Patents

Literature

39 results about "Plasma volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma volume. the total volume of plasma in the body, elevated in diseases of the liver and spleen and in vitamin C deficiency and lowered in Addison's disease, dehydration, and shock. The normal plasma volume in males is 39 mL/kg of body weight; in females, 40 mL/kg. The total quantity of plasma in the body.

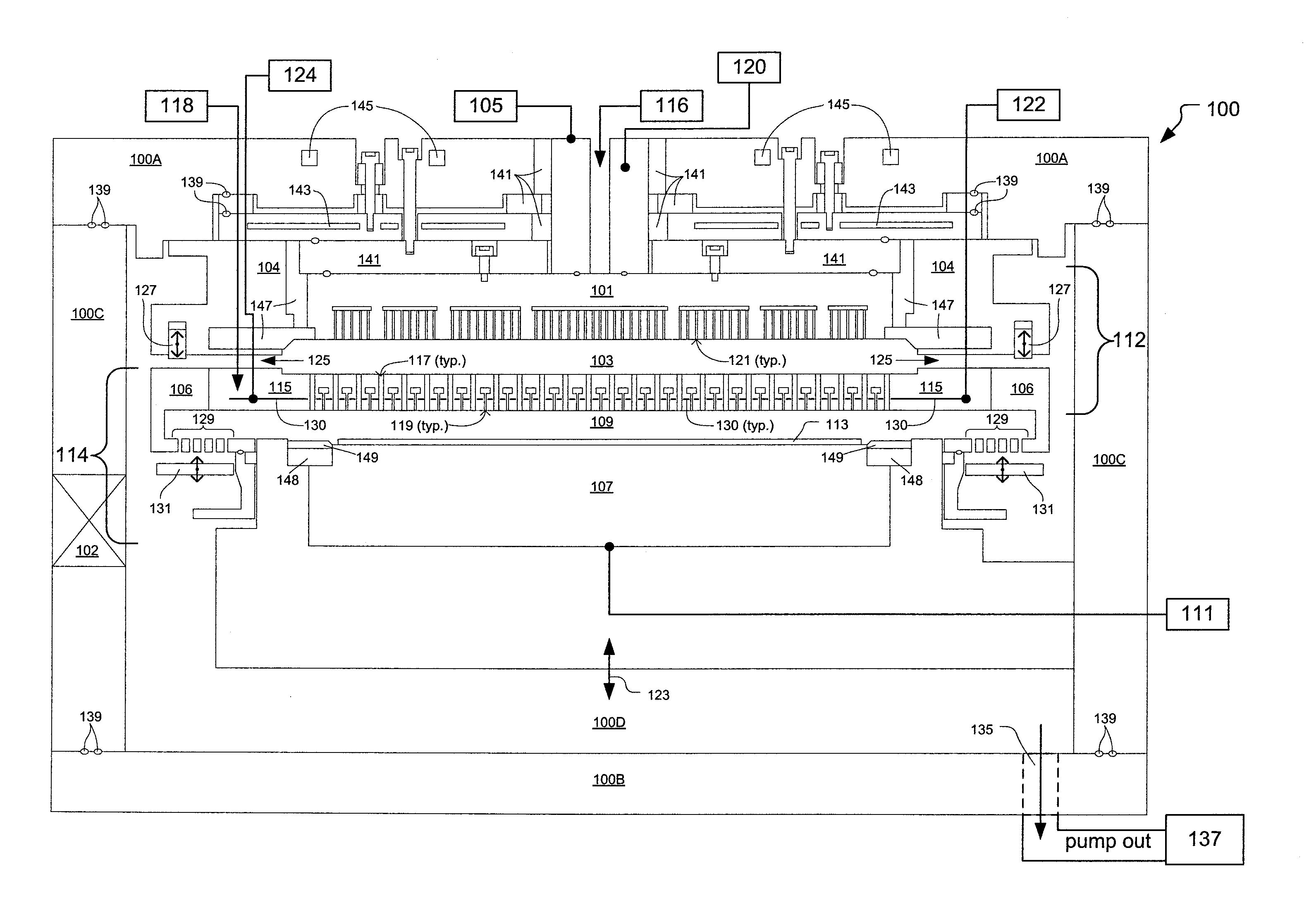

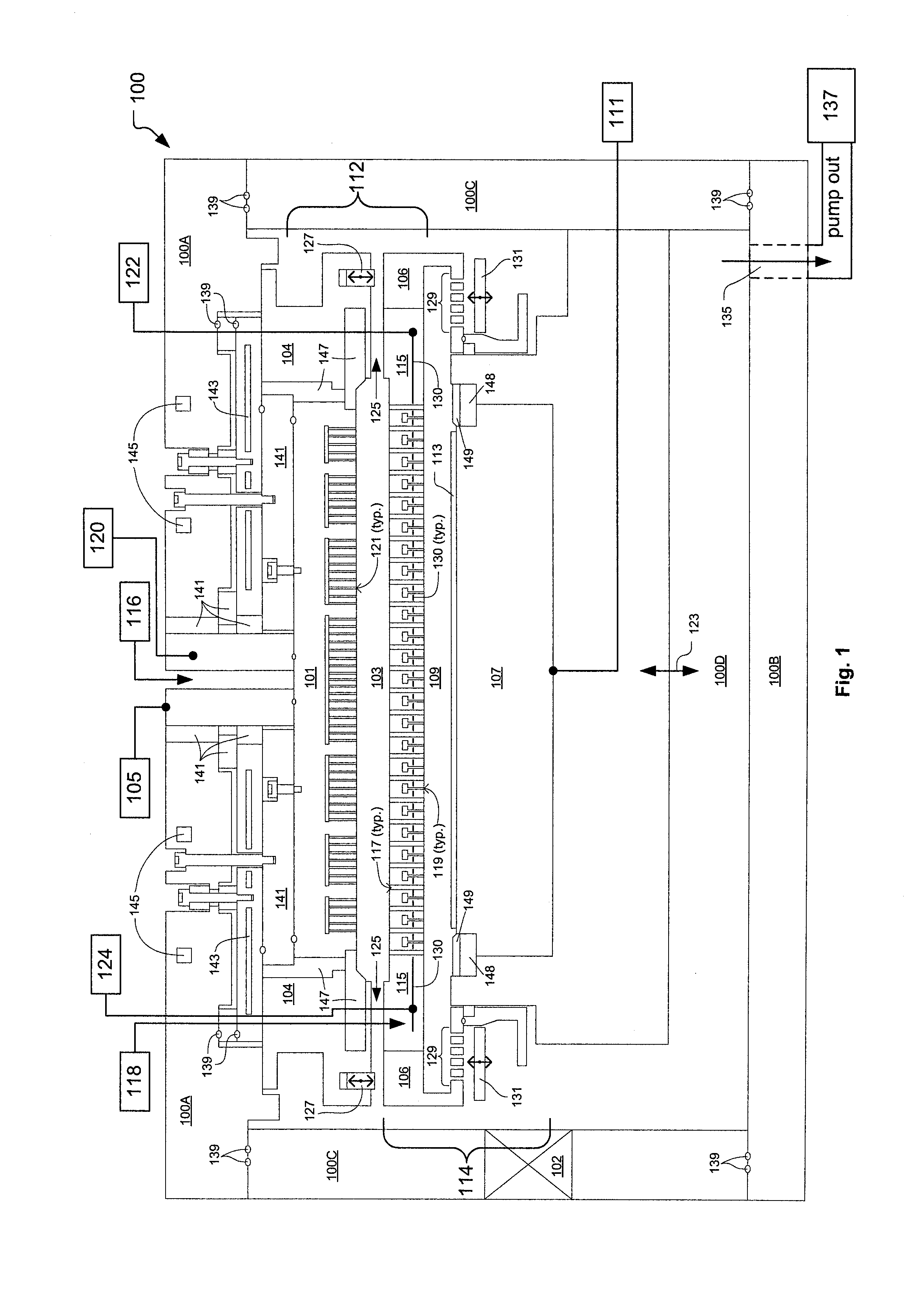

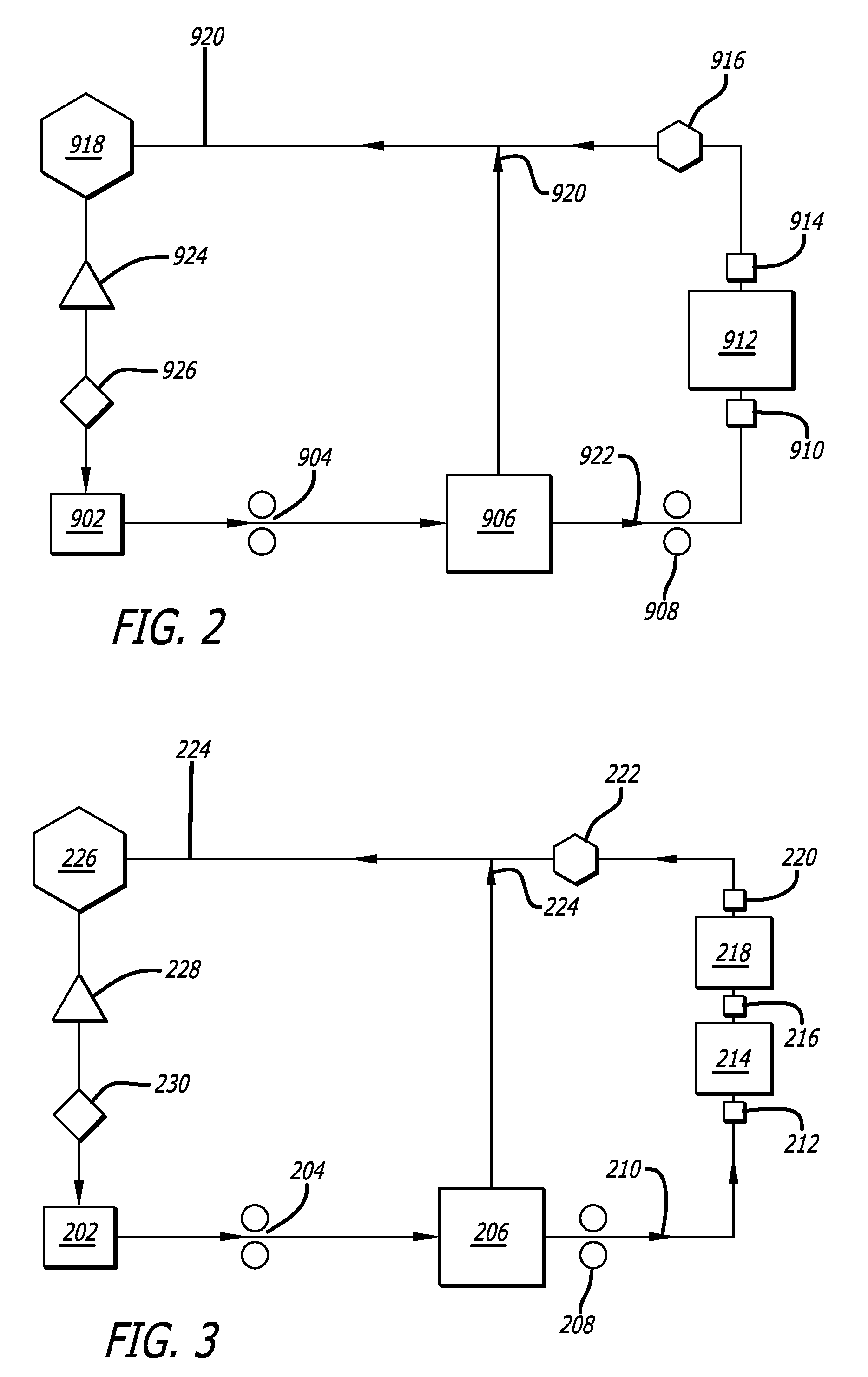

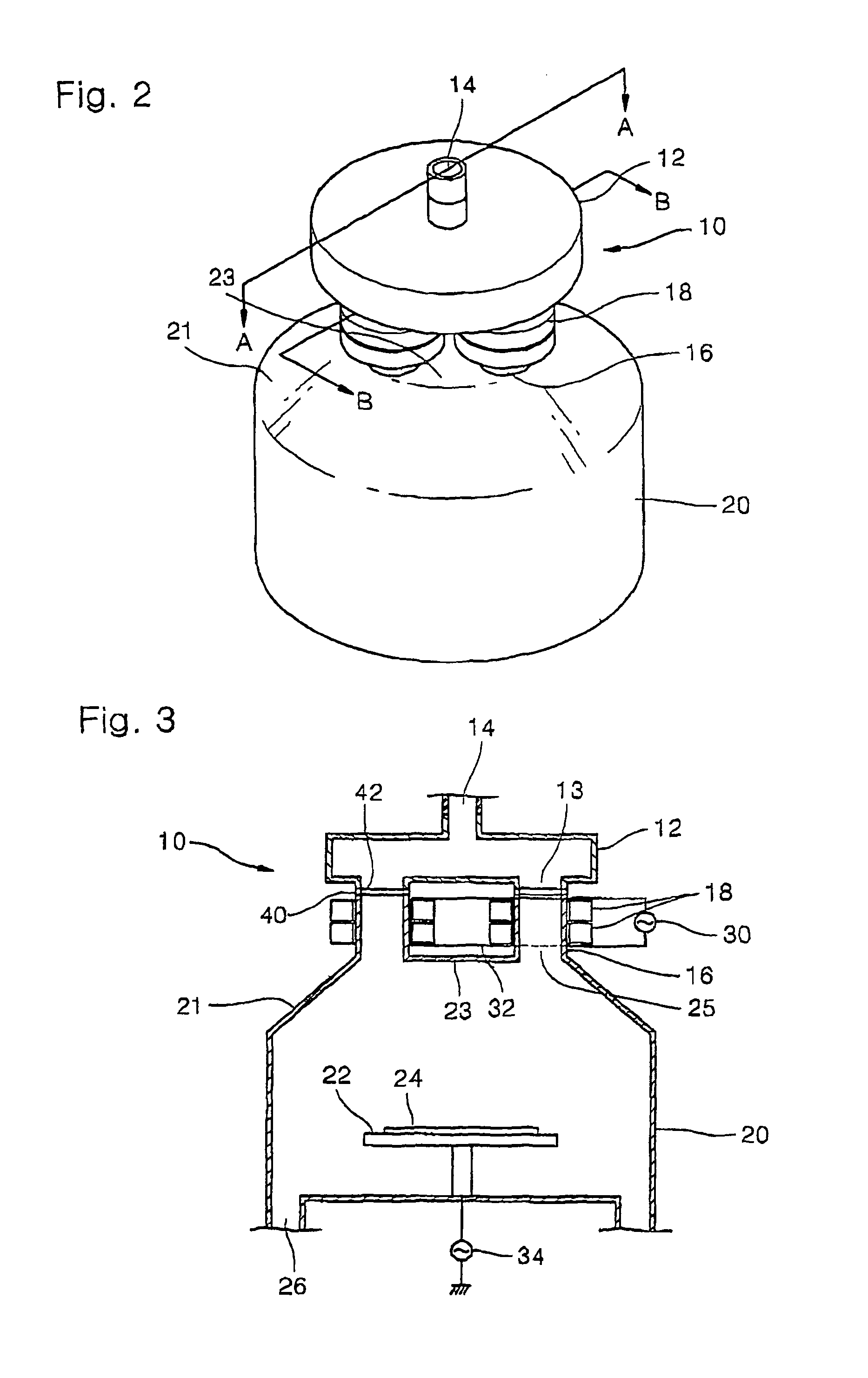

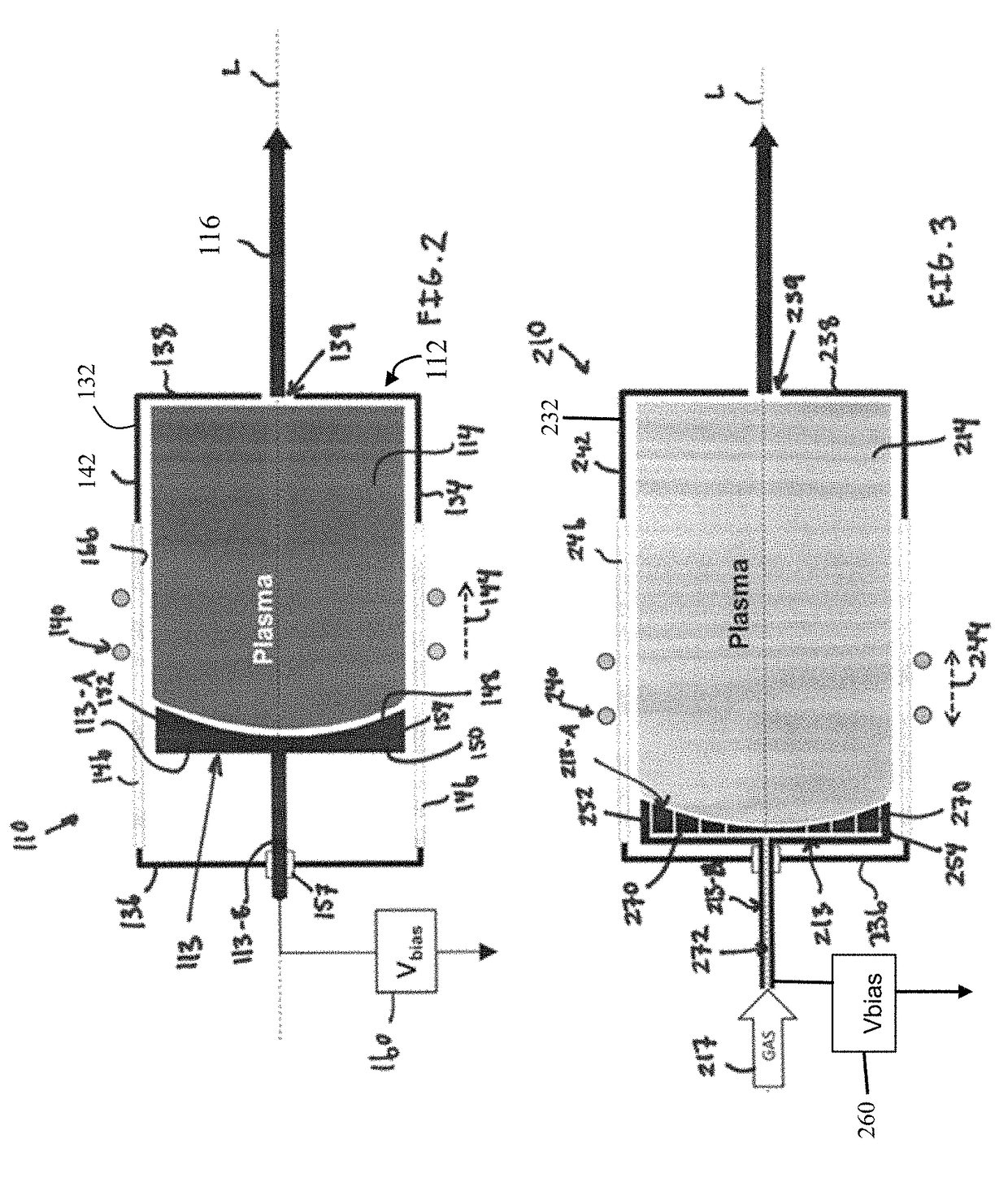

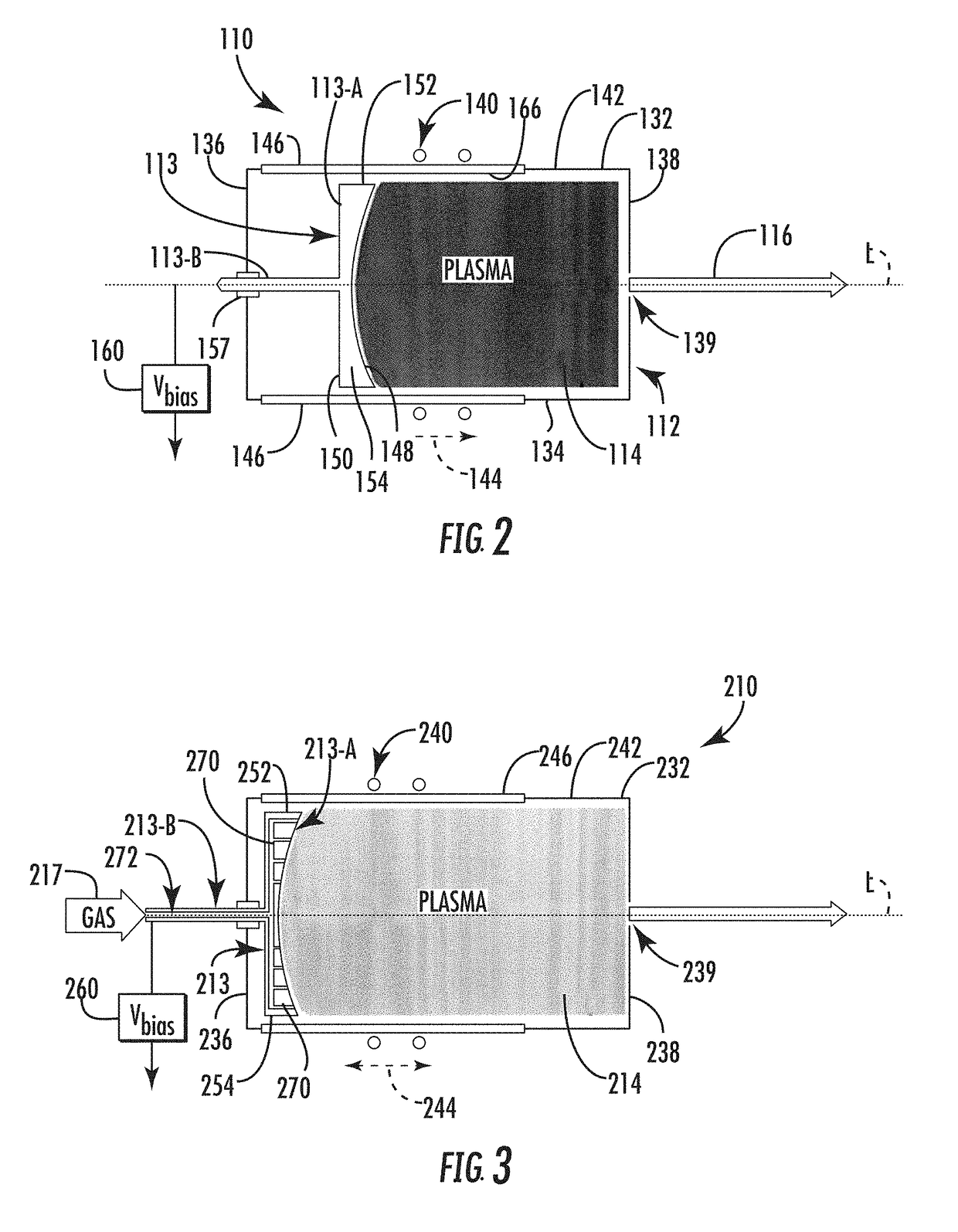

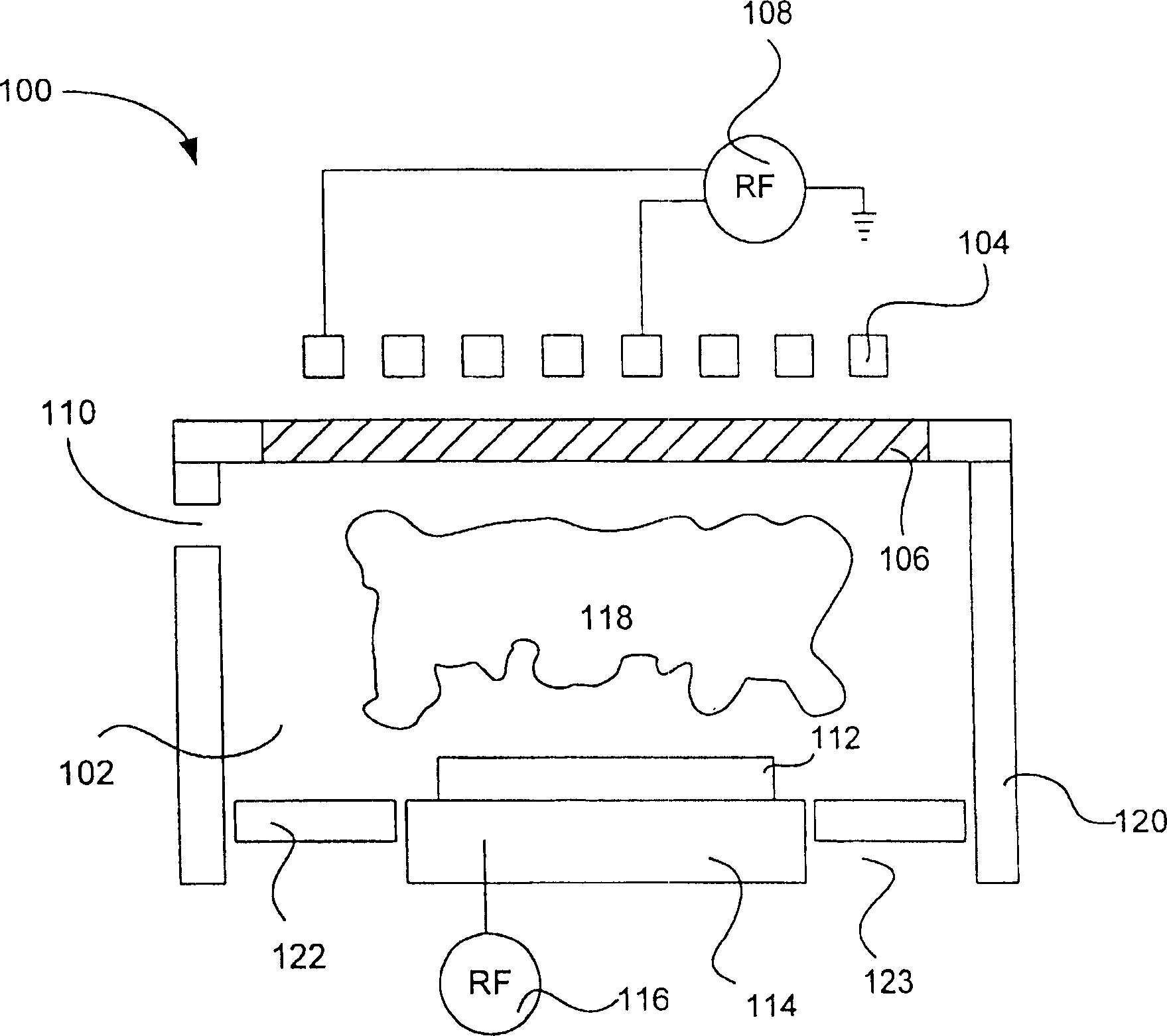

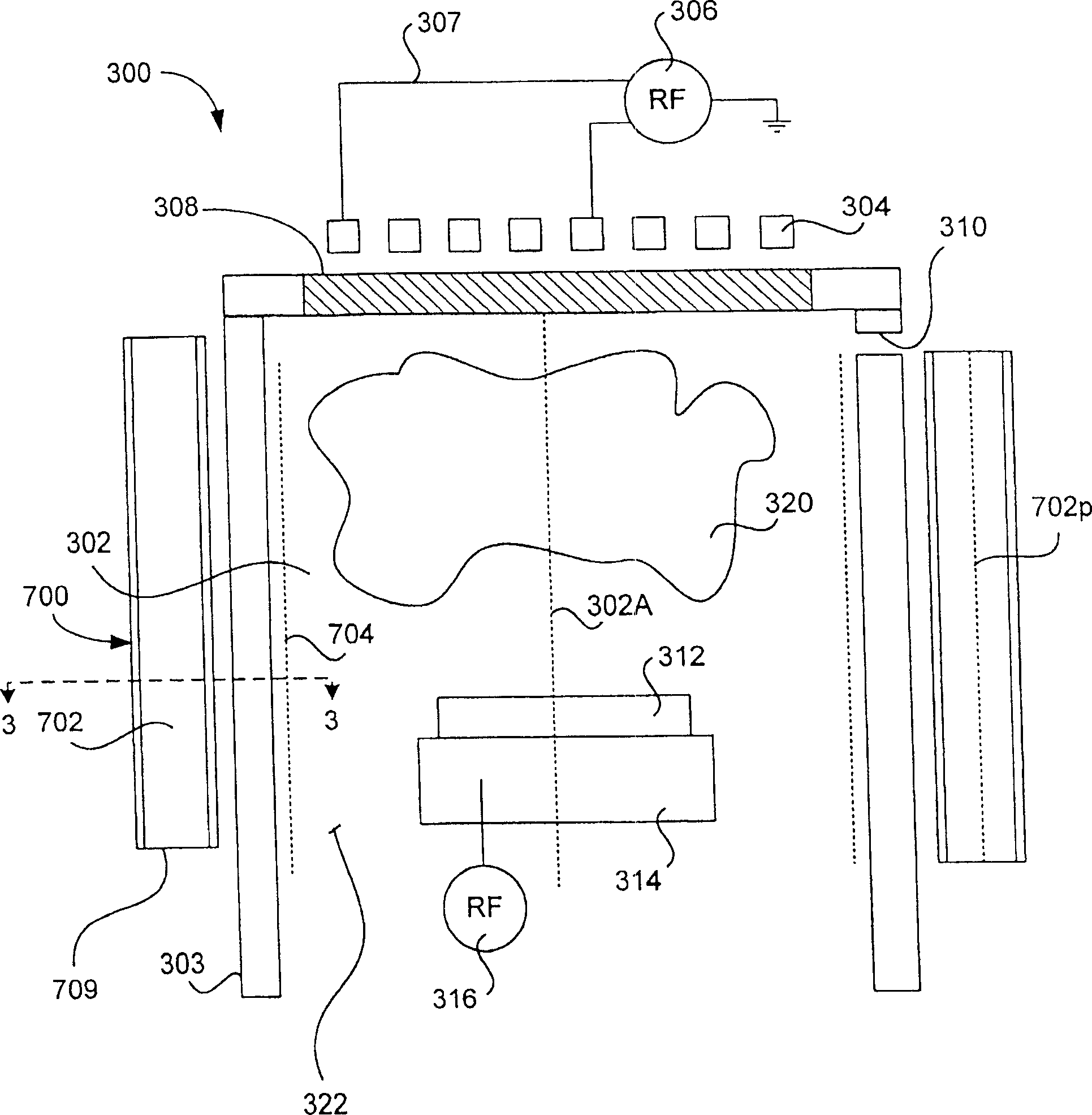

Dual Plasma Volume Processing Apparatus for Neutral/Ion Flux Control

ActiveUS20120031559A1Semiconductor/solid-state device testing/measurementElectric discharge tubesGas supplySemiconductor

A semiconductor wafer processing apparatus includes a first electrode exposed to a first plasma generation volume, a second electrode exposed to a second plasma generation volume, and a gas distribution unit disposed between the first and second plasma generation volumes. The first electrode is defined to transmit radiofrequency (RF) power to the first plasma generation volume, and distribute a first plasma process gas to the first plasma generation volume. The second electrode is defined to transmit RF power to the second plasma generation volume, and hold a substrate in exposure to the second plasma generation volume. The gas distribution unit includes an arrangement of through-holes defined to fluidly connect the first plasma generation volume to the second plasma generation volume. The gas distribution unit also includes an arrangement of gas supply ports defined to distribute a second plasma process gas to the second plasma generation volume.

