Patents

Literature

82results about How to "Good sweat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

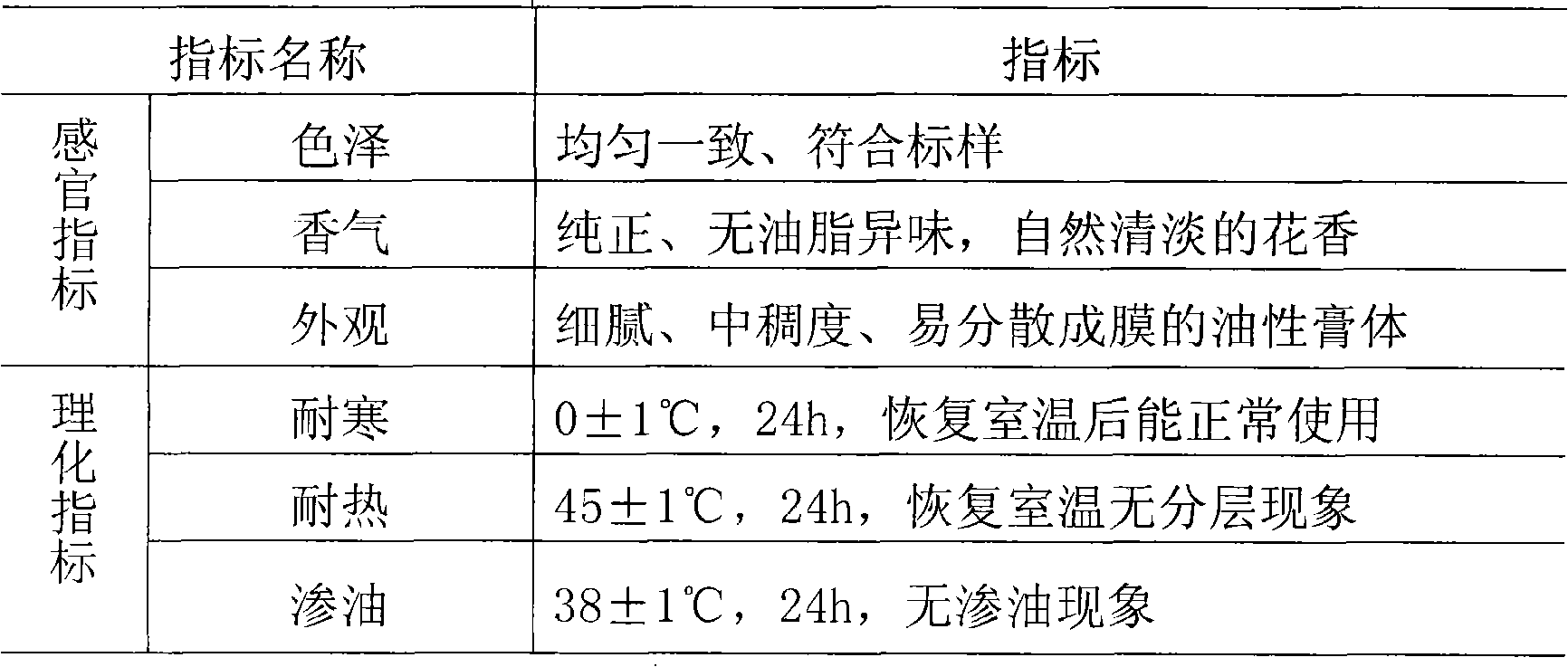

Military camouflage ointment and preparation thereof

The invention relates to a military camouflage ointment and a preparation method thereof, comprising 70 to 92 parts of matrix raw material; 1 to 8 parts of lake; 1 to 6 parts of titanium oxide; 1 to 6 parts of nano-zinc oxide; and 5 to 10 parts of DEET. Mineral oil and dimethyl silicone oil are firstly mixed and stirred, hydrogenated castor oil, ceresin and lanolin are added till the dissolution; talcum powder, the titanium oxide and the nano-zinc oxide are further added and stirred for even mixing; the lake and the DEET are added, and then the homogenization, the filling, the sealing and the preservation are carried out. The ointment of the invention can solve the technical problems that the existing military camouflage ointment can not simultaneously meet the purposes of meeting camouflage, preventing UV burns, infrared ray, visible light and mosquito bites, the ointment of the invention can prevent the UV burns, the mosquito bites and the infrared ray, thus having the advantages of safety, no allergy, no toxicity or side effects, mild aroma, good air permeability, insolubility in water, easy cleaning, high performance-price ratio, convenient carrying and good stability.

