseng-astragalus polysaccharides and its preparing method

InactiveCN1813787AStrong immune boosting effectDefinite curative effectOrganic active ingredientsImmunological disordersAstragalus polysaccharideFreeze-drying

The present invention relates to a shenqi polysaccharide composition. It is formed from polysaccharides which are respectively extracted by utilizing 1-3 portions of pilose asiabell root and 1-3 portions of astragalus root and purified, in which the polysaccharide content whose molecular weight range is 10000-10000 is above 80% of total solid substance content. It can be made into shenqi polysaccharide injection and injection freeze-dried powder, and its quality is stable, and can be controlled. Said invention has strong immunologic enhancement.

Owner:广东仁泰药业有限公司

High and low temperature type anti-corrosion viscoelastic body filler, and preparation method thereof

InactiveCN103709949ALiquidFunctionalNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterTectorial membrane

The invention discloses a high and low temperature type anti-corrosion viscoelastic body filler. The high and low temperature type anti-corrosion viscoelastic body filler is characterized by comprising a protective film, a viscoelastic body paste layer and an isolation film. The protective film is a polyethylene film; the isolation film is a polyester isolation film; and the viscoelastic body paste layer is composed of the following raw materials by mass: 33-36% of middle molecular weight polyisobutylene, 10.5-12.5% of low molecular weight polyisobutylene, 50-55% of precipitated barium sulphate, 1-1.5% of an antioxidant and 0.5-0.6% of phthalocyanine green. A preparation method of the high and low temperature type anti-corrosion viscoelastic body filler comprises the steps of kneading the raw materials to obtain daub; sending the daub into a reaction kettle for mixing; extruding by an extruder; coating on the isolation film; plying up the protective film; and rolling by a double-roller machine to obtain a product. The high and low temperature type anti-corrosion viscoelastic body filler is not restricted by the high and low temperatures, has self-repairing functions, is used as a sealing and filling anti-corrosion material for special-shaped pipes such as special-shaped steel elbows, bends, three-way gate valves and flanges, is environment-friendly and convenient for use, and has a good filling and sealing effect.

