Amylopectin pretreatment method and use thereof

A pullulan and pretreatment technology, applied in the preparation of medium molecular weight hydroxyethyl starch, in the field of medium molecular weight hydroxyethyl starch, can solve the problems of inappropriate removal of bacterial endotoxin, impact on yield, loss of main drug components, etc. Achieve the effect of reducing the level of bacterial endotoxin, improving the internal quality of products, and having no occupational hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

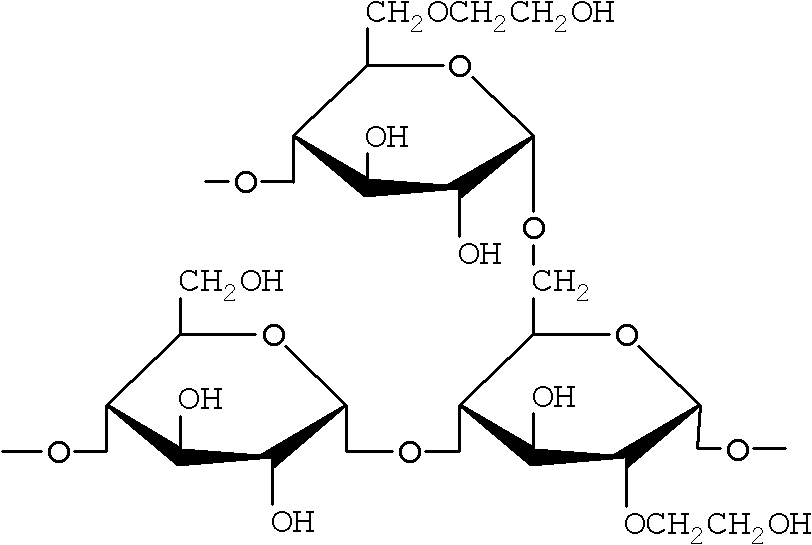

Image

Examples

Embodiment 1

[0060] 1. Amylopectin pretreatment method

[0061] Add 200L of positive ion water and 100kg of amylopectin into the mixing tank, start stirring to mix the two evenly, keep warm at 30°C for 15 minutes, then centrifuge and wash the filter cake with 100L of positive ion water. Processed amylopectin.

[0062] 2. The preparation process of medium molecular weight hydroxyethyl starch

[0063] 1) Hydrolysis

[0064] Add 500L of purified water and 5L of hydrochloric acid solution (36%-38%) into the hydrolysis tank, start stirring, then add the pretreated amylopectin, after stirring evenly, turn on steam heating to maintain the temperature in the tank at 82-92°C, Use the viscosity method to control the hydrolysis process, and stop the hydrolysis when the hydrolysis meets the process requirements.

[0065] 2) Etherification

[0066] First, dissolve 16Kg of solid sodium hydroxide in 200L of purified water to make a solution, stir and cool the above acid hydrolyzed material to 25°C, a...

Embodiment 2

[0079] 1. Amylopectin pretreatment method

[0080] Add 500L of positive ion water and 100kg of amylopectin into the mixing tank, start stirring to mix them evenly, keep warm at 30°C for 15 minutes, then centrifuge and wash the filter cake with 200L of positive ion water. Processed amylopectin.

[0081] 2. The preparation process of medium molecular weight hydroxyethyl starch

[0082] With embodiment 1.

[0083] 3. Detection method

[0084] With embodiment 1.

[0085] The specific experimental results are shown in Table 1 below.

Embodiment 3

[0087] 1. Amylopectin pretreatment method

[0088] Add 800L of positive ion water and 100kg of amylopectin into the blending bucket, start stirring to mix the two evenly, keep warm at 30°C for 15 minutes, then centrifuge and wash the filter cake with 500L of positive ion water. Processed amylopectin.

[0089] 2. The preparation process of medium molecular weight hydroxyethyl starch

[0090] With embodiment 1.

[0091] 3. Detection method

[0092] With embodiment 1.

[0093] The specific experimental results are shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com