Corner connecting structure for shade-shed

A corner connection and pergola technology, applied in tents/canopies, building types, buildings, etc., can solve the problems of inconvenient handling, parts occupying a large space, consuming manpower, material resources and time, and achieve convenient disassembly and assembly. The effect of increasing the difficulty of assembly and increasing the amount of packing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

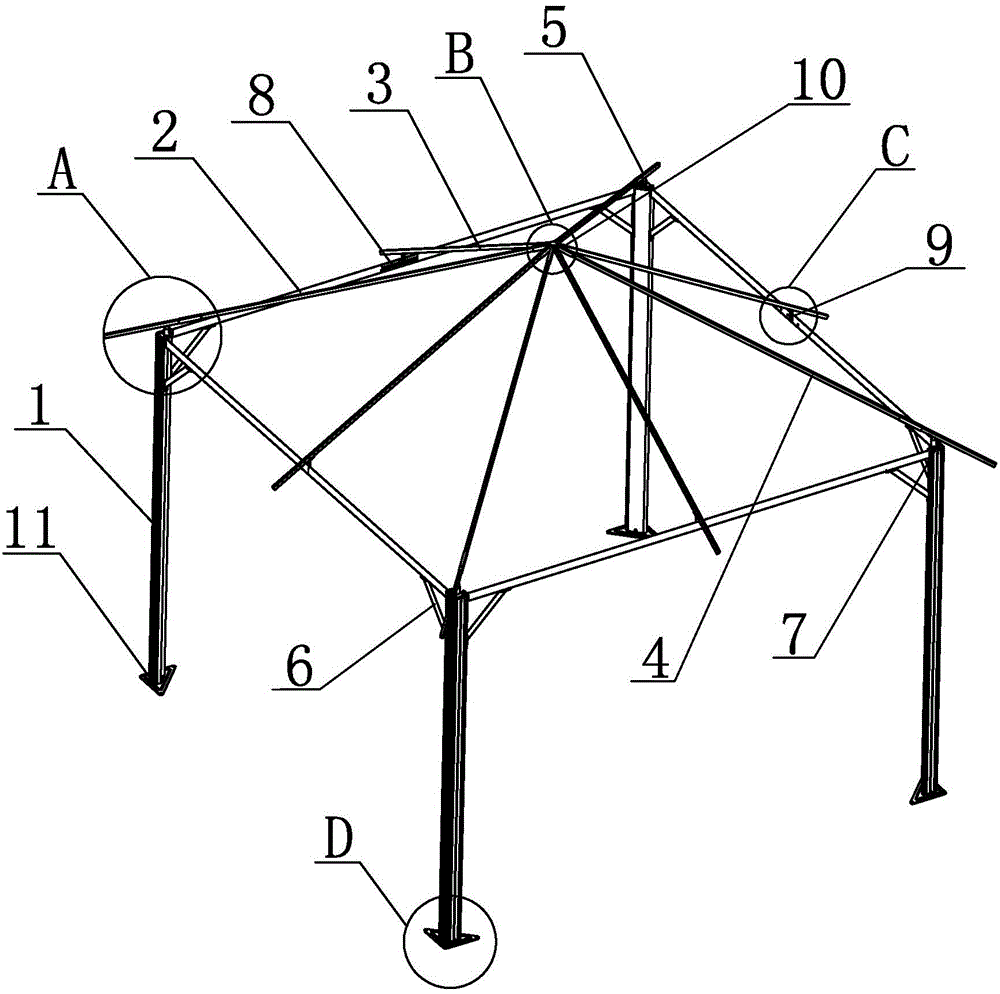

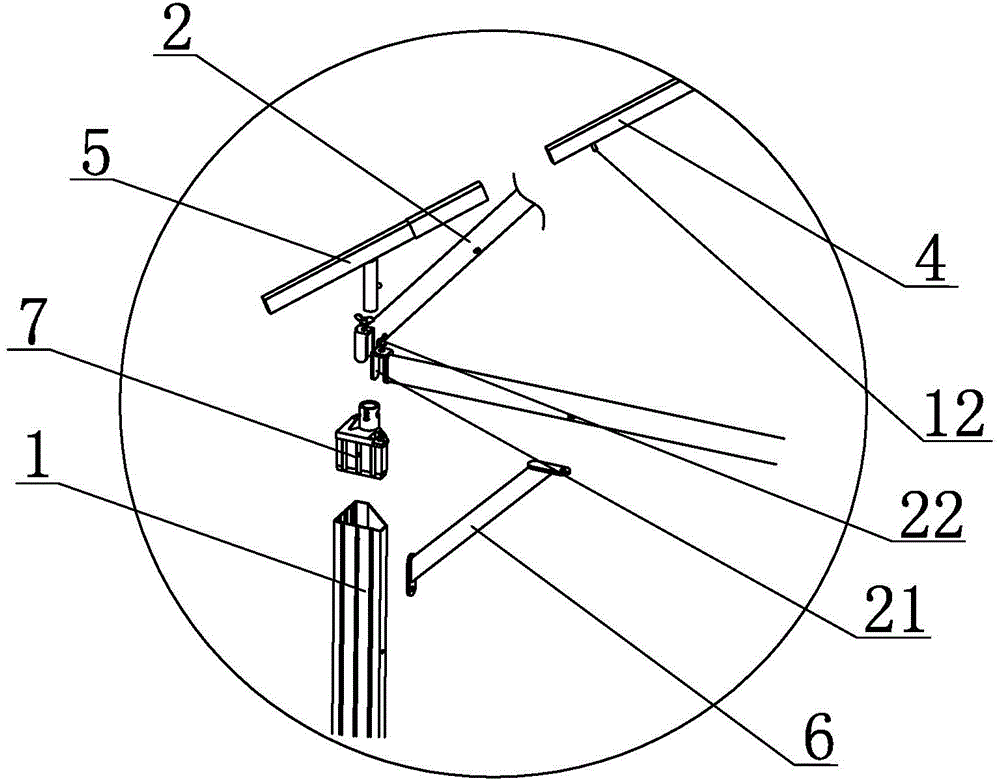

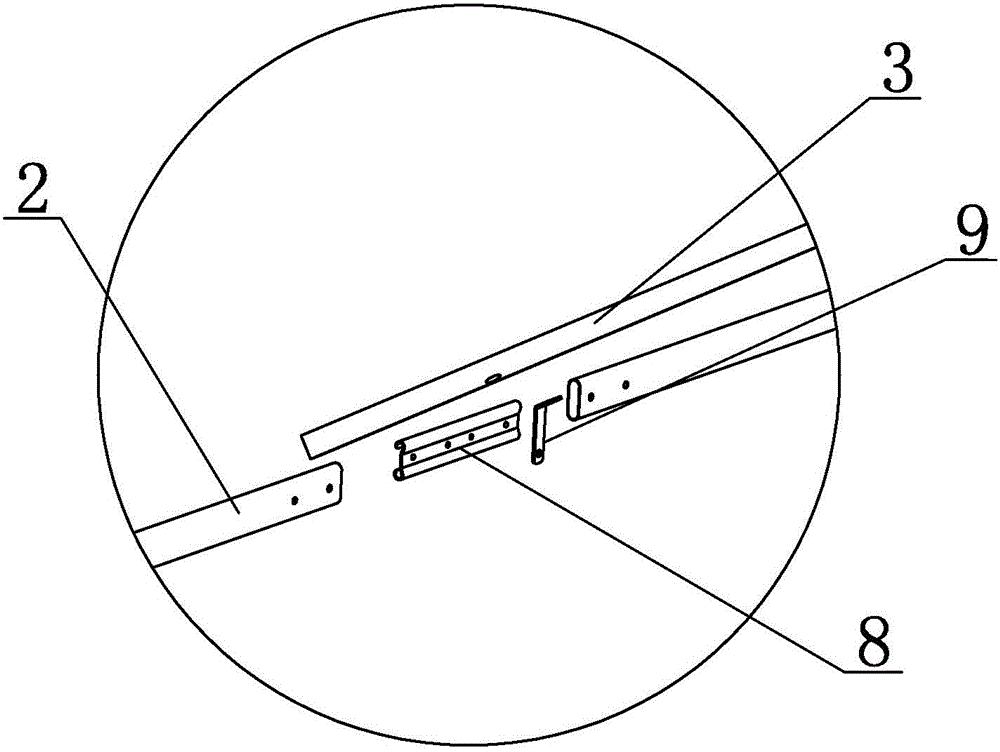

[0019] Such as Figure 1-Figure 7 The shown awning includes a ceiling frame, a tarpaulin and a support frame, the tarpaulin is covered on the upper end of the ceiling frame, and the tarpaulin is tied to the ceiling frame, and the ceiling frame includes a multi-way piece 10, a ceiling pipe 3, Ceiling inclined pipe 4, inclined pipe connecting pipe 5 and connecting piece 9, described multi-way piece 10 comprises central cylindrical block and a plurality of hollow casings, and described hollow casings are evenly distributed around the central cylindrical block, and the hollow casings One end is welded to the side wall of the central cylindrical block, the hollow sleeves are all inclined downwards, and the other end of the hollow sleeves has a through hole on the lower end surface; one end of the ceiling pipe 3 and the ceiling incline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com