Owner:绵阳市振华长森科技有限公司

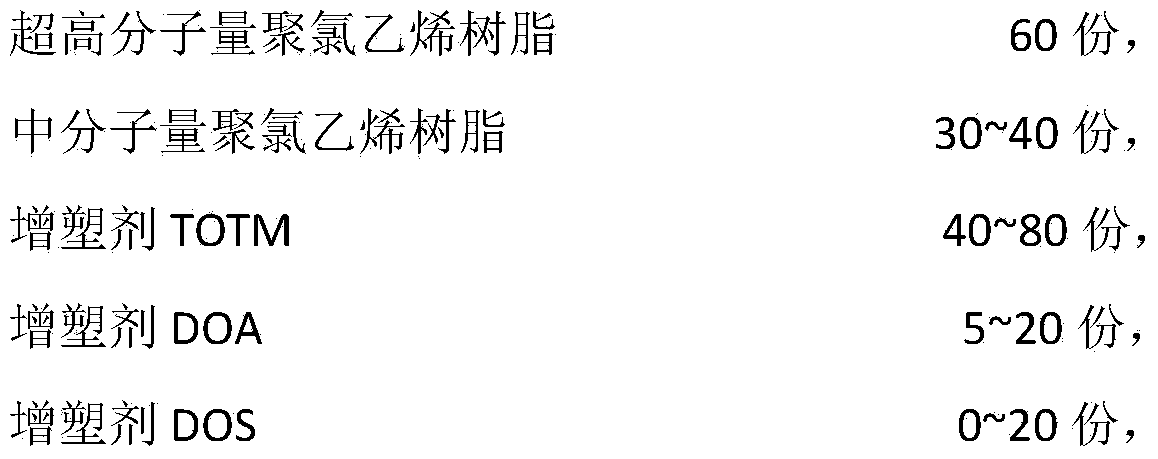

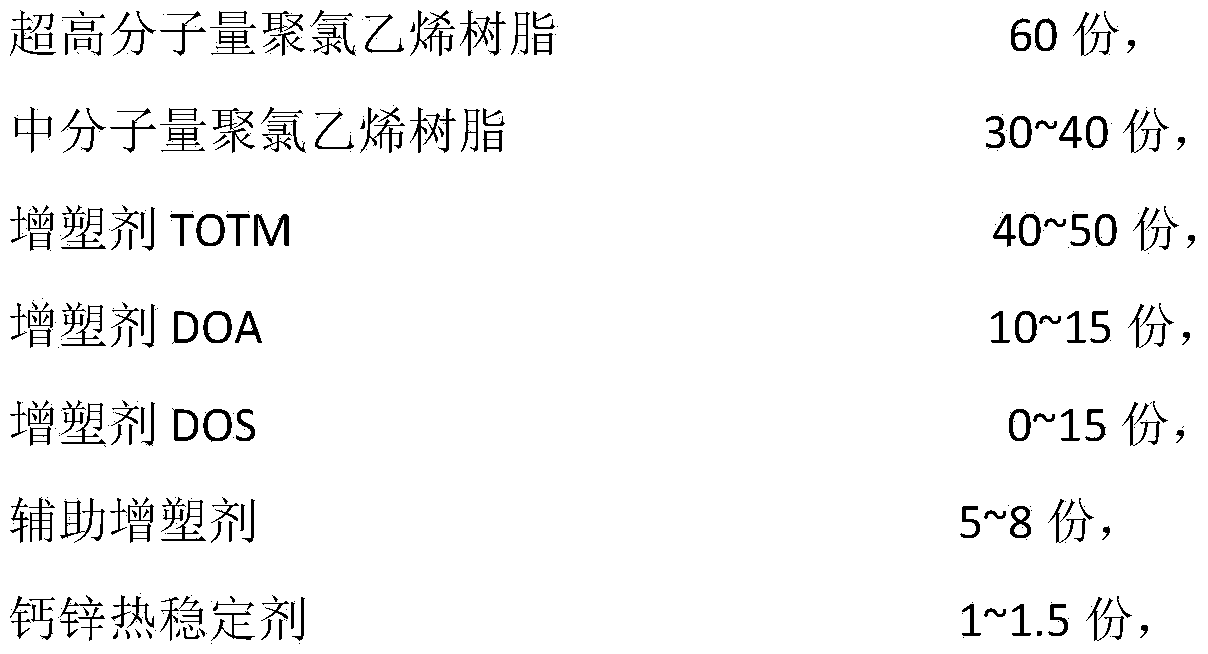

Polyvinyl chloride material with high oxygen permeability and preparation method thereof

The invention discloses a polyvinyl chloride material with high oxygen permeability and a preparation method thereof. The polyvinyl chloride material with high oxygen permeability comprises the following components in parts by weight: 60 parts of polyvinyl chloride resin with super-high molecular weight, 30-40 parts of polyvinyl chloride resin with middle molecular weight, 40-80 parts of plasticizer TOTM (Trioctyl Trimellitate), 5-20 parts of plasticizer DOA (Dioctyl Adipate), 0-20 parts of plasticizer DOS (Dioctyl Sebacate), 3-10 parts of secondary plasticizer and 0.5-5 parts of calcium and zinc thermal stabilizer. The basic resin used in the material disclosed by the invention is polyvinyl chloride resin which has high oil absorption and is prepared by a super-high molecular weight and middle molecular weight suspension method, the plasticizer TOTM with low mobility is selected, the cold-resistant plasticizers DOA and DOS are compounded in use, and epoxy plant oil plasticizer with the thermal stabilizing effect is used as an assistant, so that the low-temperature resistance and extraction resistance of the product are ensured, and the material has a high gas exchange rate and characteristic of high oxygen permeability and is suitable for blood storage, and particularly suitable for storage of blood platelets. The prepared PVC material with high oxygen permeability can make sure that blood platelets can be stored for 7 days at 22 DEG C, so that the material is suitable for preparation of blood platelet storage bags.

