Method for harnessing and recovering producing waste water of cyadox

A technology of cydox and recovery solution, which is applied in the direction of heating water/sewage treatment, organic chemistry, etc., can solve the problems of no patents and relevant literature reports on recycling methods, and reduce the difficulty of treatment, with obvious and good effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

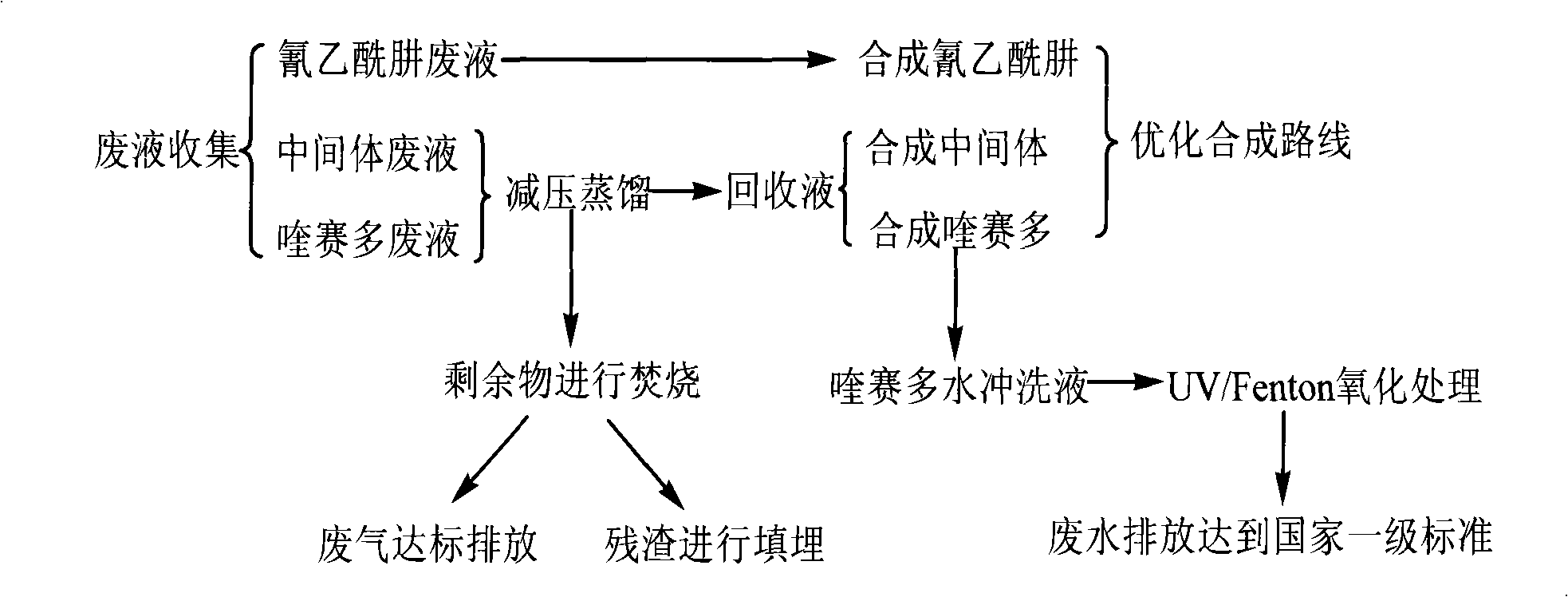

Method used

Image

Examples

Embodiment 1

[0034] Take 400mL of intermediate waste liquid, 200mL of methanol washing liquid, 500mL of cydox waste liquid and 200mL of absolute ethanol washing liquid respectively, and add them to a 1000mL round bottom flask, carry out vacuum distillation on a rotary evaporator, and the temperature gradually rises from room temperature to At 90°C, the pressure was controlled at 0.9MPa, and the recoveries reached 61.3%, 95.5%, 91.8% and 95.0%, respectively.

[0035] Take 2kg of the waste liquid distillation product, put it into the incinerator, ignite it electronically, and incinerate in about 3 minutes. The exhaust gas emission reaches the national standard. Collect about 70g of ash residue and landfill it according to the national standard.

[0036]Add 50mL of hydrazine hydrate and 60mL of cyanoacetylhydrazine waste liquid into a 500mL four-necked reaction flask equipped with a conventional electric stirrer, thermometer and dropping funnel, and slowly add 70mL of ethyl cyanoacetate dropwi...

Embodiment 2

[0041] Take 400mL of intermediate waste liquid, 200mL of methanol washing liquid, 500mL of cydox waste liquid and 200mL of absolute ethanol washing liquid respectively, and add them to a 1000mL round bottom flask, carry out vacuum distillation on a rotary evaporator, and the temperature gradually rises from room temperature to At 97°C, the pressure was controlled at 0.1MPa, and the recoveries reached 62.3%, 96.5%, 93.4% and 95.6%, respectively.

[0042] Take 5kg of the waste liquid distillation product, put it into the incinerator, ignite it electronically, and incinerate in about 7 minutes. The exhaust gas emission meets the national standard. About 167g of ash residue is collected and landfilled according to the national standard.

[0043] Add 50mL of hydrazine hydrate and 110mL of cyanoacetylhydrazine waste liquid into a 500mL four-necked reaction flask equipped with a conventional electric stirrer, thermometer and dropping funnel, and slowly add 120mL of ethyl cyanoacetate ...

Embodiment 3

[0048] Take 500mL of intermediate waste liquid, 300mL of methanol washing liquid, 500mL of quincydox waste liquid and 300mL of absolute ethanol washing liquid and add them to a 1000mL round bottom flask respectively, carry out vacuum distillation on a rotary evaporator, and the temperature gradually rises from room temperature to At 95°C, the pressure was controlled at 0.097MPa, and the recoveries reached 63.5%, 96.3%, 93.6% and 95.8%, respectively.

[0049] Take 10kg of the waste liquid distillation product, put it into the incinerator, ignite it electronically, and incinerate in about 15 minutes. The exhaust gas emission meets the national standard. Collect about 329g of ash residue and landfill it according to the national standard.

[0050] Add 50mL of hydrazine hydrate and 80mL of cyanoacetylhydrazide waste liquid into a 500mL four-necked reaction flask equipped with a conventional electric stirrer, thermometer and dropping funnel, and slowly add 100mL of ethyl cyanoacetat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com