Owner:LAM RES CORP

Method and apparatus for blood separations

InactiveUS20060226090A1Reduces direct collectionReduce processing costsWater/sewage treatment by centrifugal separationCentrifugal force sediment separationWhole blood productMedicine

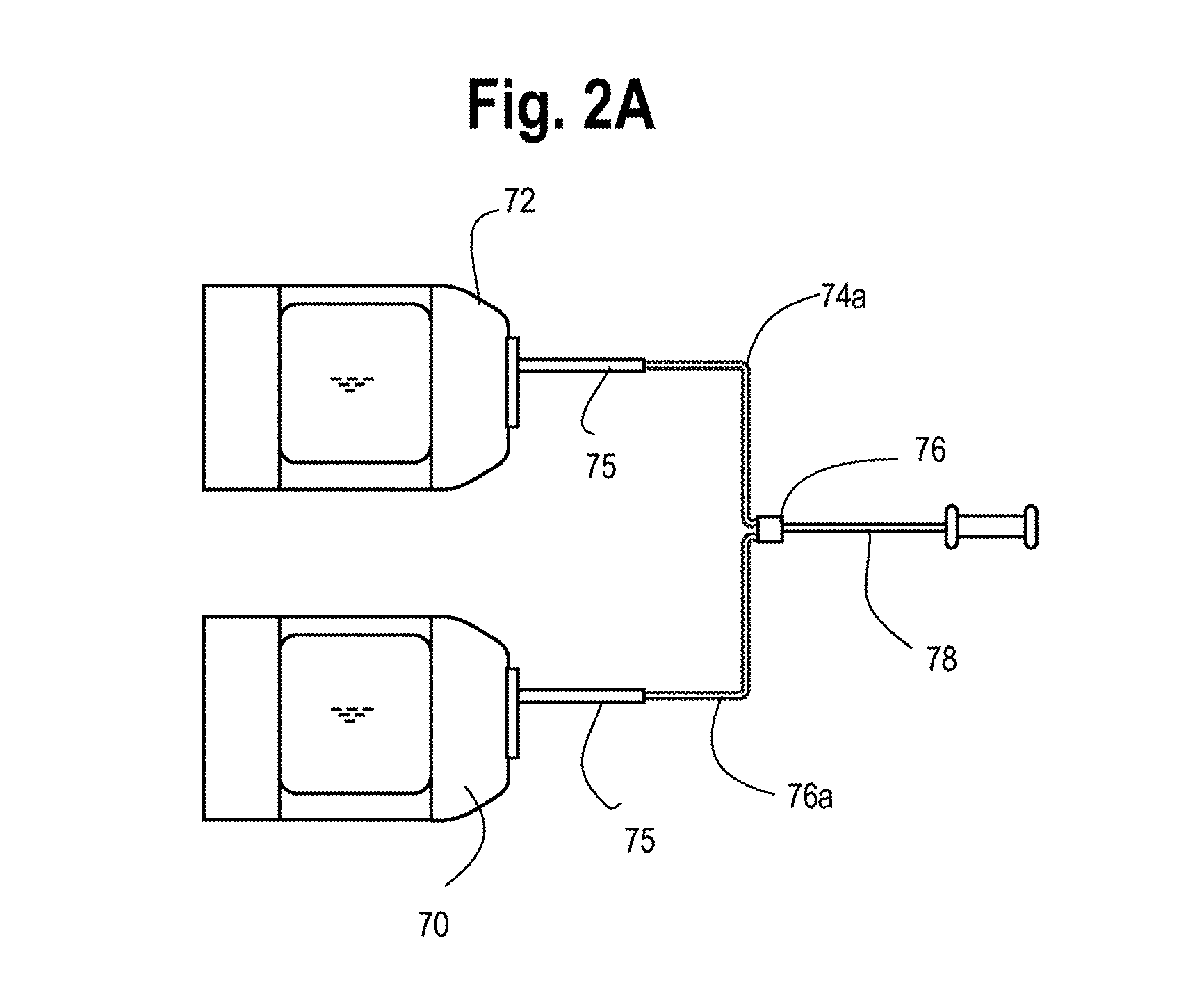

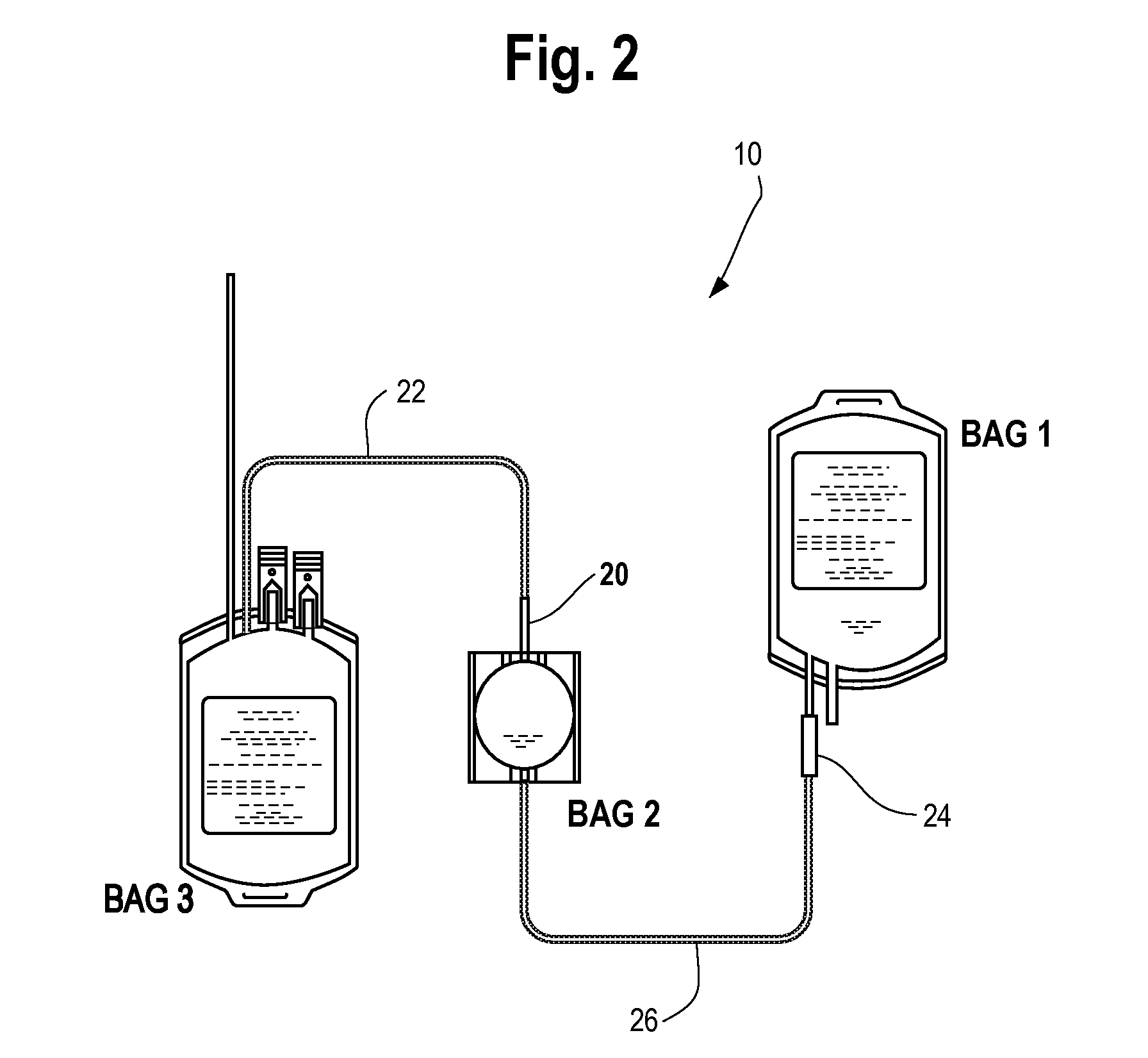

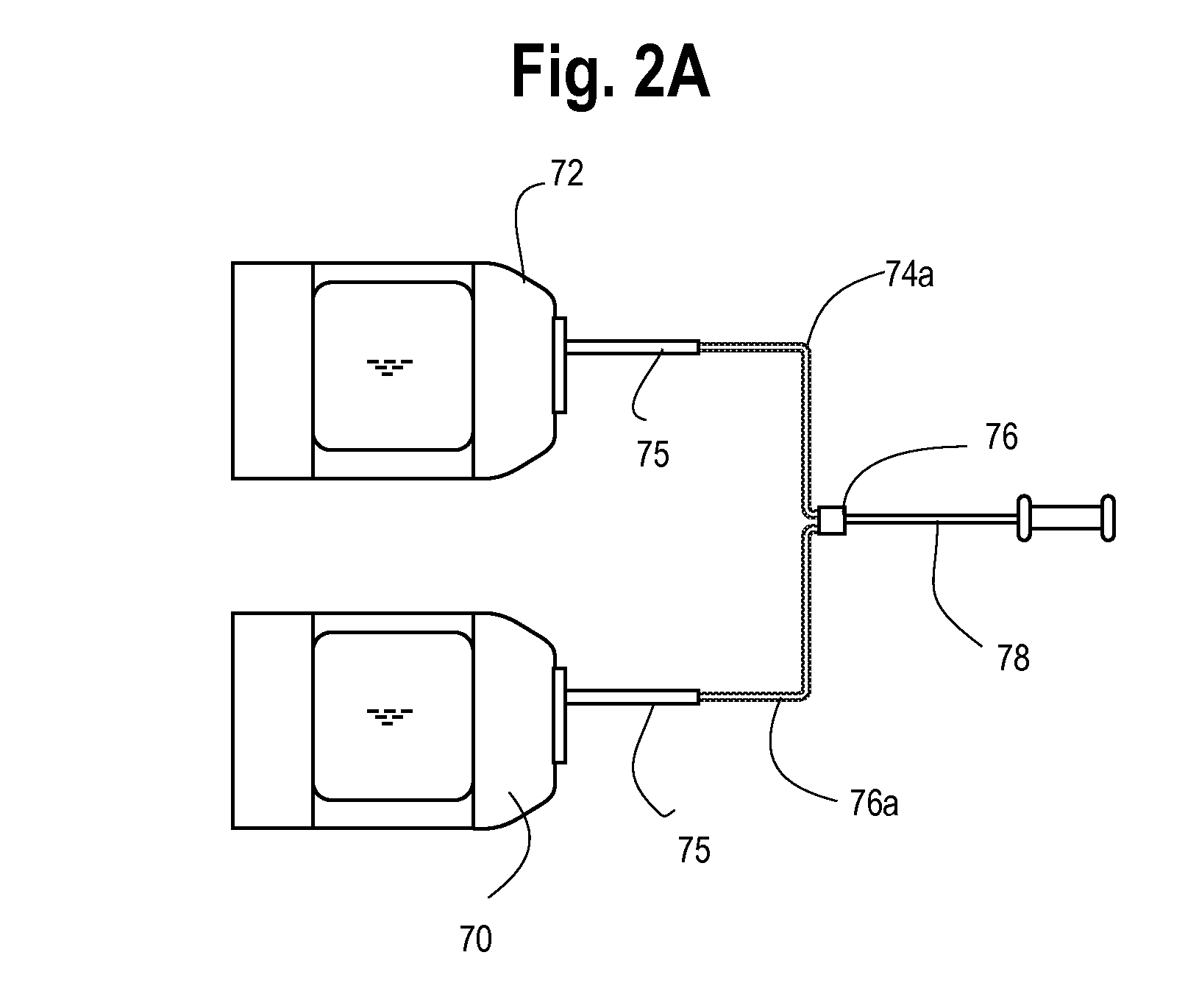

Described herein is a method and apparatus for collecting and separating whole blood into its components, including collecting an amount of plasma and red blood cells. The collection and separation system includes a console and a disposable set. The method may include processing the blood through the centrifuge, collecting plasma, collecting red blood cells and returning red blood cells until a desired plasma volume is reached. Then a final volume of red blood cells and plasma may be collected. The disposable set may include a manifold, a CFC, and various components attached by tubing. These components may include one or more solution bags, blood product bags, bacterial filters, leukofilters, and a donor blood collection tube with access needle.

