Composite field electronic emitting material and preparation method and use thereof

An electron emission material and composite field technology, which is applied in the manufacture of electrode systems, discharge tube electron guns, discharge tubes/lamps, etc., can solve the problems of high cost and high equipment requirements, and achieve the effect of improving the performance of field electron emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Use semiconductor standard cleaning technology for silicon wafers (such as: Yan Zhirui, Development Direction of Semiconductor Silicon Wafer Cleaning Technology, Special Equipment for Electronic Industry, 2003, September, p23-26), to clean single-sided polished silicon wafers. Using a pulsed laser deposition system (such as Xin Chen, Wenjie Guan, Guojia Fang, Xingzhong Zhao, Influence of substratetemperature and post-treatment on properties of ZnO: Al thin films prepared by pulsed laserdeposition, AppL.Surf.Sci., 2005, 252( 5): 1561-1567.), depositing a zinc oxide film with a thickness of 100-500nm on the polished surface of the cleaned silicon wafer.

[0026] 2. Put 0.1-1 gram of zinc oxide and graphite powder mixture (molar ratio 1:1) at the bottom of the sealed end of the quartz tube sealed at one end, and put the silicon wafer deposited with the zinc oxide film into the quartz tube sealed at one end , and 5-10cm away from the bottom of the sealed end.

[0027] 3...

Embodiment 2

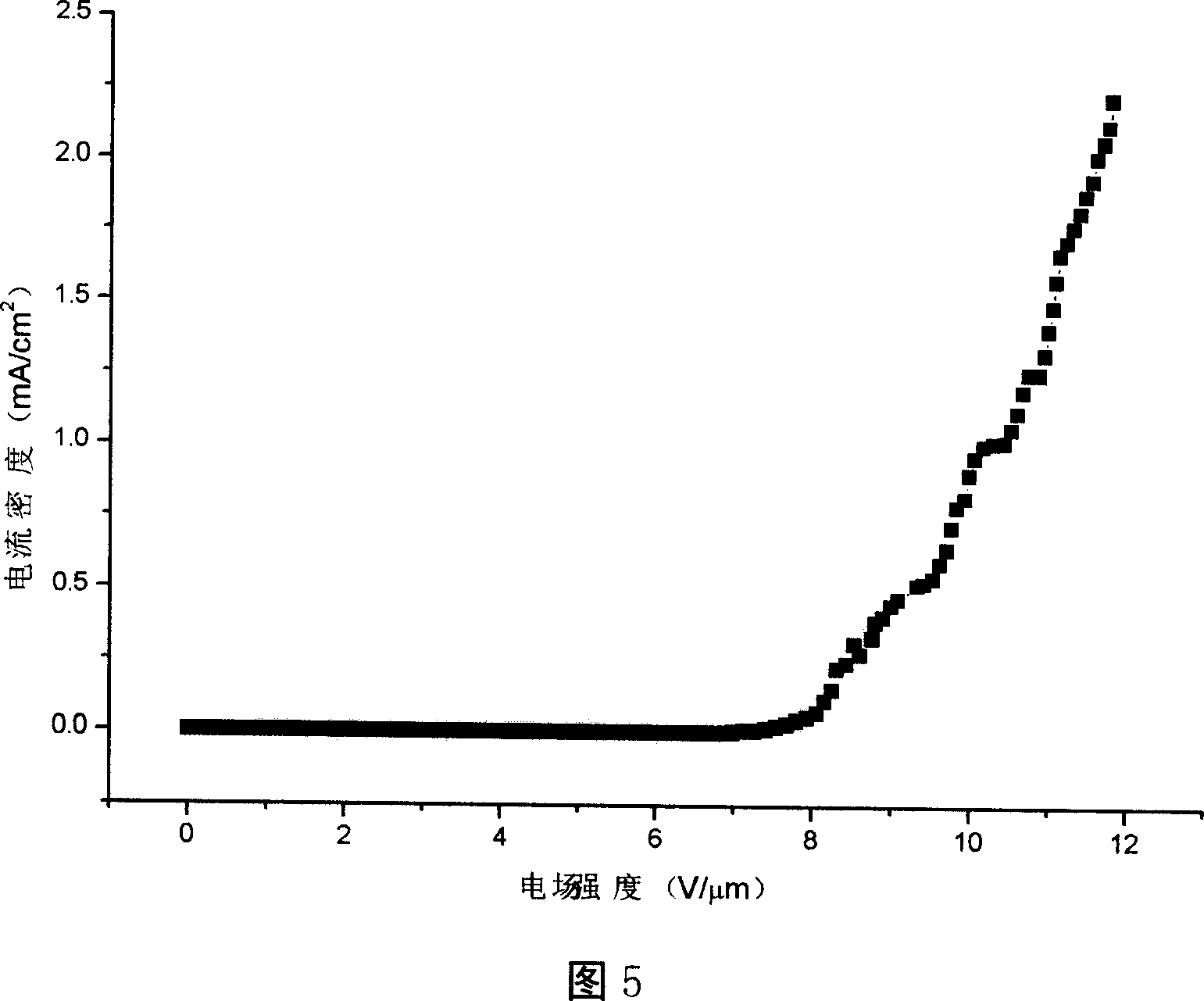

[0032] Embodiment 2: use magnetic on the obtained indium oxide nanowires (preparation method is the same as reference Qing Wan, Eric N Dattoli, Wayne Y.Fung, et al., Nano Letters, 2006, 6 (12): 2909-2915) Metal iron with a thickness of about 5 nanometers was plated by controlled sputtering. Burn in liquefied petroleum gas flame for 5 minutes. Carbon nanotubes and carbon nanofibers can be grown on indium oxide nanowires to obtain a one-dimensional carbon nanomaterial cathode emitter based on indium oxide nanowires. (other subsequent processing is the same as example 1). The measured electric field intensity and current density characteristic curves of the indium oxide nanowire array / one-dimensional carbon nanomaterial composite cathode emitter are shown in Figure 4.

Embodiment 3

[0033] Embodiment 3: 1. Use magnetron sputtering to plate a gold film with a thickness of about 10 nanometers on the polished surface of a silicon wafer as a catalyst. 2. Put the silicon chip coated with gold film together with the powder mixture of tin dioxide and graphite (molar ratio 1:1) into the tubular atmosphere furnace, place the silicon chip under the air flow, about 5cm away from the powder mixture, 900-1100 degrees for 30-60 minutes, argon gas flow 50-200sccm. Then it can be taken out with the furnace cooling down to normal temperature, and the tin dioxide nanobelt can be obtained on the silicon wafer. 3. Plating 50nm cobalt (Co) on tin dioxide nanoribbons. Put the nickel-plated surface of the substrate down, and burn it in the middle of the burning acetylene flame for 10 minutes. Carbon nanotubes and carbon nanofibers can grow on the tin oxide nanobelts, and one-dimensional carbon nanometers based on tin oxide nanobelts can be obtained. Material Cathode Emitter. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com