Transfer film, resin laminate, method for producing the transfer film, and method for producing the resin laminate

A manufacturing method, transfer film technology, applied in the direction of synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problems of high surface tension, insufficient oleophobic performance, etc., and achieve excellent scratch resistance , Excellent hydrophobicity and oleophobicity, and excellent sweat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

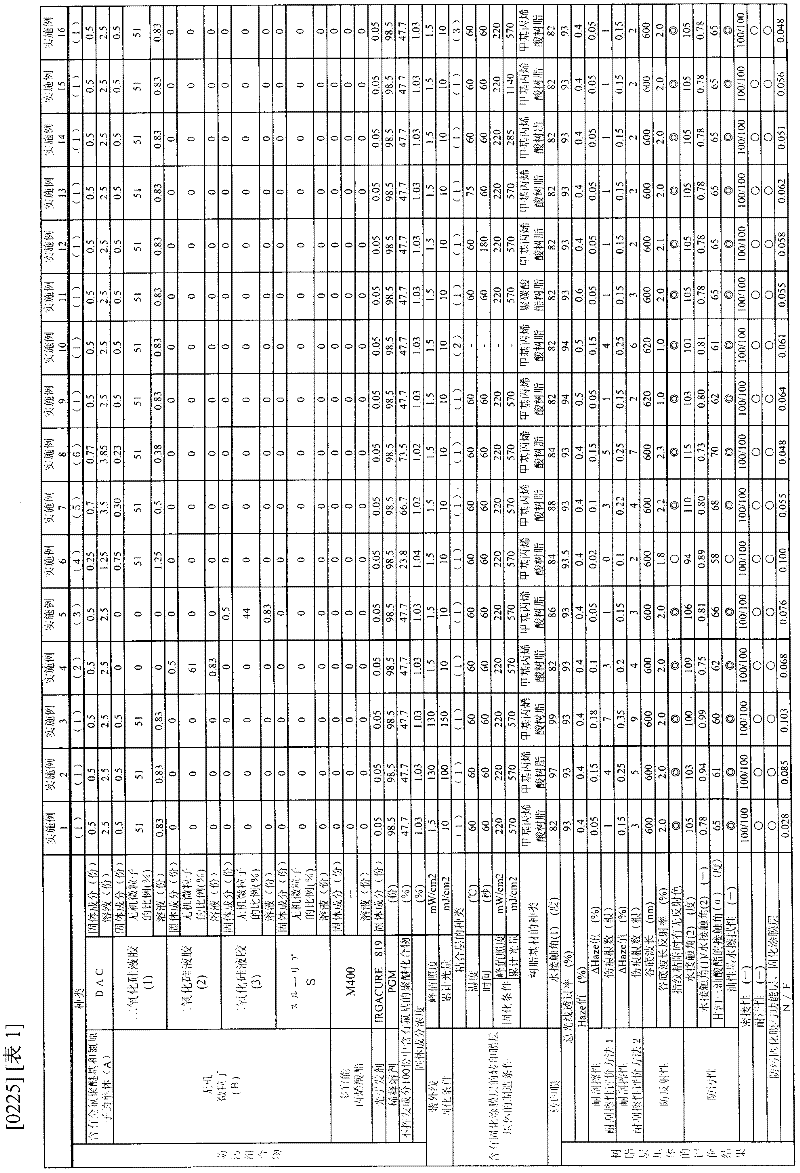

[0203] Hereinafter, this embodiment will be described by way of examples. The abbreviations of the compounds used in Examples and Comparative Examples are as follows. In addition, below, "part" and "%" represent "part by mass" and "% by mass", respectively.

[0204] "TAS": condensation mixture of succinic acid / trimethylolethane / acrylic acid (molar ratio 1 / 2 / 4) (manufactured by Osaka Organic Chemical Industry Co., Ltd.)

[0205] "C6DA": 1,6-hexanediol diacrylate (manufactured by Osaka Organic Chemical Industry Co., Ltd., trade name)

[0206] "M305": Pentaerythritol triacrylate (manufactured by Toagosei Co., Ltd., trade name)

[0207] "M400": dipentaerythritol hexaacrylate (manufactured by Toagosei Co., Ltd., brand name)

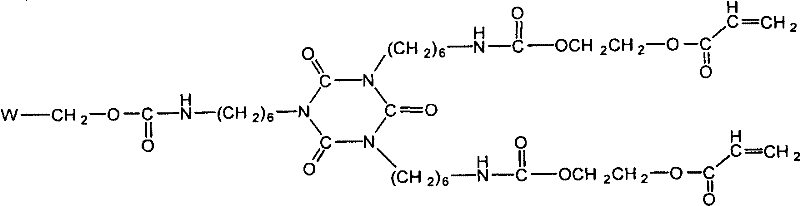

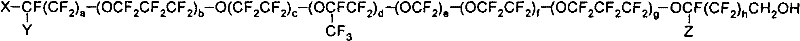

[0208] "OPTOOL DAC (オプツ-ルDAC)": a solution of a fluorine-containing polyether compound having a perfluoropolyether group and an active energy ray-reactive group (manufactured by Daikin Industries, Ltd., solid content concentration 20%, 2, 2,3,3-Tetrafluoro...

manufacture example 1

[0271] [Manufacture Example 1] Manufacture of hydrolysis-treated and condensation-reaction-treated silica gel (1)

[0272] 63 g of Sul-ria S was placed in a 4-necked flask reaction vessel equipped with a stirrer and a condenser, and then 12 g of KBM503 was added. Thereafter, 4.4 g of water and 0.1 g of an aqueous 0.01 mol / l hydrochloric acid solution were sequentially added with stirring, and heated at 80° C. for 2 hours. Next, the reaction system was brought into a reduced pressure state, and the volatile components were distilled off until the solid content concentration became 40%, and then 38 g of toluene was added thereto, followed by heating at 80° C. for 2 hours. Then, the reaction system was put in a reduced pressure state, and the volatile components were distilled off to a solid content concentration of 60%, and further heated at 80° C. for 2 hours to prepare a hydrolysis-treated and condensation-reaction-treated silica gel (1).

[0273] Silica gel (1) is a white tu...

manufacture example 2

[0274] [Manufacture Example 2] Manufacture of hydrolysis-treated and condensation-reaction-treated silica gel (2)

[0275] Except having added 8 g of KBM503, it carried out similarly to manufacture example 1, and produced the silica solution gel (2) of the hydrolysis process and the condensation reaction process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| critical surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com