Safe and sulfur-free firework bursting powder and propelling powder and preparing method thereof

A technology of propellant and breaking charge, which is applied in the field of propellant and its preparation, safe sulfur-free fireworks breaking charge, and can solve the problem of high material cost and production cost, unsatisfactory propellant launch force, easy fire or burning, etc. Explosion and other problems, to achieve the effect of improving quality, small lateral force, and easy to catch fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

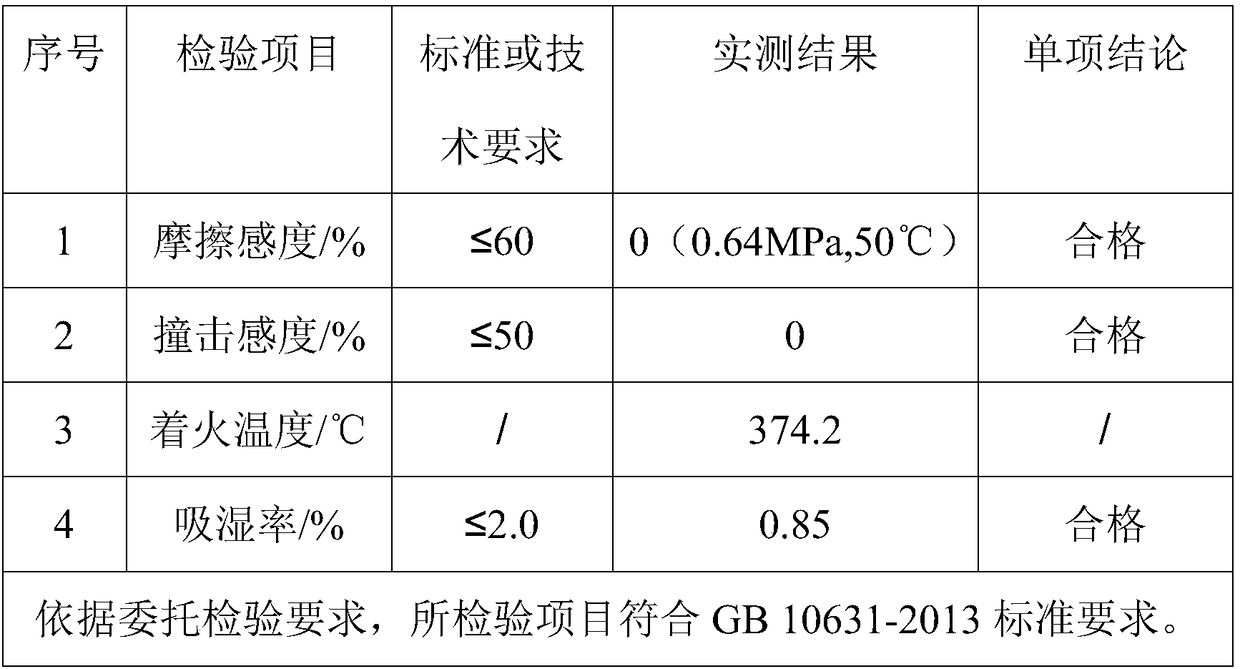

Examples

Embodiment 1

[0021] A safe sulfur-free fireworks explosive, comprising the following raw materials in parts by weight: 35 parts of carbon powder, 60 parts of potassium perchlorate, and 15 parts of potassium nitrate, wherein the particle diameter of carbon powder is 220-260 mesh, and the particle size of potassium perchlorate is The diameter is 150-200 mesh, and the particle diameter of potassium nitrate is 150-200 mesh; the preparation is to mix various raw materials.

Embodiment 2

[0023] A safe sulfur-free fireworks explosive, comprising the following raw materials in parts by weight: 15 parts of carbon powder, 5 parts of potassium perchlorate, and 70 parts of potassium nitrate, wherein the particle diameter of carbon powder is 280-330 mesh, and the particle size of potassium perchlorate is The diameter is 200-250 mesh, and the particle diameter of potassium nitrate is 200-250 mesh; the preparation is to mix various raw materials.

Embodiment 3

[0025] A safe sulfur-free fireworks explosive, comprising the following raw materials in parts by weight: 25 parts of carbon powder, 30 parts of potassium perchlorate, 35 parts of potassium nitrate, wherein the particle diameter of carbon powder is 240-300 mesh, and the particle size of potassium perchlorate The diameter is 180-240 mesh, and the particle diameter of potassium nitrate is 170-220 mesh; its preparation is to mix various raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com