Electron emitter and electron emitting element

An electron emitter and electron emission technology, applied in electrical components, discharge tube/lamp parts, circuits, etc., can solve problems such as poor electron emission ability, achieve large emission current, improve field emission performance, and reduce electric field shielding effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

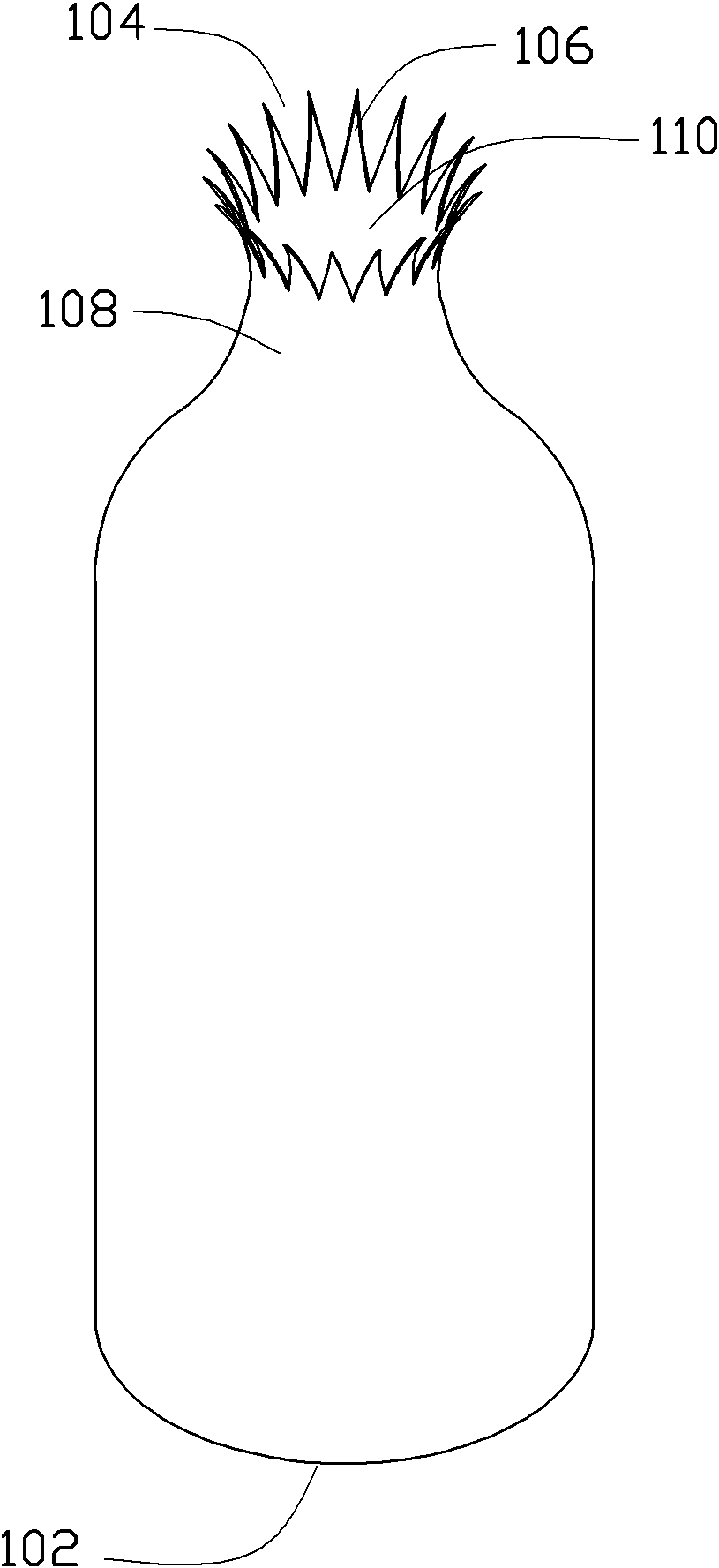

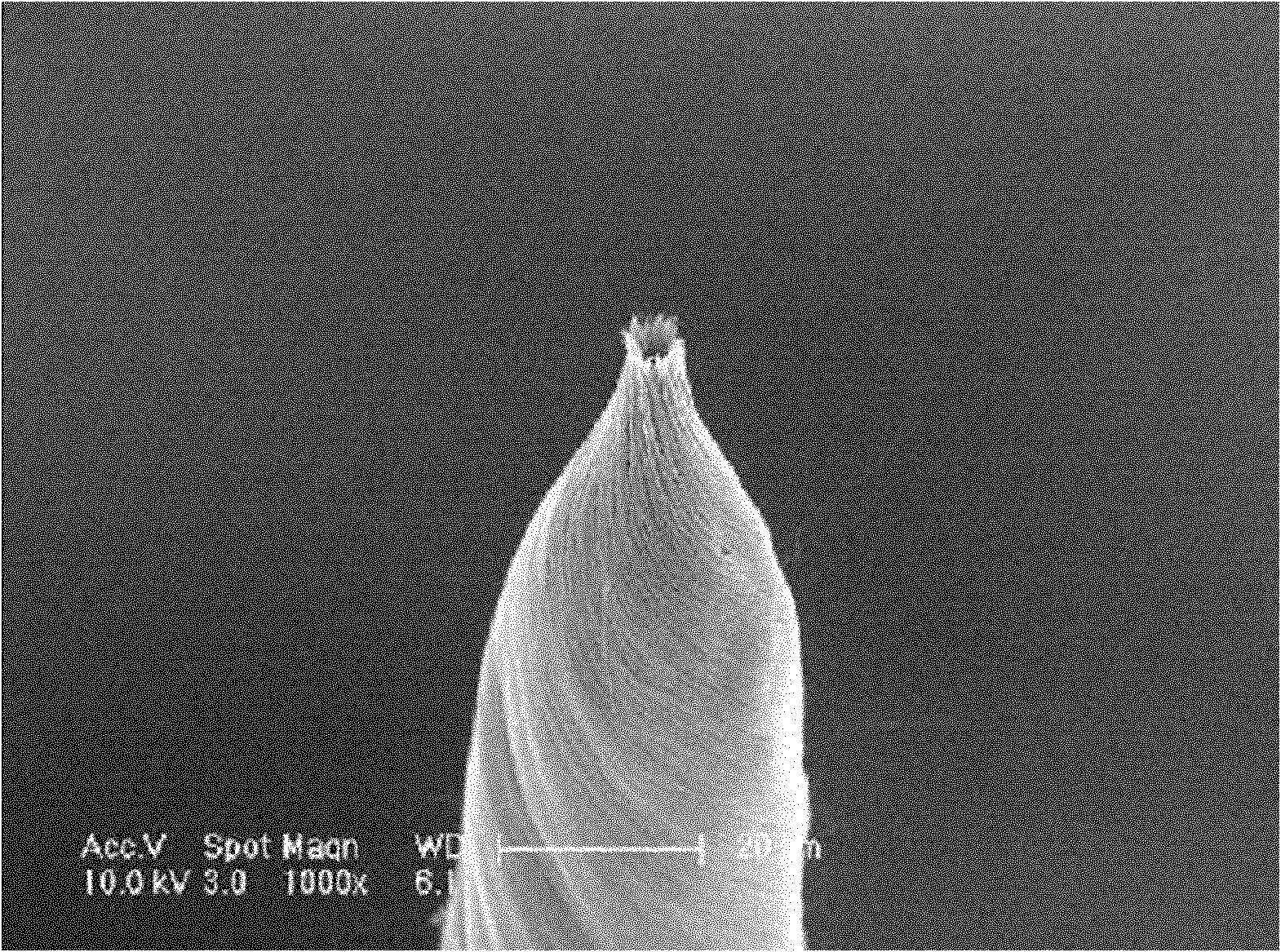

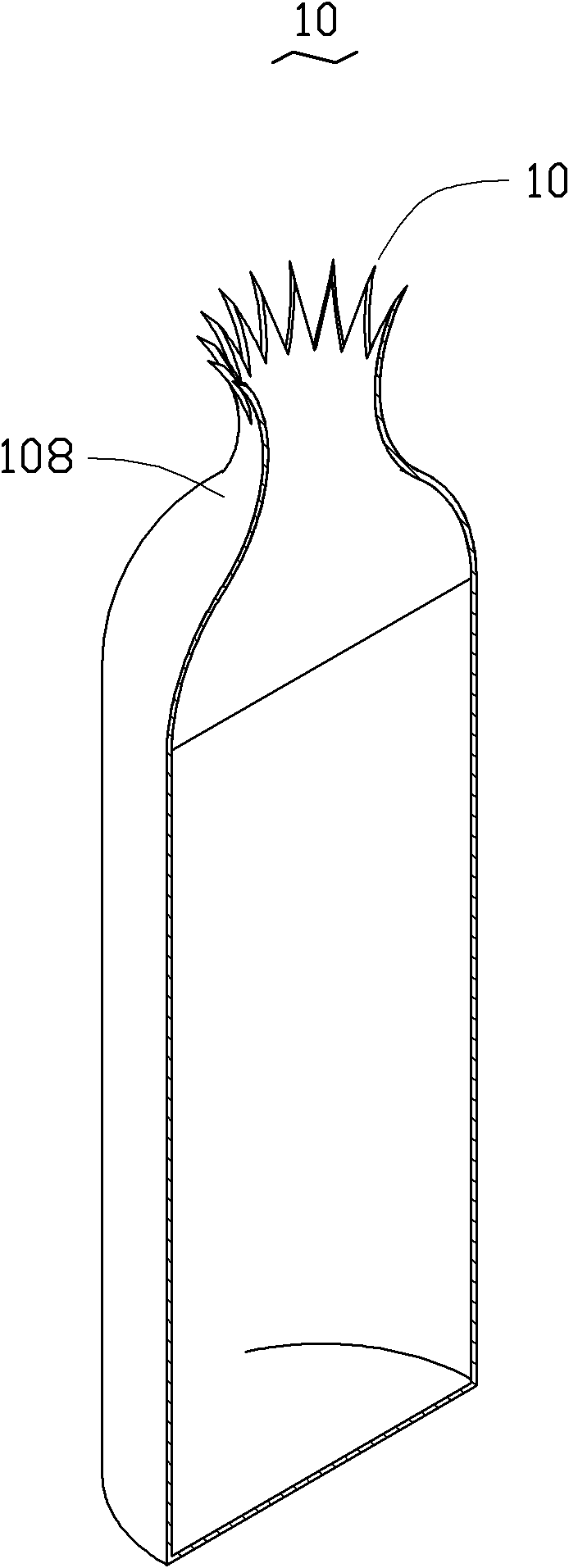

[0037] The preparation method of the electron emitter 10 includes the following steps: (S10) providing a linear support; (S20) providing at least one carbon nanotube film or at least one carbon nanotube wire, and the at least one carbon nanotube film or At least one carbon nanotube wire is wound on the surface of the linear support to form a carbon nanotube layer; (S30) removing the linear support to obtain a tubular carbon nanotube preform surrounded by the carbon nanotube layer; And (S40) fusing the tubular carbon nanotube preform to form the electron emitter.

[0038] In step (S10), the linear support body can not only rotate around its central axis but also move linearly along the direction in which the central axis extends under the control of a control device.

[0039] The material of the linear support can be a simple metal, a metal alloy, or a polymer material. The elemental metal includes gold, silver, copper or aluminum, etc., and the metal alloy includes copper-tin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com