Owner:TERUMO MEDICAL CORP

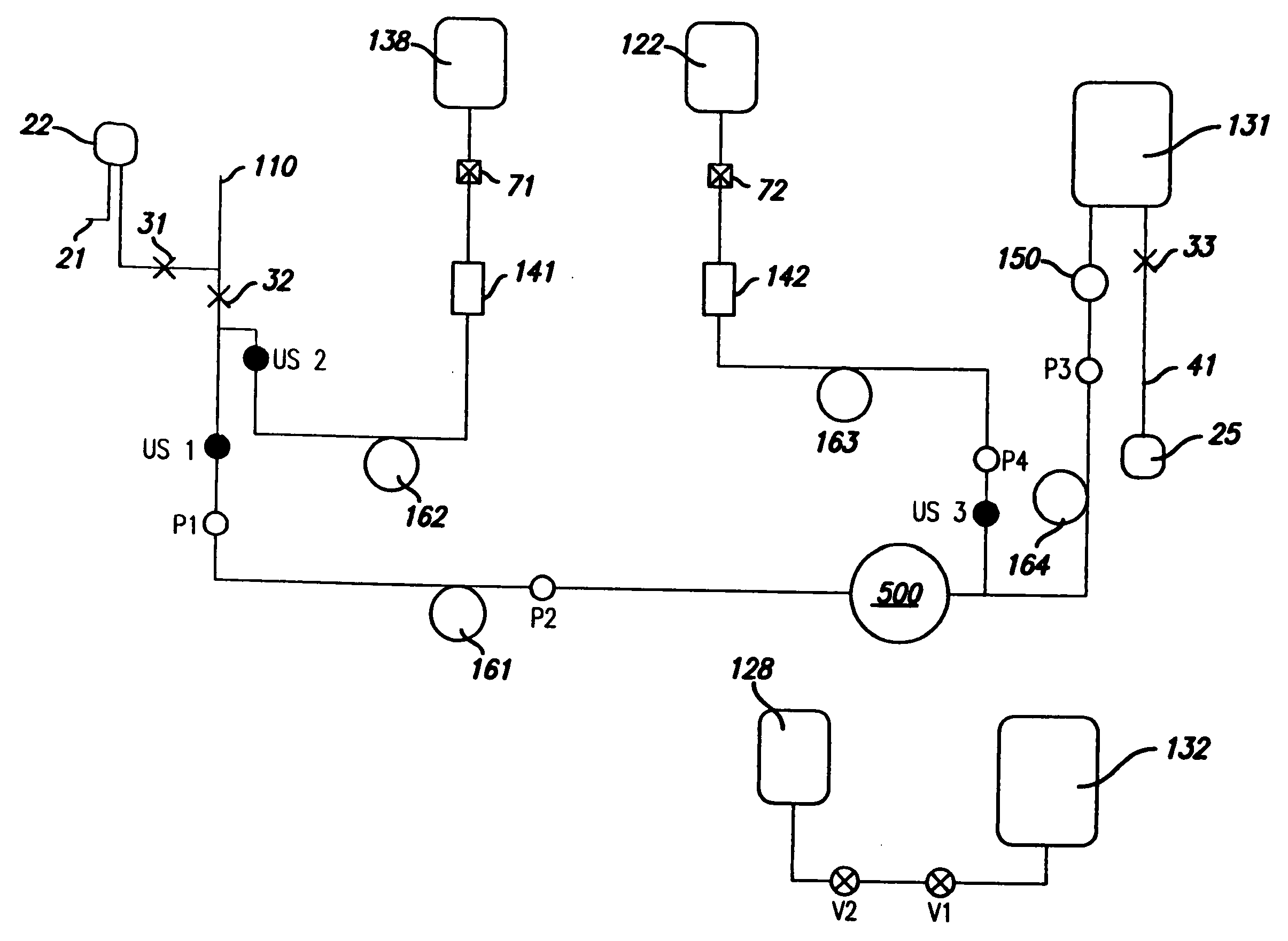

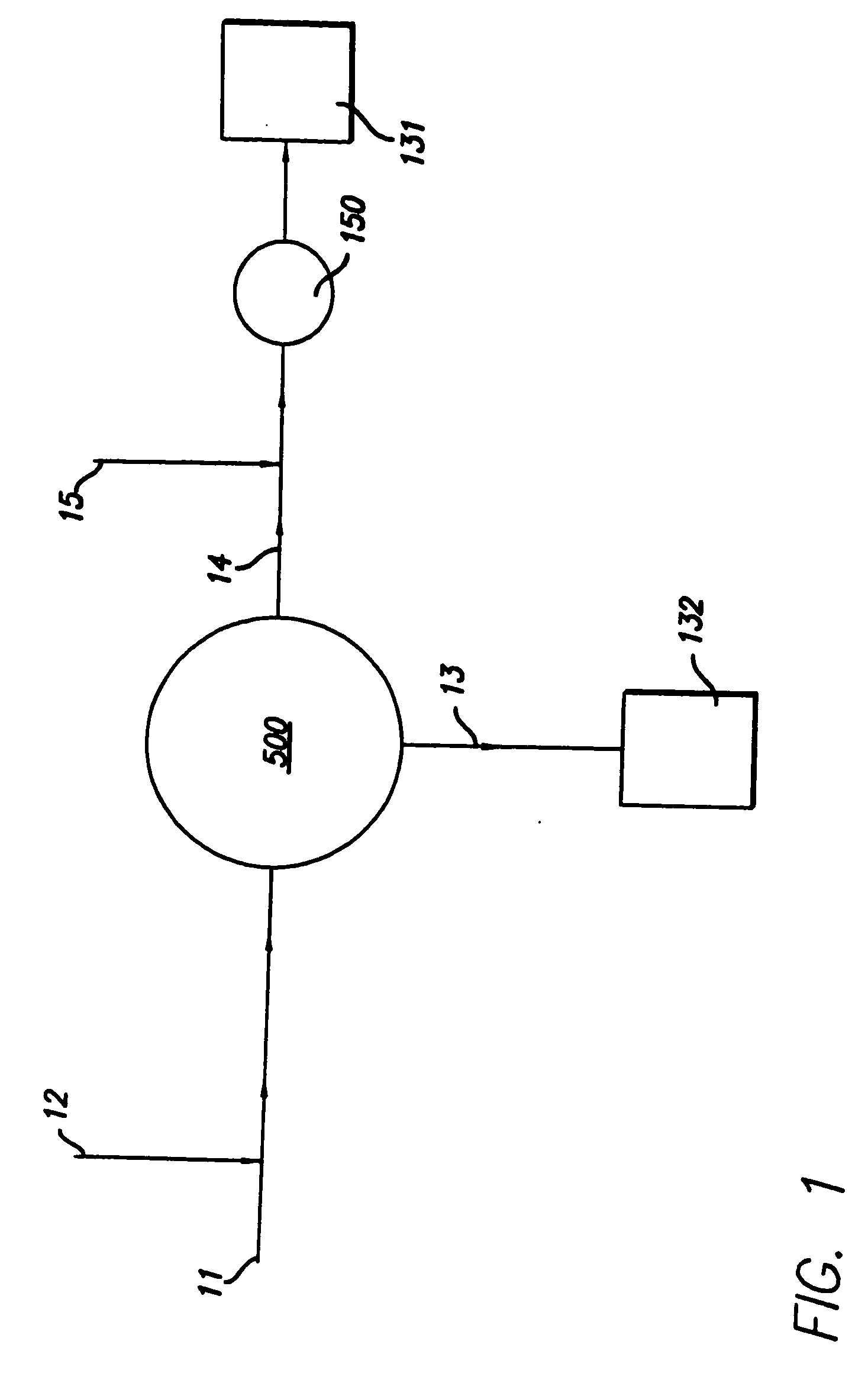

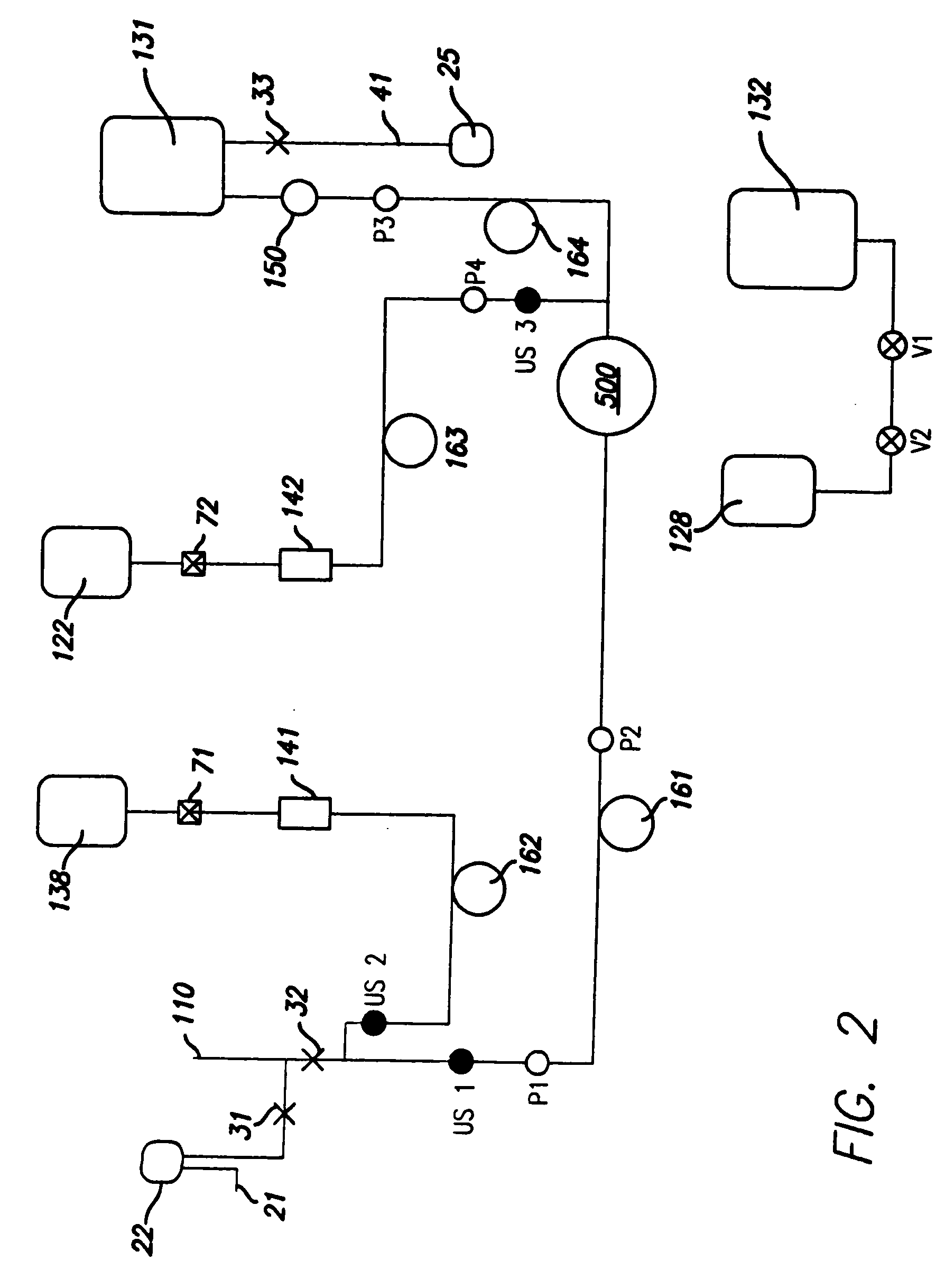

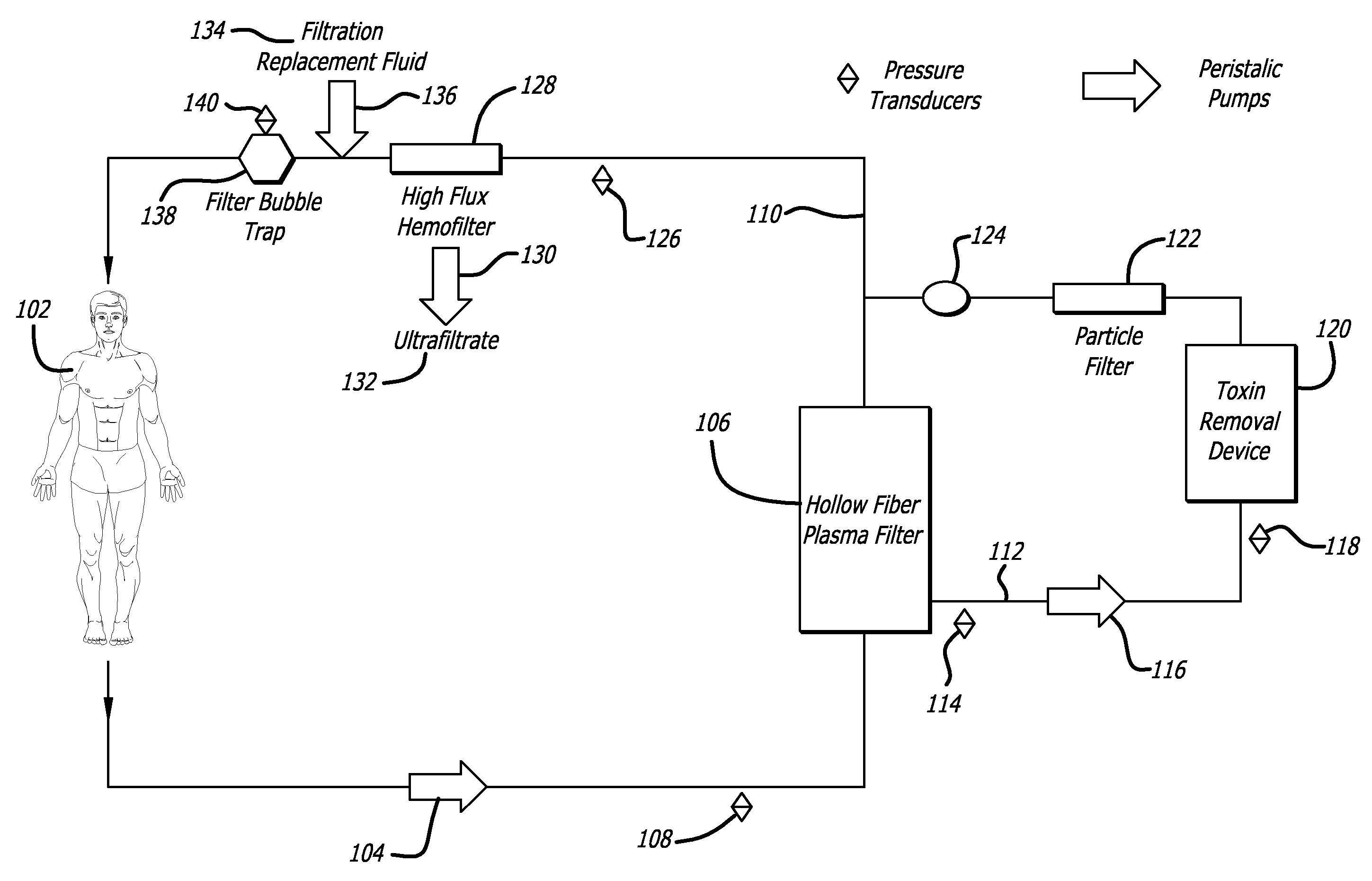

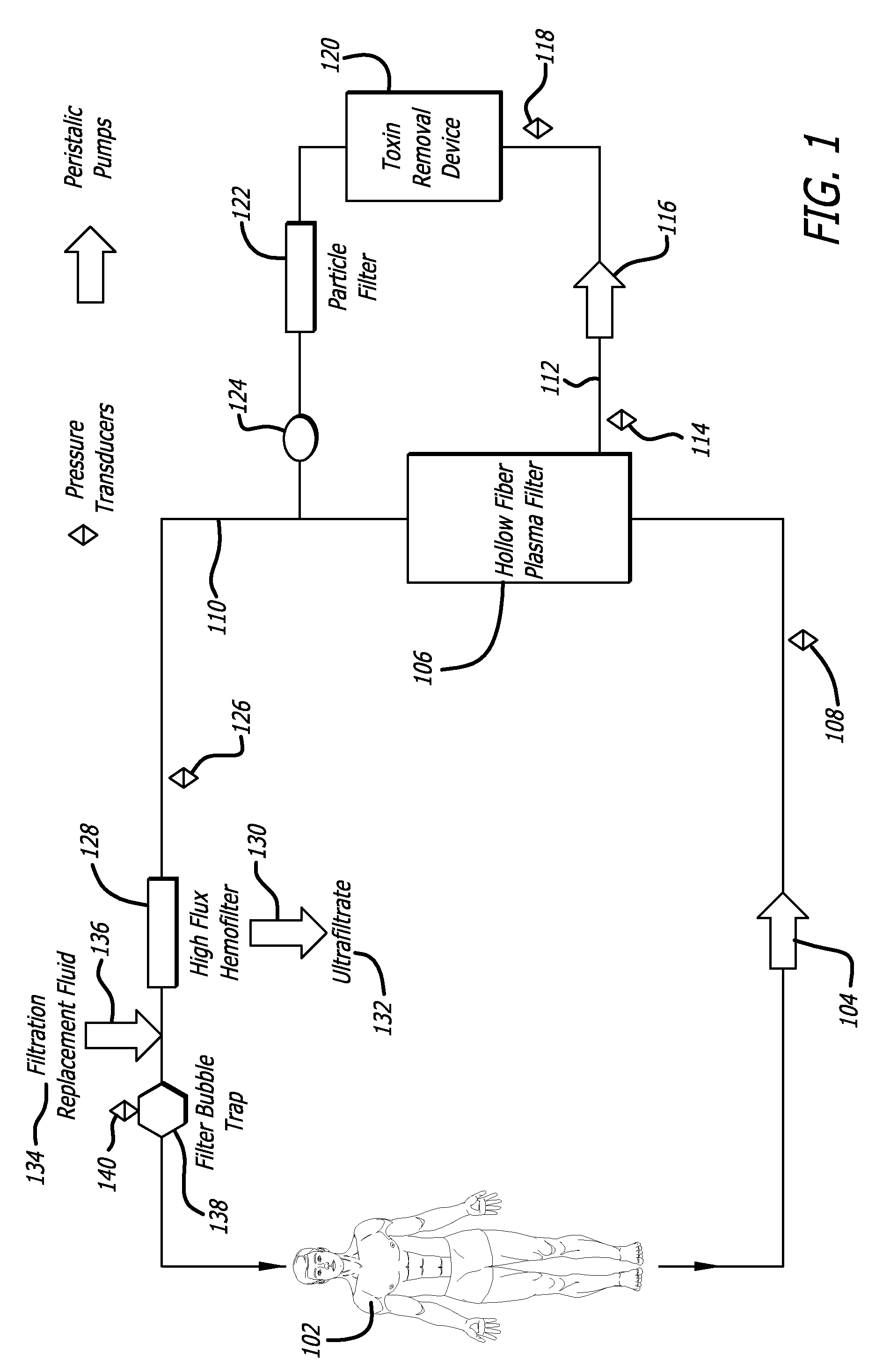

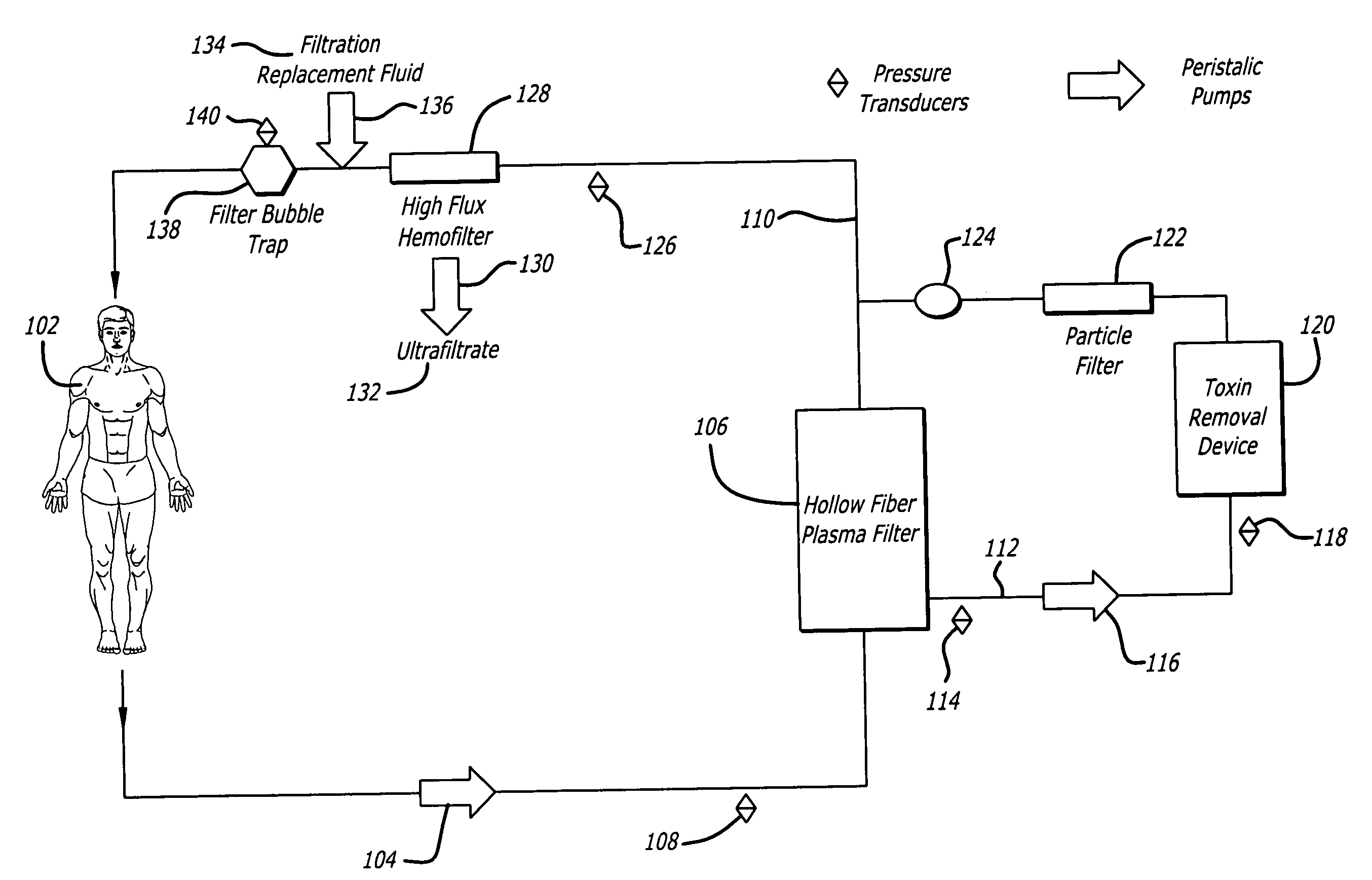

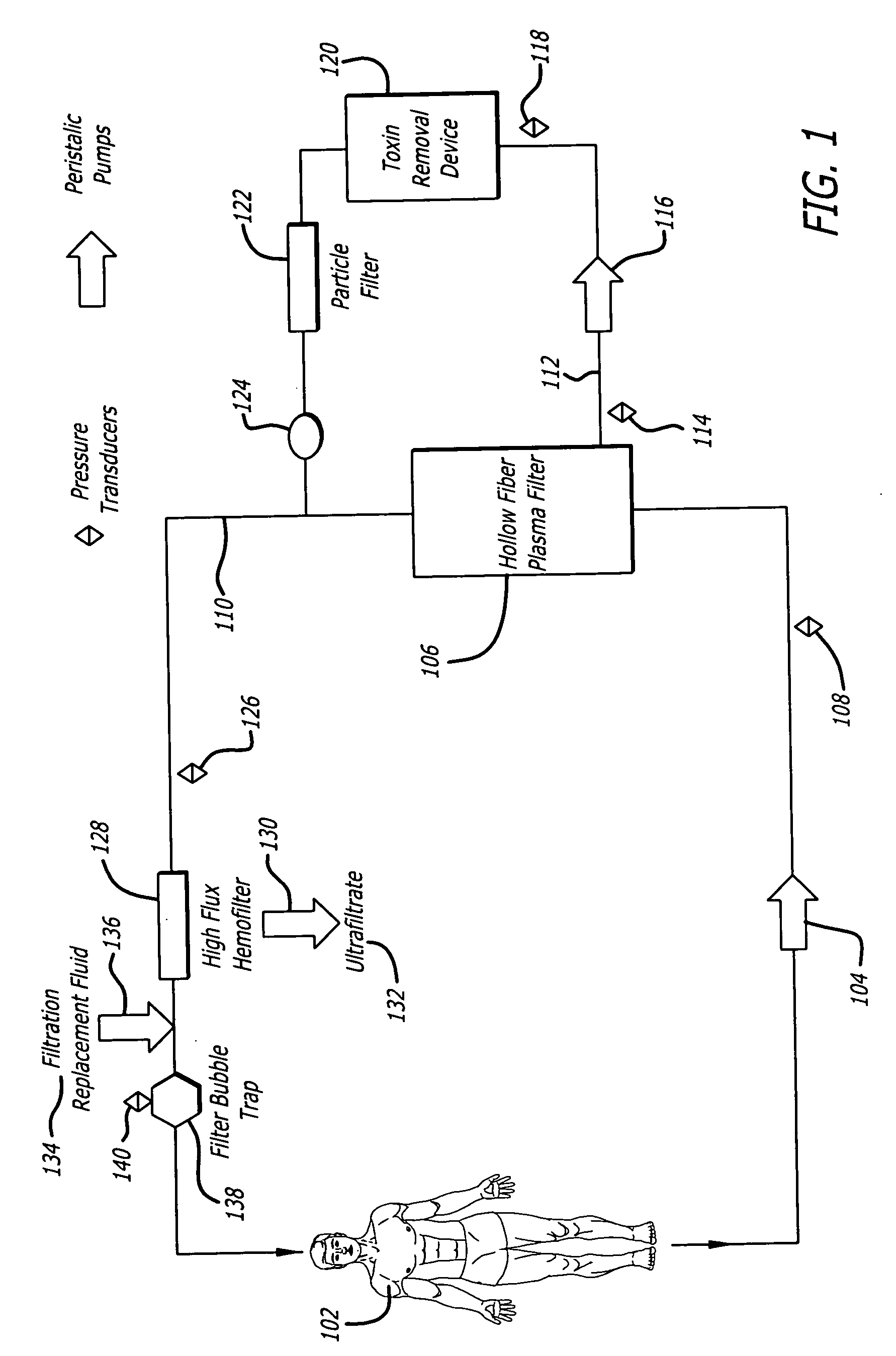

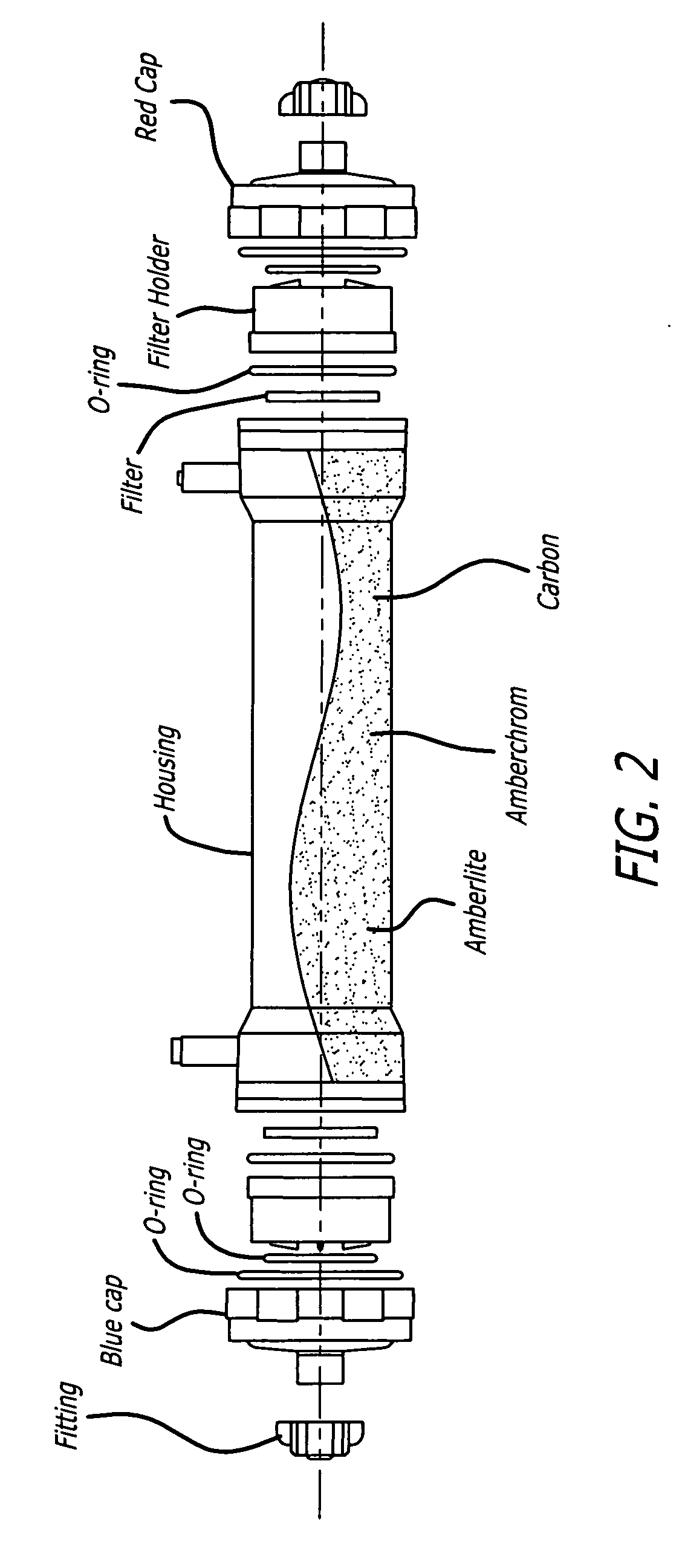

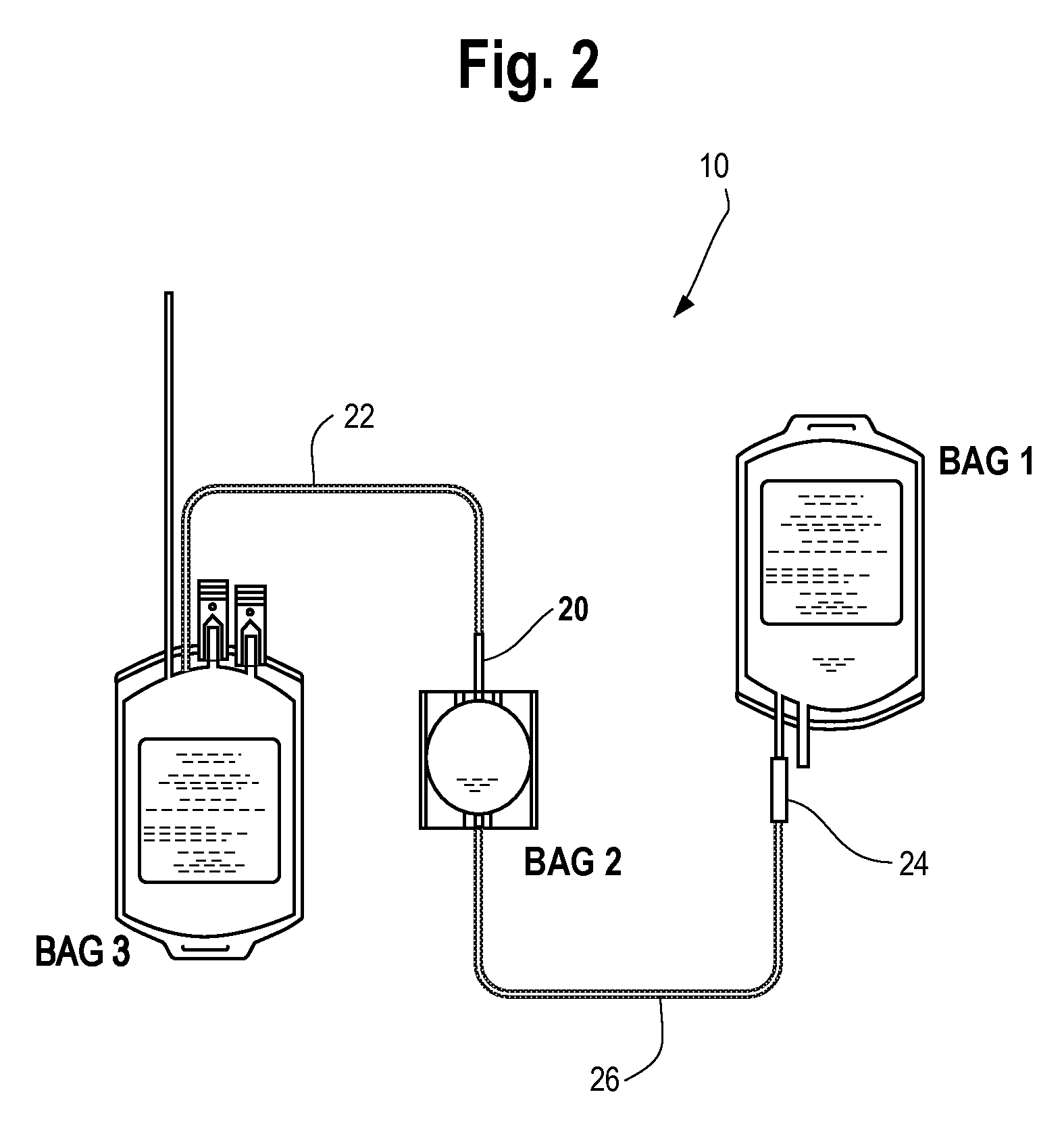

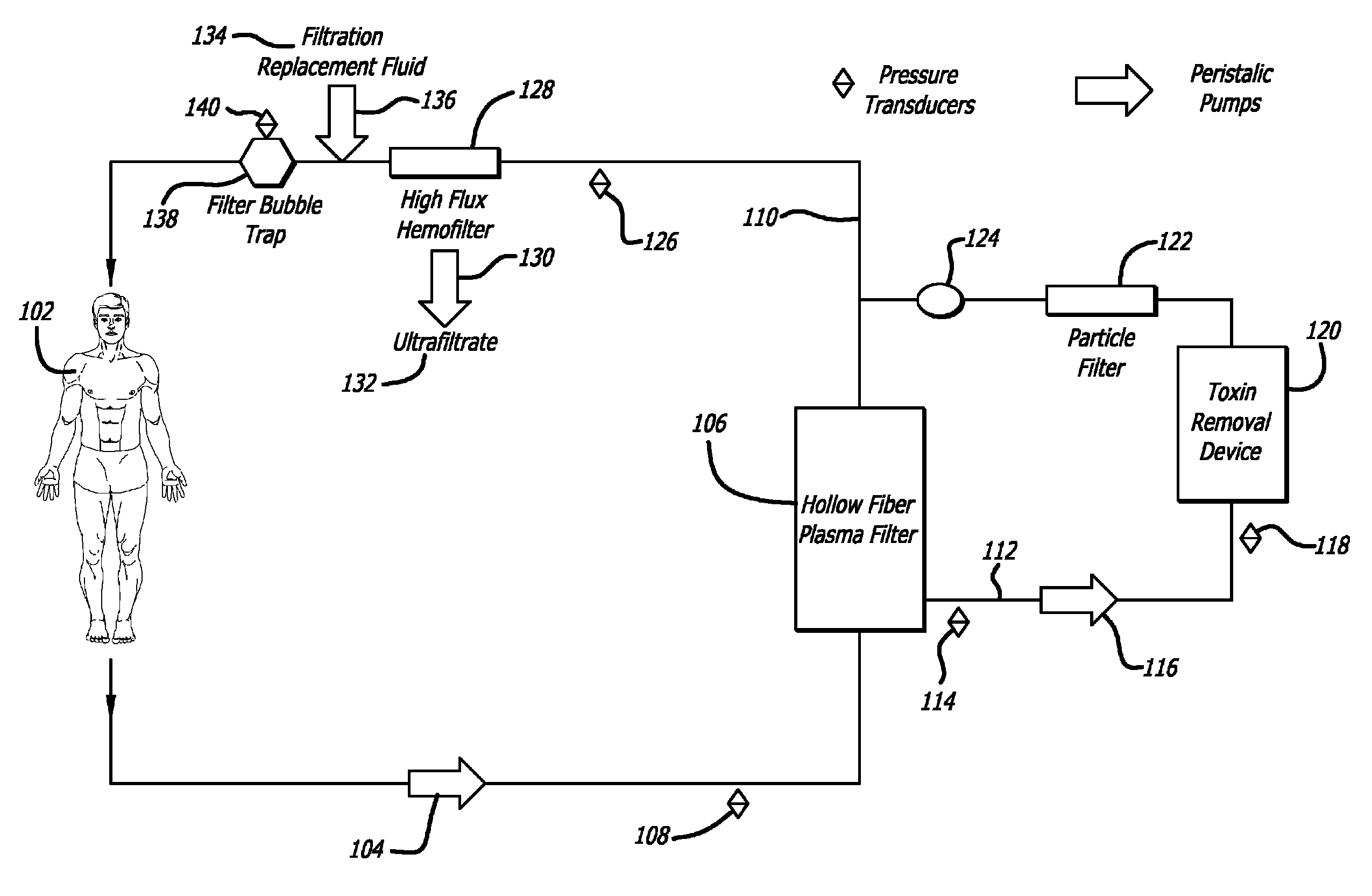

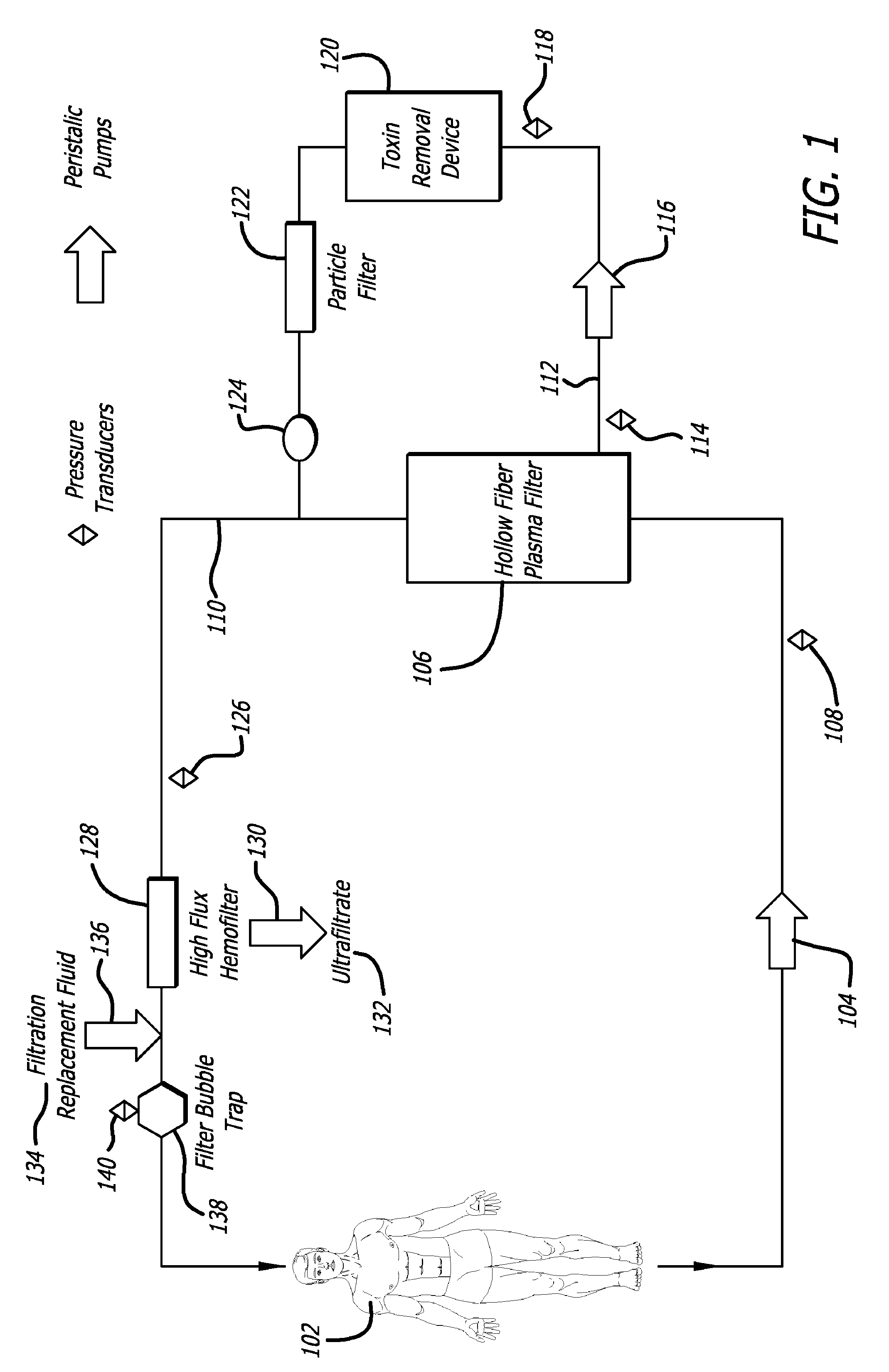

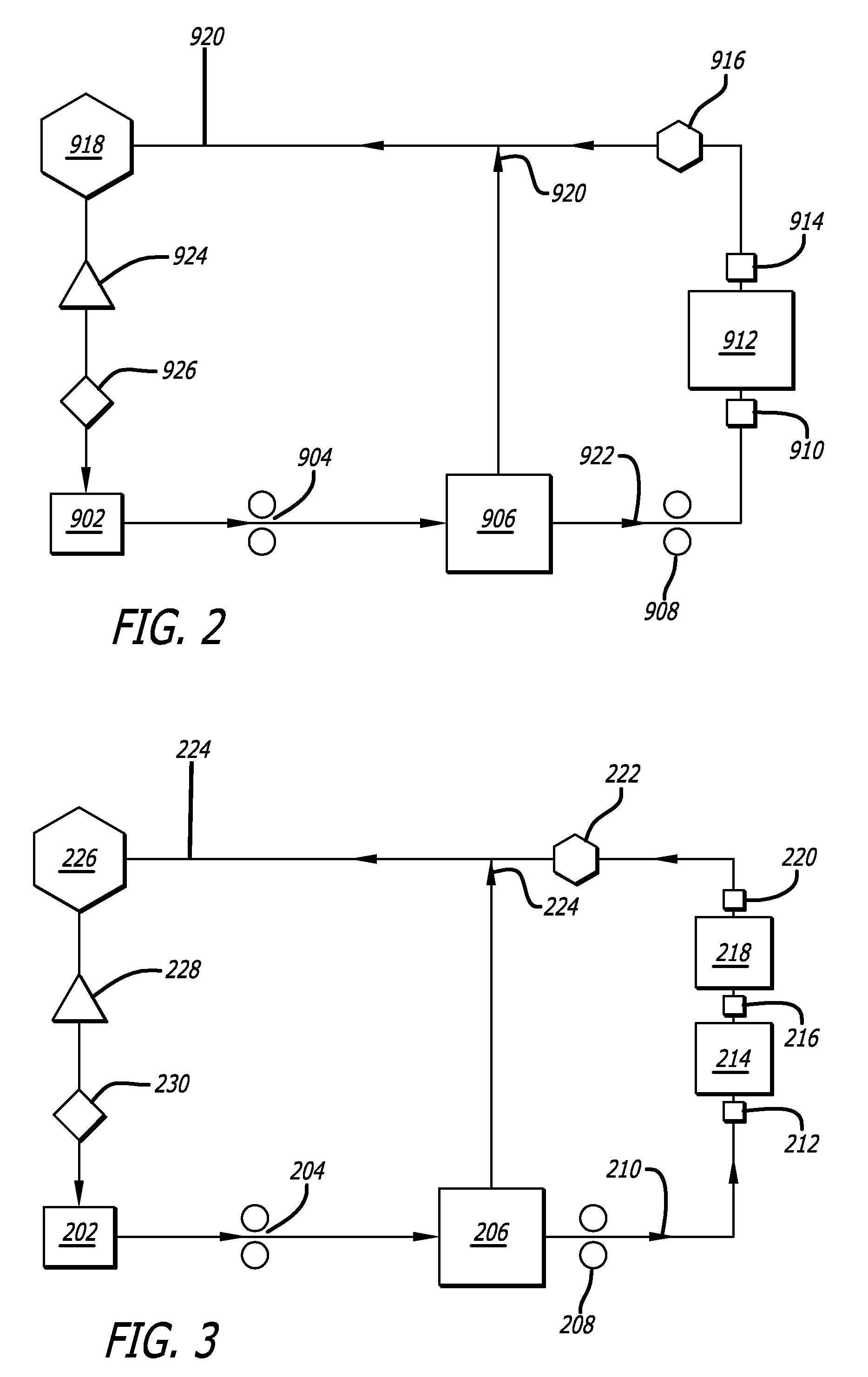

Plasma detoxification and volume control system and methods of use

ActiveUS20070181499A1Effectively detoxify human plasma and balance blood volumeSolvent extractionSolid sorbent liquid separationIon exchangeBlood plasma

An extracorporeal circuit for removing toxins from the blood and plasma volume control in patients suffering from sepsis and renal failure. The extracorporeal circuit disclosed herein comprises a plasma filter, a toxin removal device and optionally a hemofilter that minimizes electrolyte and protein depletion from the treated plasma while effectively removing both free and protein-bound toxins. The toxin removal device comprises adsorbent materials selected from the group consisting of activated carbon, ion exchange resins and non-ionic exchange resins and the adsorbent materials are coated with albumin. Also provided are associated methods for treating patients suffering from sepsis and renal failure using the disclosed extracorporeal circuit and toxin removal device.

Owner:MARKER HLDG AG

Plasma detoxification and volume control system and methods of use

InactiveUS20050281809A1Effectively detoxify human plasma and balance blood volumeSemi-permeable membranesSolvent extractionBlood plasmaPlasma volume

An extracorporeal circuit for removing toxins from the blood and plasma volume control in patients suffering from sepsis and renal failure. The extracorporeal circuit disclosed herein comprises a plasma filter, a toxin removal device and optionally a hemofilter that minimizes electrolyte and protein depletion from the treated plasma while effectively removing both free and protein-bound toxins. Also provided are associated methods for treating patients suffering from sepsis and renal failure using the disclosed extracorporeal circuit and toxin removal device.

