Plasma volume reducing system and method for processing nuclear facility solid waste

A plasma and solid waste technology, applied in nuclear engineering, radioactive purification, etc., can solve the problem that the order of arrangement cannot meet the requirements of environmental protection for discharge, and achieve the effect of high safety and high volume reduction ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

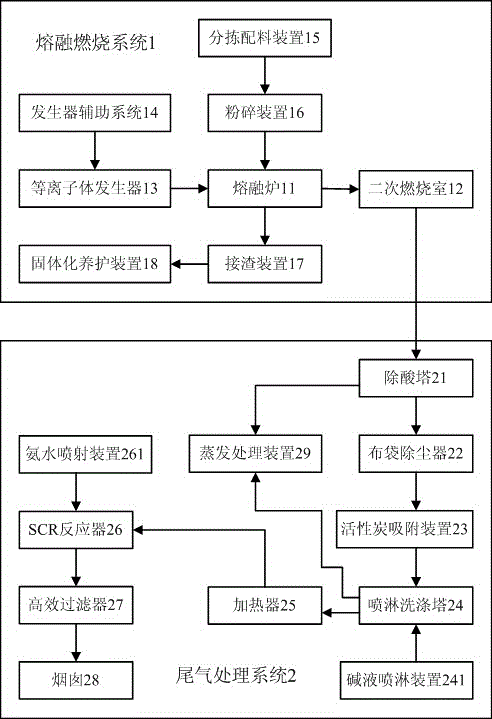

[0099] please refer again Figure 5 As shown, corresponding to Embodiment 1 of the present invention, Embodiment 2 of the present invention provides a plasma volume reduction method for treating nuclear facility solid waste, including:

[0100] Step S1, using plasma to pyrolyze and melt the sorted and pulverized nuclear solid waste;

[0101] Step S2, fully burning the pyrolyzed product to generate flue gas to be treated;

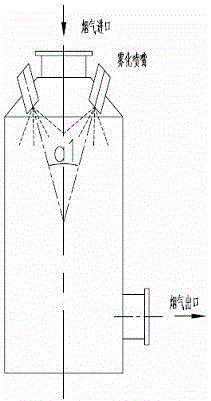

[0102] Step S3, using the sprayed lye to cool the flue gas to be treated and neutralize the acid gas therein according to the semi-dry quenching method;

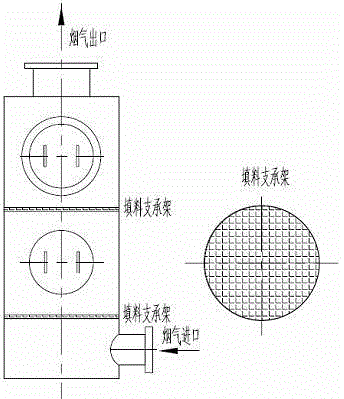

[0103] Step S4, using the cloth bag method to capture dust, coke and radionuclides in the flue gas treated in step S3;

[0104] Step S5, using a wet method to scrub the flue gas treated in step S4 to remove acid gas and radionuclides therein;

[0105] Step S6, using a selective catalytic reduction method to remove nitrogen oxides in the flue gas treated in step S5.

[0106] Specifically, before step S1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com