Polyvinyl chloride material with high oxygen permeability and preparation method thereof

A technology of polyvinyl chloride and polyvinyl chloride resin, applied in the field of modified polyvinyl chloride materials and their preparation, can solve the problems of difficult processing of PVC materials, short survival time of platelets, high melt viscosity, etc., to ensure safety, Ensure low temperature resistance and extraction resistance, and improve air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

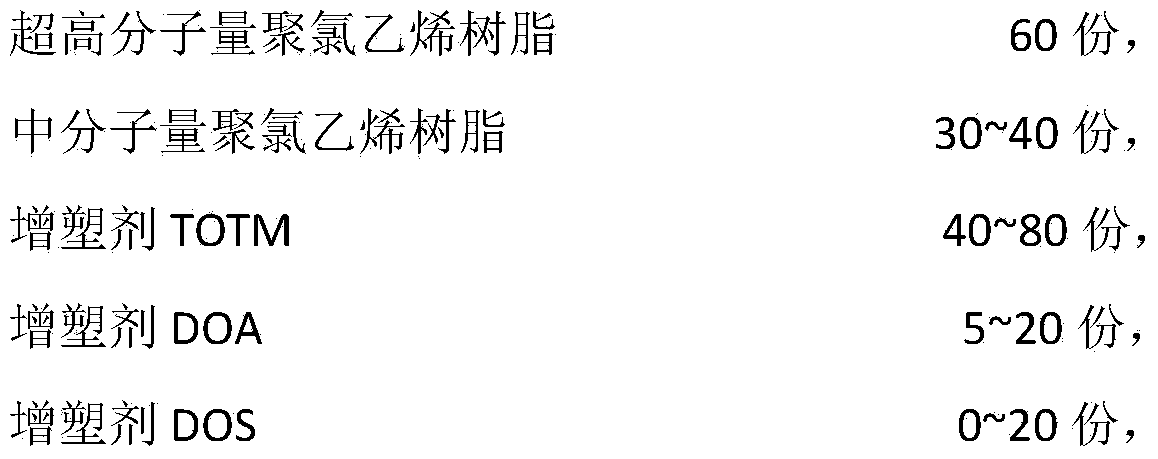

[0027] Formula: (parts by weight)

[0028]

[0029] Preparation steps:

[0030] Mixing: Add PVC, plasticizer, and auxiliary plasticizer to the high-speed mixer, set the speed to 360rpm, add stabilizer and antioxidant after 1min, add lubricant after 3min, mix to 130℃ and cool down The mixer has a speed of 10 rpm, and the material is discharged when the temperature of the material reaches 40°C.

[0031] Granulation: Add the above-mentioned cooling material into a twin-screw extruder for extrusion granulation. The barrel temperature is: Zone I 100℃, Zone II 130~℃, III150℃, IV150℃, die temperature 155℃, screw speed 70rpm , The material is plasticized by the extruder and then granulated by air cooling. Get the product.

[0032] The ASTM D1434-82 standard was used for testing, and the results are shown in Table 1.

Embodiment 2

[0034]

[0035] Mixing: Add PVC, plasticizer, and auxiliary plasticizer to the high-speed mixer, set the speed to 360rpm, add stabilizer and antioxidant after 1min, add lubricant after 3min, mix to 110℃ and cool down The mixer has a speed of 10 rpm, and the material is discharged when the temperature of the material reaches 50°C.

[0036] Granulation: Add the above-mentioned cooling materials to a twin-screw extruder for extrusion granulation. The barrel temperature is: 120°C in zone I, 150°C in zone II, 160°C in III, 160°C in IV, 160°C, die temperature 165°C, screw speed 70rpm, The material is plasticized by the extruder and then granulated by air cooling. Get the product.

[0037] The test results are shown in Table 1.

Embodiment 3

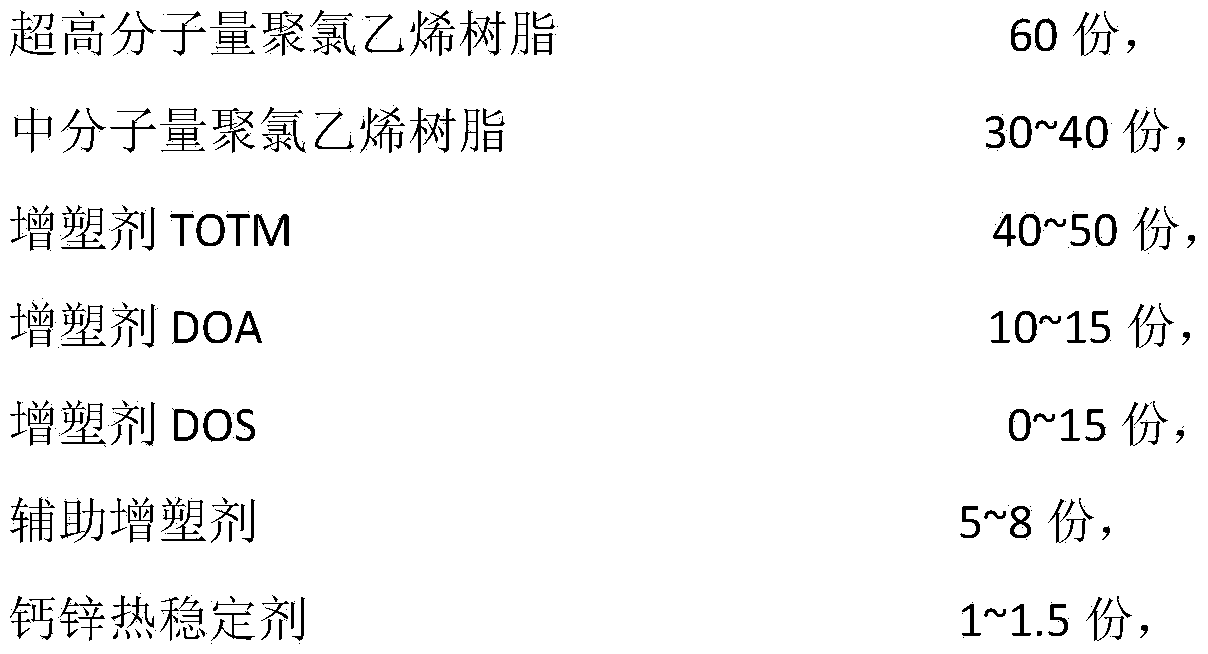

[0039]

[0040]

[0041] The preparation method is the same as in Example 1.

[0042] Table 1 Oxygen transmission rate of different examples

[0043] Numbering

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com