Owner:上海新上化高分子材料有限公司 +1

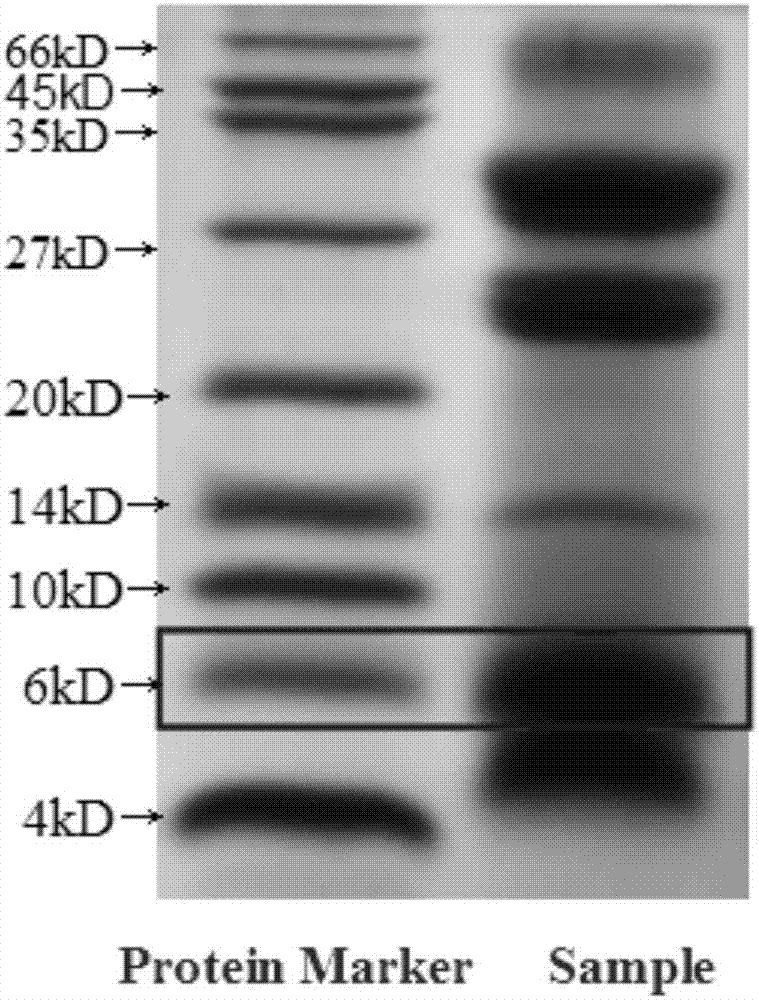

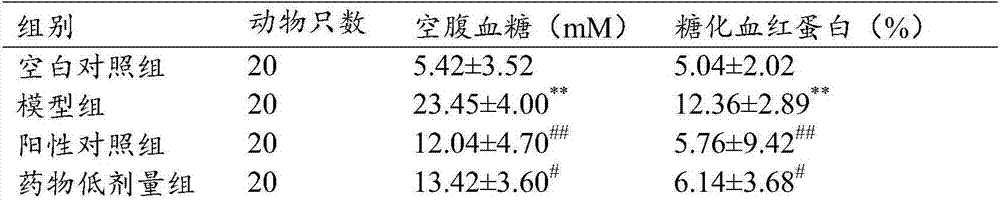

Blood sugar decreasing polypeptide-k compound capsule and preparation method thereof

ActiveCN107412721AEasy to takeStrong receptor binding abilityOrganic active ingredientsHeavy metal active ingredientsMiddle molecular weightPlant Preparations

The invention provides a blood sugar decreasing polypeptide-k compound capsule and a preparation method thereof and belongs to the field of functional food health or medicine. The compound capsule comprises, by weight, 3-5 parts of a polypeptide-k extract, 2-4 parts of a ginseng saponin extract, 1-3 parts of a kudzu flavonoid extract, 1-3 parts of an astragalus polysaccharide extract and 0.6-0.8%. of trace element chromium. The content of polypeptide-k protein in the polypeptide-k extract is not less than 20%, the content of polypeptide-k 5.5-7kDa in molecular weight accounts for 18-25%, and the polypeptide fragmentation is close to the molecular weight in size. The preparation method includes: mixing the raw materials of the above recipe weight with auxiliaries prior to performing drying and sieving; pelleting by adopting a wet process after superfine grinding before performing drying, sieving and size stabilizing to have the capsule filled according to specifications. The polypeptide-k compound capsule is a pure plant preparation, components with homology of medicine and food are reasonable, the function of blood sugar reduction is remarkable, and the compound capsule can be used for preventing and treating diabetes.

Owner:李玉保 +2

Medicament carrier solution for abdominal cavity chemotherapy and pharmaceutical composition thereof

InactiveCN101130087AExtended retention timeReduce adhesionPharmaceutical delivery mechanismPharmaceutical non-active ingredientsHigh concentrationHydroxyethyl starch

The invention provides a medium-molecular-weight hydroxyethylated starches applied to abdominal cavity chemotherapy drug carrier agent, wherein the molecular weight Mw of the medium-molecular-weight hydroxyethylated starches is 60000-600000 dalton, molar degree of substitution is 0. 15-0. 5 and hydroxyethylating substitution ratio in C2 and C6 is >=5. The invention provides carrier liquid including the medium-molecular-weight hydroxyethylated starches and the chemotherapy drug to make the big bulk extend existing time in the abdominal cavity with lasting high concentration through using the carrier liquid, which can contact the drug with the visceral and peritoneal surface in a large area to invade the remained nodules and caner stove to enhance antineoplastic effect to reduce the abdominal cavity adhesion.

Owner:BEIJING FRESENIUS KABI PHARM CO LTD

Preparation process for reducing disubstitution proportion of hydroxyethyl starch with middle molecular weight

The present invention relates to the fields of medicine and chemical industry, and in particular relates to a preparation process for reducing disubstitution proportion of hydroxyethyl starch with middle molecular weight. The preparation process comprises steps of: dispersing amylopectin of suitable molecular weight with purified water; adding a catalyst of sodium hydroxide; respectively carrying out a flow mixing reaction and a flow insulation reaction with an alkylating agent; carrying out decarbonization filtration, ultrafiltration and spray drying on a feed liquid to obtain the hydroxyethyl starch raw material with middle molecular weight. The method can avoid further reaction of the alkylating agent and the generated hydroxyethyl starch, and reduce generation of disubstituted hydroxyethyl starch.

Owner:SHANDONG QIDU PHARMA

Inorganic whisper reinforced polyolefin composite material in-situ filled polymerization preparing method

The invention relates to a kind of insitu filling polymerization-manufacturing method of inorganic whisker intensification polyolefin composite material. Load olefinic polymerization catalyst in the surface of inorganic whisker with preliminary stirring-dispersing treatment, and then take alkene monomer polymerization in its surface in order to get polyolefin / whisker composite material. The composite material is composed with 3-80% inorganic mineral whisker and 20-97% polyolefin polymer. The manufacturing method in the invention is convenient. The composite material manufactured by the method has high filling extent of whisker, retentive slenderness ratio of whisker, and also the whisker has well distribution in matrix polymer and fine adhesion with matrix interface, so that it can give full play to intensification characteristic of whisker, in order to get polyolefin / inorganic whisker composite material with the advantages such as easiness to formation and processing, fine cleanliness of product, and excellent mechanical property. Plastics matrix can be manufactured into polyolefin from low molecular weight, middle molecular weight, and high molecular weight to superhigh molecular weight, such as polypropylene or polythene. The material acquired can be used not only as structural material by direct injection formation, but also as masterbatch after having crossblend with commercial polyolefine.

