A method for treating anion exchange resin by oxidation of molten carbonate salt and fully oxidized anion exchange resin

An exchange resin and oxidation treatment technology, which is applied in the field of carbonic acid molten salt oxidation treatment of anion exchange resin and fully oxidized anion exchange resin, can solve the problems of large area and large heat consumption of the product, reduce waste and improve the degradation rate. , Improve the effect of volume reduction ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

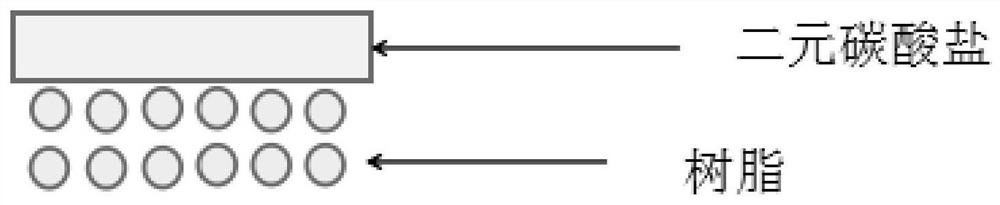

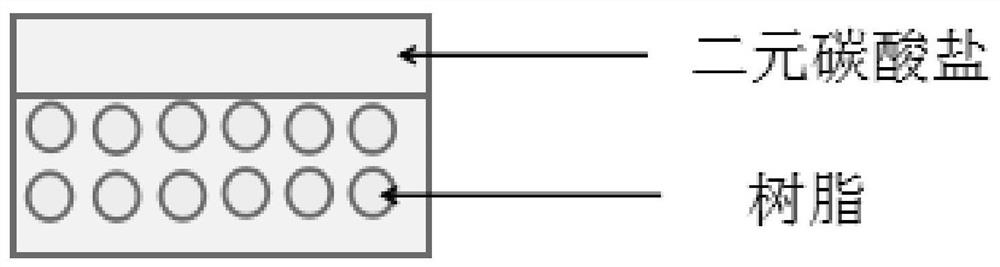

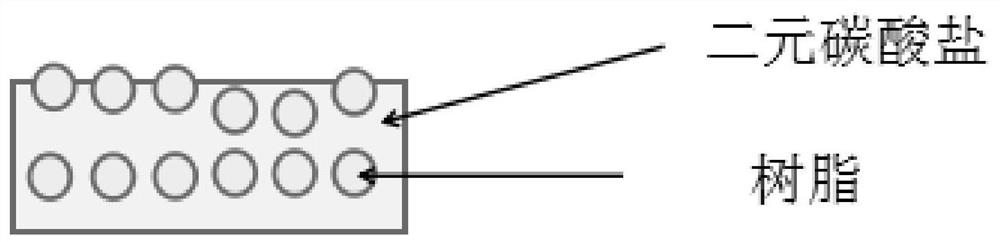

Method used

Image

Examples

Embodiment 1

[0054] Take Na 2 CO 3 +K 2 CO 3 is the oxidation system (Na 2 CO 3 :K 2 CO 3 =1:1), the ratio of anion exchange resin to system is 1:1, the mixing method is direct covering method, the oxidation time is 1h, and the final residual carbon content accounts for 14.49% of the original resin content.

Embodiment 2

[0056] Take Na 2 CO 3 +K 2 CO 3 is the oxidation system (Na 2 CO 3 :K 2 CO 3 =1:1), the ratio of anion exchange resin to system is 1:1, the mixing method is direct covering method, the oxidation time is 2h, and the final remaining carbon content accounts for 11.63% of the original resin content.

Embodiment 3

[0058] Take Na 2 CO 3 +K 2 CO 3 is the oxidation system (Na 2 CO 3 :K 2 CO 3 =1:1), the ratio of anion exchange resin to system is 1:1, the mixing method is direct covering method, the oxidation time is 3h, and the final residual carbon content accounts for 5.02% of the original resin content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com