Method for waste incineration ash and slag co-melting

A waste incineration ash, waste incineration technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of heavy metal leakage and high heavy metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

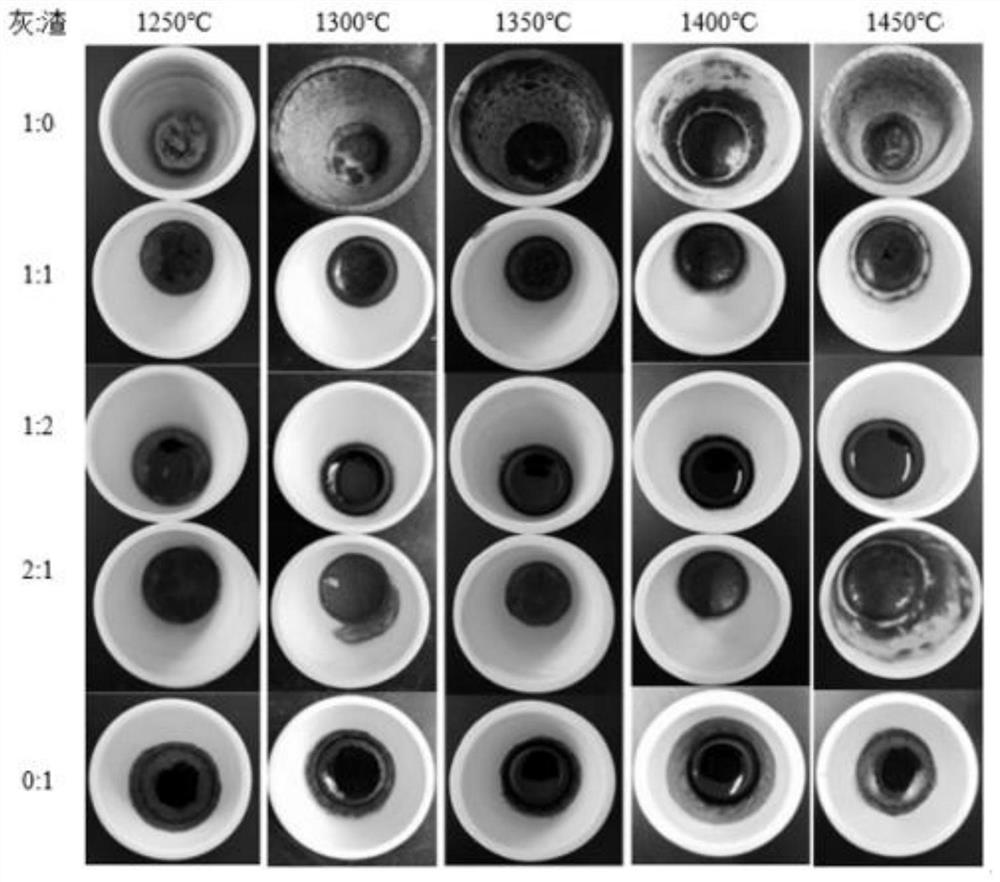

[0032] The fly ash and slag were compounded and melted at different temperatures to observe the state of the molten product. The mass ratios of fly ash and slag were 1:0, 1:1, 1:2, 2:1, 0:1, the compounded ash-slag mixture at each ratio was co-melted at 1250°C, 1300°C, 1350°C, 1400°C, and 1450°C, and the co-melting time was 4 hours. The observations on the product are as follows figure 2 shown.

[0033] according to figure 2 It can be seen that when the mass ratio of fly ash to slag is 1:1, vitreous slag can be obtained at 1400 °C; when the mass ratio of fly ash to slag is 2:1, vitreous slag can be obtained at 1500 °C.

[0034] When the mass ratio of fly ash to slag is 1:2, the color of the molten product is brown, the surface is smooth, and the vitrification is obvious, indicating that adding slag to the fly ash is beneficial to reduce the melting temperature, reduce the volatilization of salts and heavy metals in the fly ash, and achieve solidification of heavy metals. ...

