A method for controlling water seepage from concrete floor and wall cracks

A technology for concrete floor and cracks, which is applied in the field of water seepage in wall cracks and treatment of concrete floor, can solve the problems of low grouting pressure in penetration holes, not too much grouting, damage and other problems, so as to reduce the amount of grouting liquid and cement, The effect of shortening the construction period and improving the impermeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following examples are only used to illustrate the present invention, but not to limit the protection scope of the present invention.

[0016] A method for controlling water seepage from concrete floor and wall cracks of the present invention comprises the following steps:

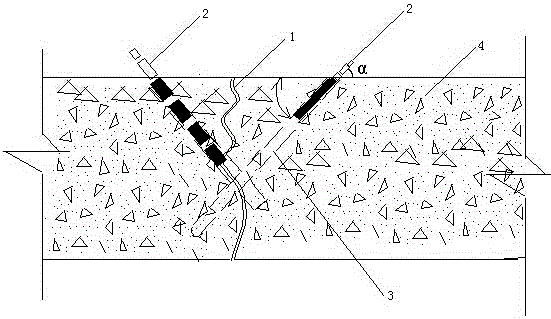

[0017] a. Hole layout: search for leaks one by one from one side of the structural surface of the wall, and mark them with red spray paint. The marking method is determined according to the different leaking parts. Large-scale leaks are marked with dense red dots. Crack leakage is marked with a red ×, alternately marked on both sides every 10-12cm along the direction of crack 1, and a single seepage point is marked with a red ○;

[0018] b. Drilling construction: After the hole layout is completed, use a hand-held electric drill to drill a hole (grouting hole 3) at an angle of α at 3-4cm next to the leak point and the base surface according to the red mark (grouting hole 3). The diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com