Owner:XIAN HANGJIE CHEM TECH

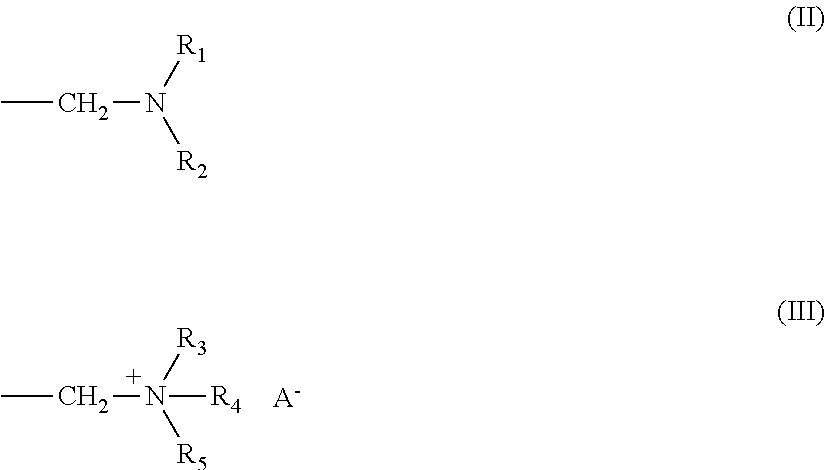

Electrocoat composition imparting sweat resistance and methods for using the same

InactiveUS20060249389A1Good sweat resistanceLiquid surface applicatorsElectrolysis componentsAcrylic resinChemistry

An electrodepositable coating composition comprising a cationic acrylic resin derived from an epoxy function acrylic resin and an IPDI trimer and coated substrates having improved sweat resistance are disclosed. Methods for using the coatings are also disclosed.