Owner:HEMOLIFE MEDICAL

Method for determining the recirculation of blood in a vascular access and a system for implementing same

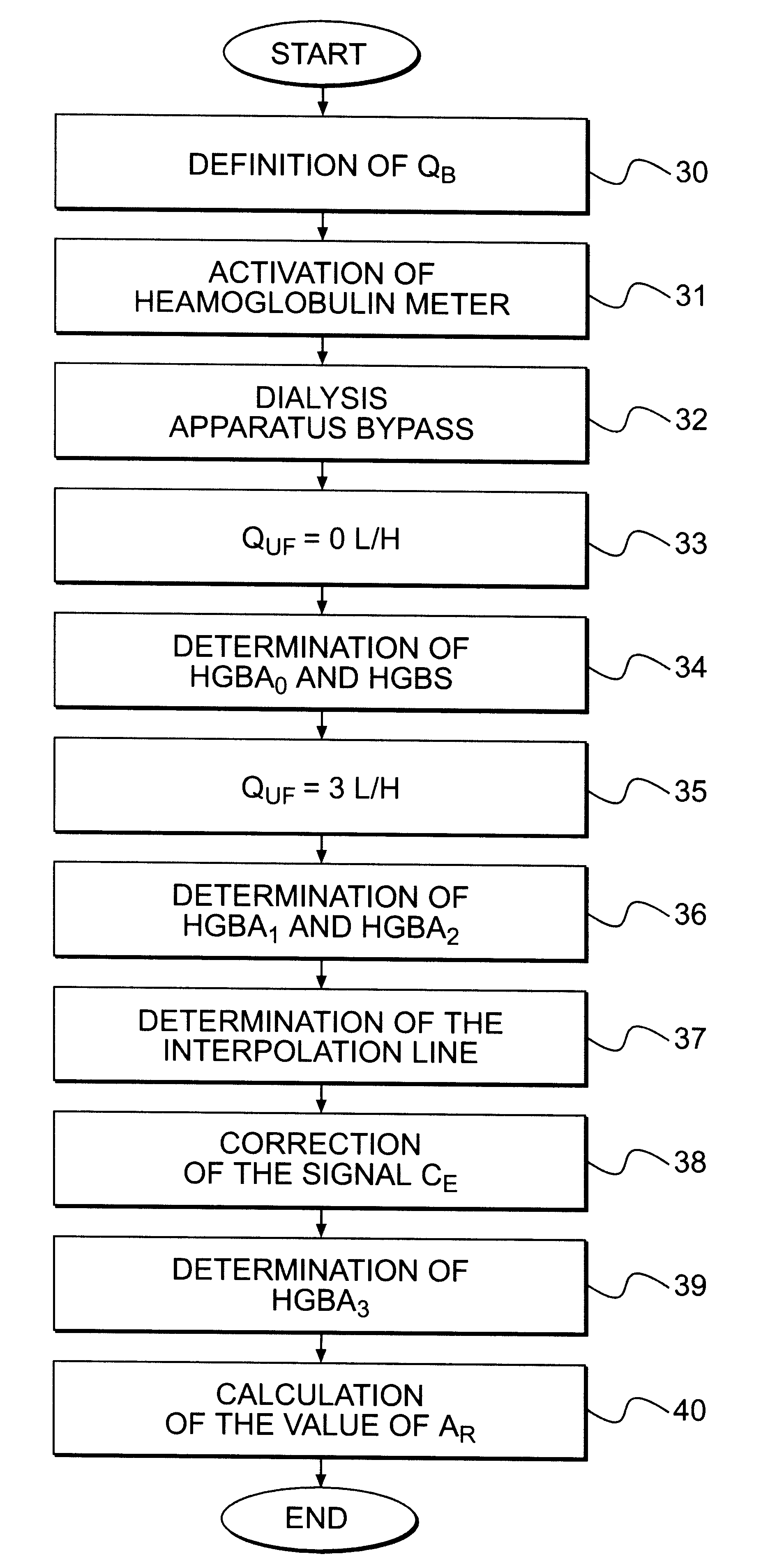

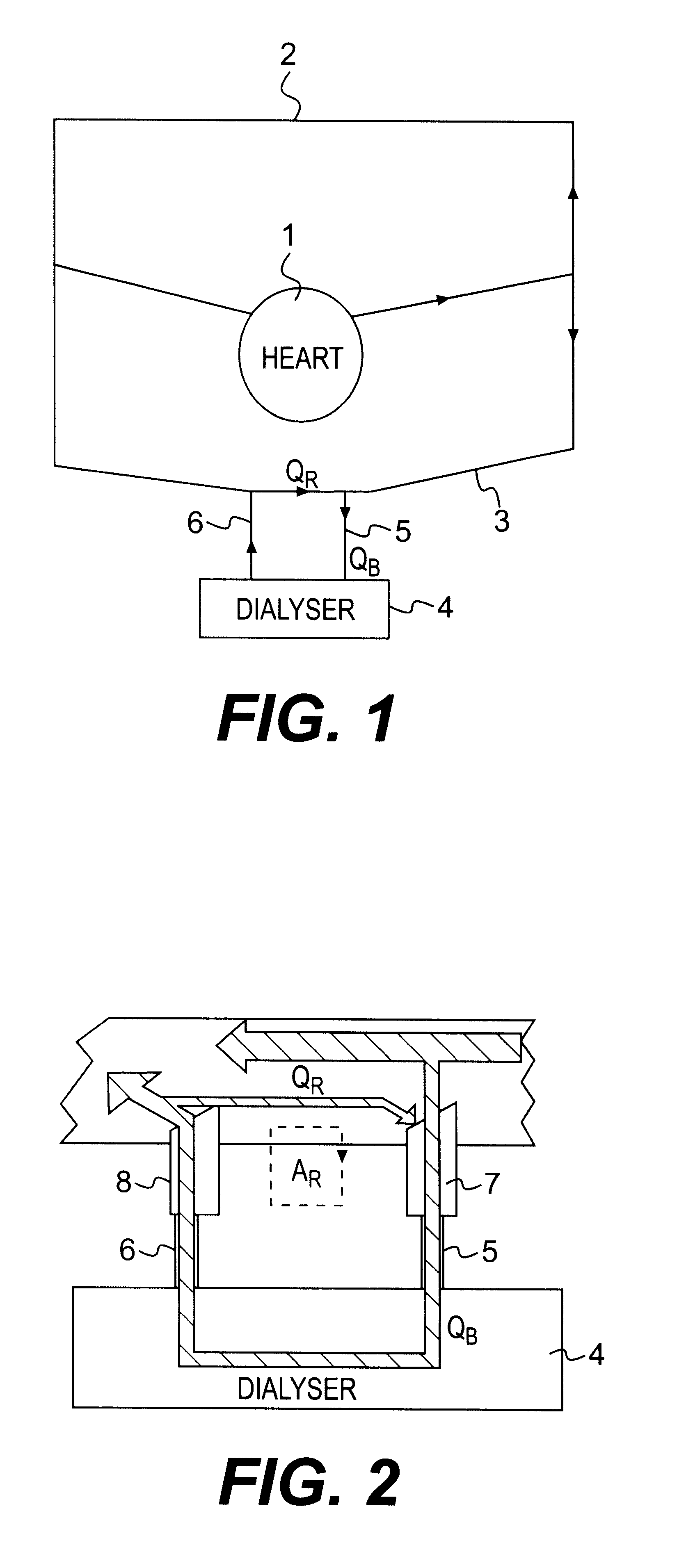

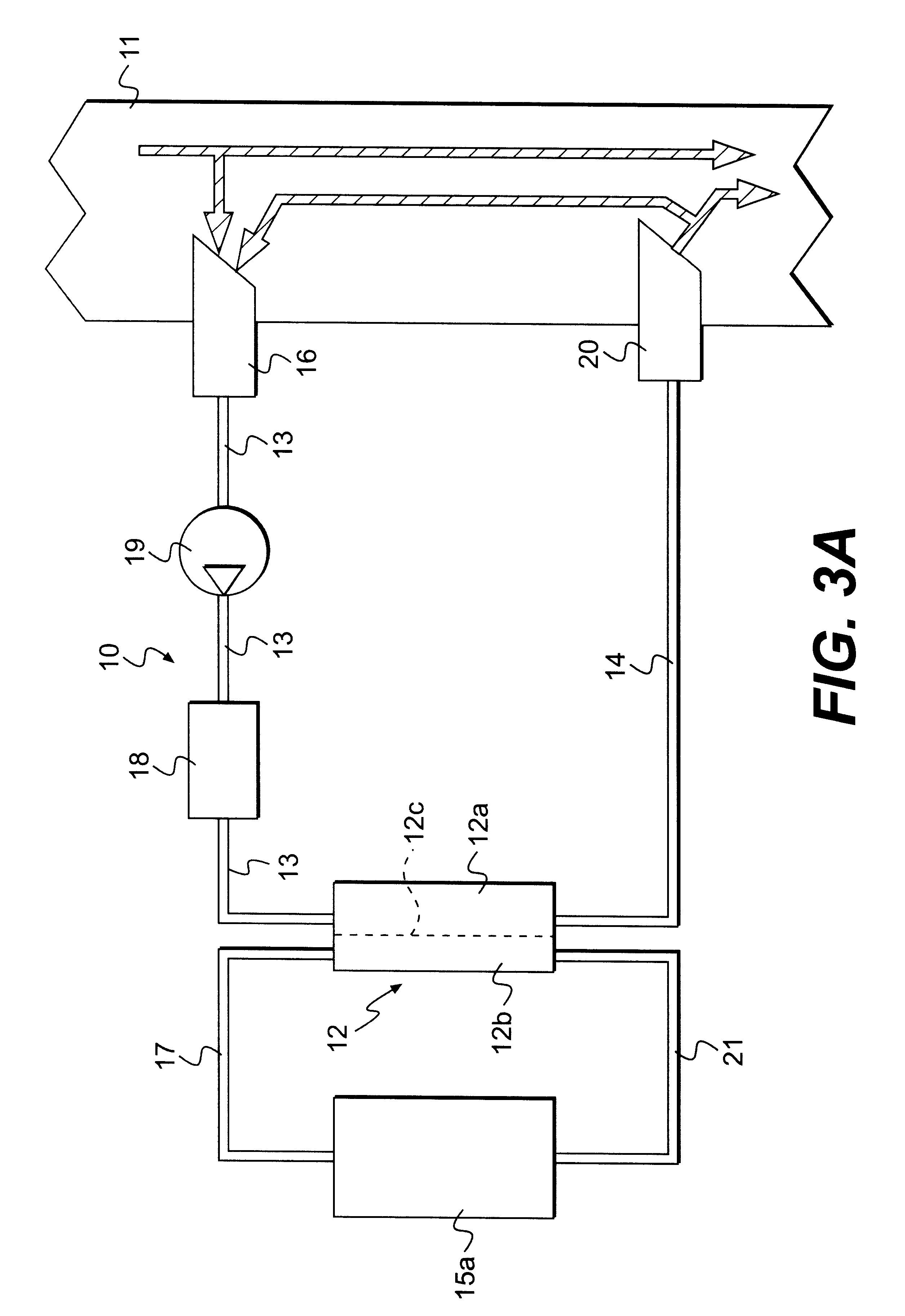

In an extracorporeal blood treatment system, non-treated blood may be withdrawn from a patient through an arterial line connected to a first compartment of a blood treatment apparatus. The blood treatment apparatus also includes a second compartment separated from the first component by a semi-permeable membrane. Treated blood may be returned to the patient through a venous line connected to the second compartment. In order to determine blood recirculation, i.e., a mixture of treated blood and non-treated blood in the arterial line, the ultrafiltration rate of plasma water through the semi permeable membrane of the treatment apparatus may be temporarily increased or decreased, and the resulting variation of the blood concentration, i.e., of the ratio of the volume of the plasma volume to the blood volume, is determined. The extent of the mixture of the treated blood and the non-treated blood in the arterial line may then be calculated as a function of the blood flow rate in the treatment apparatus, of the amplitude of the variation of the ultrafiltration rate, and of at least two values of the blood concentration, determined before and during the variation of the ultrafiltration flow rate, respectively.

Owner:BAXTER HEALTHCARE SA

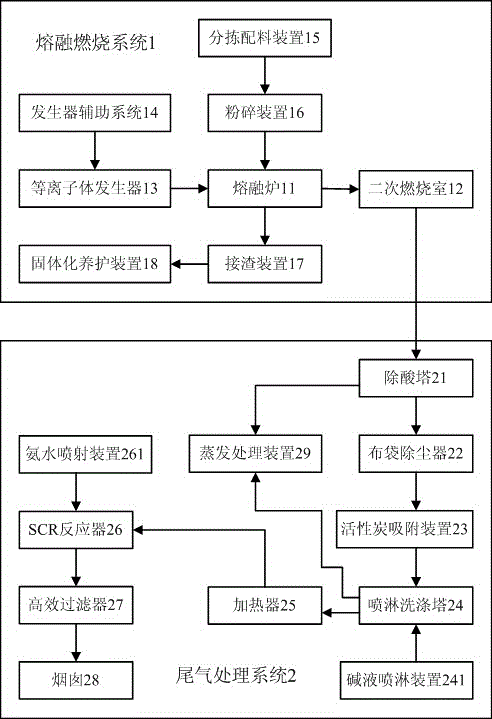

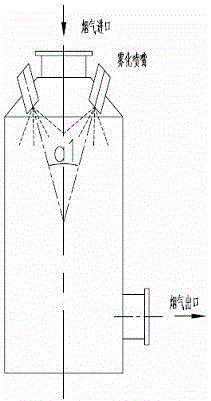

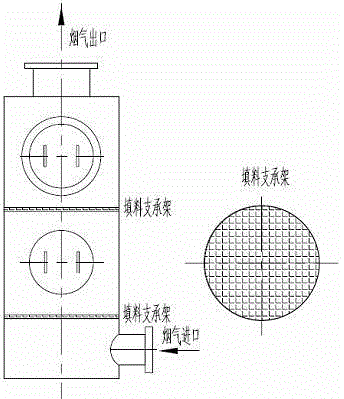

Plasma volume reducing system and method for processing nuclear facility solid waste

InactiveCN104637561AHigh capacity reduction ratioImprove securityRadioactive decontaminationCombustion systemSolid mass

The invention provides a plasma volume reducing system and method for processing nuclear facility solid waste. The plasma volume reducing system comprises a fusion burning system and a tail gas processing system. The fusion burning system further comprises a fusion furnace and a secondary burning chamber. Low-and-intermediate level radioactive solid waste is processed through a combination mode of plasma pyrolysis fusion and secondary combustion. Tail gas generated by secondary combustion is processed in a combination mode of a half-drying-quick-cooling method, a cloth bag, a wet method and denitration. Various kinds of waste can be processed, the size of the waste is lowered to 1 / 6, radionuclide can be stably solidified in a solidifying body, and exhaust gas emission can reach the national standard. Comprehensively, the high volume reduction ratio and the high safety in the volume reduction technology can be achieved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

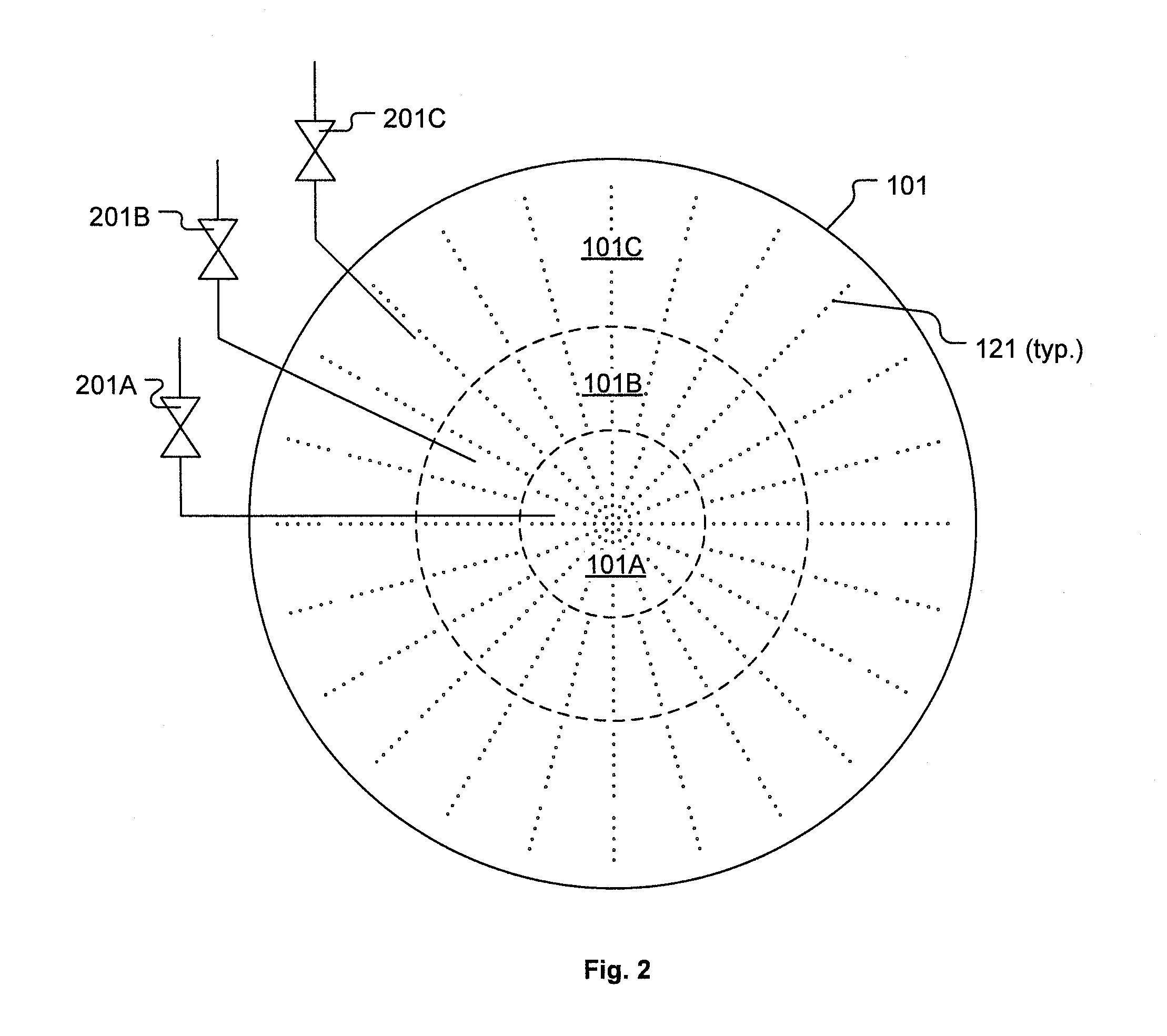

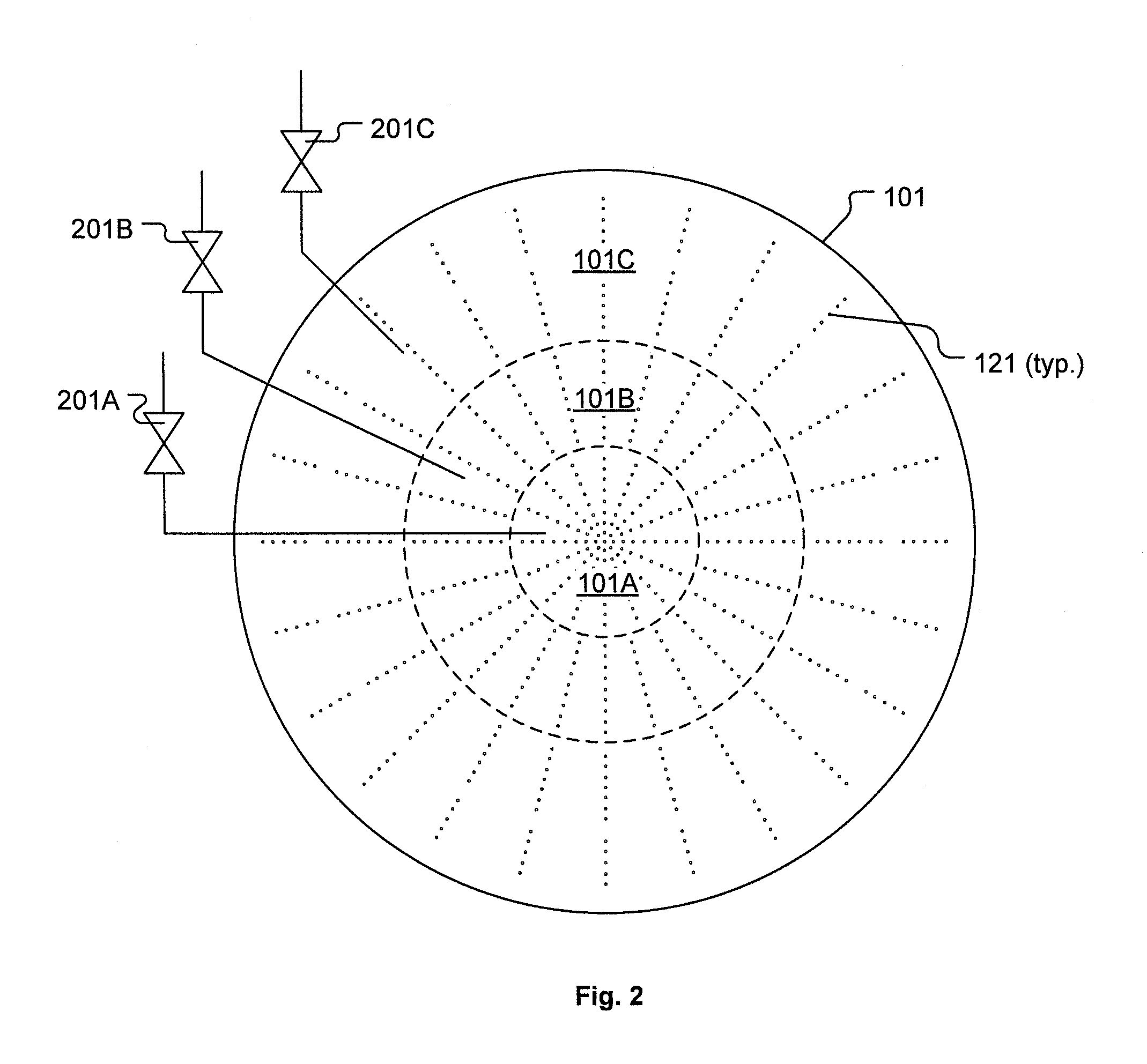

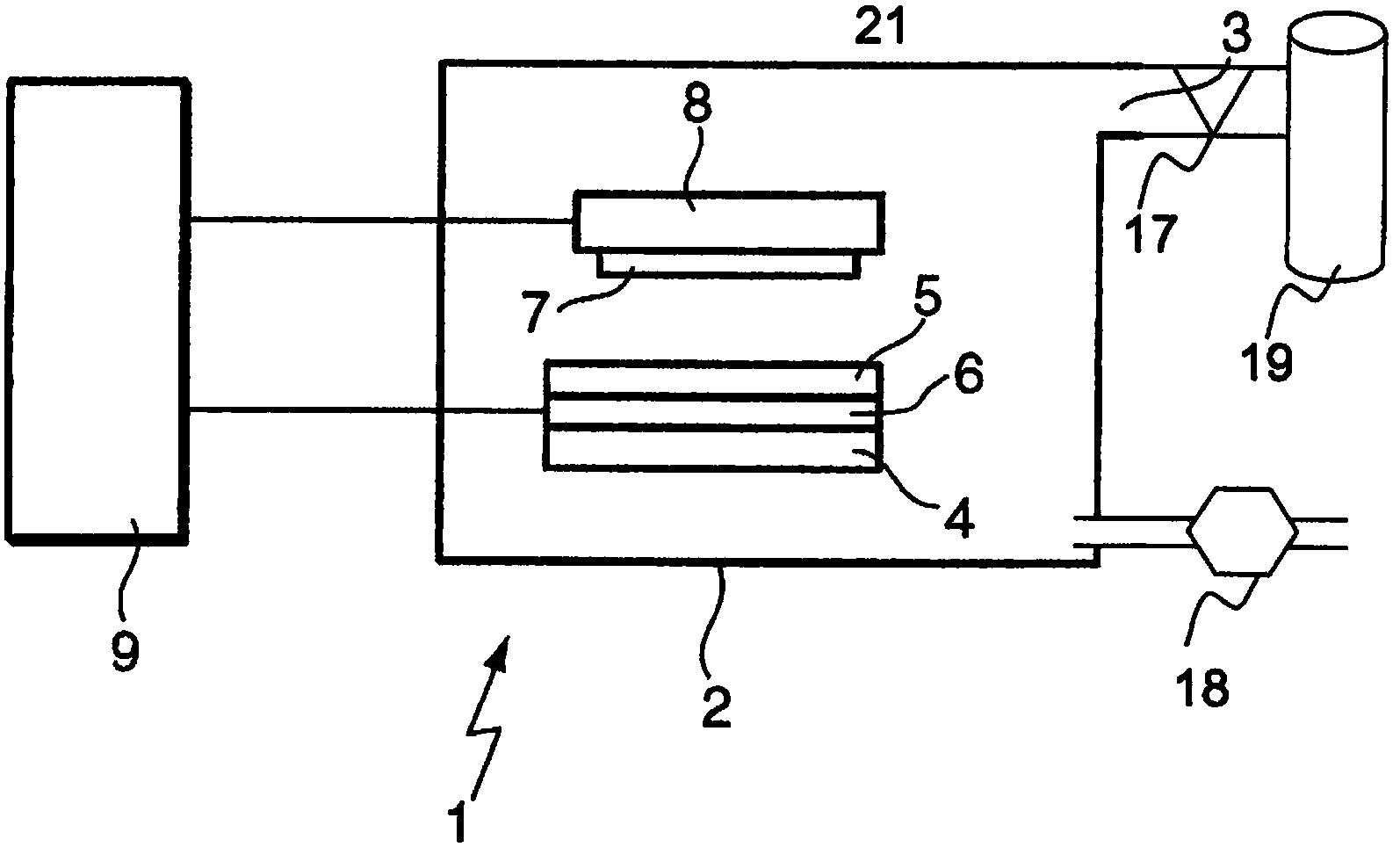

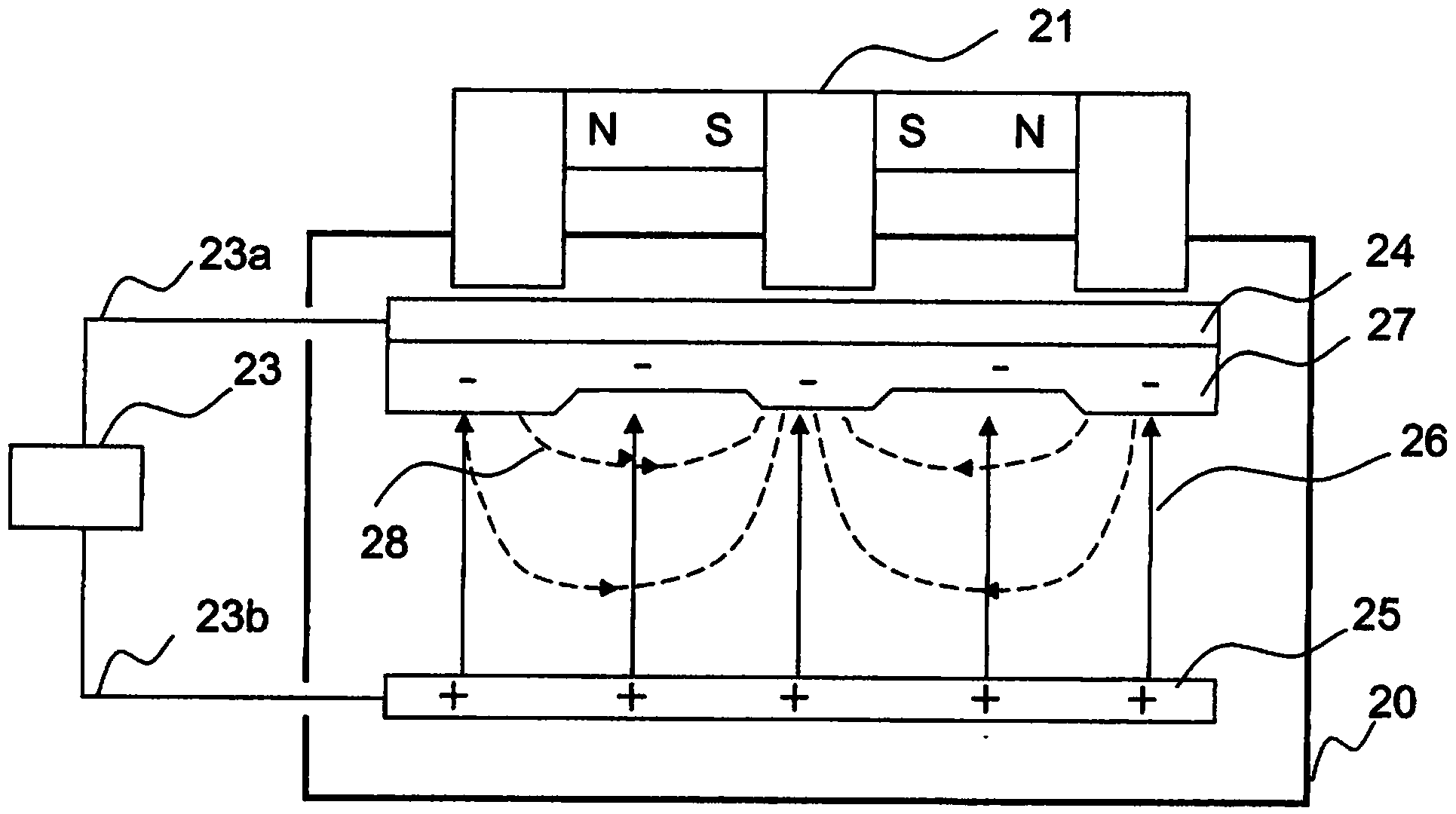

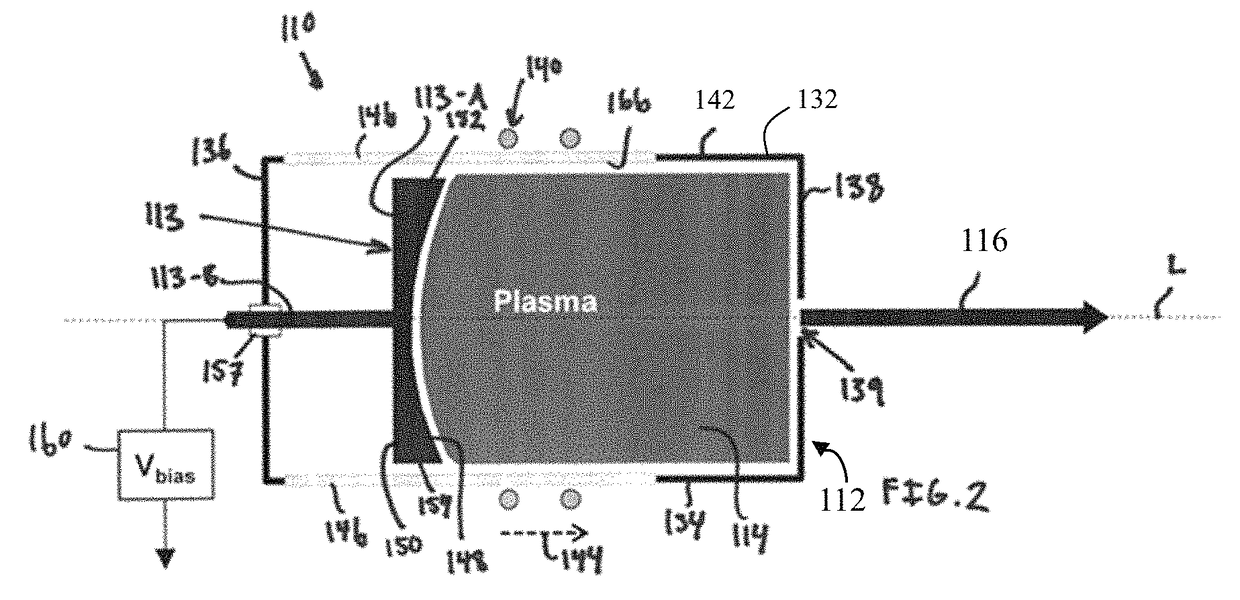

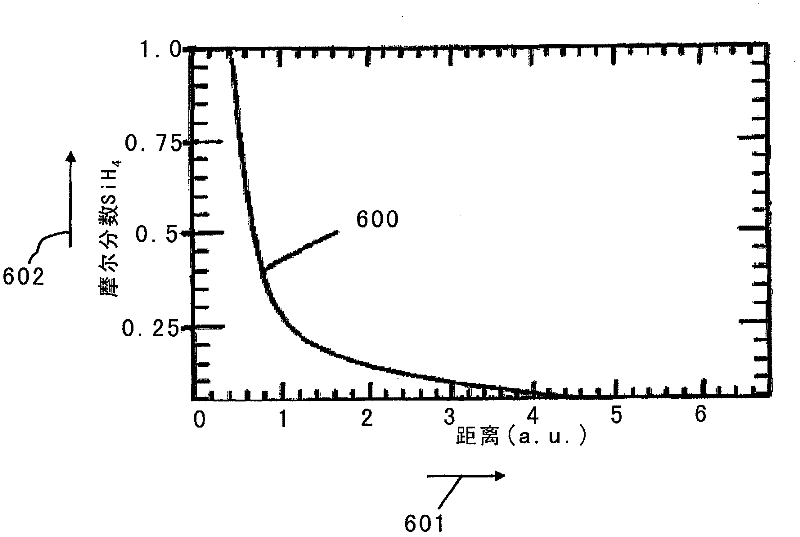

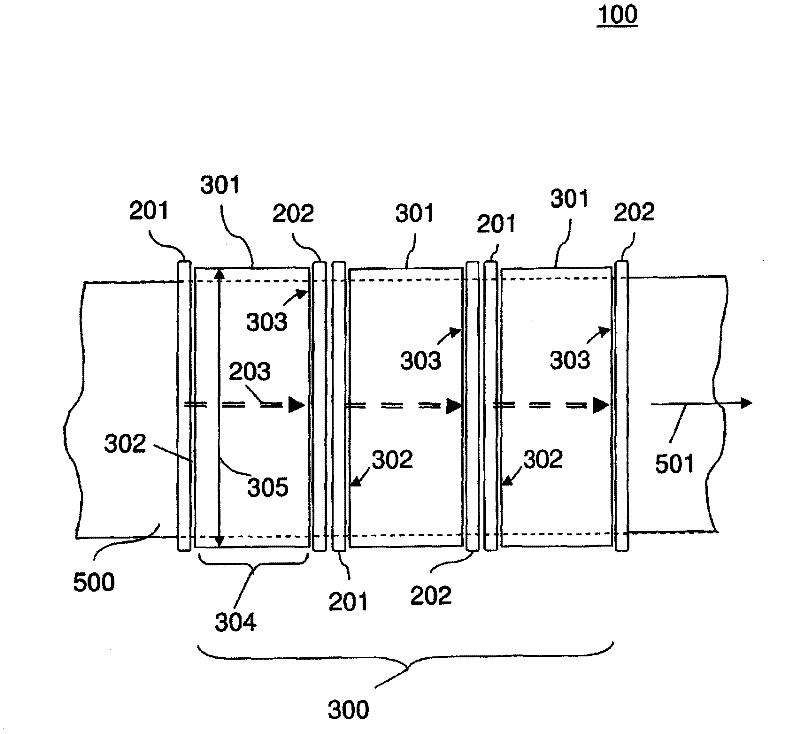

Dual plasma volume processing apparatus for neutral/ion flux control

ActiveUS9184028B2Semiconductor/solid-state device testing/measurementElectric discharge tubesGas supplyPlasma volume

A semiconductor wafer processing apparatus includes a first electrode exposed to a first plasma generation volume, a second electrode exposed to a second plasma generation volume, and a gas distribution unit disposed between the first and second plasma generation volumes. The first electrode is defined to transmit radiofrequency (RF) power to the first plasma generation volume, and distribute a first plasma process gas to the first plasma generation volume. The second electrode is defined to transmit RF power to the second plasma generation volume, and hold a substrate in exposure to the second plasma generation volume. The gas distribution unit includes an arrangement of through-holes defined to fluidly connect the first plasma generation volume to the second plasma generation volume. The gas distribution unit also includes an arrangement of gas supply ports defined to distribute a second plasma process gas to the second plasma generation volume.

