Glass matrix composition of lead-boron polyethylene, glass cured body and preparation method of glass cured body

A lead-boron-polyethylene and glass-based technology, applied in the field of nuclear shielding materials, can solve problems such as vitrification of lead-boron-polyethylene, which is not suitable for nuclear shielding materials, and achieve the effects of excellent chemical stability, high volume reduction ratio and simple composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of the glass solidified body of an embodiment of the present invention, comprises the following steps:

[0050] S1. Breaking the radioactive lead-boron polyethylene simulants to form fragments;

[0051] Crushing is achieved by mechanical crushing. The fragment size of the radioactive lead boron polyethylene simulant formed after crushing shall not exceed 1cm.

[0052] S2. Evenly mix the pieces of the radioactive lead-boron polyethylene simulant and the glass matrix composition according to the mass ratio of 25:1-4:1 to form a mixture.

[0053] In glass matrix compositions, SiO 2 SiO 2 Form join, B 2 o 3 with B 2 o 3 or H 3 BO 3 Join in the form of Na 2 O to Na 2 CO 3 Form join, K 2 O to K 2 CO 3 Form to join, Al 2 o 3 with Al(OH) 3 or Al 2 o 3 Form to join, Co 2 o 3 With Co 2 o 3 Added in the form of SrO, SrO, SrCl 2 or SrCO 3 Added as a stable compound, Cs 2 O to Cs 2 CO 3 Or a stable compound of CsCl is added.

[00...

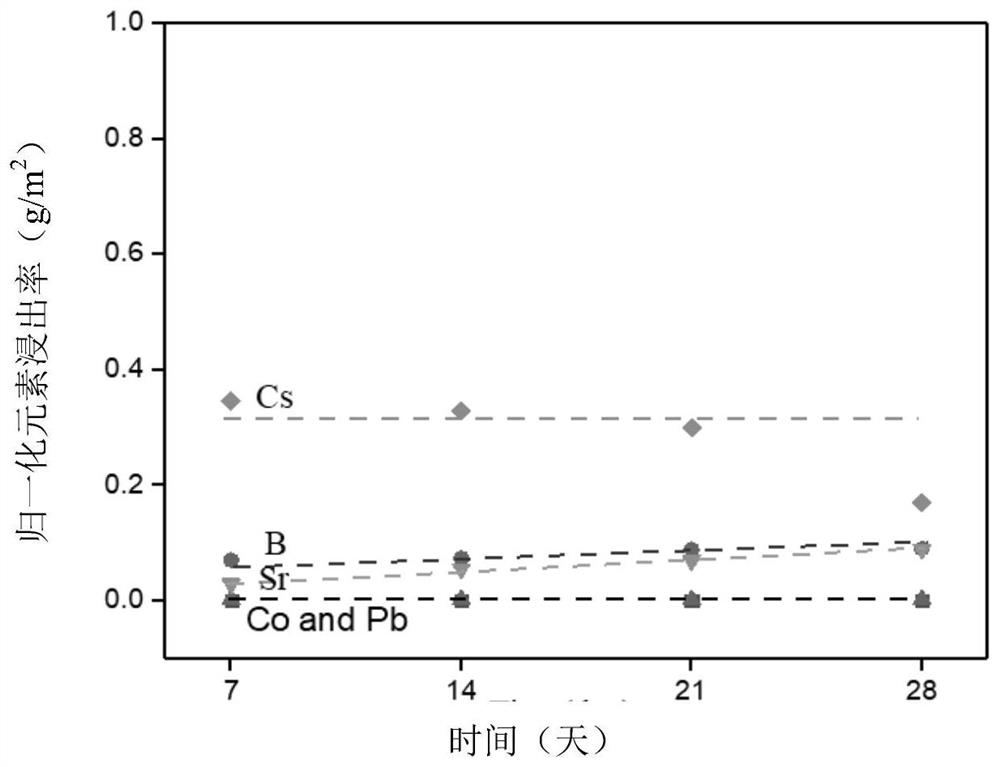

Embodiment 1

[0075]Take by weighing 84 parts (mass parts) of radioactive lead-boron polyethylene simulants after fragmentation, wherein the simulated nuclide Co 2 o 3 , SrO, Cs 2 The total amount of O addition accounts for 0.6wt% of the total mass of radioactive lead-boron polyethylene simulant; weigh 16 parts of glass matrix composition (55wt% SiO 2 +45wt%Al 2 o 3 ), mixed with crushed radioactive lead boron polyethylene simulant. Put the mixture in a corundum crucible, put it into a muffle furnace and raise the temperature to 900°C with the furnace at a heating rate of 10°C / min; keep it at 900°C for 0.5-2h and then pour it into a metal mold preheated at 400°C Formed, immediately moved to an electric furnace at 400°C for 2 hours, and then cooled to room temperature with the furnace to obtain a glass solidified body. The components of the glass cured body are shown in Table 1 below (calculated as oxides).

[0076] Table 1

[0077] components Content / wt% PbO 65.62 ...

Embodiment 2

[0084] Weigh 80 pieces of broken radioactive lead-boron polyethylene simulant, wherein the simulated nuclide Co 2 o 3 , SrO, Cs 2 The total amount of O added accounts for 0.5wt% of the total mass of the radioactive lead-boron polyethylene simulant; weigh 20 parts of the glass matrix composition (65wt% SiO 2 +35wt% Al 2 o 3 ). The radioactive lead-boron polyethylene simulant is placed in a corundum crucible, sent into a muffle furnace and raised to 900°C with the furnace at a heating rate of 5°C / min; after holding at 900°C for 0.5-2h, take out the remaining solid residue in the crucible. The solid residue was ground into a powder in an agate mortar, and then uniformly mixed with the glass matrix composition. The mixture is melted in a muffle furnace at 900°C for 0.5h, poured into a metal mold preheated at 400°C for molding, immediately moved to an electric furnace at 400°C for 2h, and cooled to room temperature with the furnace to obtain glass cured body. The components ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com