Owner:INST OF CHEM CHINESE ACAD OF SCI

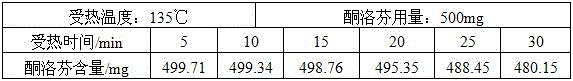

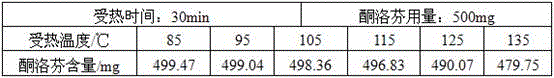

Novel chemical drug patch ketoprofen paster and preparation method thereof

ActiveCN106822049AShort heating timeImprove effectivenessOrganic active ingredientsAntipyreticMedicineAdhesive

The present invention discloses a novel chemical drug patch ketoprofen paster and a preparation method thereof. The novel chemical drug patch ketoprofen paster comprises a styrene-isoprene-styrene triblock copolymer, a styrene-isoprene diblock copolymer, a tackifier, a softener and an antioxygen; the patch has the characteristics that the stimulation to skins is very slight, an adhesive is free from the stimulation to the skins, the drug stabilization in long-term storage is good, the pasting with the skins is good, the repeatable pasting is realized, pasting is kept when contacted with water, particularly the pasting with knees, elbows and other parts; the adhesive in the patch comprises components in percentage by weight: 10%-55% of the styrene-isoprene-styrene triblock copolymer and the styrene-isoprene diblock copolymer totally, less than 22% of polyisobutene with high molecular weight, less than 30% of polyisobutene with middle molecular weight, less than 25% of polyisobutene with low molecular weight, 10%-60% of the tackifier, and 12%-55% of the softener; the antioxygen accounts for 0.01%-2.5% of the sum amount of framework materials.

Owner:北京乳凝创智生物技术研发中心(有限合伙)

