Treatment method of radioactive spent ion exchange resin

A technology of ion exchange resin and treatment method, which is applied in the field of radioactive waste ion exchange resin treatment, and can solve the problems of reducing the volume reduction ratio of radioactive waste ion exchange resin, increasing the production of radioactive wastewater, and leakage of radioactive waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

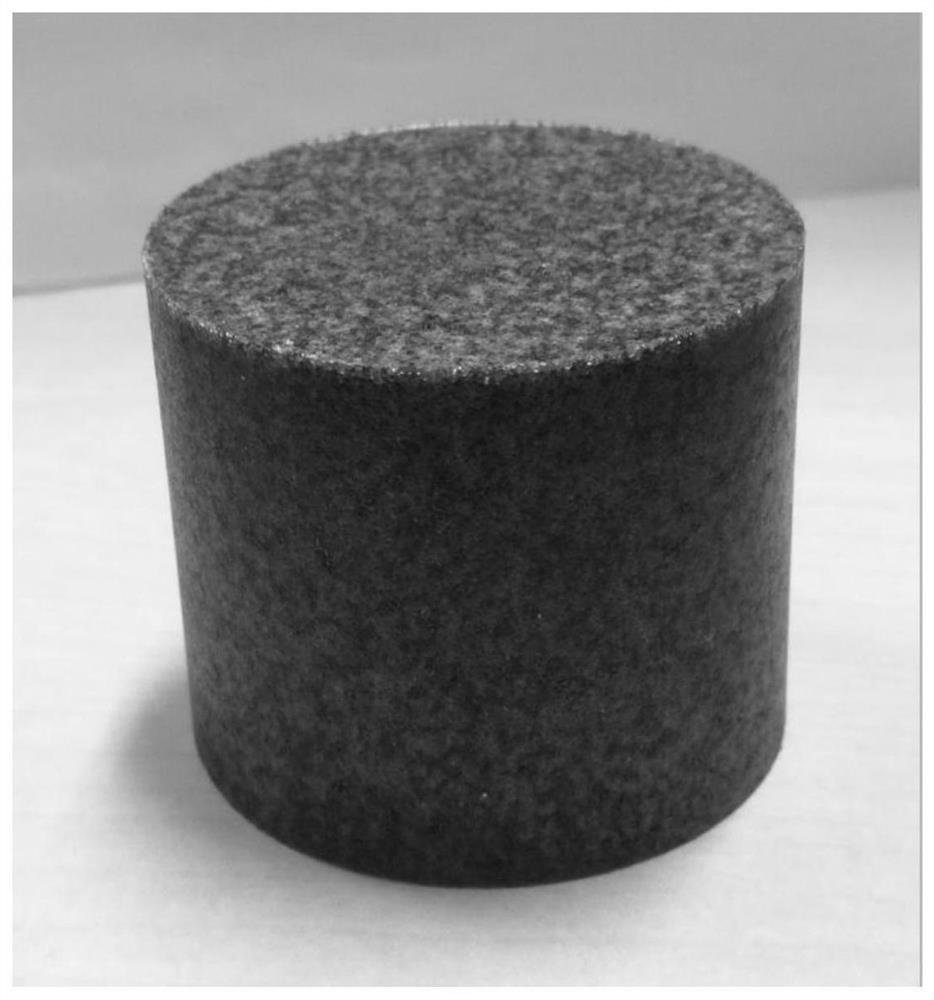

[0046] Take by weighing 5 grams of polyurethane (MDI trimer), add 1.5 grams of triethylene glycol at room temperature and stir quickly, then add 100 grams of radioactive waste ion exchange resin dried to constant weight at 160 ° C and cooled to room temperature, stir After uniformity, transfer to a mold (diameter of the mold is 53mm), and press at 130°C and 130Bar pressure for 150 minutes. The resin block was taken out, and the measured geometric dimensions of the resin block were 45 mm in height, 53.4 mm in diameter, 3.69 in volume reduction ratio, and 32 MPa in compressive strength.

[0047] In the present invention, the volume reduction ratio is equal to the solid volume of the radioactive waste ion exchange resin before treatment divided by the volume of the resin block obtained after treatment. The compressive strength is obtained by testing according to the method specified in the standard GB 14569.1-2011 "Performance requirements for low and medium level radioactive was...

Embodiment 2

[0049] Weigh 10 grams of polyurethane (MDI trimer), add 1.15 grams of 1,6-hexanediol at room temperature, mix quickly and uniformly, then add 110 grams of radioactive waste ions dried at 160°C to constant weight and cooled to room temperature The resin was exchanged, stirred evenly, transferred to a mold (diameter of the mold was 53mm), and pressed at 130°C and 130Bar pressure for 150 minutes. The resin block was taken out, and the geometric dimensions of the resin block were measured to be 50 mm in height, 53.4 mm in diameter, 3.65 in volume reduction ratio, and 31.7 MPa in compressive strength.

Embodiment 3

[0051] Weigh 5 grams of epoxy resin E51, add 1.8 grams of polyethyleneimine, stir evenly, pour 100 grams of radioactive waste ion exchange resin that has been dried at 160°C to constant weight and cooled to room temperature, stir evenly, and then put the resin- The binder mixture was transferred into a mold (53mm diameter mold) and then pressed at 130°C under 130 Bar pressure for 150 minutes. The resin block was taken out, and the measured geometric dimensions of the resin block were 48.7 mm in height, 53.0 mm in diameter, 3.63 in volume reduction ratio, and 34.5 MPa in compressive strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com