Owner:LAM RES CORP

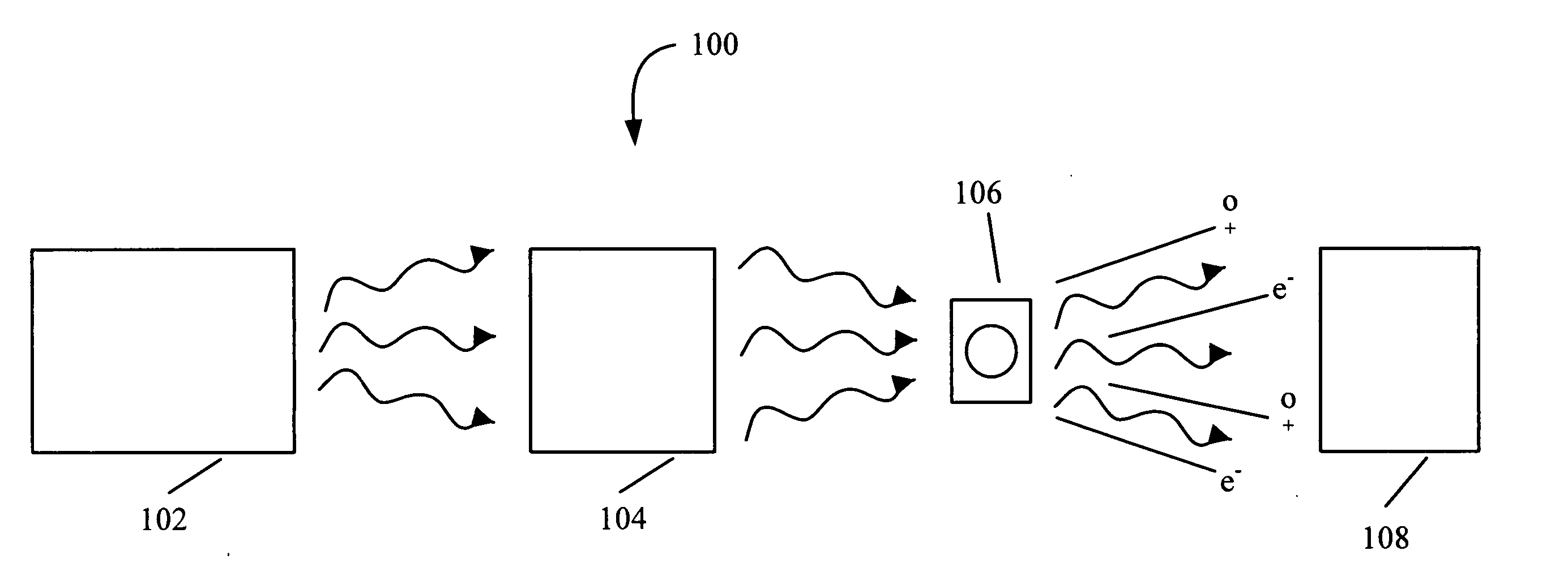

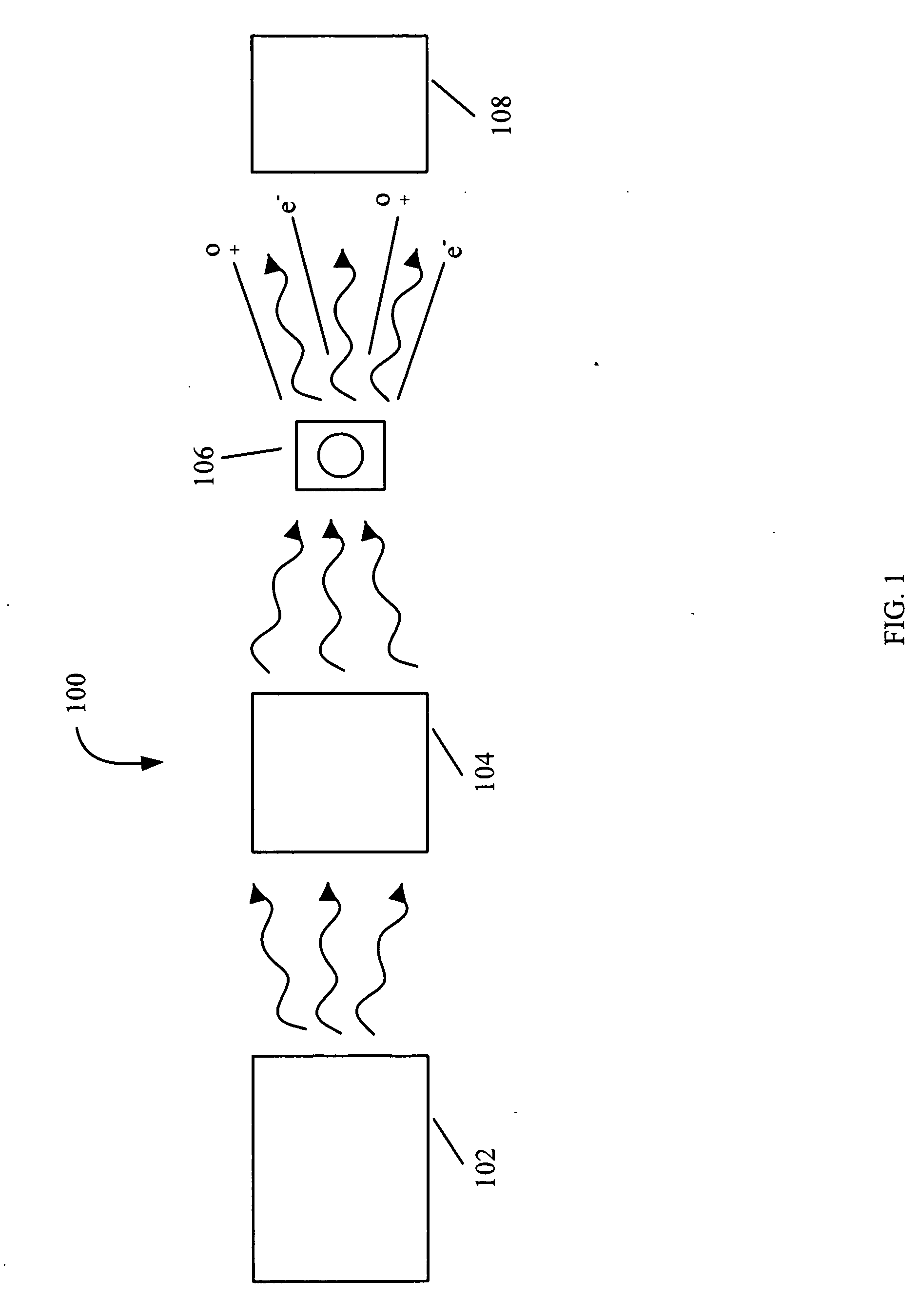

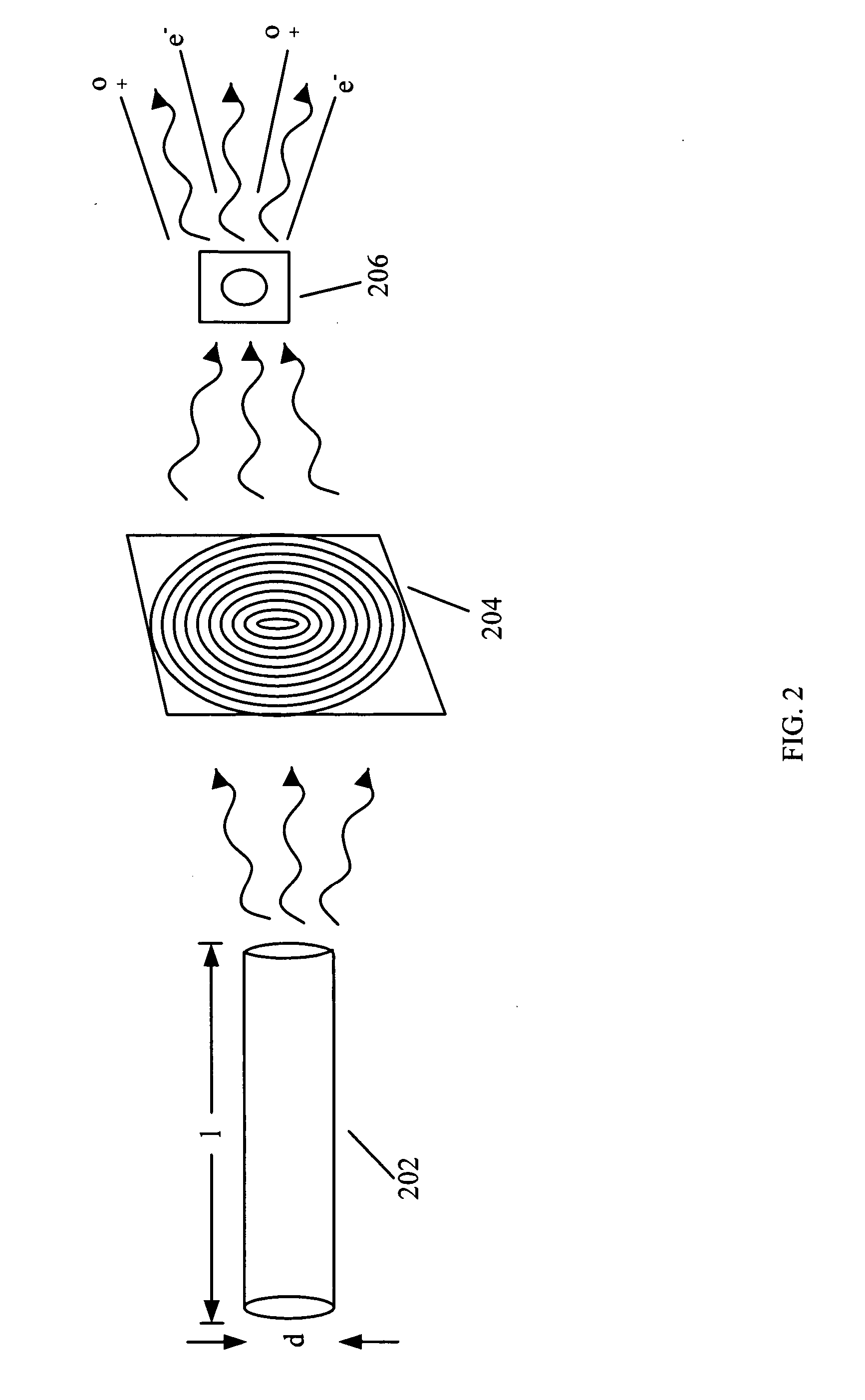

Method and apparatus for nanoscale surface analysis using soft X-rays

InactiveUS20060098781A1Laser detailsMaterial analysis using wave/particle radiationSoft x raySoft X-rays

A nano-scale surface analysis system comprises an electrically powered apparatus for the generation of soft x-ray laser radiation. The apparatus comprises an excitation circuit having at least two or more electrically conducting structures separated by a liquid dielectric for providing a high current excitation pulse, and a capillary structure having a capillary with a length to diameter ration of about 20 to 1000 for enclosing a selected lasing material, wherein the excitation circuit is capable of generating a plasma volume within the capillary structure to produce a population inversion. The generator further comprises a focusing optic for receiving the soft x-ray radiation from the emissions source and focus the soft x-ray radiation onto a target for forming a nanoplasma, the soft x-ray radiation being focused onto an area of the target having a diameter of less than 100 nm.

Owner:JMAR LLC A DELAWARE LLC

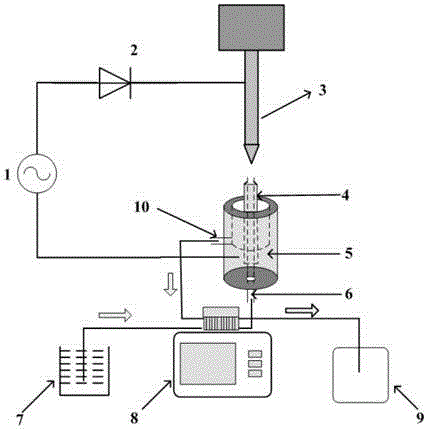

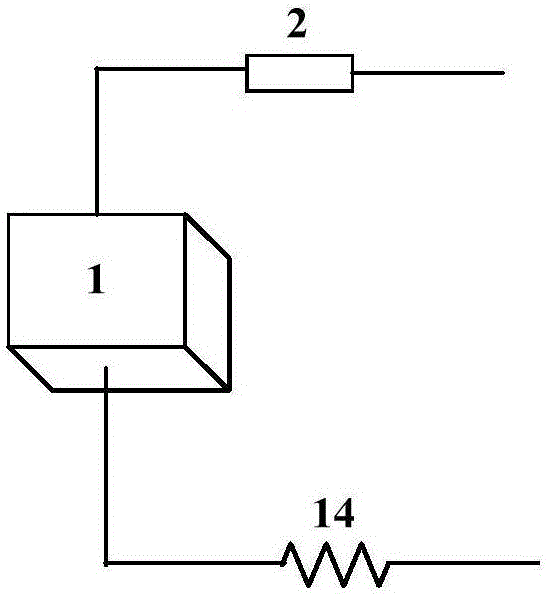

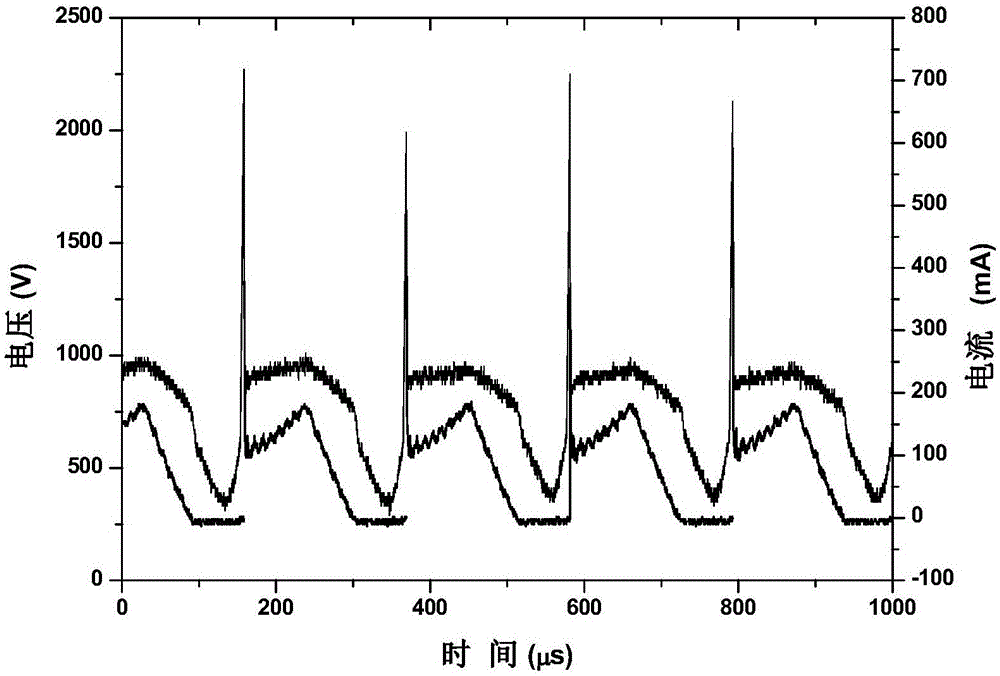

Pulse voltage driven arc discharge plasma source and portable element spectrometer

ActiveCN106596515AAvoid conversion implementationEasy to operateAnalysis by electrical excitationAnalysis by thermal excitationPeristaltic pumpSpectral emission

The invention discloses a pulse voltage driven arc discharge plasma source for liquid sample detection. The pulse voltage driven arc discharge plasma source includes a discharge driving system, a plasma generation chamber, and a sample introduction and discharge system. The sample introduction and discharge system includes a sample pool, a two-channel peristaltic pump, a liquid collecting pool, a sample inlet pipe and a drain pipe. A sample solution is introduced into the plasma generation chamber, an alternating current high voltage power supply modulated by an alternating current modulation module is employed to apply high pressure between a metal electrode and an auxiliary electrode so as to generate arc discharge plasma. A plasma atomizer prepared by the invention has the characteristics of small plasma volume, plasma spectral emission, same optimum spectral emission position of elements, low spectral background signal, autoignition and good stability, etc. The advantages bring greater convenience to people in terms of detecting metal elements in water, improve work efficiency, and expand the work area of the prepared detection equipment.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

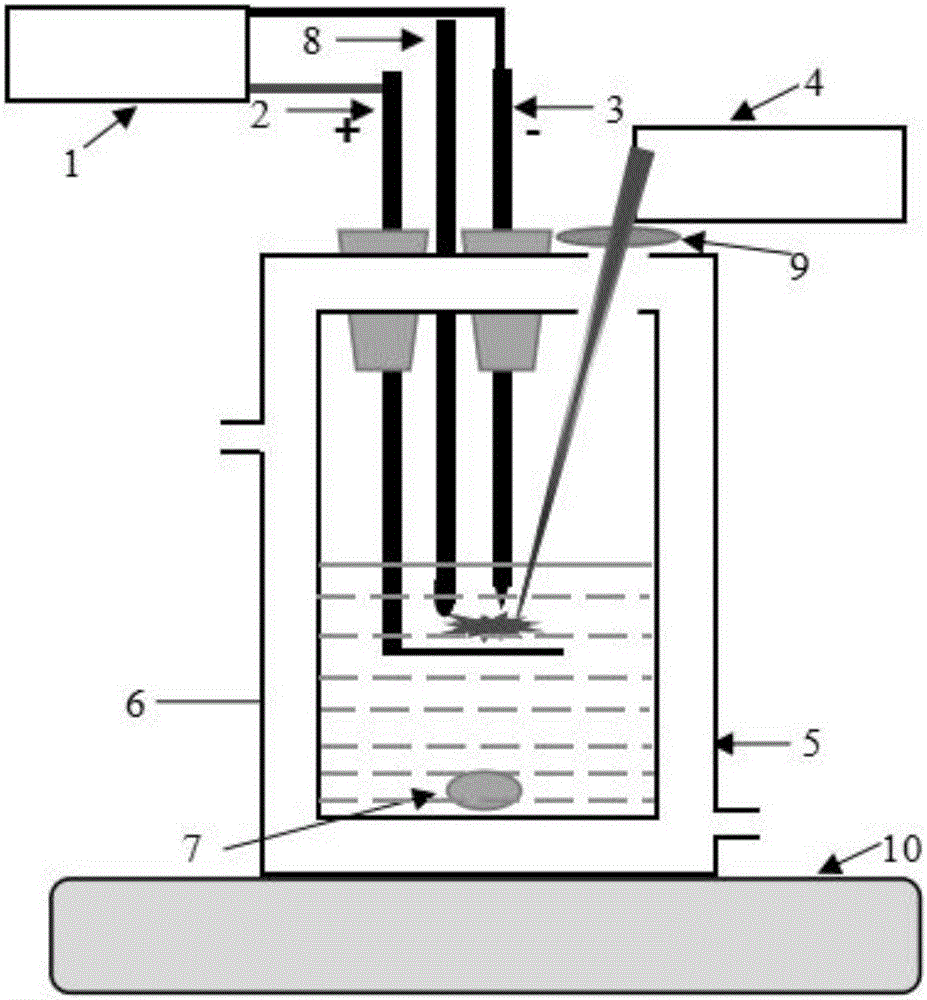

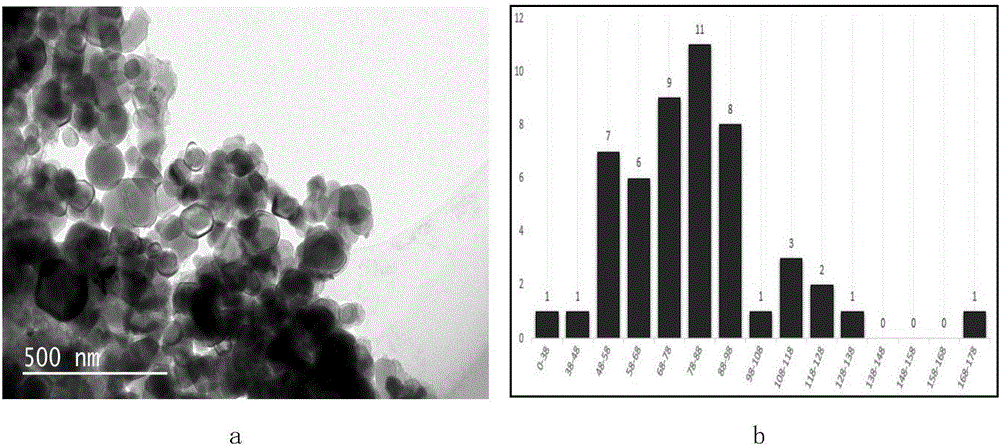

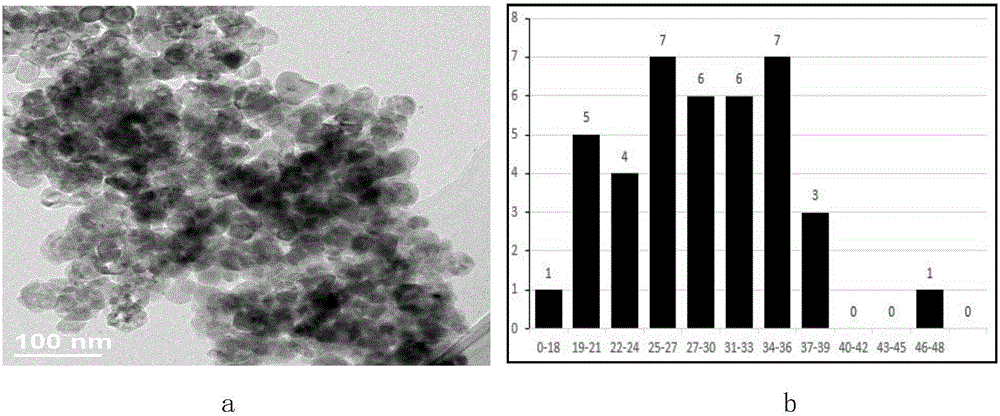

Device for synthesizing nano particles through glow discharge and synthesis method thereof

InactiveCN106744676ALower threshold voltageHigh strengthMaterial nanotechnologyNanostructure manufactureChemical synthesisHigh power lasers

The invention provides a method for synthesizing nano particles through glow discharge based on laser aiding and belongs to the field of plasma electrochemical synthesis of nano materials. Plasma produced by laser on the metal anode surface of a glow discharge device, plasma produced through laser induction and plasma produced through glow discharge are utilized to produce a synergistic effect and jointly act on a precursor solution, accordingly a glow discharge phenomenon is intensified, and the problems of small plasma volume, short discharge time, insufficient electrolyte electrolysis and large nano particle product size fluctuation of an existing glow discharge technology are solved. By adopting the method for synthesizing the nano particles through glow discharge based on laser aiding, high-energy-density plasma produced through high-power laser induction and the glow discharge plasma are effectively coupled, the nano particle preparation efficiency and nano particle size controlling capability is greatly improved, and the purposes of aiding glow discharge and rapidly and effectively synthesizing the nano particles are achieved. The method can be used for rapid nano particle pre-preparation and production.

Owner:SHANGHAI LANGYAN OPTOELECTRONICS TECH +1

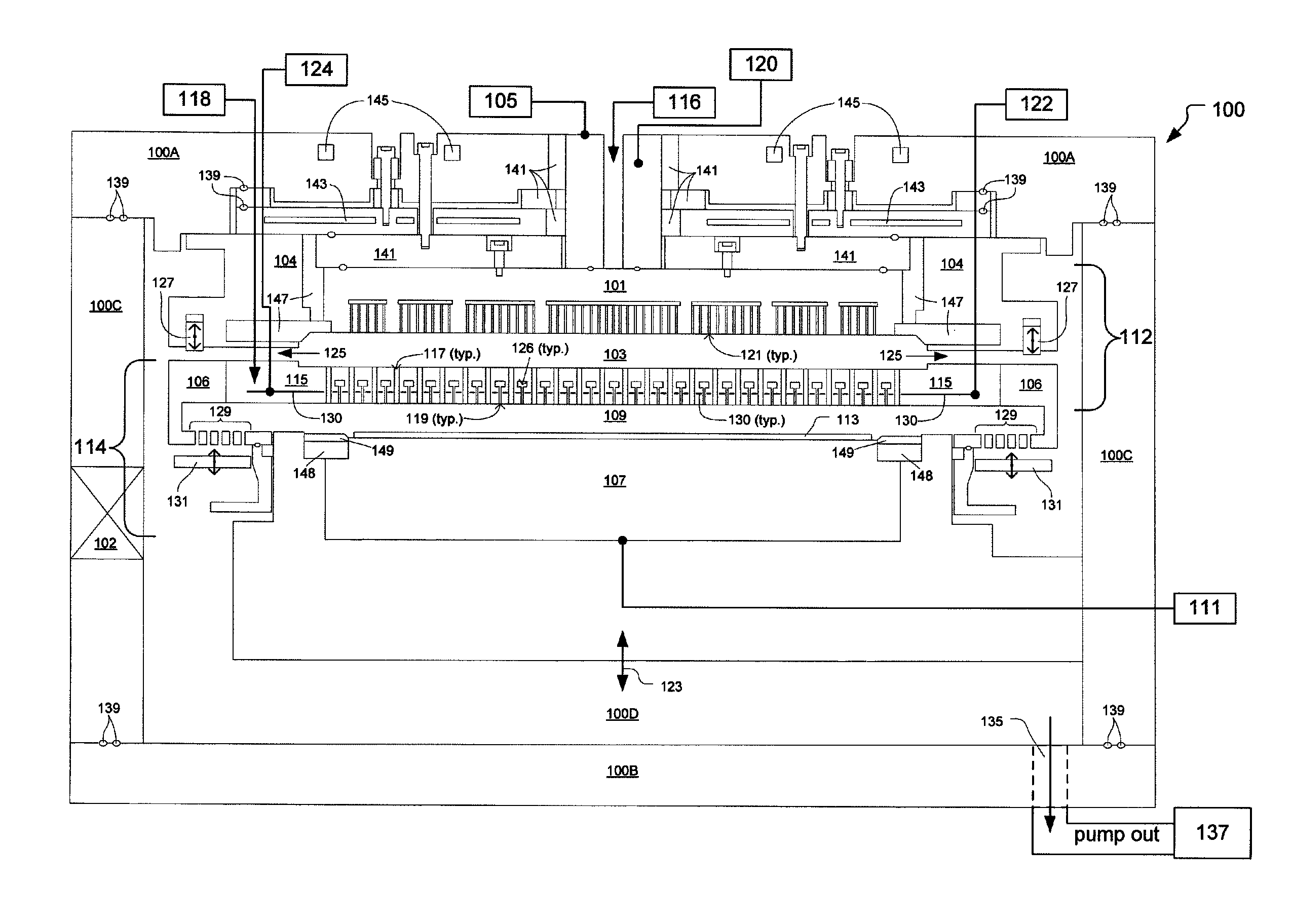

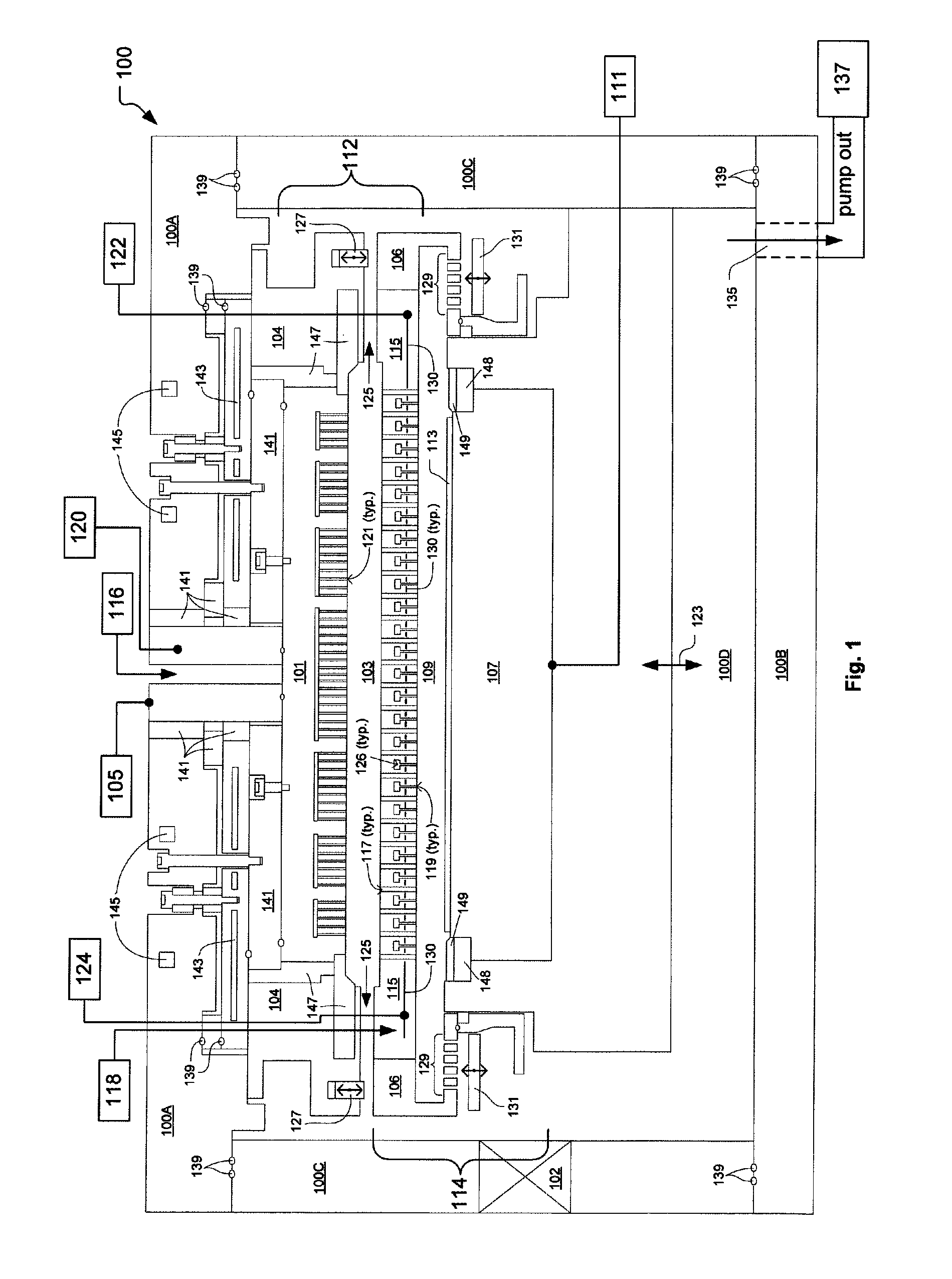

Automated methods and systems for providing platelet concentrates with reduced residual plasma volumes and storage media for such platelet concentrates

Automated systems and methods for providing platelet concentrates and synthetic storage media with reduced residual plasma volumes are disclosed. The disclosed systems and methods reduce the residual volume of plasma in platelet concentrate to obtain a platelet product having a volume of plasma that is approximately 5% or less of the total platelet product volume. The disclosed systems and methods also reduce the residual volume of plasma in platelet concentrate to obtain a washed platelet product, wherein the volume of plasma in the washed platelet product is approximately 1% or less of the total washed platelet product volume. Storage media for platelets including less than approximately 10% plasma are also disclosed.