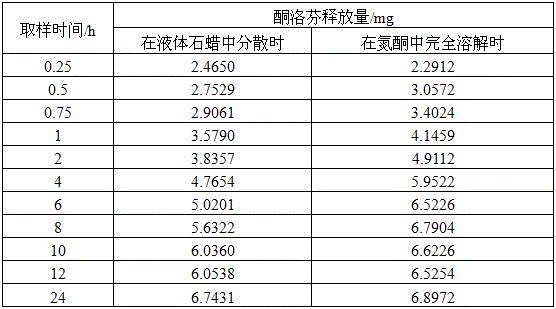

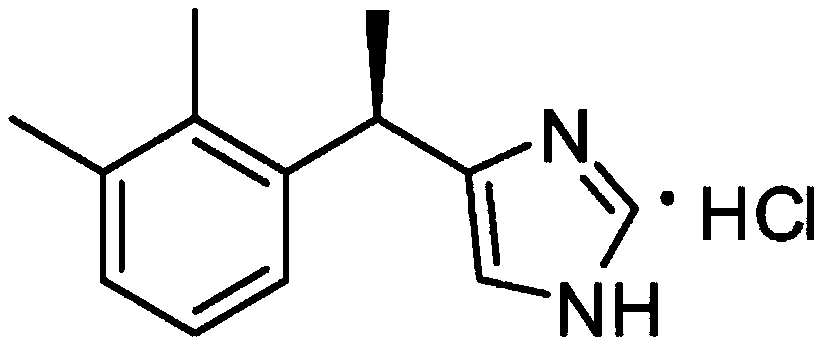

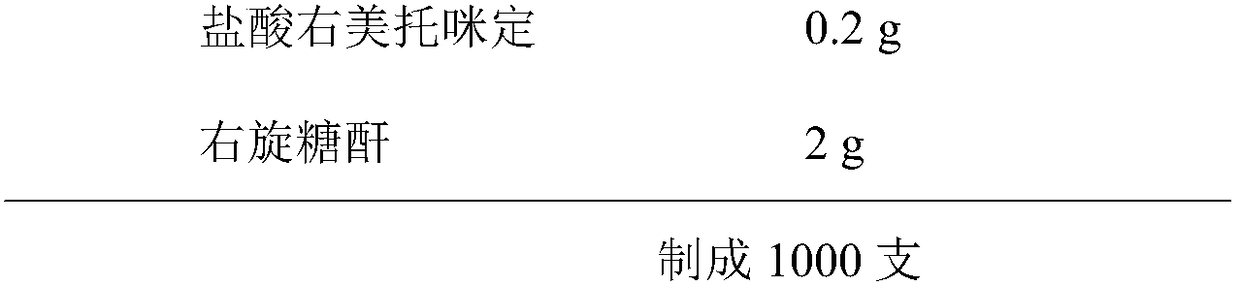

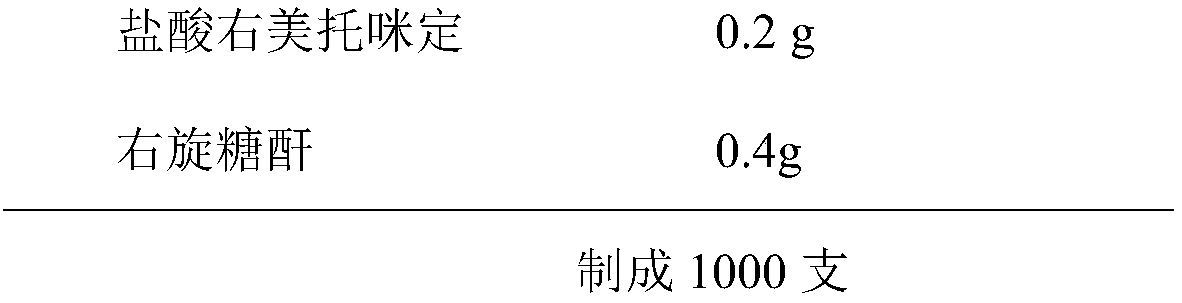

Dexmedetomidine hydrochloride lyophilized powder injection and preparation method

InactiveCN108743551AExcellent indicatorsEasy to storePowder deliveryOrganic active ingredientsFreeze-dryingMiddle molecular weight

The invention relates to a dexmedetomidine hydrochloride lyophilized powder injection and a preparation method, and belongs to the field of pharmaceutical preparations. The dexmedetomidine hydrochloride lyophilized powder injection comprises, by weight, 1 part of dexmedetomidine hydrochloride and 2-20 parts of middle molecular weight dextran. The method comprises the steps that the dextran is dissolved by adding part of injection water, and stirring and filtering are conducted; the dexmedetomidine hydrochloride is taken, after the dexmedetomidine hydrochloride is dissolved by adding in citricacid-sodium citrate buffering liquid, the dexmedetomidine hydrochloride is added to a decarburized solution, and the injection water is additionally added to the full amount; the PH value is adjustedto 5.0-6.0, microfiltration is conducted, and the injection is obtained after freezing drying is conducted. The injection has the advantages of being good in resolubility, and high in stability and safety.

Owner:宁波蒙曼生物科技有限公司

Adhesive composition for controlling light leakage and optical film coated with the same for display device

InactiveCN101735751AReduce shrinkage stressResidual Stress MinimizationNon-macromolecular adhesive additivesPolarising elementsPolymer scienceAdhesive

The present invention relates to an adhesive composition used for controlling light leakage and an optical film coated with the same for display device. The adhesive composition can reduce the contraction stress of adhesive for supplementing light leakage property and minimizing the residual stress caused by the dimension change of the substrate of the optical film and the adhesive. Therefore, the adhesive composition comprises the following components: (A) reactive high molecular weight acrylic acid copolymer with weight-average molecular weight of 2,000,000-2,500,000; (B) reactive middle molecular weight acrylic acid copolymer with weight-average molecular weight of 1,500,000-2,000,000; (C) reactive low molecular weight acrylic acid copolymer with weight-average molecular weight of 100,000-500,000; and (D) crosslinking agent. The invention is characterized in that the high modular weight, the middle modular weight and the low modular weight acrylic acid copolymers are the reactive copolymers polymerized by the following substances: (a) 90-99.9 parts by weight of alkyl acrylate with the alkyls with 4-12 carbon atoms; and (b) 0.1-10 parts by weight of vinyl monomer with the functional groups which can crosslink with the crosslinking agent.

Owner:TORAY SAEHAN

Composite catalyst for polyisobutylene synthesis, and preparation method and application thereof

The invention relates to a novel boron / titanium composite catalyst for polyisobutylene synthesis, and a preparation method and application thereof. In an isobutylene raw material system, a composite catalyst system formed by compounding a BF3 oxygen-containing complex, a titanium-containing compound and an oxygen-containing and / or nitrogen-containing ligand is used to initiate isobutylene polymerization; middle-molecular-weight and high-molecular-weight polyisobutylene having narrow molecular weight distribution can be prepared at a high temperature; the weight average molecular weight of the polyisobutylene is 50000-5000000; the catalyst has very high polymerization activity; and the maximum activity capable of being detected can be up to 1.03x10<7>gPIB.mol(BF3+TiCl4)<-1>.h<-1>.

Owner:WANHUA CHEM GRP CO LTD

High-low temperature anti-corrosion viscoelastic filler and preparation method thereof

InactiveCN103709949BFunctionalEasy to fillNon-macromolecular adhesive additivesFilm/foil adhesivesTectorial membranePolyester

Owner:绵阳市振华长森科技有限公司

Moderate molecular weighted chondroitin sulfate injection and its preparing process

InactiveCN1689583AEasy to separateEasy to manufactureOrganic active ingredientsNervous disorderMiddle molecular weightOrganic chemistry

The present invention discloses the injection of chondroitin sulfate in medium molecular weight and its preparation process. The injection of chondroitin sulfate includes chondroitin sulfate in medium molecular weight of 10,000-30,000 daltons and / or its salt and medicinal additive, and the medium molecular weight chondroitin sulfate is prepared through ultrafiltering and nanofiltering. Compared with common injection of chondroitin sulfate, the injection of the present invention has smaller molecular weight, higher pharmacological activity and higher purity, and can meet the requirement for safe administration.

