Generating, a highly ionized plasma in a plasma chamber

A plasma, highly ionized technology, applied in the field of ions, which can solve problems such as reducing membrane adhesion and target poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

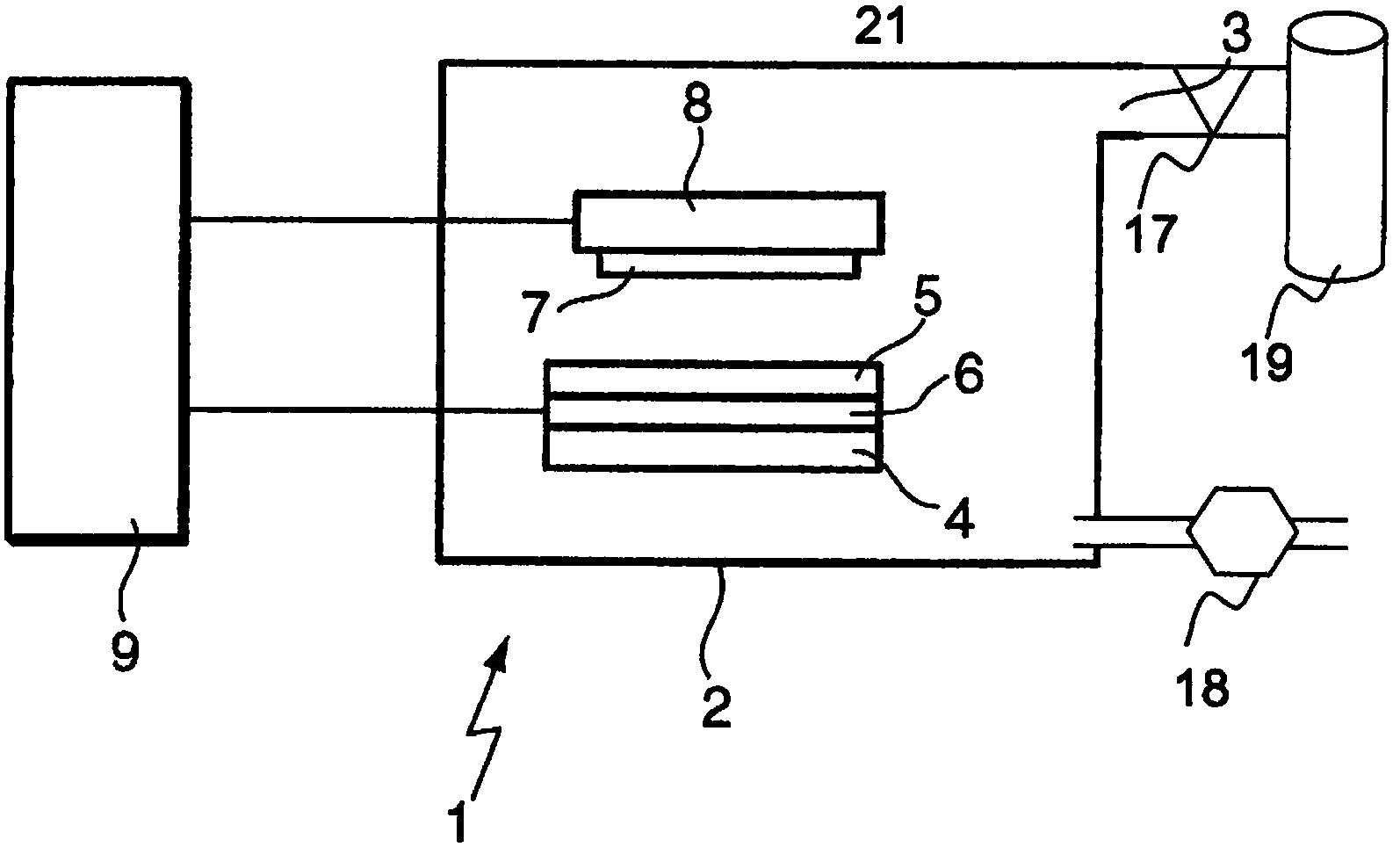

[0102] figure 1 An apparatus 1 suitable for sputtering is shown. The device 1 comprises a plasma chamber 2 with a gas inlet 3 for supplying a neutral gas. The plasma chamber 2 is evacuated by a vacuum pump 18 . The neutral gas to be ionized is admitted from a gas container 19 via a valve 17 .