Owner:FENWAL

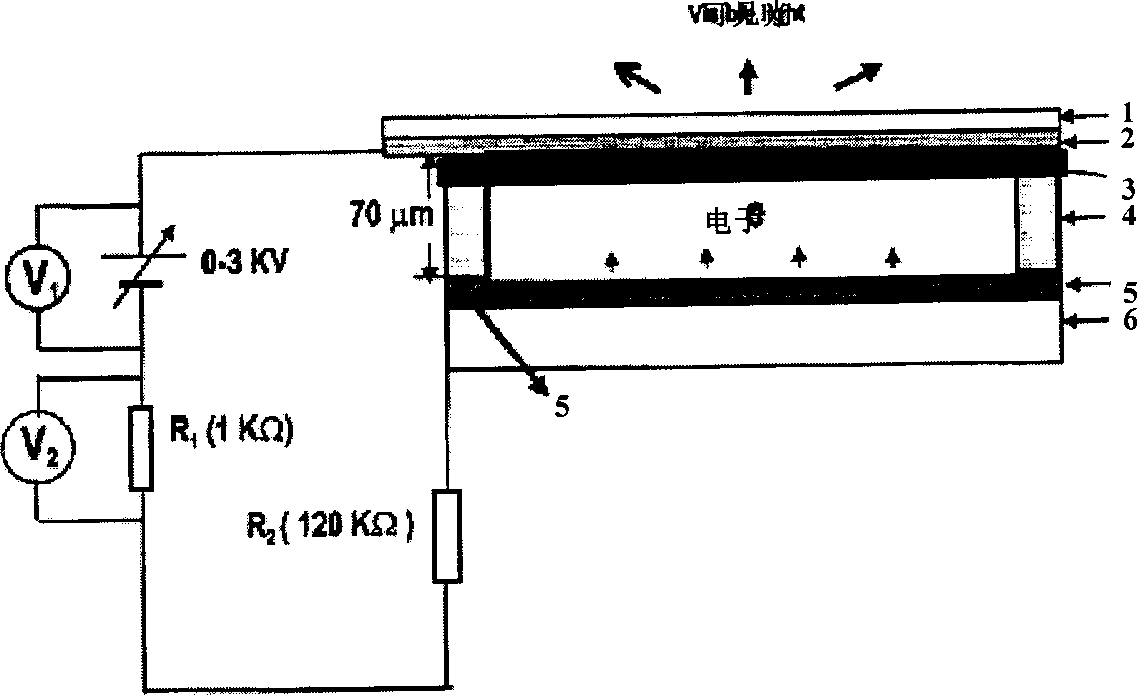

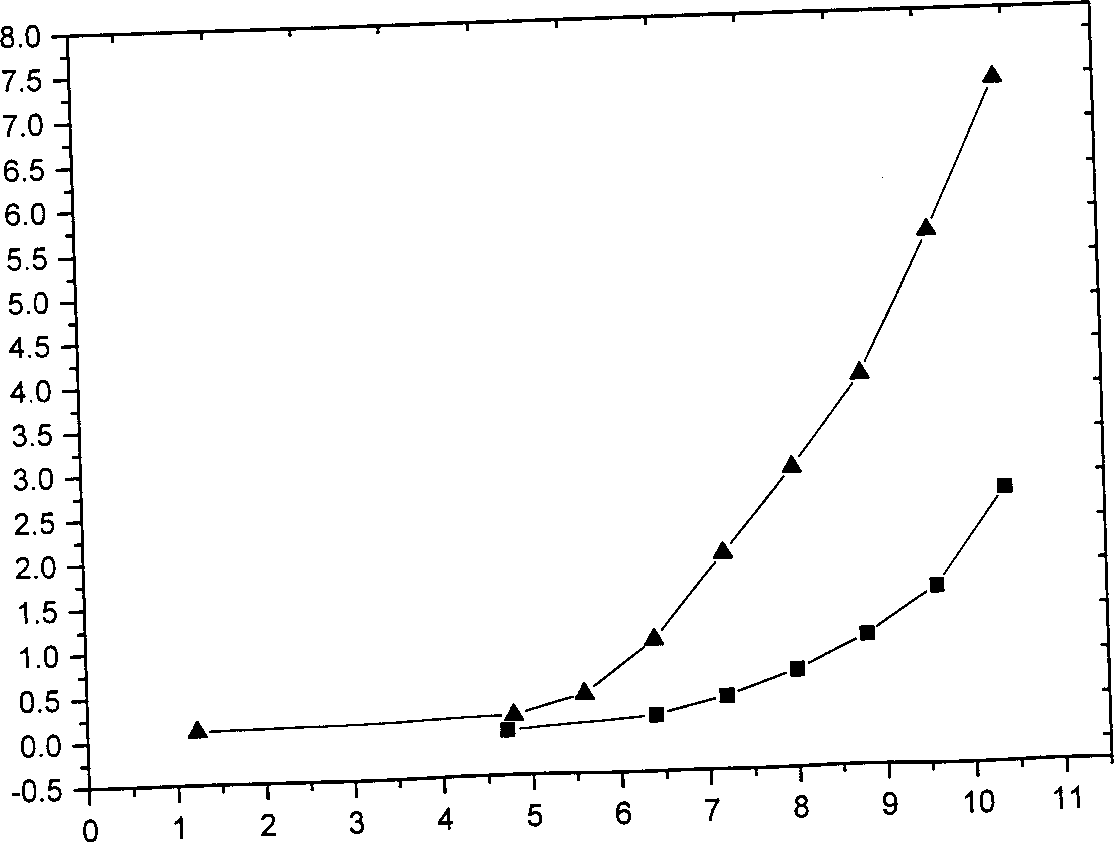

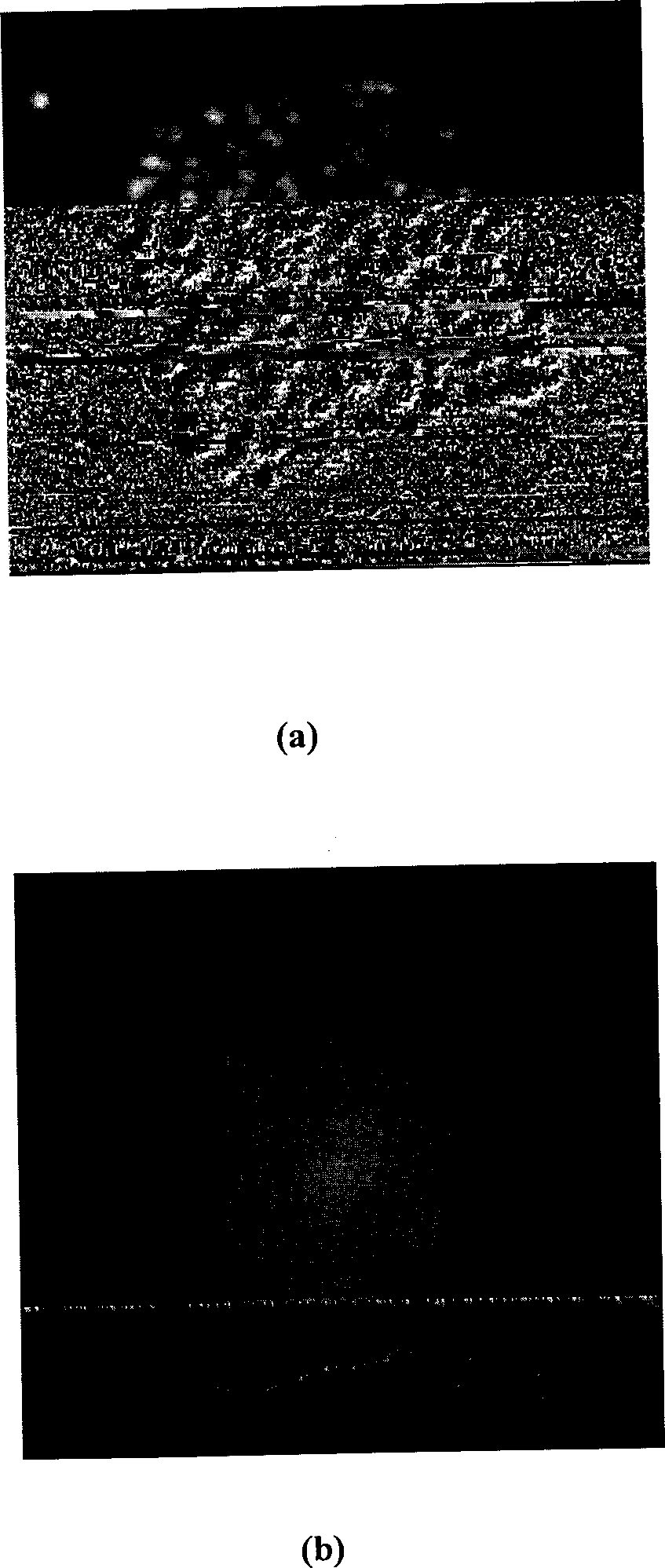

Method of raising the field electron emitting performance of carbon nanotube film

InactiveCN1349241AImprove field electron emission performanceIncrease current densityNanostructure manufactureNanoinformaticsCarbon nanotubeElectron

The characteristic is to use heat treating technology and plasma volume surface processing technology for CNT film cathode produced by transfer method and use plasma surface processing technology forthe CNT film cathode produced by direct growing method. The technology parameter of plasma surface process is power density 0.1 to 3 W / cubic m, the processing time is 5 to 6 minutes. H2 or hydrogen-containing compound is used. By processing according to the invention method, current density of CNT film can be increased three times, density of electric emitting point can be increased more than three times and the uniformity is increased obviously. The film cathode grown by transfer method is organic combined by two processing technologies to increase field emitting function of CNT film cathode.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

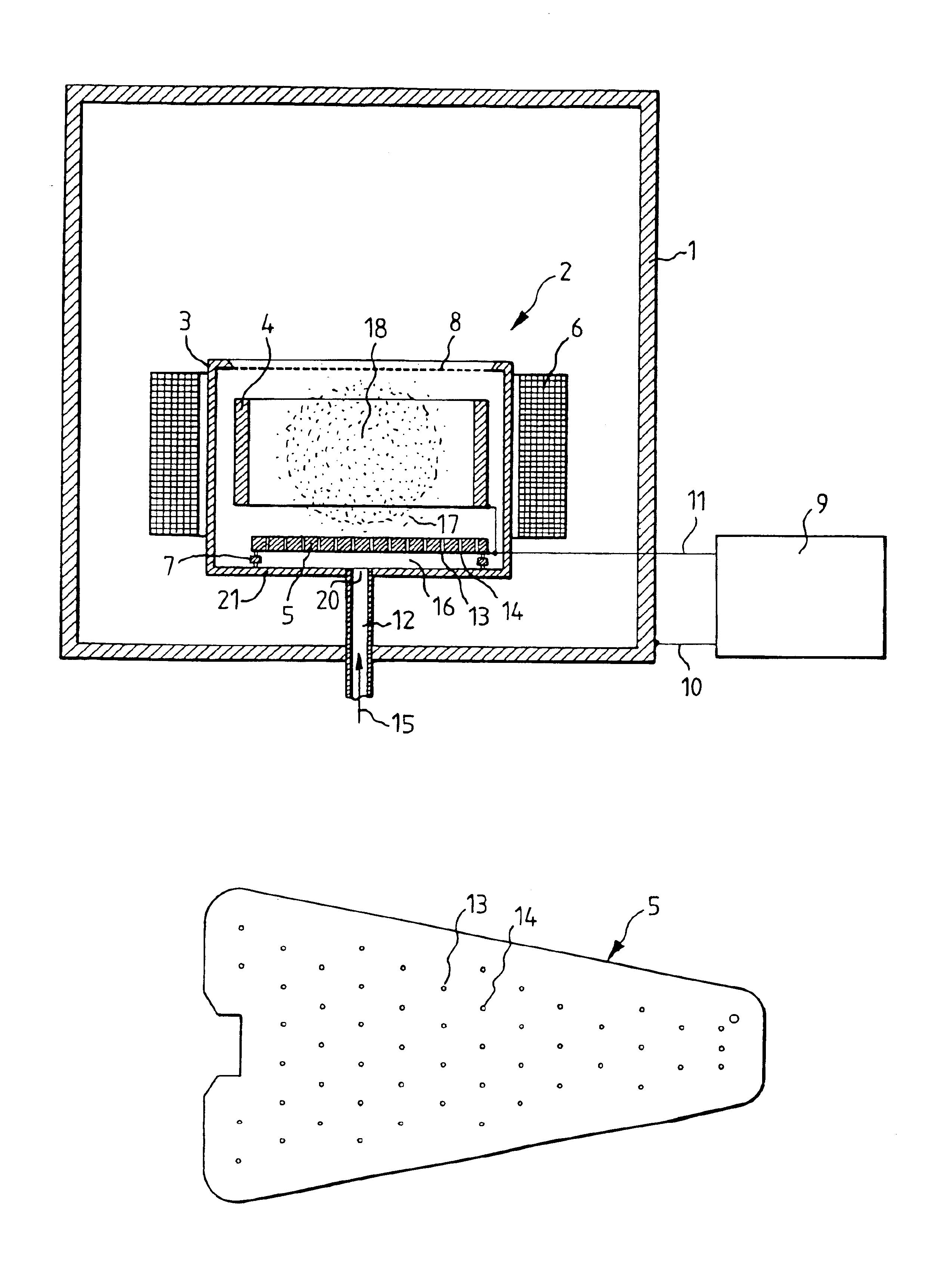

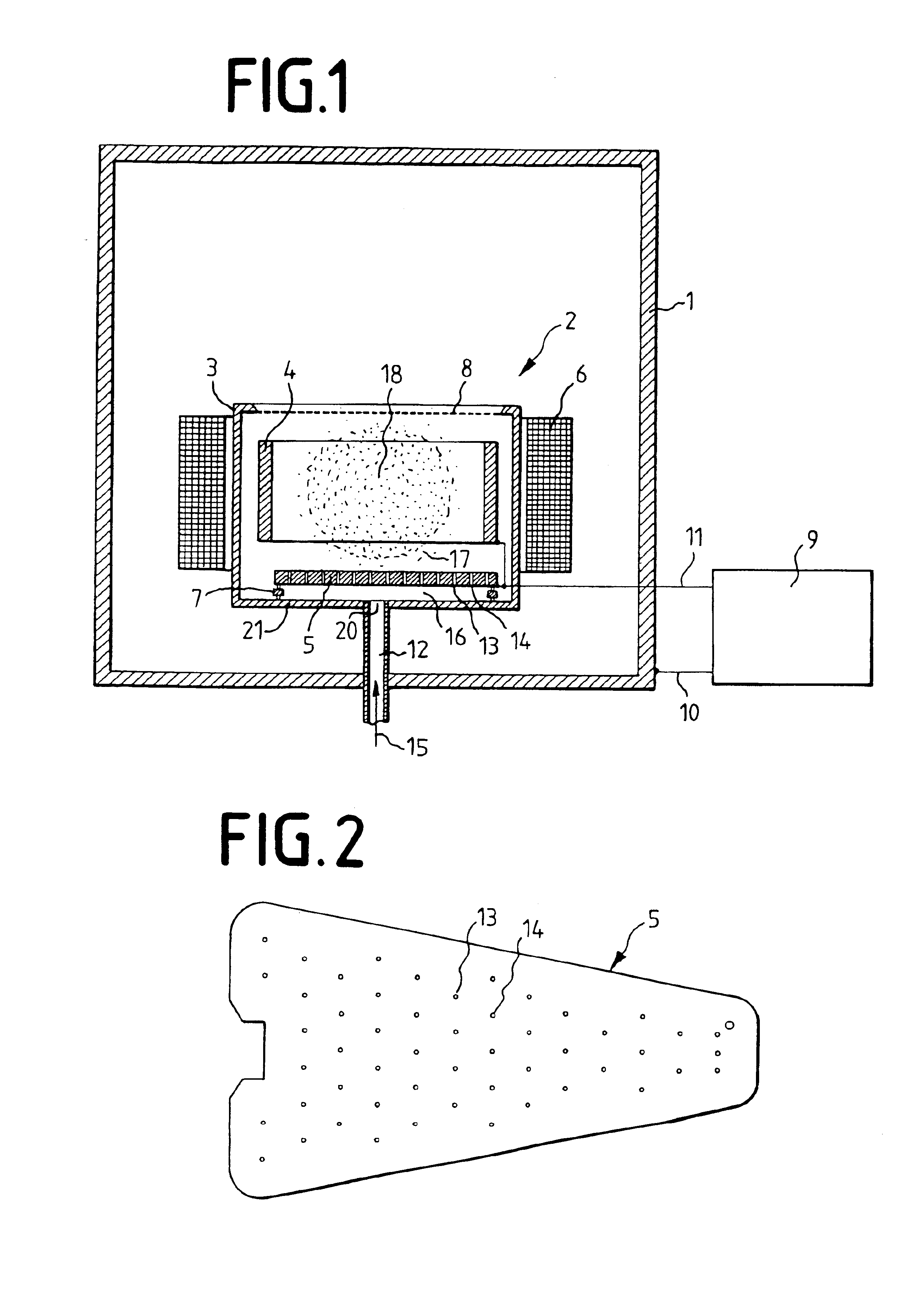

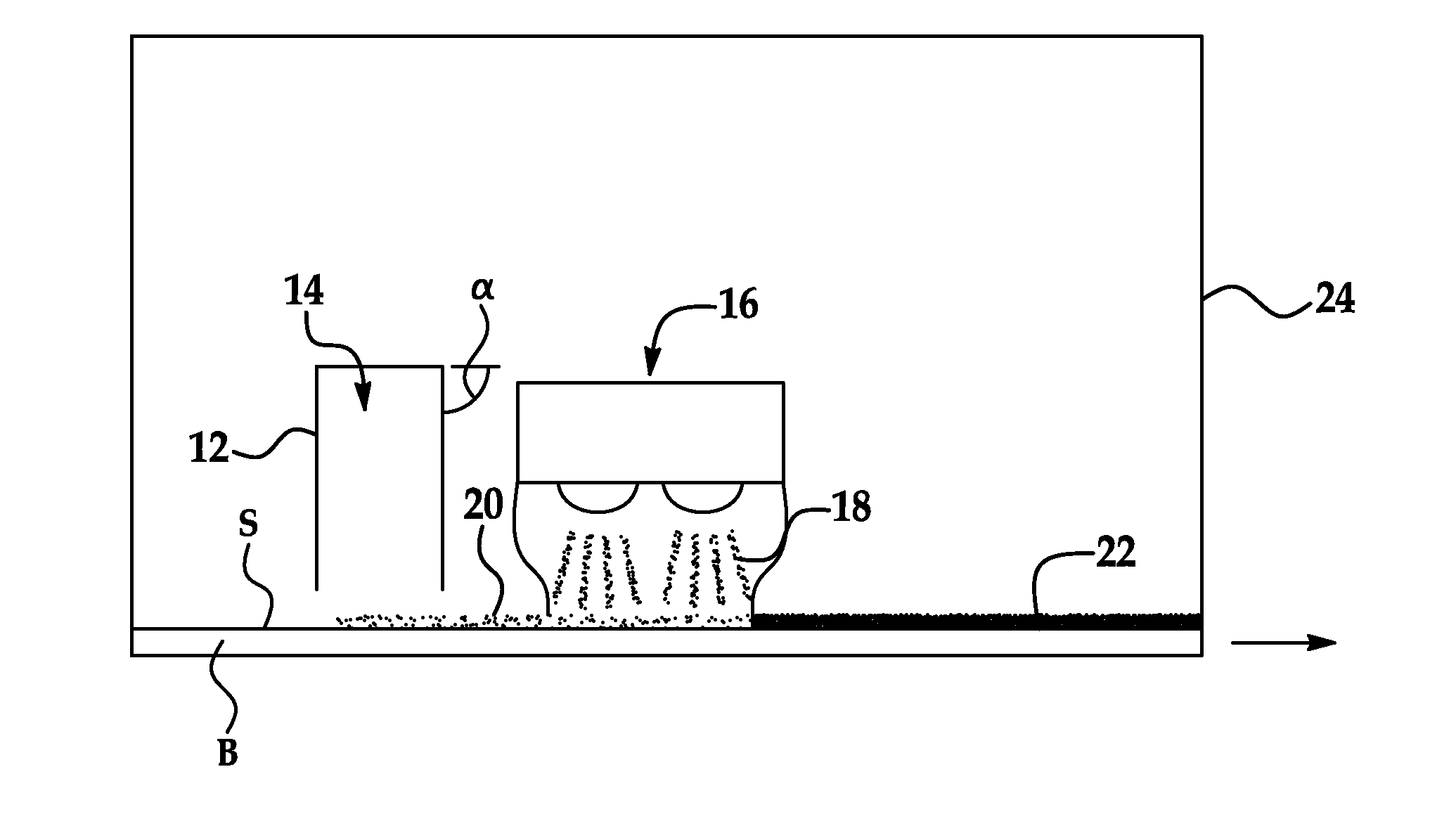

Plasma source with reliable ignition

The invention relates to a plasma source whose plasma is ignited by an electric voltage. To be able to carry out the ignition at relatively low voltages, a plate (5) provided with holes (13, 14) is provided beneath a plasma volume (17), which is disposed above a wall (21) of a plasma chamber (3). Through this plate (5) an ignition volume (16) is formed beneath the plasma volume (17) with a higher pressure than in the plasma volume (17), in which the plasma ignites first. The ignition is subsequently propagated through the holes of the plate (5) into the plasma volume (17).

Owner:LEYBOLD OPTICS

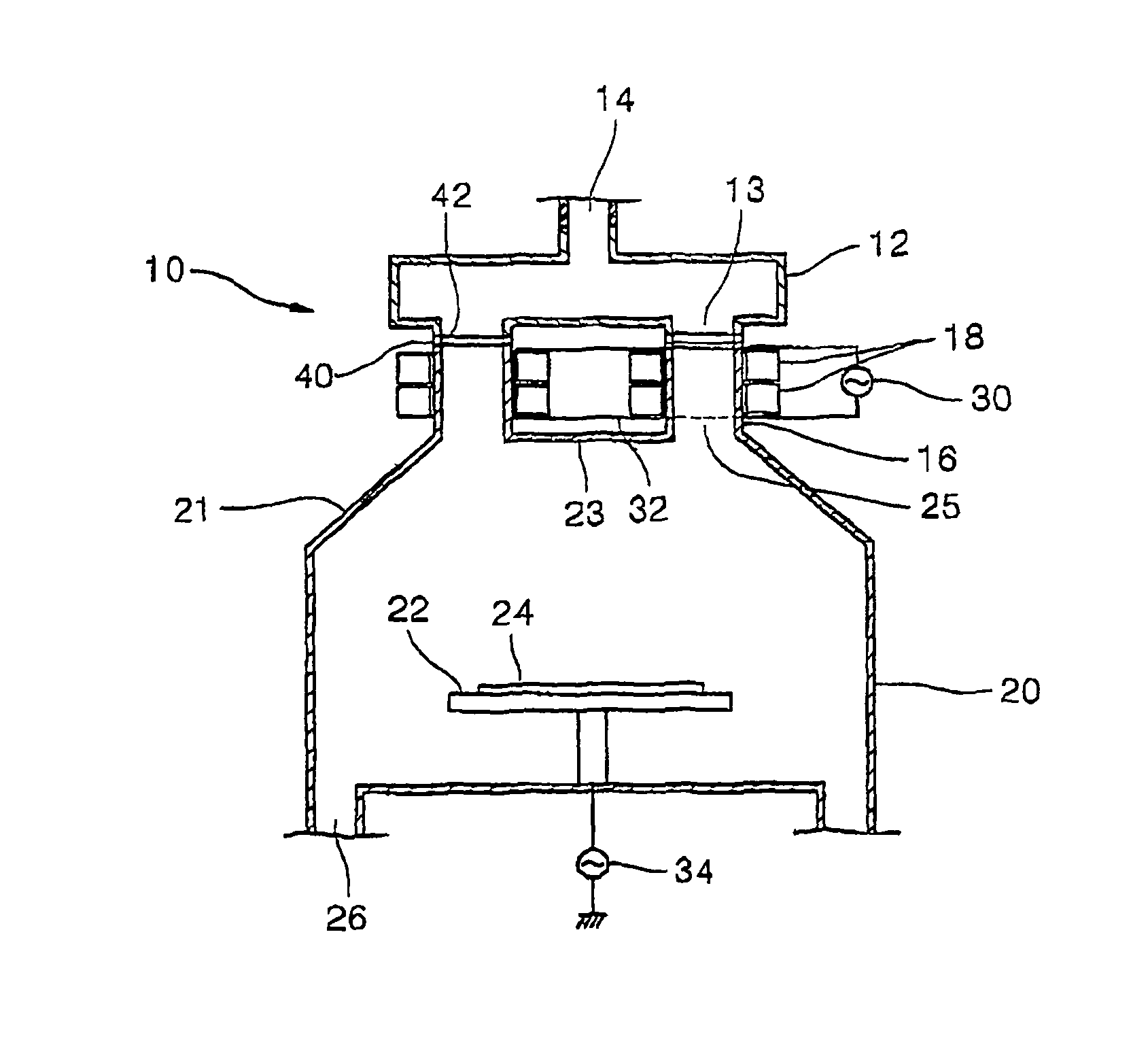

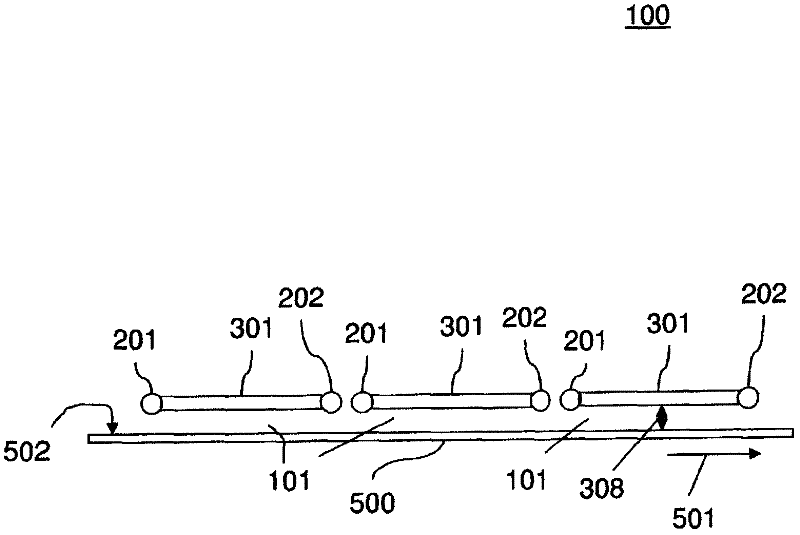

Inductive plasma chamber having multi discharge tube bridge

An inductive plasma chamber of the present invention comprises a plurality of discharge tube bridges connected between a discharge tube head and a process chamber. The discharge tube head is disc shaped and a cylindrical gas inlet which a gas is injected is disposed in its center. A susceptor on which a workpiece is placed is disposed inside a process chamber and a flange of upper certain area has an inclined surface which is upward centrally inclined. The discharge tube bridge is provided with at least one ferrite core, and the ferrite core has a winding connected to a power supply source. When a process gas is injected via the gas inlet and a RF power from the power supply source is supplied with a winding, the electromotive force is transmitted inside the discharge tube head, the discharge bridge and the process chamber so that the plasma discharge is occurred in the plasma chamber. The plasma chamber comprises a switching means enabling plasma discharge paths to be alternately formed between the plurality of discharge tube bridges. The switching means switches in a predetermined period to be alternately formed the plasma discharge paths between the plurality of discharge tube bridges. The inductive plasma chamber can obtain high-density plasma while enhancing uniformity as well as enlarging plasma volume.

Owner:NEW POWER PLASMA CO LTD

Automated methods and systems for providing platelet concentrates with reduced residual plasma volumes and storage media for such platelet concentrates

ActiveUS20140037750A1Plasma-reduced plateletBiocideInorganic phosphorous active ingredientsBlood plasmaWashed platelet

Automated systems and methods for providing platelet concentrates and synthetic storage media with reduced residual plasma volumes are disclosed. The disclosed systems and methods reduce the residual volume of plasma in platelet concentrate to obtain a platelet product having a volume of plasma that is approximately 5% or less of the total platelet product volume. The disclosed systems and methods also reduce the residual volume of plasma in platelet concentrate to obtain a washed platelet product, wherein the volume of plasma in the washed platelet product is approximately 1% or less of the total washed platelet product volume. Storage media for platelets including less than approximately 10% plasma are also disclosed.

