Two-stage A/O vertical flow artificial wetland sewage treatment system

A technology for sewage treatment system and constructed wetland, which is applied in the field of two-stage A/O type vertical flow constructed wetland sewage treatment system to achieve the effects of enhancing oxygen mass transfer capacity, reducing floor space and extending operating life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add domestic sewage with average concentrations of COD, ammonia nitrogen, total nitrogen, and total phosphorus of 178mg / L, 18.7mg / L, 15.6mg / L, and 2.55mg / L, respectively, to strengthen the composite filler multi-stage alternating wetland system for COD, ammonia nitrogen, The removal rates of total nitrogen and total phosphorus are 95%, 98%, 96% and 99% respectively, and the average concentrations of COD, ammonia nitrogen, total nitrogen and total phosphorus in the treated effluent are 8.9mg / L, 0.374mg / L and 0.624mg / L , 0.03mg / L, reaching the sewage reuse standard.

Embodiment 2

[0020] From farm sewage, water body SS, COD, BOD, total nitrogen, PO 4 3- The concentration is 85-178mg / L, 210-378mg / L, 87-245mg / L, 210-350mg / L, 49-90mg / L, the raw water passes through the two-stage A / O type vertical flow artificial wetland treatment system, and the effluent SS, COD, BOD, total nitrogen, PO 4 3- The removal rates were 92%, 94%, 90%, 95%, 98%.

Embodiment 3

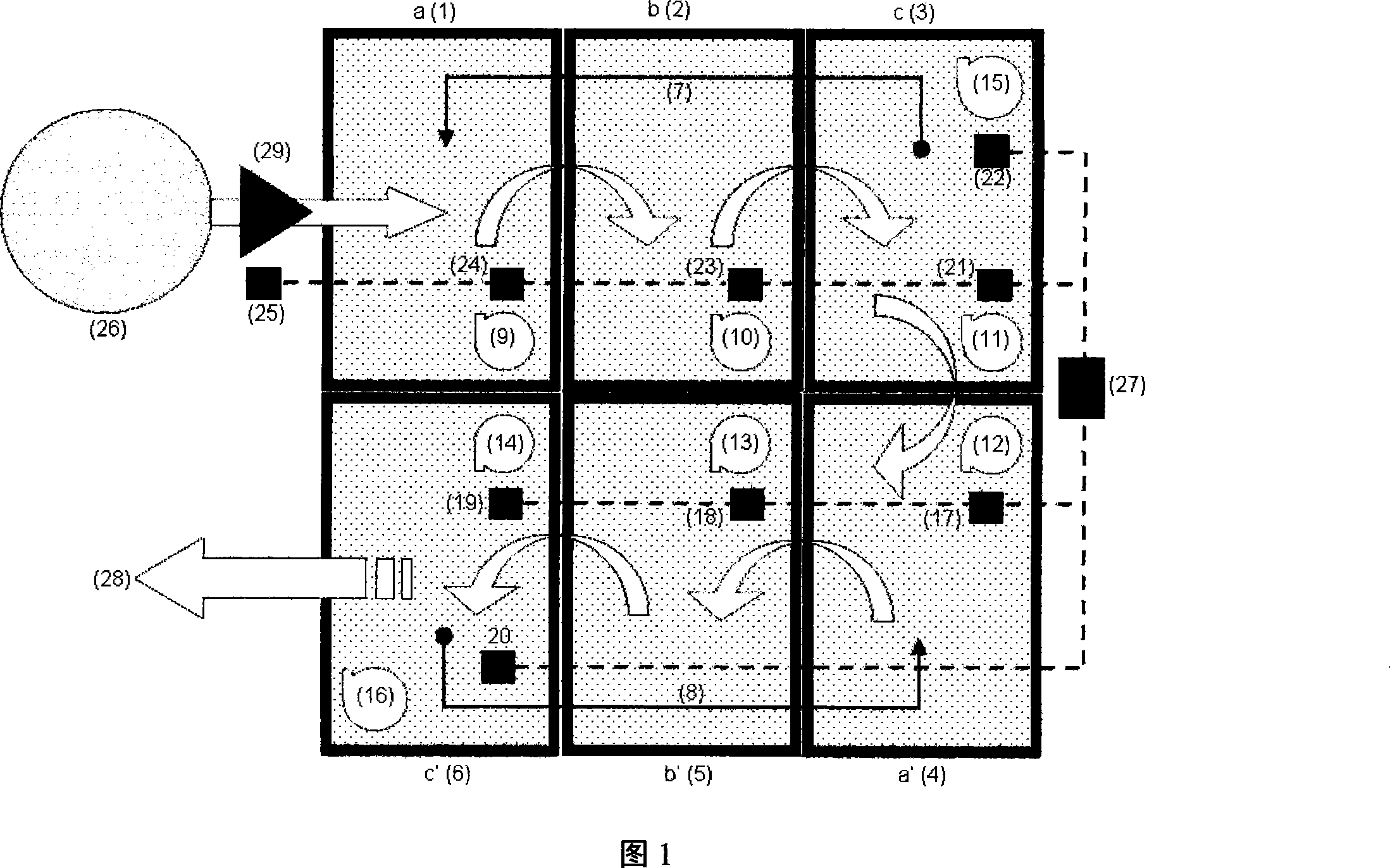

[0022] A two-stage A / O type vertical flow artificial wetland sewage treatment system device, the system device includes a pretreatment grit chamber and a multistage vertical flow artificial wetland, the outlet of the pretreatment grit chamber and the outlet of the multistage vertical flow artificial wetland The water inlet is connected, and the adjacent two levels of the multi-level vertical flow constructed wetland are connected. The first treatment unit of each level is an anoxic treatment unit, and the rest are "wet / dry" alternates of water intake, emptying, and idle For the aerobic operation unit, the last aerobic "wet / dry" alternate operation state processing unit of each level is connected with the anoxic processing unit of its corresponding level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com