Adhesive composition for controlling light leakage and optical film coated with the same for display device

A display device, composition technology, applied in optics, adhesive type, nonlinear optics, etc., can solve problems such as adhesive flow or contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0085] Examples 1-6: Production of acrylic copolymers

[0086] For Examples 1-6, at first, n-butyl acrylate, methyl acrylate, acrylic acid and (meth)acrylic acid as polymerized monomers are provided to the reaction chamber in the following Table 1 in the content (the unit is "parts by weight") 4-hydroxybutyl ester; 100 g of ethyl acetate as a solvent; and azobisisobutyronitrile (AIBN) as a polymerization initiator.

[0087] After replacing the air in the reaction chamber with nitrogen, the mixture was stirred while raising the temperature of the mixture to 63° C., and then polymerized for the reaction time shown in Table 1 below. After the polymerization reaction, the resulting mixture was diluted with 100 g of ethyl acetate to obtain a solid acrylic copolymer liquid. In the polymer liquid, after measuring the initial weight of the binder and then evaporating the solvent at 100° C. for 30 minutes, the weight of the solid was measured by a solid measuring machine. The molecul...

Embodiment 7~14

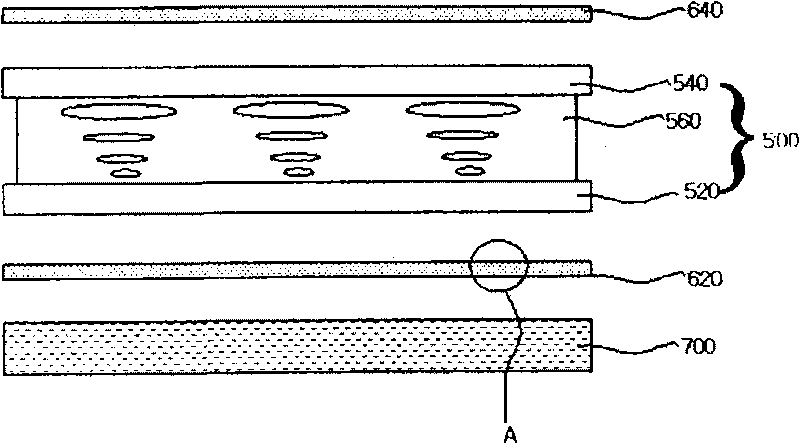

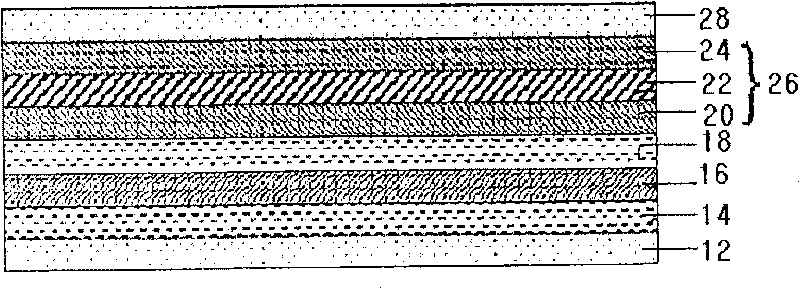

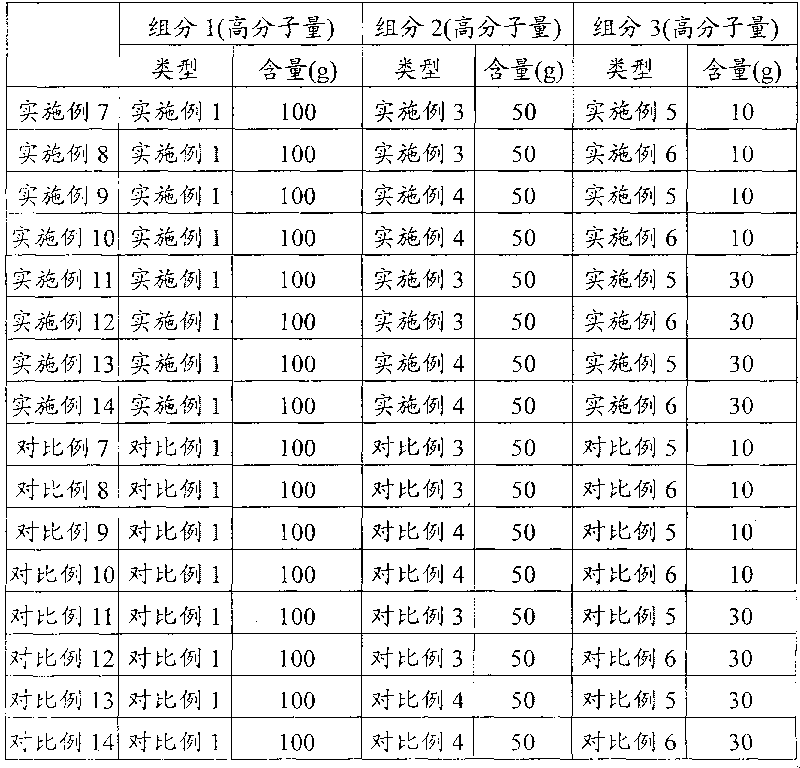

[0097] Examples 7-14: Production of polarizing plate coated with adhesive composition

[0098] The polymers obtained in Examples 1 to 6 were mixed at the mixture ratio (in "g") shown in Table 3 below, and 0.2 g of trimethylhexamethylenediamine solid was added to the mixture as an exchange. agent and stirred to obtain an adhesive composition for manufacturing a polarizing plate. The adhesive composition for producing polarizing plates thus obtained was coated on a polyester release film and the resulting coated film was dried. In this case, the coating was controlled to be 25 μm thick after drying. Subsequently, the adhesive composition coated on the release film was transferred to a 200 μm polarizing film to obtain a polarizing plate of the present invention after aging at a temperature of 23° C. and a humidity of 45% for 7 days.

[0099] The polarizing plate provided with the adhesive layer was cut into a size of 210 mm×297 mm such that the absorption axis remained at 45° w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com