Synthesis method of middle-molecular-weight hydroxyethyl starch

A technology of hydroxyethyl starch and synthesis method, which is applied in the field of medicine and chemical industry, can solve the problems of reduced reactivity, prolonged catabolism of hydroxyethyl starch, etc., and achieves the effect of easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

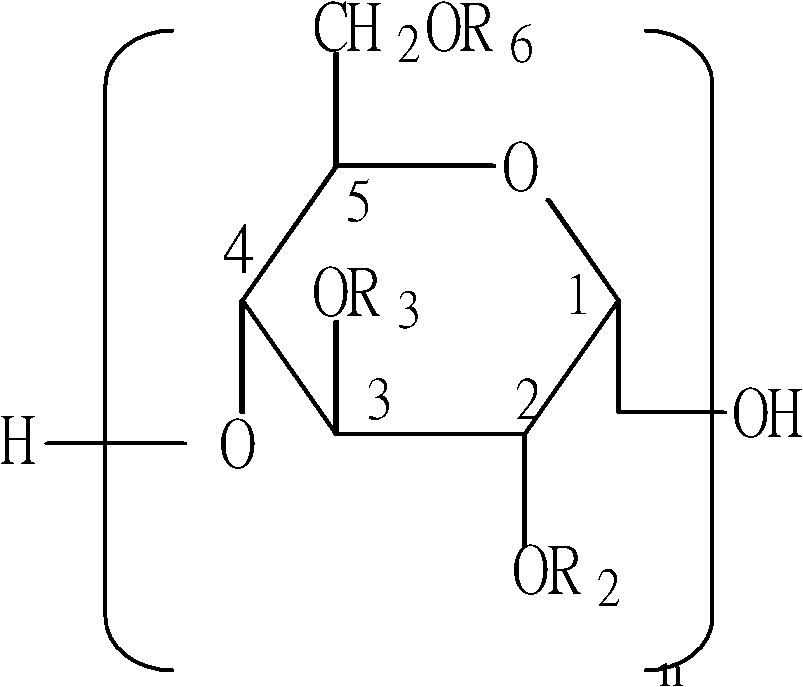

Image

Examples

Embodiment 1

[0024] Preparation of hydroxyethyl starch 130 / 0.4

[0025] Take the waxy cornstarch hydrolyzate 1800g that weight average molecular weight is 110,000-150,000 and 80% product is distributed in 15000 to 500000, add purified water and be made into 25% solution and be placed in 15L reactor, in purifying high-purity N 2 Under protection, the temperature of the jacketed water bath was controlled at about 30°C, and vigorously stirred, 804ml of 10N NaOH solution and 415g of chloroethanol were added respectively, and the stirring was continued for 8 hours, and then the reaction solution was neutralized with 10N hydrochloric acid until the pH value was close to 7. The reaction liquid is treated with a 15,000 molecular weight ultrafiltration cut-off membrane to remove sodium chloride and some low-molecular organic residual components contained in the reaction liquid. Decolorize the cut-off part of the above-mentioned membrane separation through activated carbon, filter, and spray-dry the...

Embodiment 2

[0027] Preparation of hydroxyethyl starch 200 / 0.5,

[0028] Take 20Kg of waxy corn starch hydrolyzate starch hydrolyzate with a weight average molecular weight of 180,000-290,000 and 80% product distribution in the range of 15,000 to 800,000, add purified water to form a 25% solution and place it in a 200L reactor, and pass through the purified high-purity N 2 For protection, the temperature of the jacketed water bath is controlled at about 30°C, and 10.5L of 10N sodium hydroxide solution and 5.2Kg of chloroethanol are respectively added under stirring, and the stirring is continued for 12 hours. The reaction solution was neutralized with 10N hydrochloric acid until the pH was close to 7. After the reaction solution is treated with a 30,000 molecular weight hollow fiber cut-off membrane, decolorize the membrane separation cut-off part with activated carbon, filter, and spray dry to obtain white powder hydroxyethyl starch 200 / 0.5. The product MS, C2:C6 was determined by GC met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com