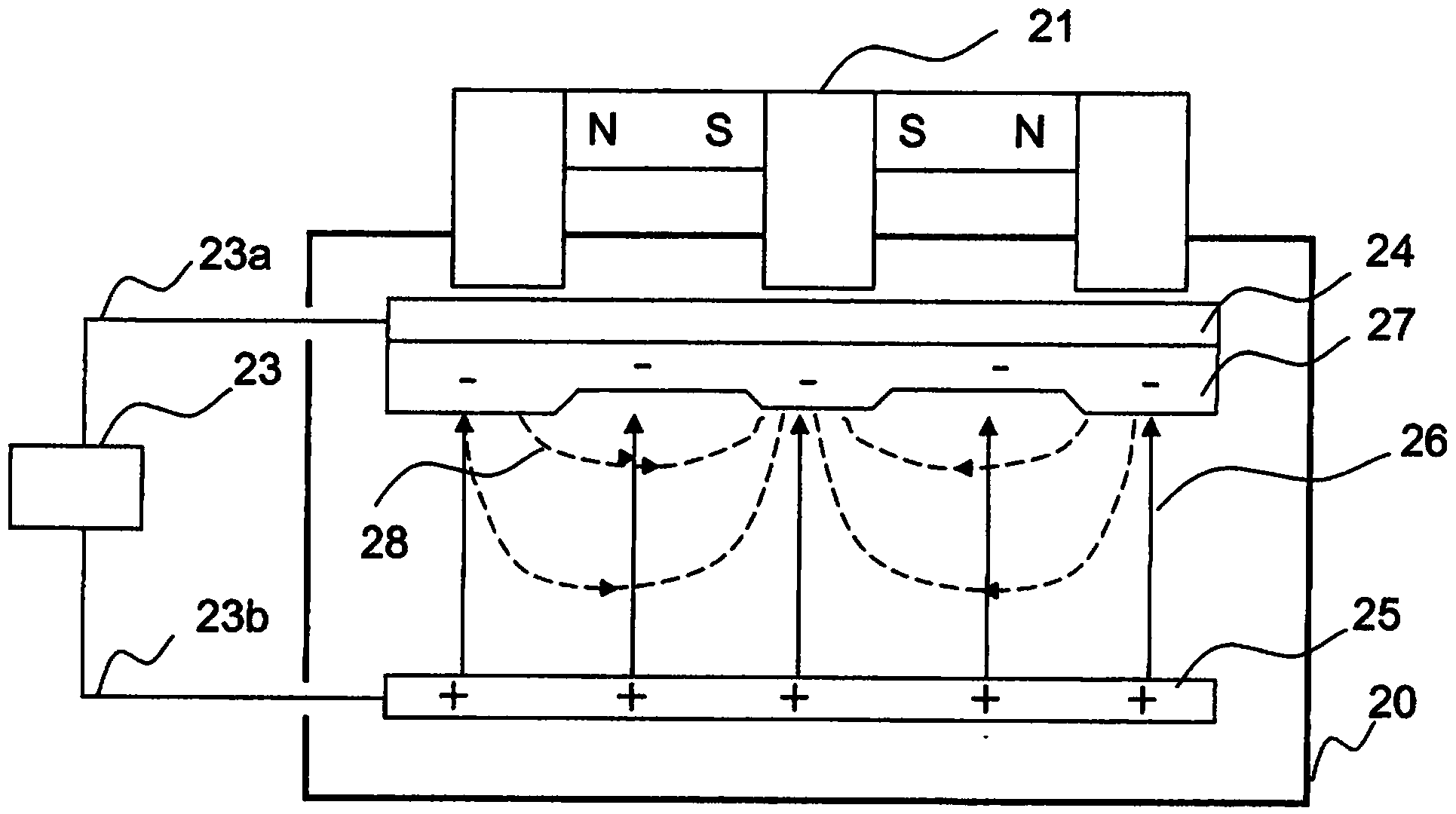

[0103] Inside the plasma chamber 2 a magnet 4 is provided providing a magnetic field on the surface of a sputtering target 5 . A target 5 is provided on top of an electrode 6 configured as a cathode. Specifically, the target 5 and the cathode 6 are electrically connected. Opposite the target 5, a substrate 7 to be coated with target material is provided. A substrate 7 is provided on the anode 8 . The anode 8 and the cathode 6 are connected to a high-energy pulse power supply 9 to apply a voltage pulse between the anode 8 and the cathode 6 in the plasma chamber 2 . The high-energy pulsed power supply 9 can be controlled to generate pulses to generate a highly ionized plasma from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com