Owner:汤毅

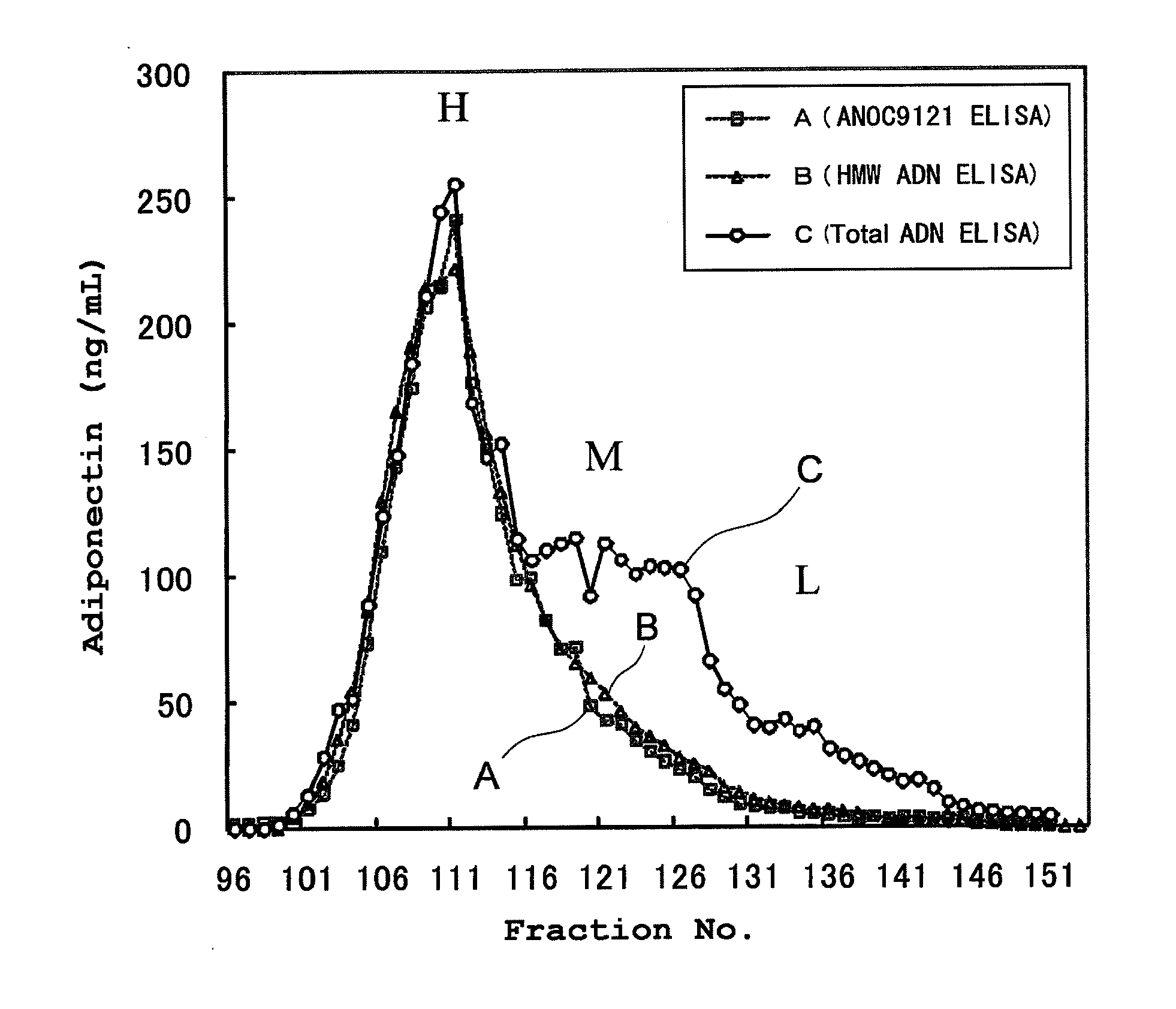

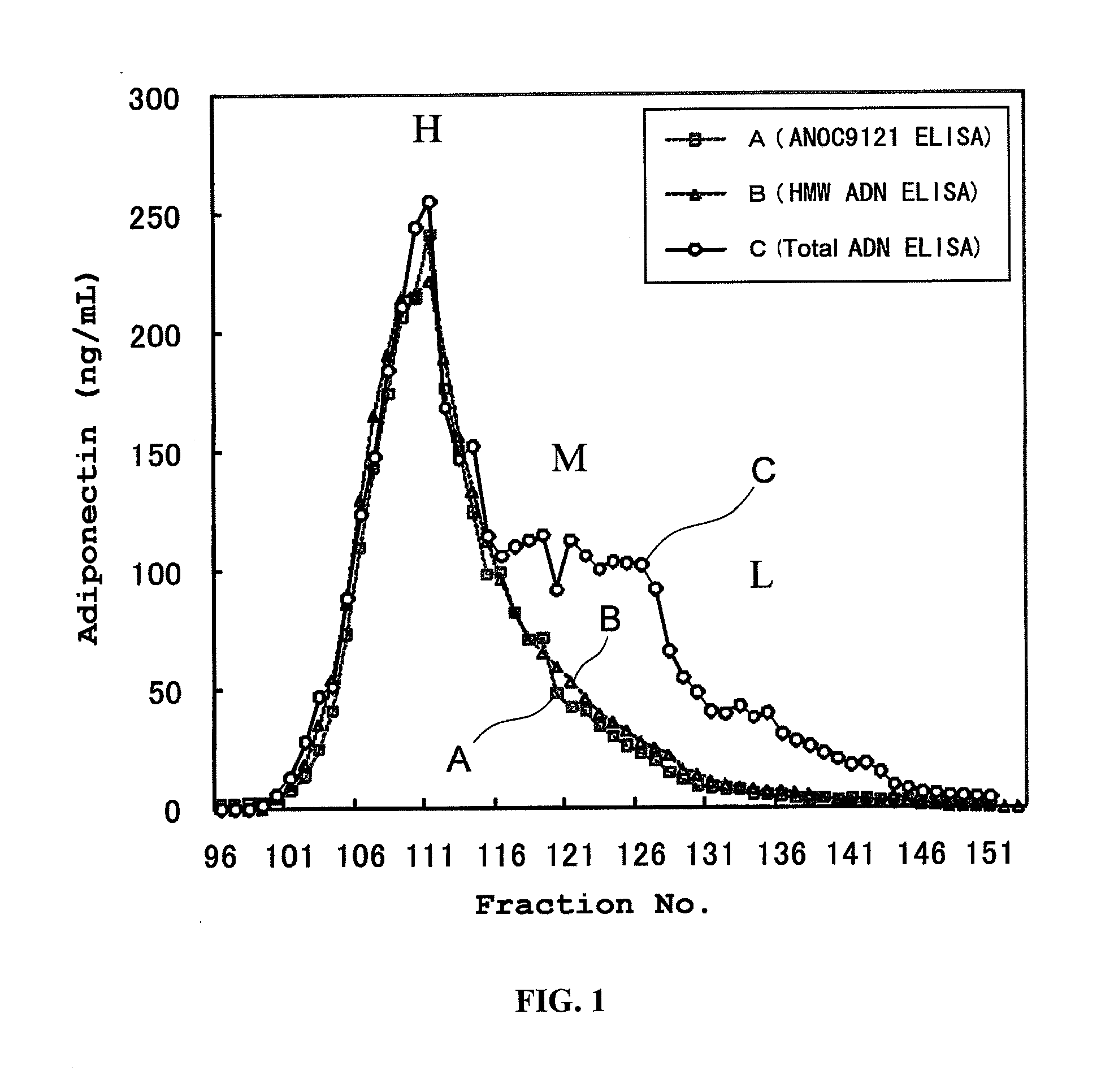

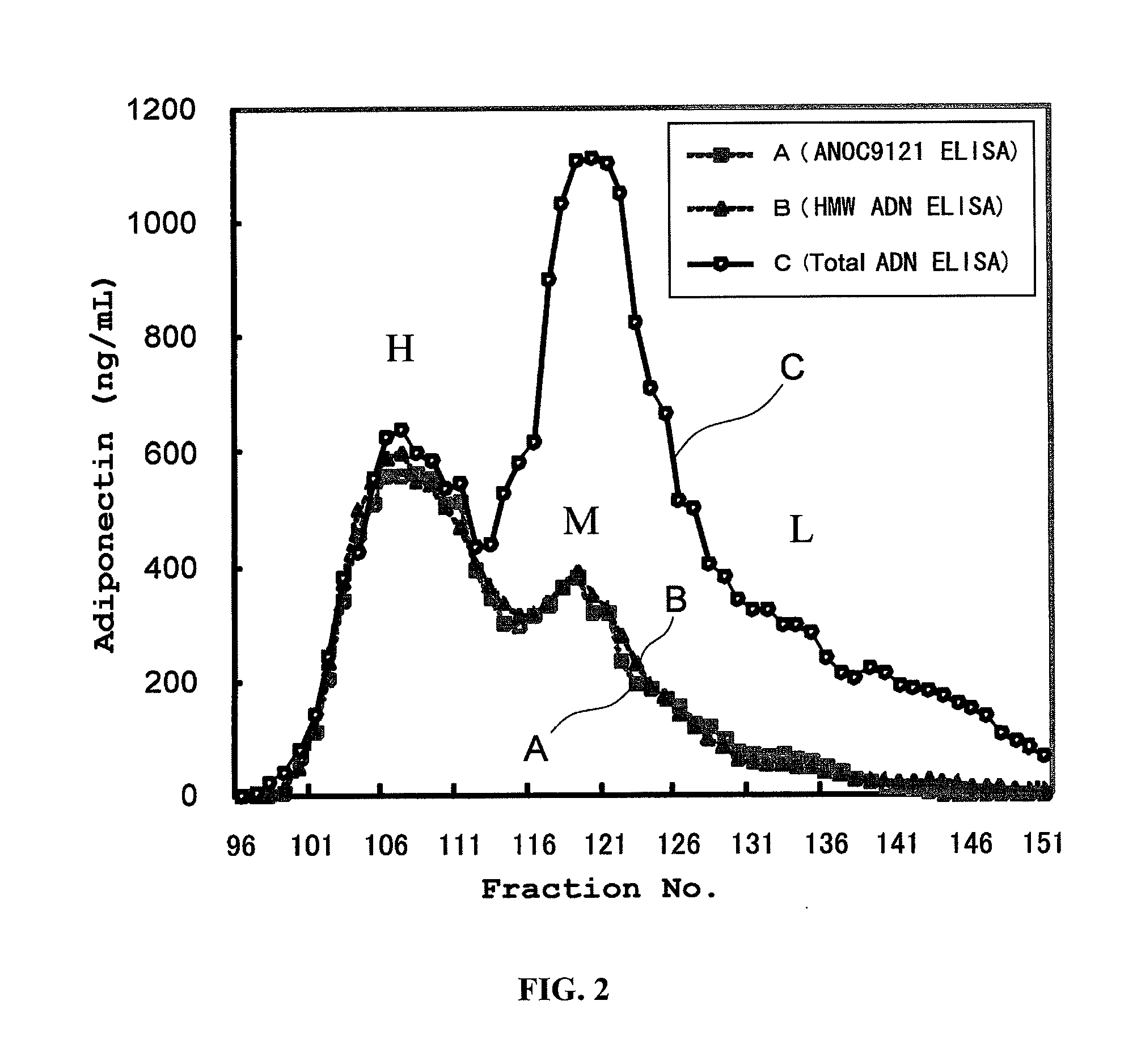

Novel monoclonal antibody for analyzing high-molecular weight adiponectin and utilization of same

ActiveUS20120052596A1Disease diagnosisImmunoglobulins against hormonesMonoclonal antibodyMiddle molecular weight

A monoclonal antibody that does not show a crossreactivity with middle-molecular weight (MMW) adiponectin and specifically reacts with high-molecular weight (HMW) adiponectin alone is disclosed. The monoclonal antibody of the present invention can be produced by using HMW adiponectin as an antigen. According to the monoclonal antibody of the present invention, a convenient, high-accurate, and versatile reagent for analyzing HMW adiponectin can be provided.

Owner:MITSUBISHI CHEM MEDIENCE

Membranes having improved performance

ActiveUS8827087B2Improve performanceInflammatory mediatorSemi-permeable membranesSolvent extractionPhosphoryl cholineProtein solution

Permselective asymmetric membranes suitable e.g. for hemodialysis, hemodiafiltration and hemofiltration of blood, and having improved sieving characteristics providing enhanced removal of middle molecular weight