Environment-friendly type elastomer modified asphalt waterproof roll

A technology of asphalt waterproofing membrane and body modification, applied in building insulation materials, asphalt layered products, building components, etc., can solve problems such as pollution, reduce production costs, prevent detachment and separation problems, and improve resistance to "lodging". "Effect of Ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

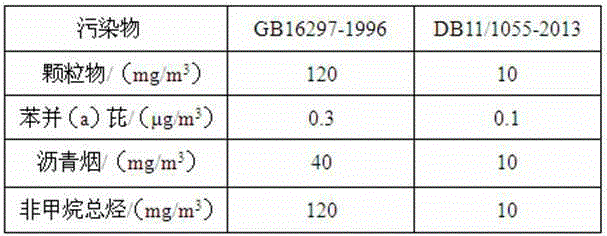

Problems solved by technology

Method used

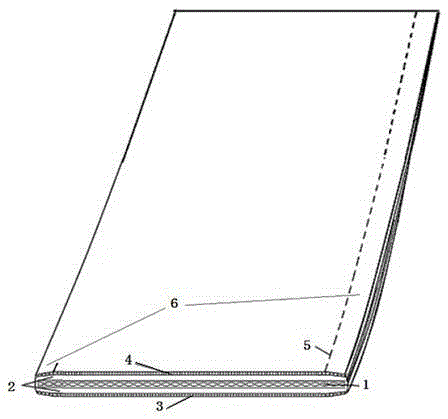

Image

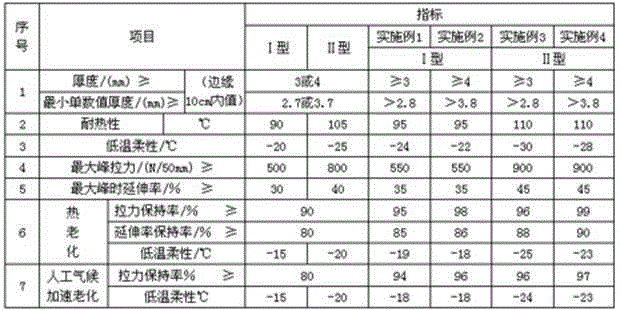

Examples

Embodiment 1

[0028] Embodiment 1: The environment-friendly elastomer modified asphalt waterproofing membrane mentioned in the present invention comprises the following preparation methods:

[0029] 1. Preparation method of environment-friendly elastomer modified asphalt:

[0030] a) Add 46 parts by mass of low-smoke pitch and 8 parts by mass of rubber process oil into a vertical batching tank, stir and mix and heat up to 130-140°C;

[0031] b) Slowly add 8 parts by mass of natural asphalt masterbatch, 6 parts by mass of SBS thermoplastic rubber and 1 part by mass of powdered styrene-butadiene rubber in sequence, continue to heat up to 160-170°C, and then use a colloid mill to grind 2 times until the materials are melted and mixed Uniform;

[0032] c) Add 1 mass part of polyolefin auxiliary agent and 1 mass part of amide wax and stir, melt and mix evenly, and the polyolefin auxiliary agent adopts a polymer copolymer of oxidized polyethylene;

[0033] d) Pump the modified asphalt into a ho...

Embodiment 2

[0039] Embodiment 2: A kind of environment-friendly elastomer modified asphalt waterproof membrane mentioned in the present invention comprises the following preparation methods:

[0040] 1. Preparation method of environment-friendly elastomer modified asphalt

[0041] a) Add 45 parts by mass of low-smoke asphalt and 5 parts by mass of rubber process oil into a vertical batching tank, stir and mix and heat up to 130-140°C;

[0042] b) Slowly add 5 parts by mass of natural asphalt masterbatch, 4 parts by mass of SBS thermoplastic rubber, 0 part by mass of polybutene elastomer and 1 part by mass of powdered styrene-butadiene rubber, and continue to heat up to 160-170 °C before use The colloid mill circulates and grinds 2 times until the material is melted and mixed evenly;

[0043] c) adding 0 mass parts of polyolefin additives and 0 mass parts of polyolefin additives to stir, melt and mix evenly, and the polyolefin additives are polymer copolymers of oxidized polyethylene;

...

Embodiment 3

[0047] Embodiment 3: A kind of environment-friendly elastomer modified asphalt waterproof membrane mentioned in the present invention comprises the following preparation methods:

[0048] 1. Preparation method of environment-friendly elastomer modified asphalt

[0049] a) Add 50 parts by mass of low-smoke asphalt and 6.5 parts by mass of rubber process oil into a vertical batching tank, stir and mix and heat up to 130-140°C;

[0050] b) Slowly add 5 parts by mass of natural asphalt masterbatch, 6 parts by mass of SBS thermoplastic rubber, 2 parts by mass of polybutene elastomer and 3 parts by mass of powdered styrene-butadiene rubber, and continue to heat up to 160-170 °C before use The colloid mill circulates and grinds 2 times until the material is melted and mixed evenly;

[0051] c) Add 0.5 parts by mass of polyolefin auxiliary agent and 1 mass part of amide wax and stir, melt and mix evenly, and the polyolefin auxiliary agent adopts a polymer copolymer of oxidized polyet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com