Method of raising the field electron emitting performance of carbon nanotube film

A field electron emission, carbon nanotube thin film technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problems of unfavorable large-area growth, high growth temperature, high cost, and improve field emission performance, reduce Threshold field strength, the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

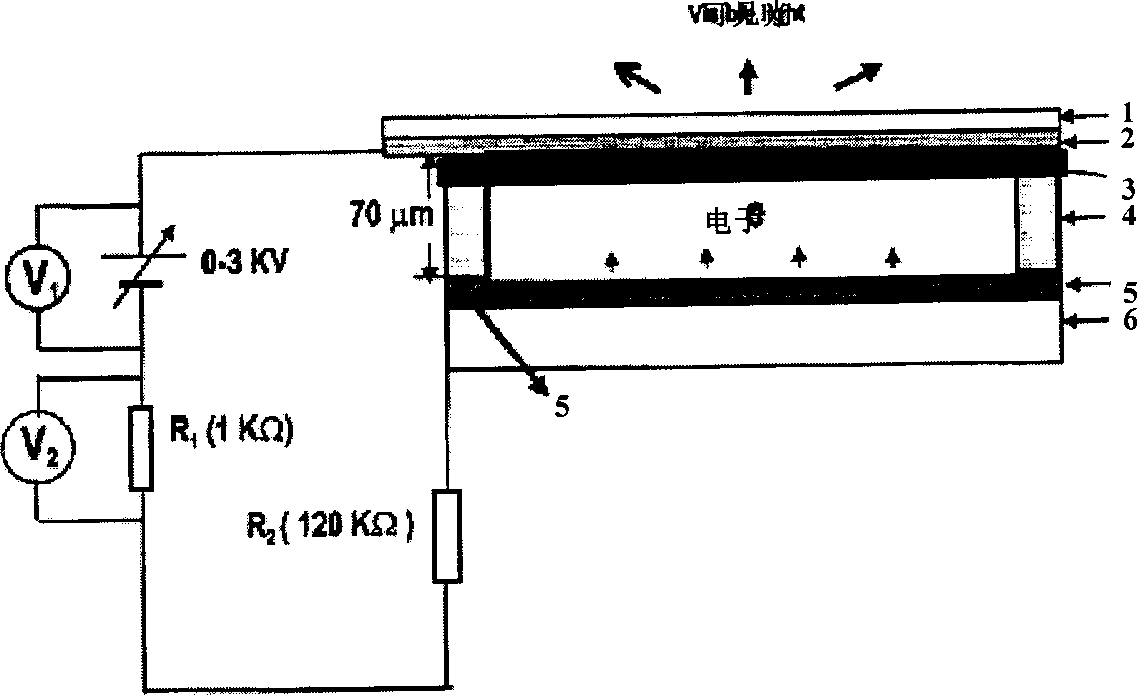

Method used

Image

Examples

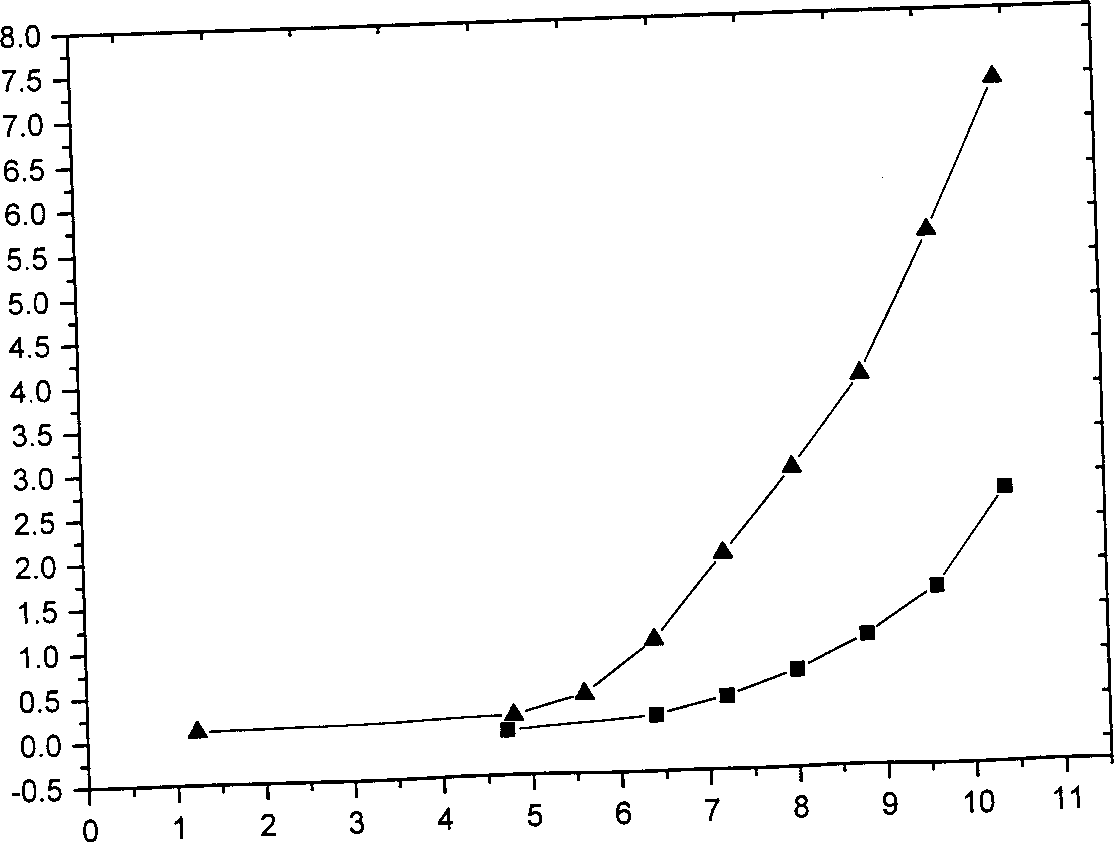

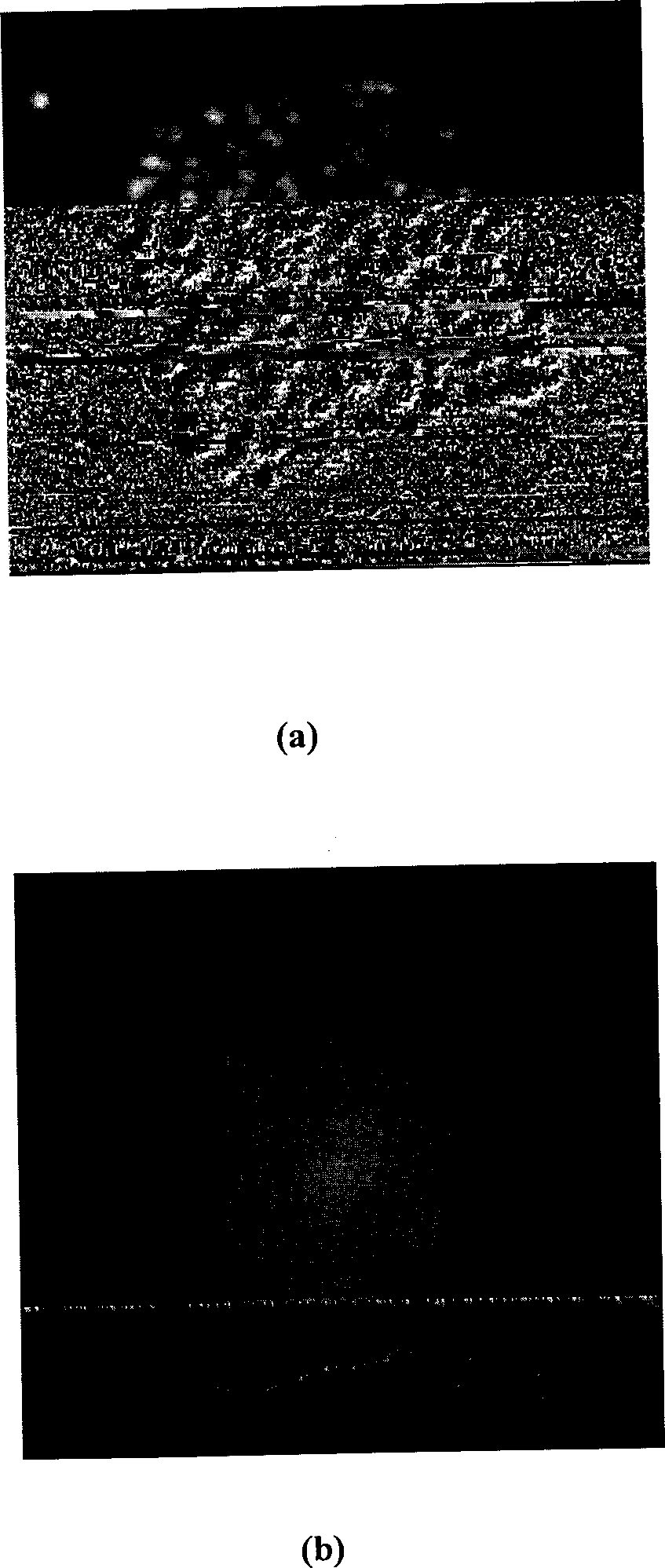

Embodiment 1

[0013] The field electron emission performance of the CNT thin film cathodes treated by the invention and not treated by the invention were tested. The CNT film cathode used is prepared by screen printing method, the substrate material is metallic nickel (Ni), the thickness of the CNT film is about 40 μm, and the effective area is 10 mm×10 mm. The tested samples are CNT films without any treatment and CNT films subjected to heat treatment and plasma surface treatment according to the method of the present invention. The heat treatment process