substances, e.g. inflammatory mediators having a molecular weight between 20 and 40 kDa. The membranes comprise polyethersulfone and polyvinylpyrrolidone and are coated with hyaluronic acid or copolymers of 2-methacryloyloxyethyl phosphoryl choline and other vinyl polymerizable monomers. Processes for the preparation of these membranes, devices comprising these membranes, and the use of these membranes in hemodialysis, hemodiafiltration and hemofiltration of blood, as well as in bioprocessing, plasma fractionation and the preparation of protein solutions.

Owner:GAMBRO LUNDIA AB

Method for preparing carbon fiber reinforced polylactic acid/hydroxy apatite composite material

The present invention discloses a method for preparing carbon-fibre reinforced polylactic acid / hydroxyapatite composite material. It is made up by using (by wt%) 75-85% of lactide, 22-14% of hydroxyapatite and 1-3% of carbon fibre as raw material, using stannous octoate as catalyst through a certain preparation process.

Owner:ZHEJIANG UNIV +1

Amylopectin pretreatment method and use thereof

ActiveCN103030818AReduce bacterial endotoxin contentLower levelHydroxyethyl starchPretreatment method

The present invention provides an amylopectin pretreatment method and use thereof. The method comprises: a) mixing the amylopectin with positive ion water so that bacterial endotoxin in the amylopectin is dissolved in the positive ion water; and b) separating the solid phase and the liquid phase of the mixing system formed by step a) to collect the solid phase, so the amylopectin after pretreatment is obtained. The present invention also provides a method for preparing hydroxyethyl starch of middle molecular weight and hydroxyethyl starch of middle molecular weight obtained by the method. The method for preparing hydroxyethyl starch of middle molecular weight provided by the present invention includes the beneficial effect that: the method can help to reduce the bacterial endotoxin content in the finished product and greatly improve the intrinsic quality of the product. The method is easy to operate, low in equipment and facility investment, low in energy consumption, and pollution-free, has no occupational hazards, does not affect the yield, and is stable in the finished product quality, convenient and easy to implement, and suitable for industrial production.

Owner:NEW FOUNDER HLDG DEV LLC +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com