Owner:FENWAL

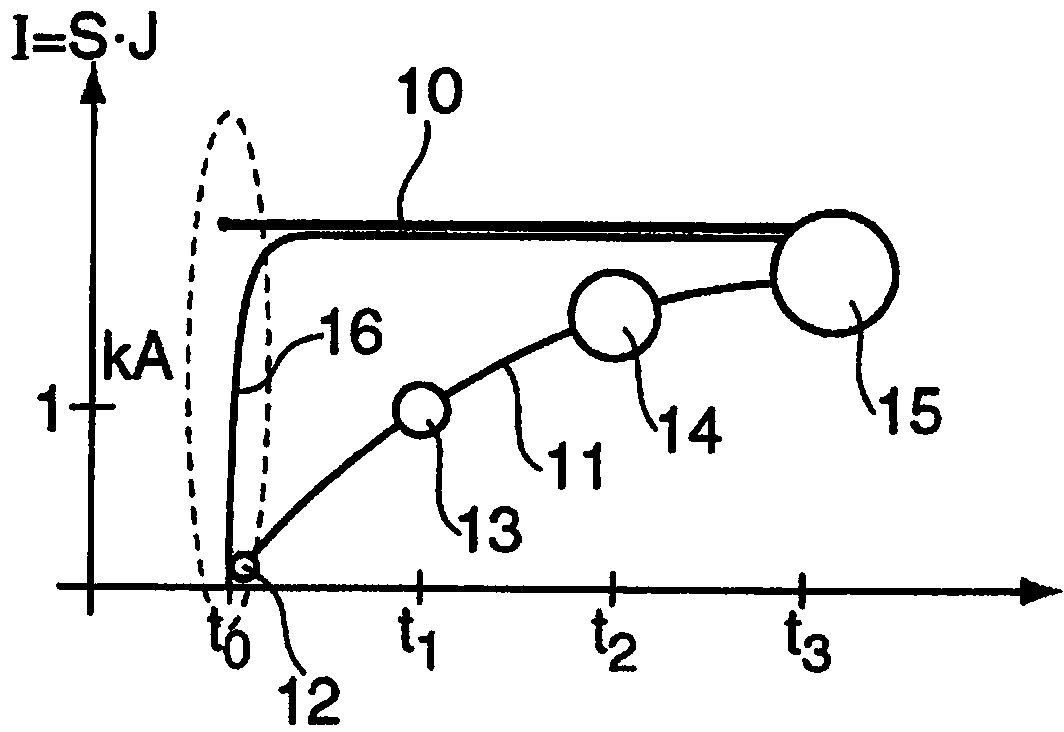

Generating, a highly ionized plasma in a plasma chamber

A method of generating a highly ionized plasma in a plasma chamber (2), comprises the steps of: a. providing a neutral gas to be ionized in the plasma chamber (2) at pressure below 50 Pa, b. supplying at least one high energy high power electrical pulse with power equal or larger than 100 kW and energy equal or larger than 10 J, to at least one magnetron cathode in connection with a target in the plasma chamber (2), c. producing a highly ionized plasma directly from the neutral gas in a plasma volume such that the plasma volume cross section increases during a current rise period, d. sputtering atoms from the target with the highly ionized plasma, e. ionizing at least part of the sputtered atoms.

Owner:TRUMPF HUETTINGER

Deposition of thin films on energy sensitive surfaces

InactiveUS20140057453A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTectorial membranePlasma deposition

A process for plasma deposition of a coating is provided that includes exposure of a surface of a substrate to a source of adsorbate molecules to form a protective layer on the surface. The protective layer is then exposed in-line to a plasma volume to react the protective film to form the coating. This process occurs without an intermediate evacuation to remove the adsorbate molecules prior to contact with the plasma volume. As a result, kinetic ion impact damage to the surface is limited while efficient operation of the plasma deposition system continues.

Owner:GENERAL PLASMA

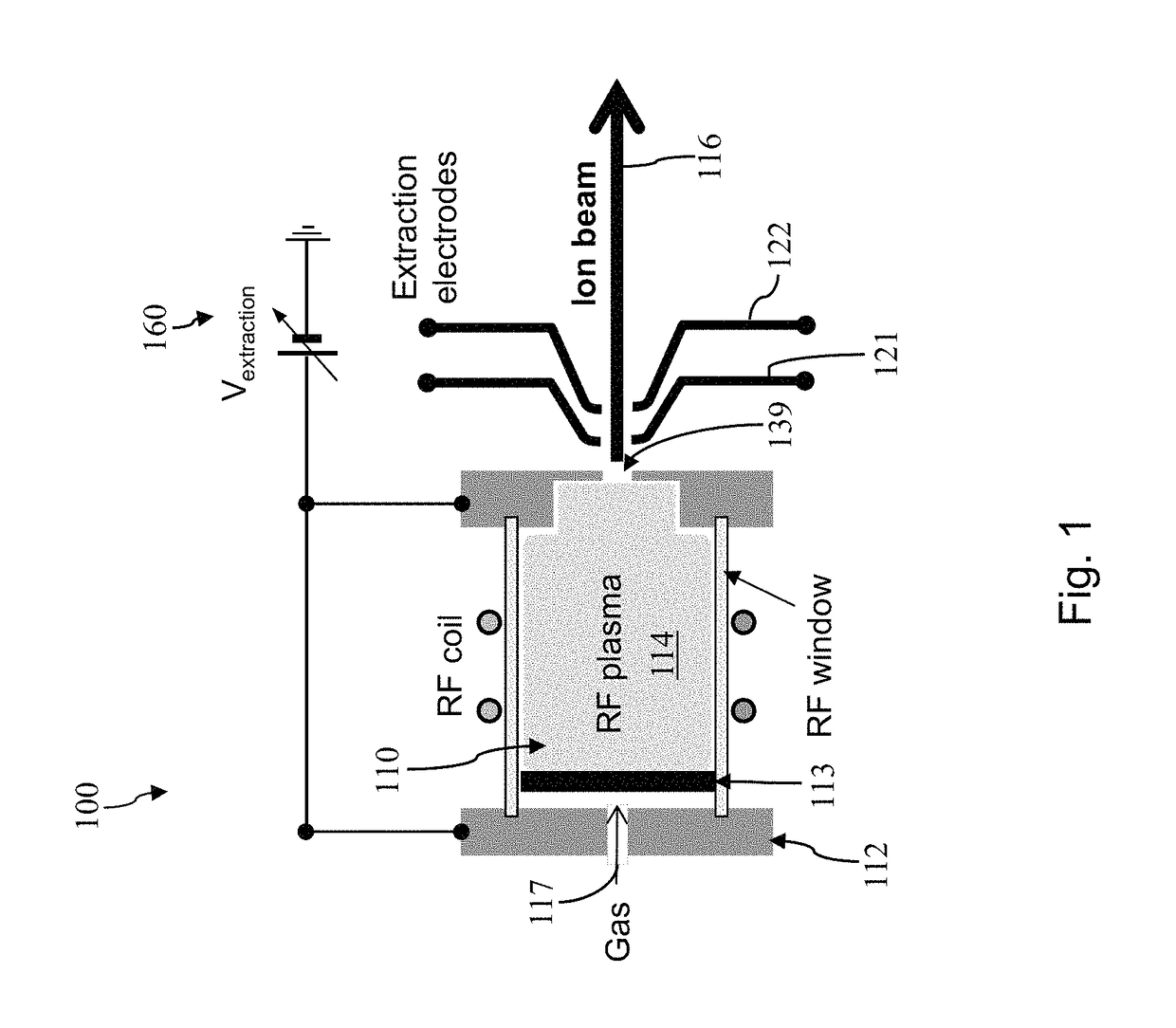

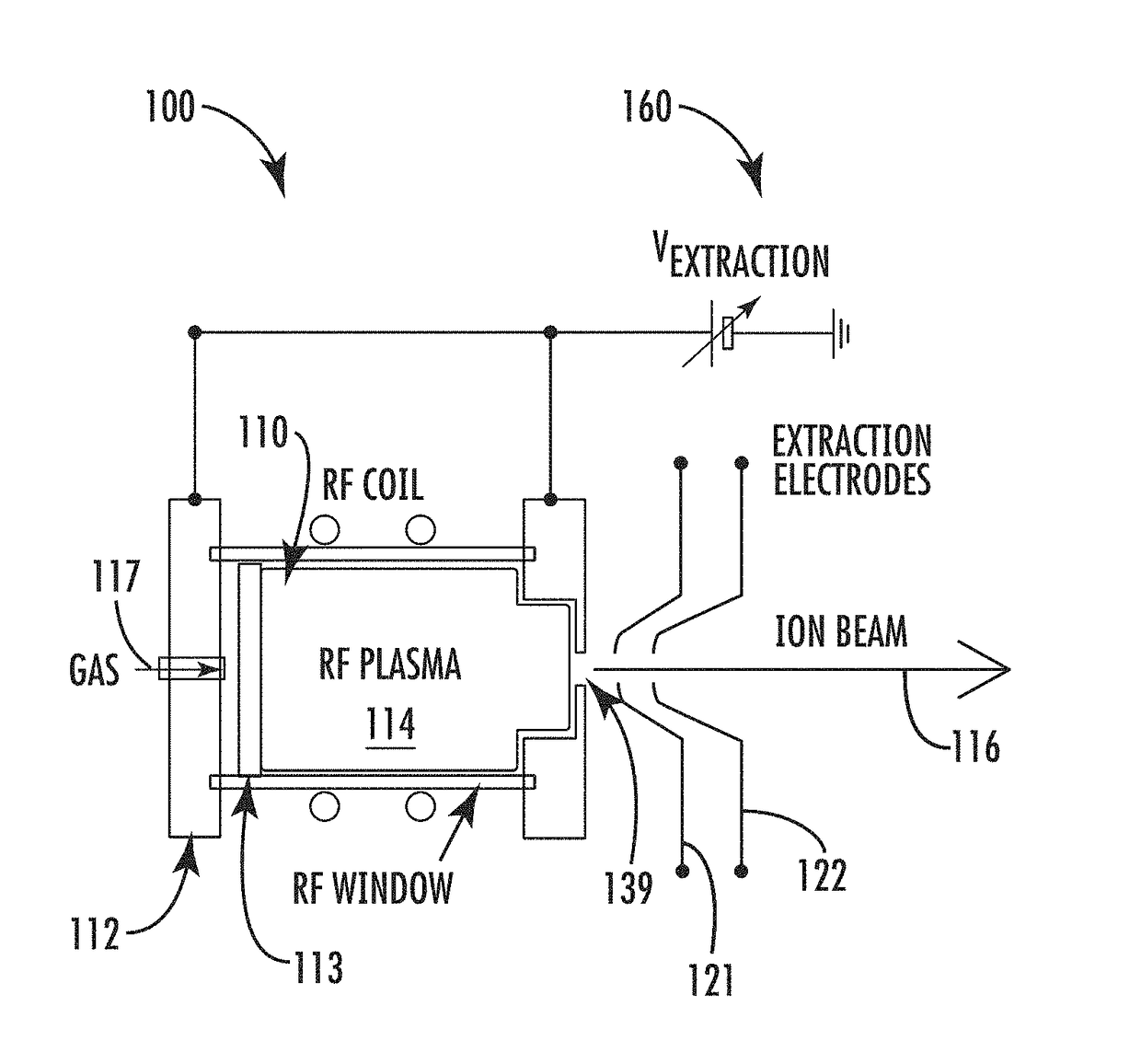

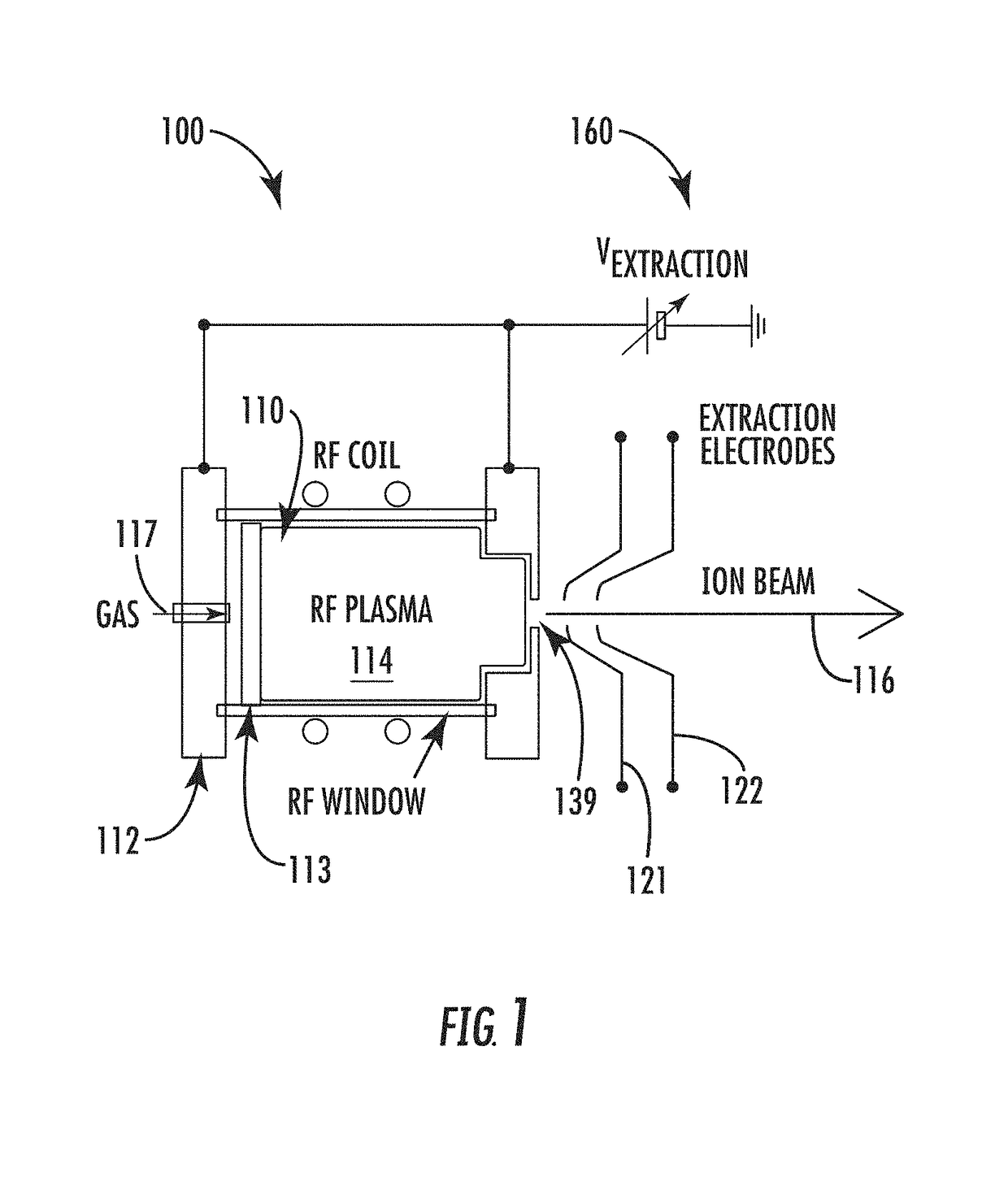

RF ion source with dynamic volume control

Provided herein are approaches for dynamically modifying plasma volume in an ion source chamber by positioning an end plate and radio frequency (RF) antenna at a selected axial location. In one approach, an ion source includes a plasma chamber having a longitudinal axis extending between a first end wall and a second end wall, and an RF antenna adjacent a plasma within the plasma chamber, wherein the RF antenna is configured to provide RF energy to the plasma. The ion source may further include an end plate disposed within the plasma chamber, adjacent the first end wall, the end plate actuated along the longitudinal axis between a first position and a second position to adjust a volume of the plasma. By providing an actuable end plate and RF antenna, plasma characteristics may be dynamically controlled to affect ion source characteristics, such as composition of ion species, including metastable neutrals.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Plasma detoxification and volume control system and methods of use

ActiveUS8038638B2Effectively detoxify human plasma and balance blood volumeSolvent extractionHaemofiltrationIon exchangeBlood plasma

Owner:MARKER HLDG AG

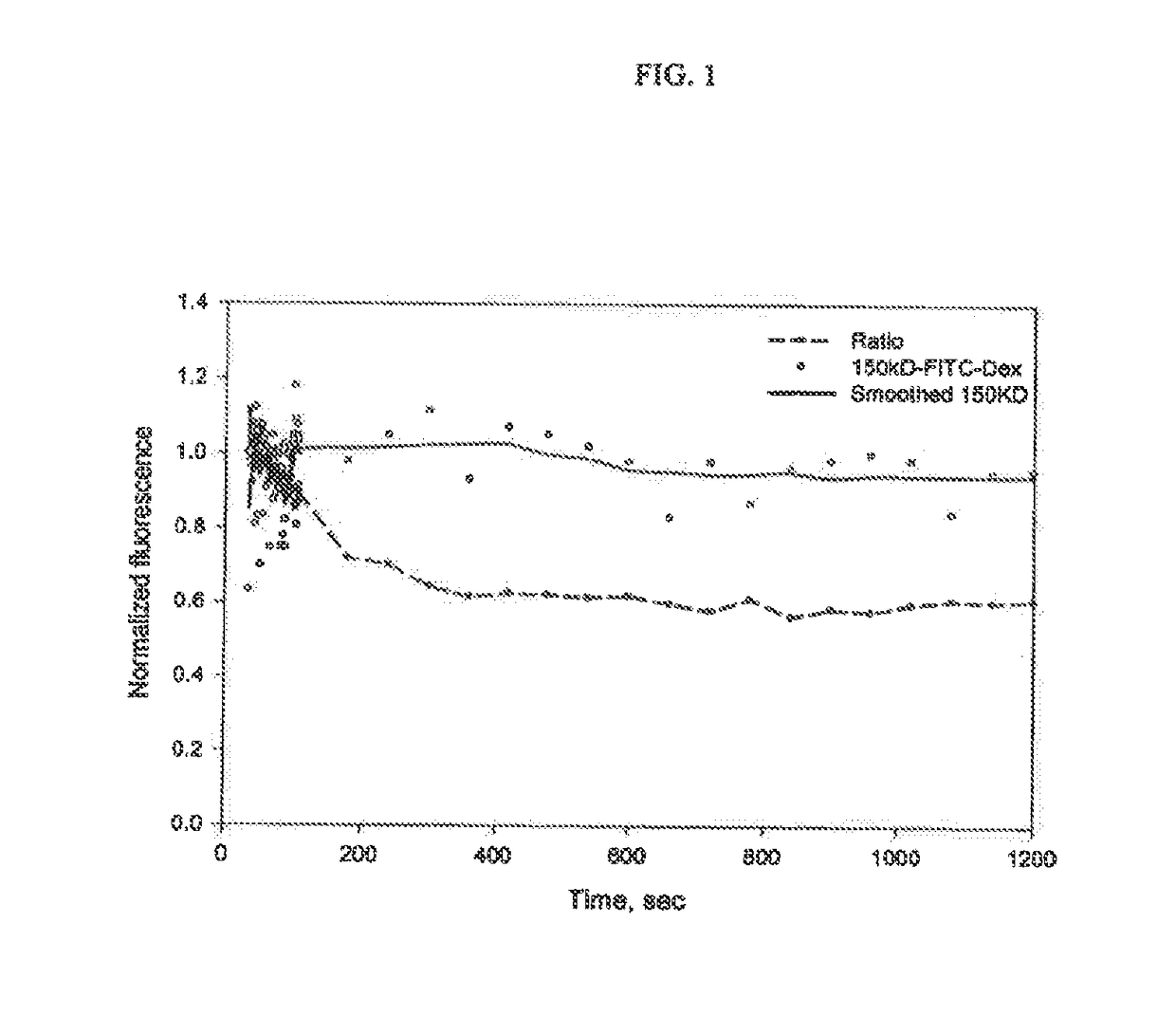

Compositions and methods for monitoring biometric indicators

InactiveUS20140369936A1Reduce quality problemsQuality improvementCompounds screening/testingUltrasonic/sonic/infrasonic diagnosticsFiltrationBlood plasma