Embodiment 2

[0036] Compound fly ash, slag and boric acid, and co-melt the mixture, wherein the mass ratio of fly ash and slag is 1:0, 1:1, 1:2, 2:1, 0:1, each ratio The amount of boric acid added is respectively 2.5%, 5%, 7.5%, and 10% of the total mass of fly ash, slag, and boric acid. The melting point of compound is tested, and the obtained results are shown in table 2:

[0037] Table 2 The melting point of the compound under different boric acid addition ratios and ash-slag ratios (°C)

[0038]

[0039]

[0040]As can be seen from Table 2, the addition of boric acid can reduce the melting point of the compound within the range of 2.5 to 10%, and the effect is the best when the addition of boric acid is 5%. Continue to increase the amount of boric acid, and the rate of decline of the melting point is not Large, controlling the addition of boric acid to 2.5-5%, can reduce the melting point of the compound on the premise of ensuring the cost.

Embodiment 3

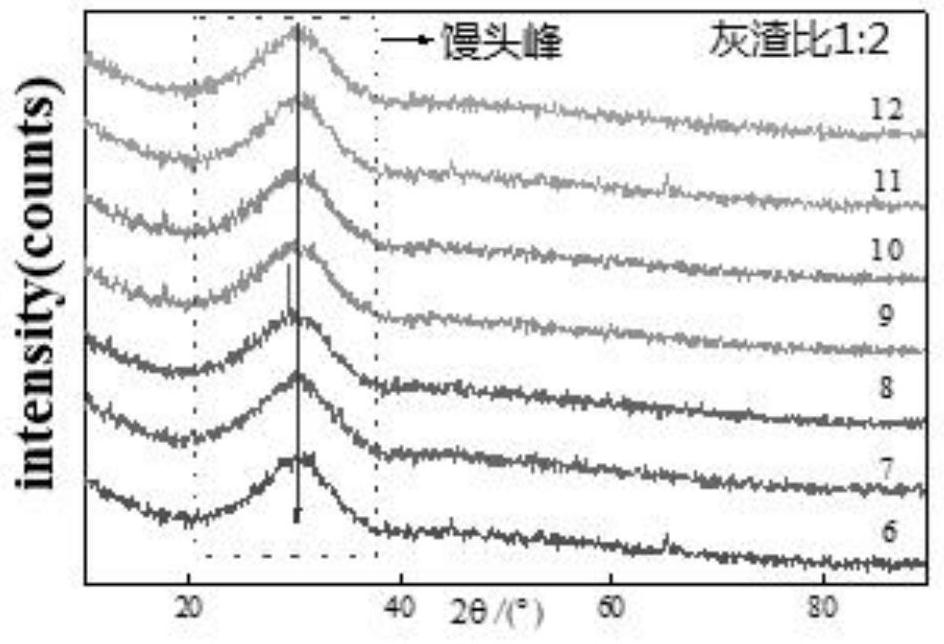

[0042] The mass ratio of fly ash and slag was controlled to be 1:2, and co-melting was carried out at different temperatures and boric acid contents, and the co-melting time was 4 hours. The XRD test was carried out on the product to detect the vitrification effect of the molten product. Among them, it is divided into seven experimental groups from 6# to 12#, and the experimental conditions are shown in Table 3;

[0043] Table 3 Experimental conditions of experimental groups 6#~12#

[0044] serial number Co-melting temperature / ℃ Addition amount of boric acid / % 6# 1300 0 7# 1350 0 8# 1400 0 9# 1250 0 10# 1250 2.5 11# 1400 2.5 12# 1400 0

[0045] The XRD test result of molten product is as image 3 shown. according to image 3 It can be seen that under the conditions shown in Table 3 (the co-melting temperature is 1250~1400°C, and the amount of boric acid added is 0 or 2.5%), in the XRD spectrum of the resulting mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com