Preparation process for reducing disubstitution proportion of hydroxyethyl starch with middle molecular weight

A technology of hydroxyethyl starch and preparation process, which is applied in the field of medicine and chemical industry, and can solve problems such as imbalance, influence on metabolism, and chemical structure change of glucose residues, and achieve the effect of improving drug safety and reducing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

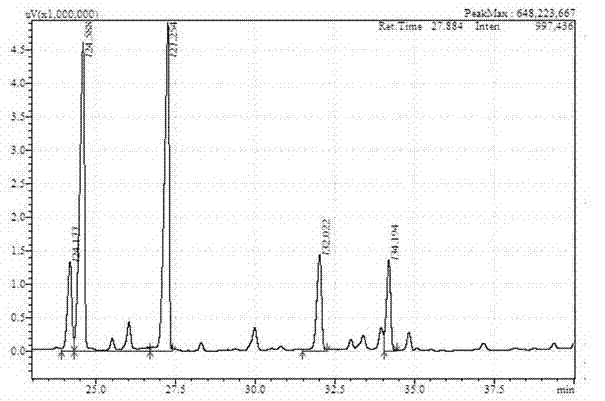

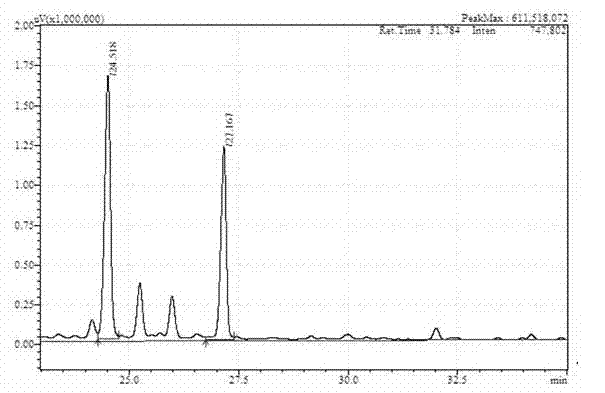

Image

Examples

Embodiment 1

[0023] Take 300 kg of amylopectin with a weight average molecular weight of 89 500, put it into 1 300 L of purified water, stir well, and slowly add 15 kg of dissolved sodium hydroxide (the molar ratio to amylopectin is 0.20) at a flow rate of 7.0 L / min Pumped into the pipeline reactor. At the same time, 50kg of ethylene oxide (with a molar ratio of 0.60 to amylopectin) was pumped into the pipeline reactor at a flow rate of 0.3L / min. The tube reactor was kept at 25°C. Feed liquid was reacted for 5 hours with the flow velocity of 7.0L / min in the pipeline reactor.

[0024] Pump the reaction feed liquid into the storage tank, add 36% hydrochloric acid (W / V), neutralize the sodium hydroxide in it to near neutrality, add 3‰ activated carbon for needles, stir and raise the temperature to 90°C, and keep it warm for 1 hour, Filtrate through a decarburization filter while hot.

[0025] The filtrate was cooled to 35°C and ultrafiltered through a plate-type ultrafiltration membrane w...

Embodiment 2

[0028] Take 450 kg of amylopectin with a weight average molecular weight of 10 200, put it into 1 300 L of purified water, stir well, and slowly add 50 kg of dissolved sodium hydroxide (the molar ratio to amylopectin is 0.40) at a flow rate of 8.2 L / min Pumped into the pipeline reactor. At the same time, 90 kg of ethylene oxide (with a molar ratio of 0.73 to amylopectin) was pumped into the pipeline reactor at a flow rate of 0.35 L / min. The tube reactor was kept at 35°C. Feed liquid was reacted for 7 hours at a flow rate of 8.0 L / min in the pipeline reactor.

[0029] Pump the reaction feed liquid into the storage tank, add 36% hydrochloric acid (W / V), neutralize the sodium hydroxide in it to near neutrality, add 3‰ activated carbon for needles, stir and raise the temperature to 90°C, and keep it warm for 1 hour, Filtrate through a decarburization filter while hot.

[0030] The filtrate was cooled to 30°C and ultrafiltered through a plate ultrafiltration membrane with a mole...

Embodiment 3

[0033] Take 500 kg of amylopectin with a weight average molecular weight of 87 500, put it into 1 300 L of purified water, stir well, and slowly add 37 kg of dissolved sodium hydroxide (the molar ratio to amylopectin is 0.33) at a flow rate of 9.0 L / min Pumped into the pipeline reactor. At the same time, 110 kg of ethylene oxide (with a molar ratio of 0.80 to amylopectin) was pumped into the pipeline reactor at a flow rate of 0.40 L / min. The tube reactor was kept at 40°C. The feed liquid was reacted in the pipeline reactor for 8 hours at a flow rate of 9.0 L / min.

[0034] Pump the reaction feed liquid into the storage tank, add 36% hydrochloric acid (W / V), neutralize the sodium hydroxide in it to near neutrality, add 3‰ activated carbon for needles, stir and raise the temperature to 90°C, and keep it warm for 1 hour, Filtrate through a decarburization filter while hot.

[0035] The filtrate was cooled to 30°C and ultrafiltered through a plate ultrafiltration membrane with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com