condition that adopts in the present embodiment is 600 ℃; H 2 -N 2 shielding gas, H 2 The flow rate is 0.2 l / min, N 2 Flow rate of 2 l / min: treatment time 10 minutes. The plasma surface treatment equipment used in this embodiment is a capacitively coupled plasma etching equipment. The process conditions are: plasma power density 0.275W / cm 3 , plasma sheath voltage 215V; hydrogen flow, gas flow rate 20 ml / min; working pressure 0.4 To...

Embodiment 2

[0015] The field electron emission performance of the CNT thin film cathodes treated by the invention and not treated by the invention were tested. The CNT thin film cathode used is prepared by screen printing method. The substrate material is glass with a layer of metal Ti grown. The growth of metal Ti adopts electron beam evaporation method with a thickness of 500nm. The thickness of the CNT film is about 40μm and the effective area is 10mm. ×10mm. The tested samples are CNT films without any treatment and CNT films subjected to heat treatment and plasma surface treatment according to the method of the present invention. Processing condition is the same as embodiment 1. The treatment effect is similar to Example 1.

Embodiment 3

[0017] The field electron emission performance of the CNT thin film cathodes treated by the invention and not treated by the invention were tested. The CNT film cathode used is prepared by screen printing method, the substrate material is silicon wafer (Si), the thickness of the CNT film is about 60 μm, and the effective area is 10mm×10mm. The tested samples are CNT films without any treatment and CNT films subjected to heat treatment and plasma surface treatment according to the method of the present invention. The heat treatment process condition that adopts in the present embodiment is 550 ℃; O 2 -N 2 shielding gas, O 2 The flow rate is 0.1 l / min, N 2 The flow rate is 2 liters / minute; the processing time is 10 minutes. The plasma surface treatment equipment used in this embodiment is a capacitively coupled plasma etching equipment. The process conditions are: plasma power density 0.275W / cm 3 , plasma sheath voltage 215V; ammonia gas flow, gas flow rate 30 ml / min; work...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com