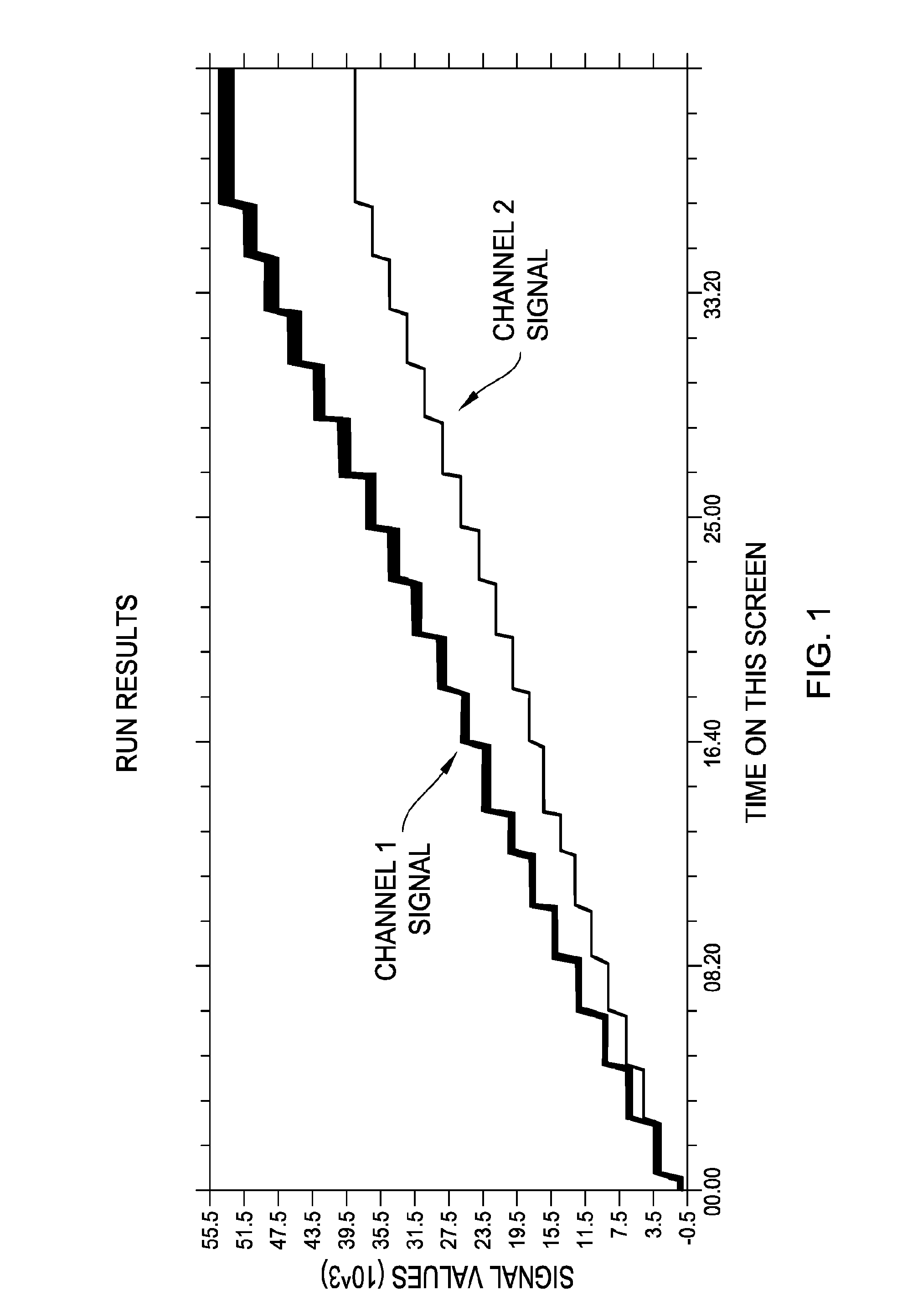

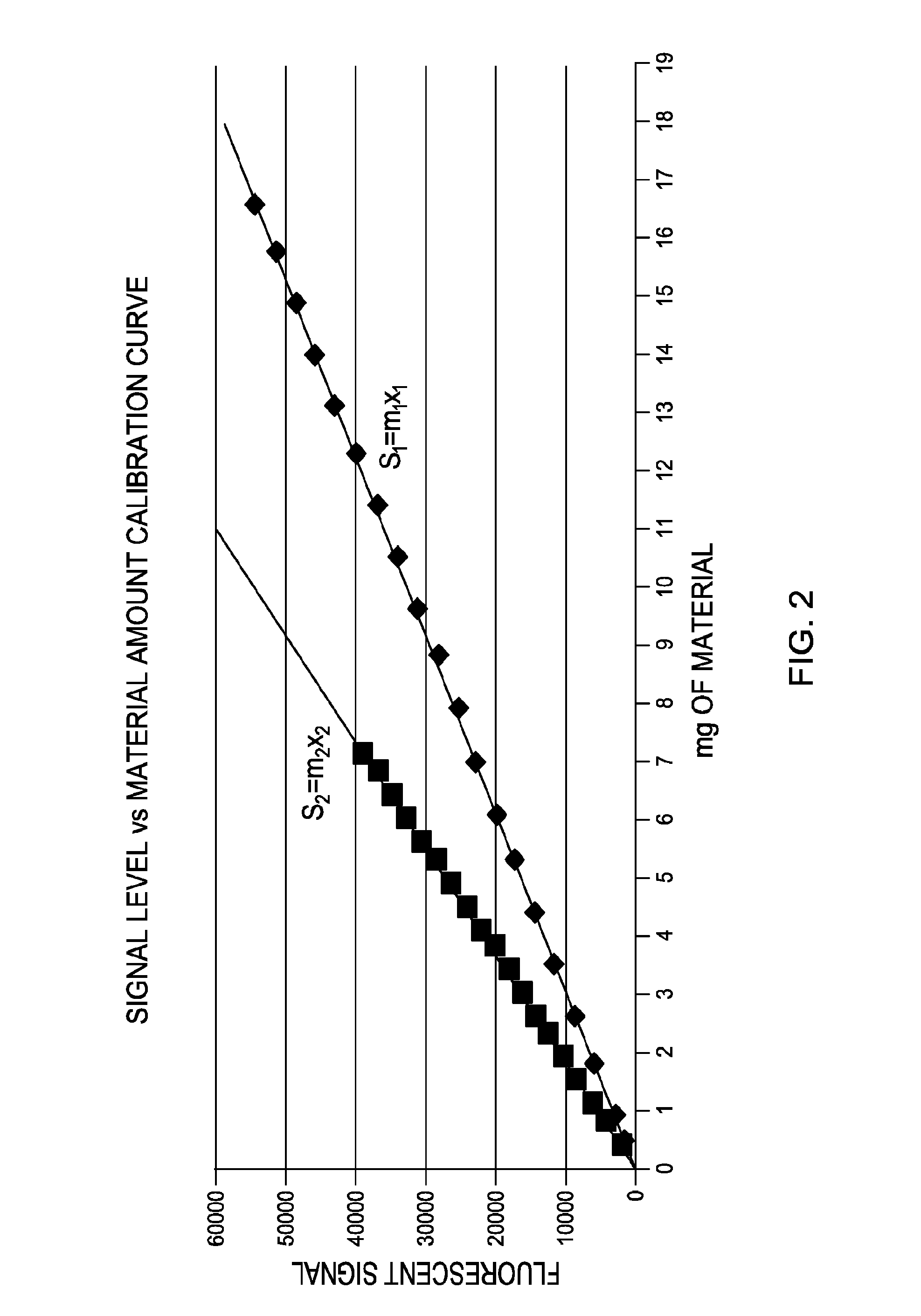

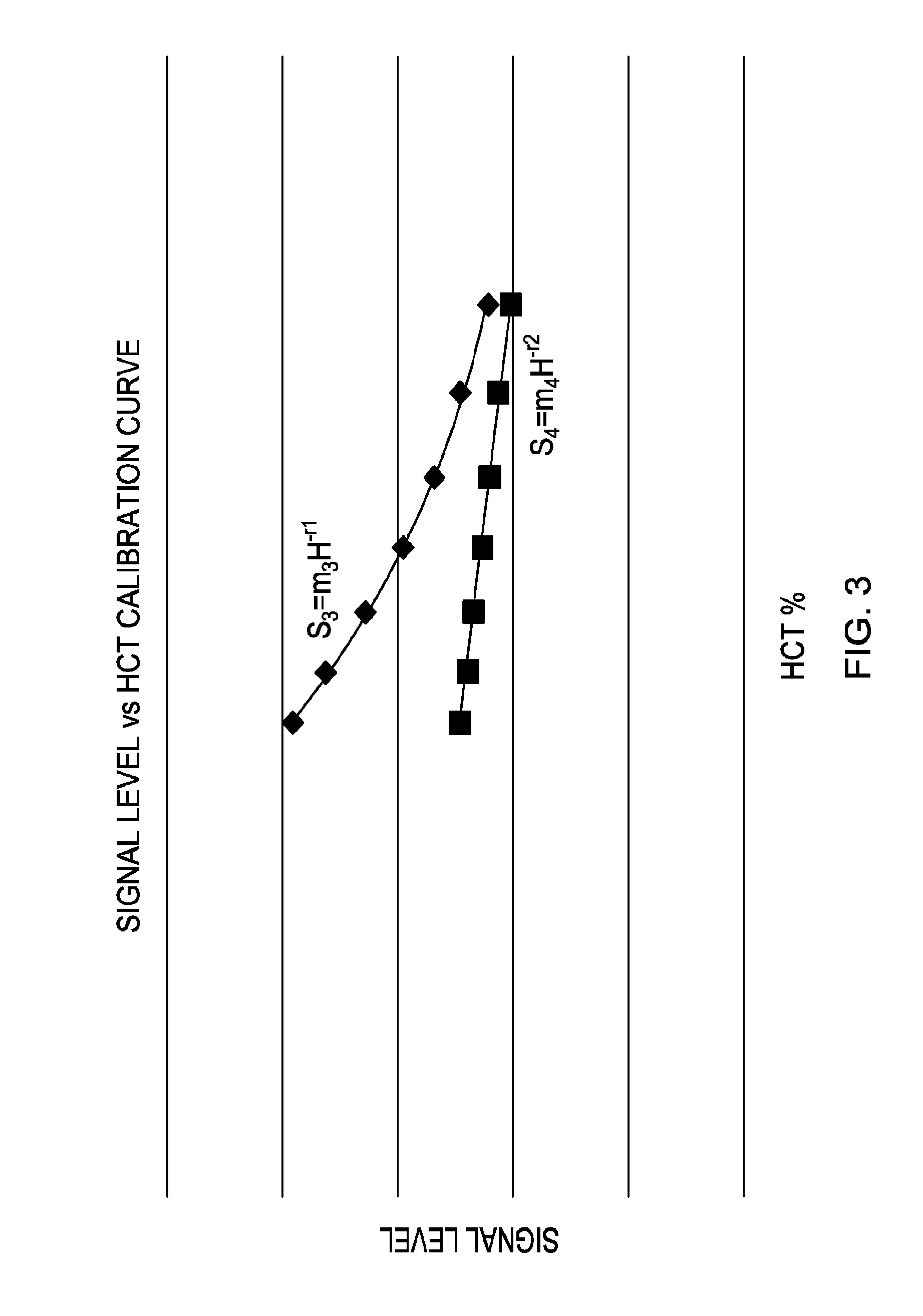

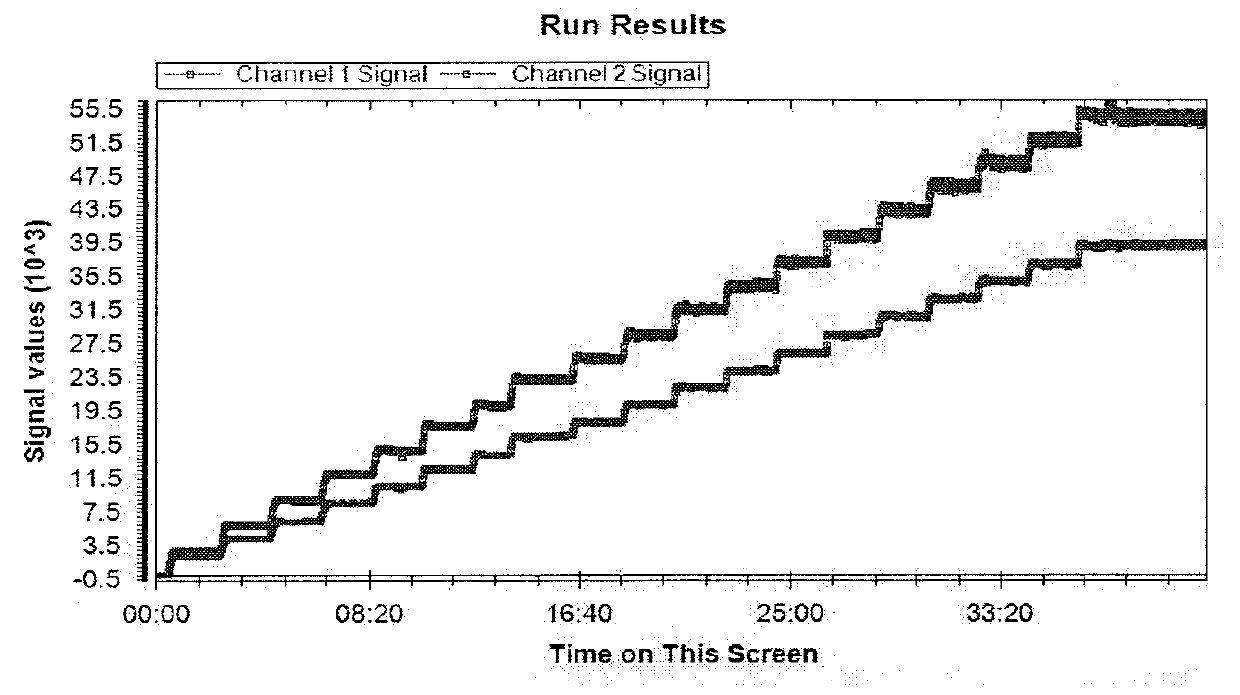

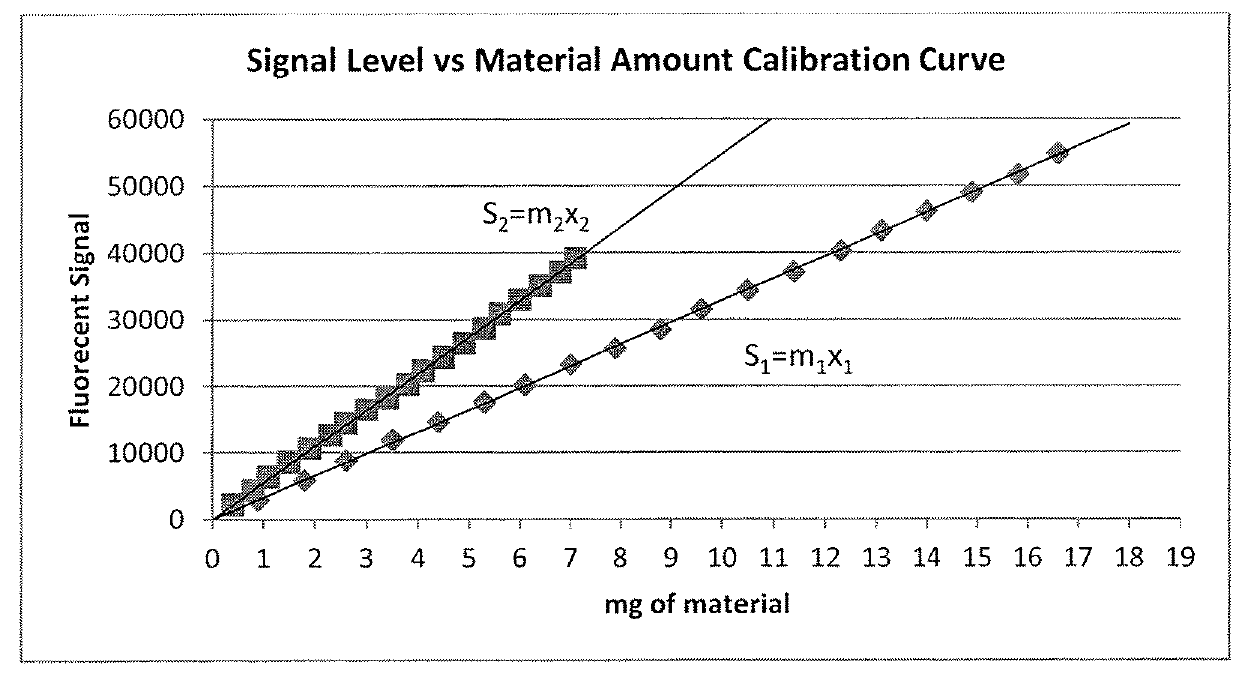

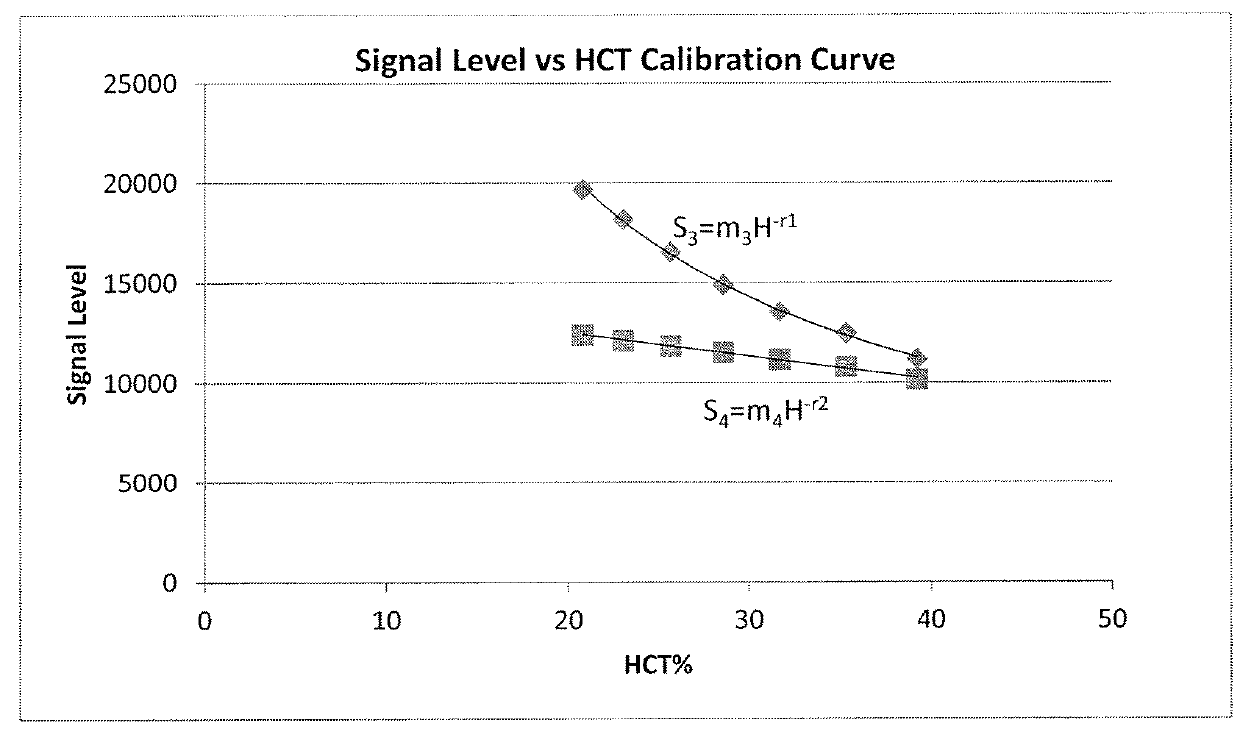

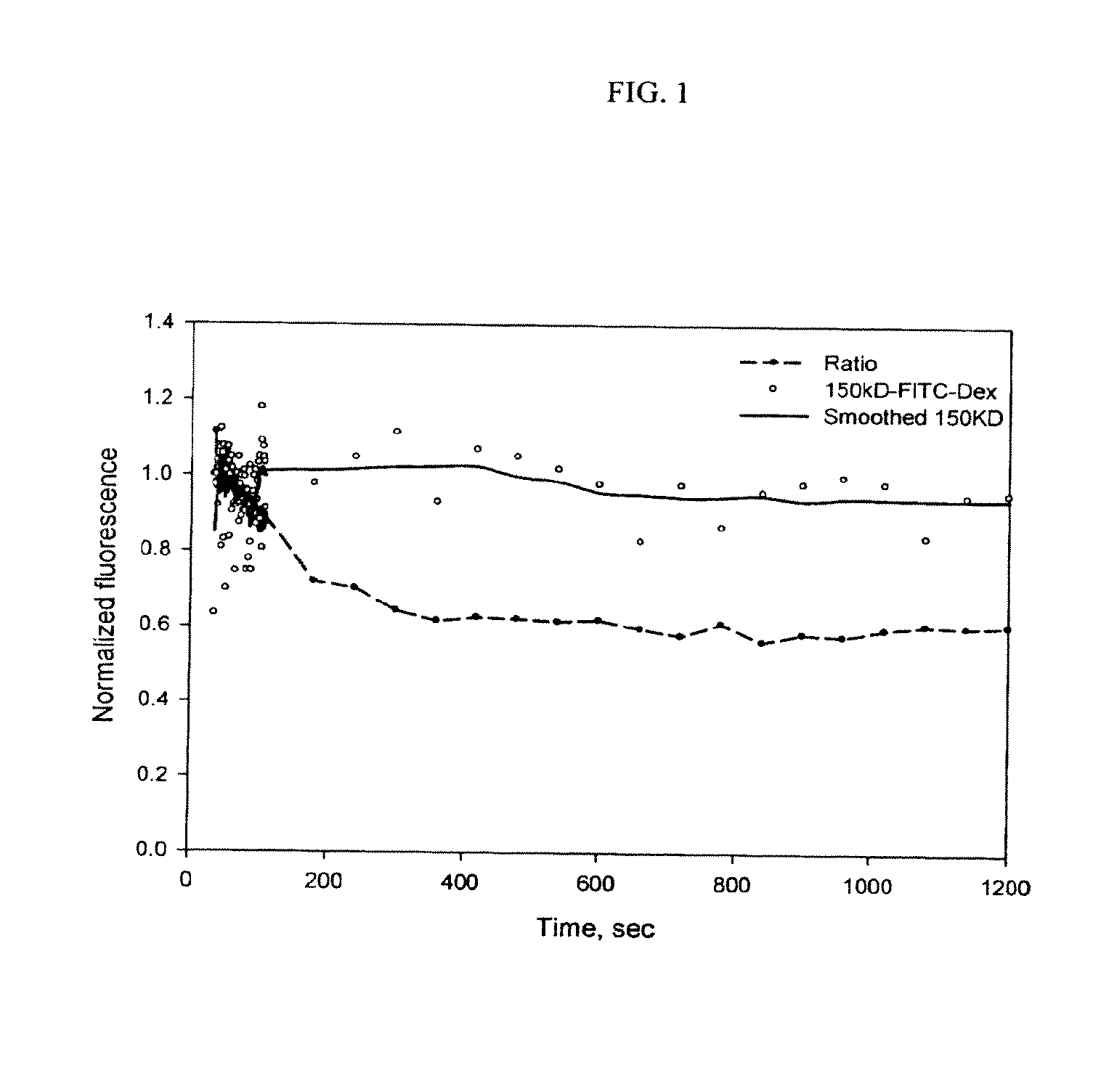

Methods of measurement of biometric indicators in a mammalian subject are described. Biometric indicators of interest include hematocrit, plasma volume, volume of distribution, and glomerular filtration rate. The methods are especially applicable to subjects with rapid blood loss and to subjects with unstable hematocrits. Hematocrit may be measured by administering an injectate with a dynamic fluorescent marker and a static fluorescent marker, or a single static marker with two fluorescent tags, into the vascular system of the subject, and monitoring the emission intensities of the markers or fluorescent tags over a period of time. Hematocrit may then be calculated using a calibrated spectrometric analyzer by determining the raw ratio of the markers at T0, calculating the apparent hematocrit, and applying a correction factor.

Owner:PHARMACOPHOTONICS INC

Method and apparatus for determining biometric indicators using multiple fluorescent markers

InactiveUS20180180622A1Accurate predictionShorten test timeDiagnostics using fluorescence emissionCatheterPlasma samplesFiltration

Disclosed are methods for determining biometric indicators such as plasma volume, hematocrit and glomerular filtration rate, in mammalian subjects such as humans. The methods utilize a plurality of fluorescent tags having distinct fluorescent characteristics, which may be associated with a single static molecule, or wherein the static molecule is labeled with a fluorescent tag and a dynamic molecule is labeled with another fluorescent tag. One or more measurements of the intensities of the fluorescent emissions are taken subsequent to introduction of an injectate which contains the fluorescent tags, which can be taken using a probe or via a blood or plasma sample. Compositions and apparatuses for practicing the methods are also disclosed.

Owner:PHARMACOPHOTONICS INC

RF ion source with dynamic volume control

Owner:VARIAN SEMICON EQUIP ASSOC INC

Measurement of body fluid volumes

InactiveUS20140193343A1Ultrasonic/sonic/infrasonic diagnosticsGeneral/multifunctional contrast agentsPlasma volumeBlood vessel

The present invention is related generally to measurement of body fluid volumes in an animal subject. The body fluid volumes of interest include extracellular fluid volume (ECFV), total vascular plasma volume (TVPV) and interstitial fluid volume (IFV). The methods are especially beneficial for subjects suffering from renal failure and particularly those undergoing renal dialysis. ECFV can be measured by administering a first molecule which is non-metabolized and permeable to vessel walls of the vascular system wherein the first molecule is distributed within the total vascular space as well as the interstitial space. TVPV can be measured by administering a second molecule which is non-metabolized and impermeable to vessel walls of the vascular system wherein the second molecule is distributed within only the vascular space. IFV can then be calculated using the equation IFV=ECFV−TVPV.

Owner:PHARMACOPHOTONICS INC

Measurement of body fluid volumes

InactiveUS20140301952A1Compounds screening/testingUltrasonic/sonic/infrasonic diagnosticsBlood vesselPlasma volume

The present invention relates generally to measurement of body fluid volumes in an animal subject. The body fluid volumes of interest include extracellular fluid volume (ECFV), total vascular plasma volume (TVPV) and interstitial fluid volume (IFV). The methods are especially beneficial for subjects suffering from renal failure and particularly those undergoing renal dialysis. ECFV can be measured by administering a first molecule which is non-metabolized and permeable to vessel walls of the vascular system, wherein the first molecule is distributed within the total vascular space as well as the interstitial space. TVPV can be measured by administering a second molecule which is non-metabolized and impermeable to vessel walls of the vascular system, wherein the second molecule is distributed within only the vascular space. IFV can then be calculated using the equation IFV=ECFV−TVPV.

Owner:PHARMACOPHOTONICS INC D B A FAST DIAGNOSTICS

Plasma deposition source and method for depositing thin films

InactiveCN102449726AElectric discharge tubesVacuum evaporation coatingPlasma depositionVacuum chamber

Owner:APPLIED MATERIALS INC

Measurement of body fluid volumes

InactiveUS20170173188A1General/multifunctional contrast agentsPharmaceutical delivery mechanismBlood plasmaBlood vessel

The present invention is related generally to measurement of body fluid volumes in an animal subject. The body fluid volumes of interest include extracellular fluid volume (ECFV), total vascular plasma volume (TVPV) and interstitial fluid volume (IFV). The methods are especially beneficial for subjects suffering from renal failure and particularly those undergoing renal dialysis. ECFV can be measured by administering a first molecule which is non-metabolized and permeable to vessel walls of the vascular system wherein the first molecule is distributed within the total vascular space as well as the interstitial space. TVPV can be measured by administering a second molecule which is non-metabolized and impermeable to vessel walls of the vascular system wherein the second molecule is distributed within only the vascular space. IFV can then be calculated using the equation IFV=ECFV−TVPV.

Owner:PHARMACOPHOTONICS INC

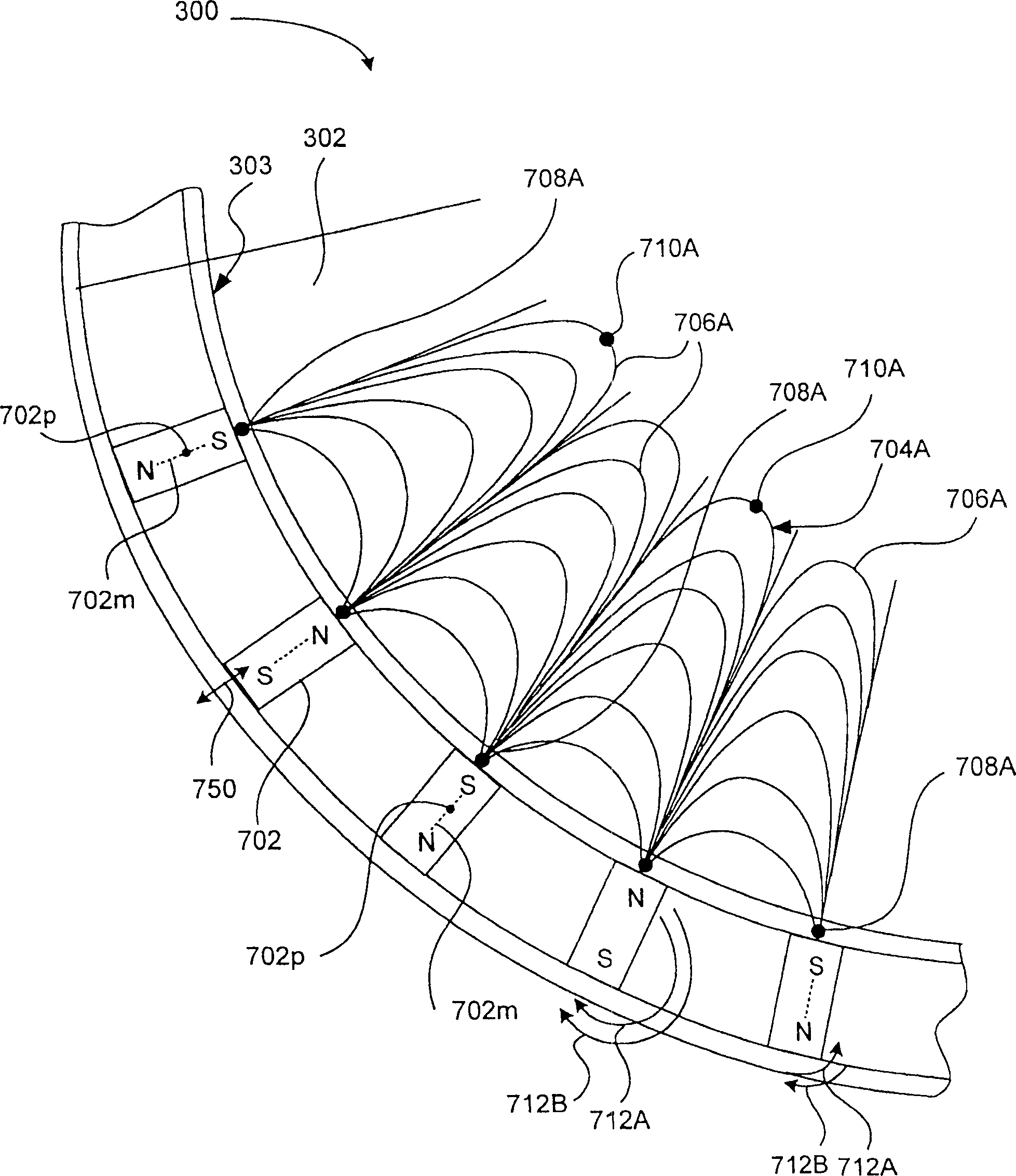

Apparutus for varying magnetic field to control volume of plasma

InactiveCN1257527CPrevent movementUniform densityElectric discharge tubesSemiconductor/solid-state device manufacturingGraphicsPlasma volume

A plasma confinement apparatus for controlling a plasma volume when a substrate is processed within a processing chamber includes a processing chamber within which a plasma processing a substrate is induced and maintained. The processing chamber is defined at least in part by chamber walls and also includes plasma confinement means. The plasma confinement device includes a magnetic matrix disposed about the periphery of the chamber and configured to generate a magnetic field that establishes a pattern of intersection points on the walls of the chamber. The pattern of intersections on the chamber walls defines areas where the plasma may damage and create cleaning problems. The intersection pattern is moved to improve the operation of the substrate processing system and reduce damage and / or cleaning problems due to plasma interaction with chamber walls. The movement of the intersection pattern can be realized by moving the magnetic matrix or the wall of the processing chamber. Movement of the magnetic elements can be continuous, i.e. rotating one or more magnetic elements or rotating all or part of the chamber wall, or incremental, i.e. periodically moving the position of one or more magnetic elements or the position of all or part of the chamber wall .

Owner:LAM RES CORP

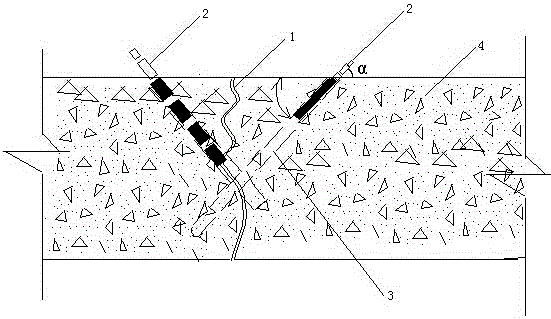

A method for controlling water seepage from concrete floor and wall cracks

ActiveCN104234090BReduce dosageImprove impermeabilityArtificial islandsProtective foundationInjection pressureHand held

The invention discloses a method for controlling water seepage from cracks in concrete floor and wall, which starts from one side of the structural surface of the concrete floor and wall to search for leaks one by one, and marks them with red spray paint; The red mark is to be drilled at an angle of 45° to the base surface at 3~4cm next to the leak point. The drilling depth is between 1 / 2 of the structure thickness and 2 / 3 of the structure thickness. Install grouting at the place where the hole is drilled Nozzle; use an electric grouting machine for grouting, when the grouting volume of each hole section is less than 5L / min, and the water absorption per meter of the inspection hole is less than 1.0L / min, the grouting is over, and then the next construction will be carried out; seal Hole out: After the grouting is finished, chisel off the grouting nozzle, and then seal it tightly with leak-stopping materials. During grouting, because one end of the grouting hole is blocked, the grouting pressure increases, and the cracks and seepage holes are quickly filled, thereby improving the anti-seepage effect; the amount of grouting fluid and cement is greatly reduced, economical and practical, and the construction period is shortened, and there will be no leakage. Large cracks and damage.

Owner:JIANGSU NANTONG SANJIAN CONSTRUCTION GROUP CO LTD

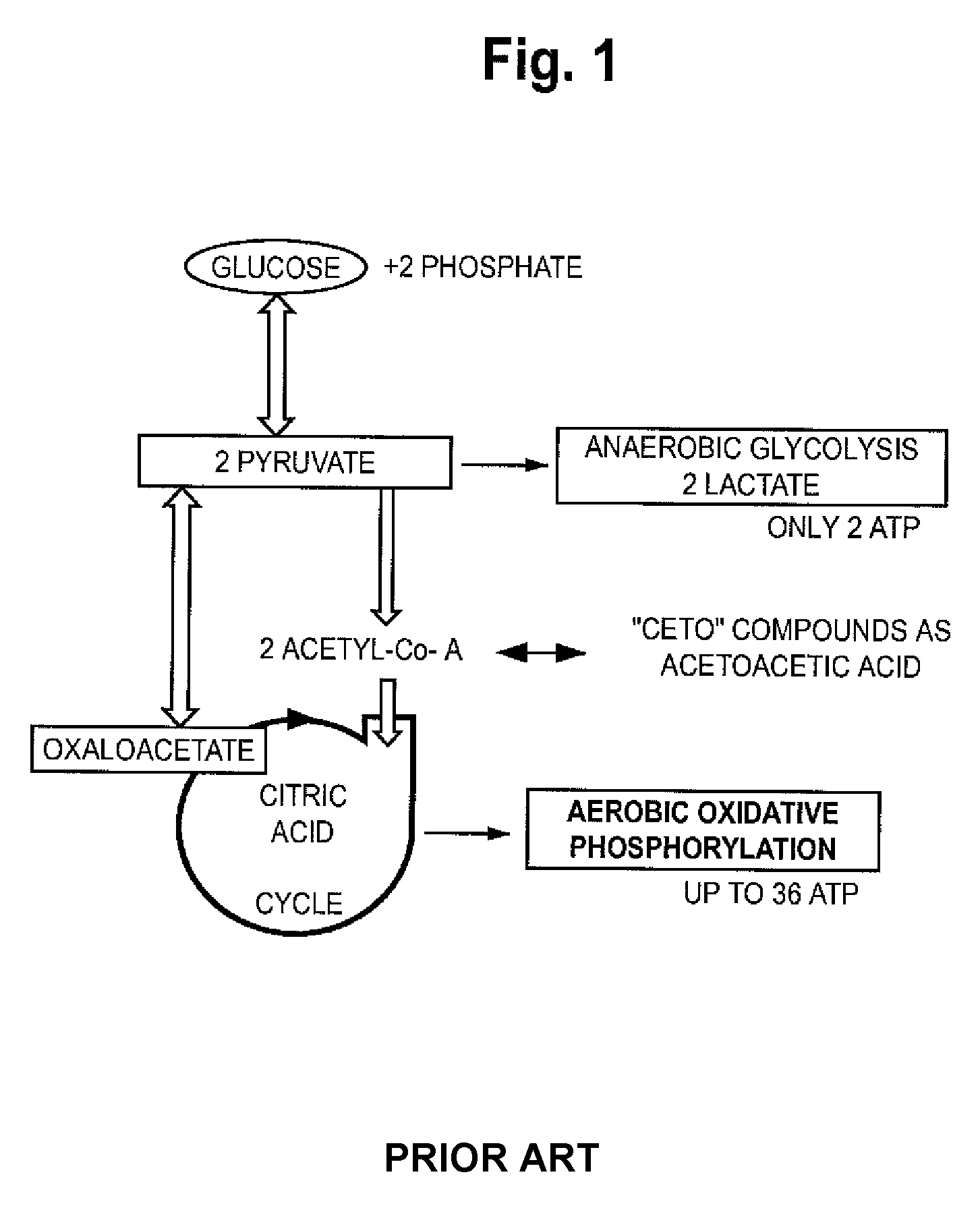

Anti-shock medicament with oxygen

InactiveCN101199856AAvoid damageGood plasma volume expansion effectOrganic active ingredientsInorganic active ingredientsHydroxyethyl starchSide effect

Disclosed is an oxygen-laden antishock drug, which is characterized in that the essential formulation is that: nanometer-sized oxygen-laden material and adverse-reaction-preventive component are added into hydroxyethyl starch solution whose concentration is 3-10% and whose molecular weight is 20-200kD. The invention has the advantages that the good-plasma-volume-expansion effect and the capacity to supply anoxic tissue with oxygen guarantees that the anoxic condition of different organs of human body can be quickly released and corrected and the normal physiological function can be restored gradually, so that the curing purpose can be achieved; meanwhile, unhealthy tendencies like edema of vascular endothelium and inflammatory reaction caused by ischemia can be prevented and treated by adding side-effect-preventive component of certain concentration in the oxygen-laden medical solution.

Owner:XIEHETONGREN TECH TIANJIN CO LTD

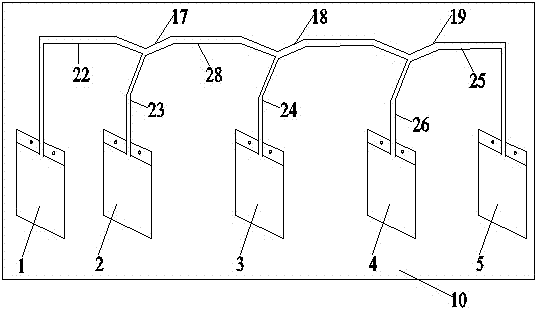

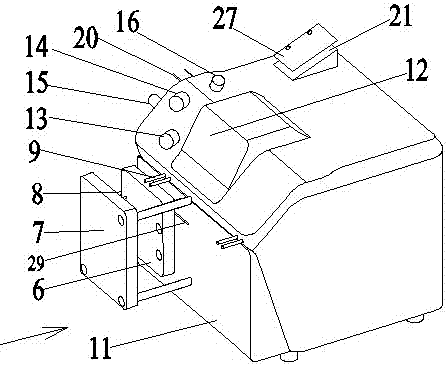

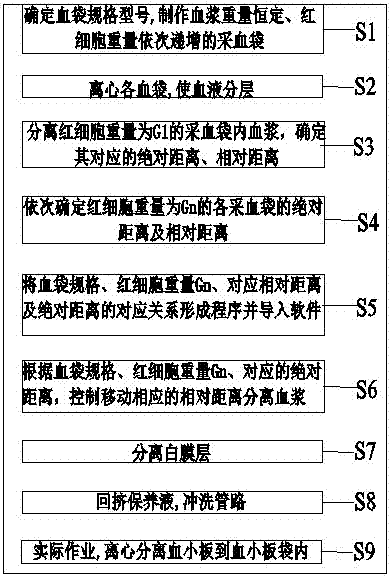

Platelet quantitative separation method applied to automatic blood component separator

ActiveCN107080869AConstant weightOther blood circulation devicesMedical devicesBlood Collection TubeBlood component separator

The invention discloses a platelet quantitative separation method applied to an automatic blood component separator and can provide a more optimized operation method for platelet separation. The automatic blood component separator comprises a front extrusion plate, a hanging arm, a heat sealing head and an inductive head. The separation method comprises the following steps: centrifuging series of blood collection bags containing constant plasma weight D and different red blood cell weight Gn, extruding the blood collection bags to enable a red blood cell level to reach an inductive head position, recording a front extrusion plate moving distance as an absolute distance Hn, setting extruded plasma volume D1 (D1=D-E) according to the platelet quantity demanded E, sequentially enabling the front extrusion plate to continuously extrude all the blood collection bags till the D1 volume of plasma is extruded, recording a change value relative distance delta n of each of the blood collection bags corresponding to the moving distance at the moment and enabling a corresponding relation among the blood bag specification, the absolute distance and the relative distance to form a program to guide into software for invoking during separation operation. The platelet quantitative separation method disclosed by the invention has the benefits that prepared platelet products are consistent in weight, and the platelet density difference is smaller.

Owner:深圳市爱康生物科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com