High-low temperature anti-corrosion viscoelastic filler and preparation method thereof

A viscoelastic, high and low temperature technology, applied in the direction of non-polymer adhesive additives, adhesives, film/sheet adhesives, etc., can solve the problem of poor corrosion protection and sealing effect of thermal insulation pipeline steel pipes. Use and other issues to achieve the effect of eliminating moisture intrusion and microbial corrosion, chemical resistance and sealing, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

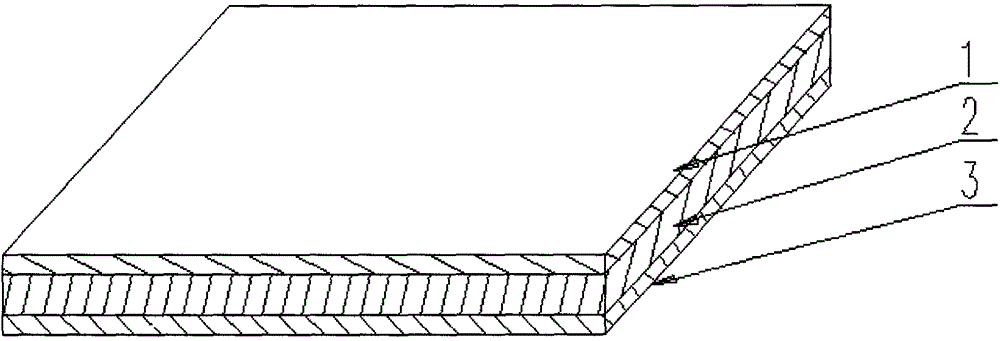

[0034] A high and low temperature type anti-corrosion viscoelastic filler, see attached figure 1 , consisting of a protective film 1, a viscoelastic paste layer 2 and an isolation film 3 arranged in sequence, the protective film 1 is pasted on one side of the viscoelastic paste layer 2, and the isolation film 3 is pasted on the other side of the viscoelastic paste layer 2;

[0035] The protective film layer 1 is a polyethylene film, and the isolation film 3 is a polyester (abbreviated as PET) isolation film;

[0036] The viscoelastic paste layer 2 is composed of the following raw material components and mass ratio: 33 kg of medium molecular weight polyisobutylene (SDG-8550), 10.5 kg of low molecular weight polyisobutylene (1300 of BASF Company), 55 kg of precipitated barium sulfate, and 55 kg of antioxidant agent (1010) 1kg, and phthalocyanine green 0.5kg.

[0037] The preparation method of the high and low temperature type anti-corrosion viscoelastic filler comprises the fol...

Embodiment 2

[0040]A high and low temperature type anti-corrosion viscoelastic filler, the viscoelastic paste layer 2 is composed of the following raw material components and mass ratio: 35kg of medium molecular weight polyisobutylene (SDG-8550), low molecular weight polyisobutylene (1300 of BASF company) 12.5kg, 51kg of precipitated barium sulfate, 0.5kg of antioxidant (1010), 1kg of pigment (phthalocyanine green);

[0041] Others are the same as embodiment 1, omitted.

Embodiment 3

[0043] A high and low temperature anti-corrosion viscoelastic filler, the viscoelastic paste layer 2 is composed of the following raw material components and mass ratios: 33kg of medium molecular weight polyisobutylene (SDG-8550), low molecular weight polyisobutylene (1300 of BASF company) 12.5kg, precipitated barium sulfate 53kg, antioxidant (1010) 0.7kg, pigment (phthalocyanine green) 0.8kg; Others are the same as embodiment 1, omitted.

[0044] When the product prepared in Example 1, 2 or 3 is in use, take the high and low temperature type anti-corrosion viscoelastic filler product (which can be strip, block or other shapes, produced and selected according to needs), and tear off the product on site. Isolation film 3, directly filled into the anti-corrosion repair of irregularities in pipes, elbows, tee flanges and other special-shaped pipe fittings (especially oil and gas pipelines), easy to use, convenient, not subject to high and low temperature restrictions, no need to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com