Owner:PPG IND OHIO INC

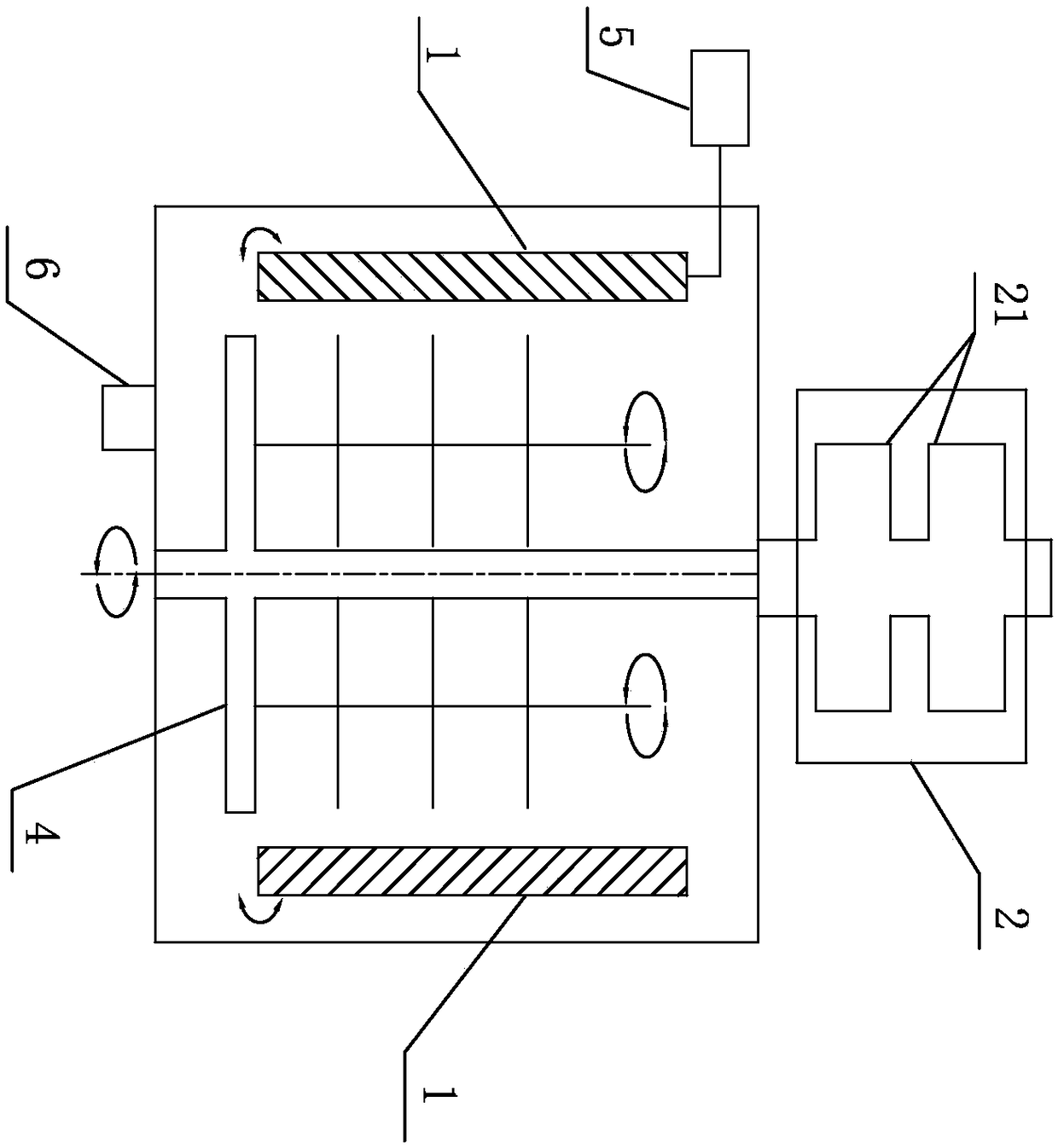

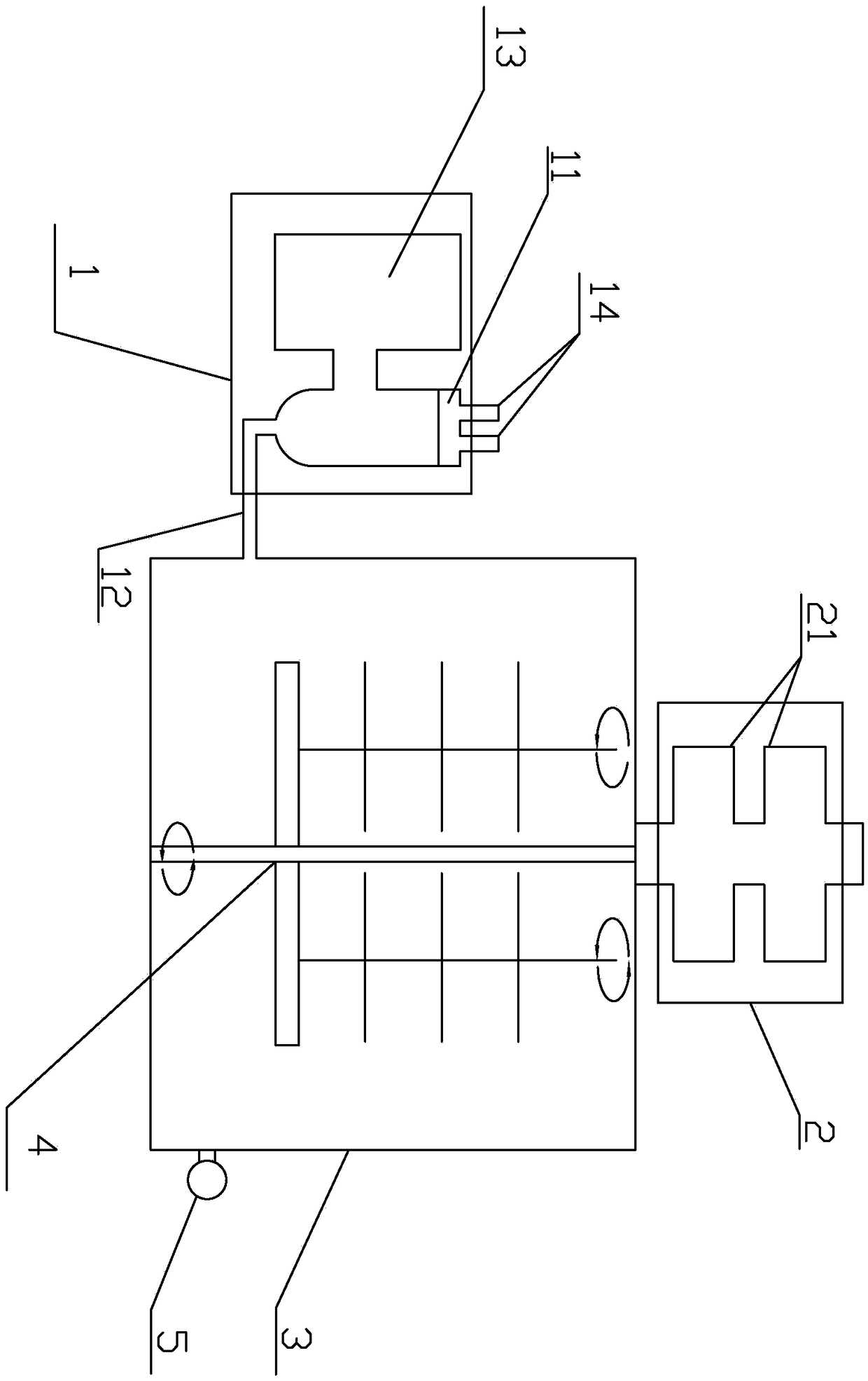

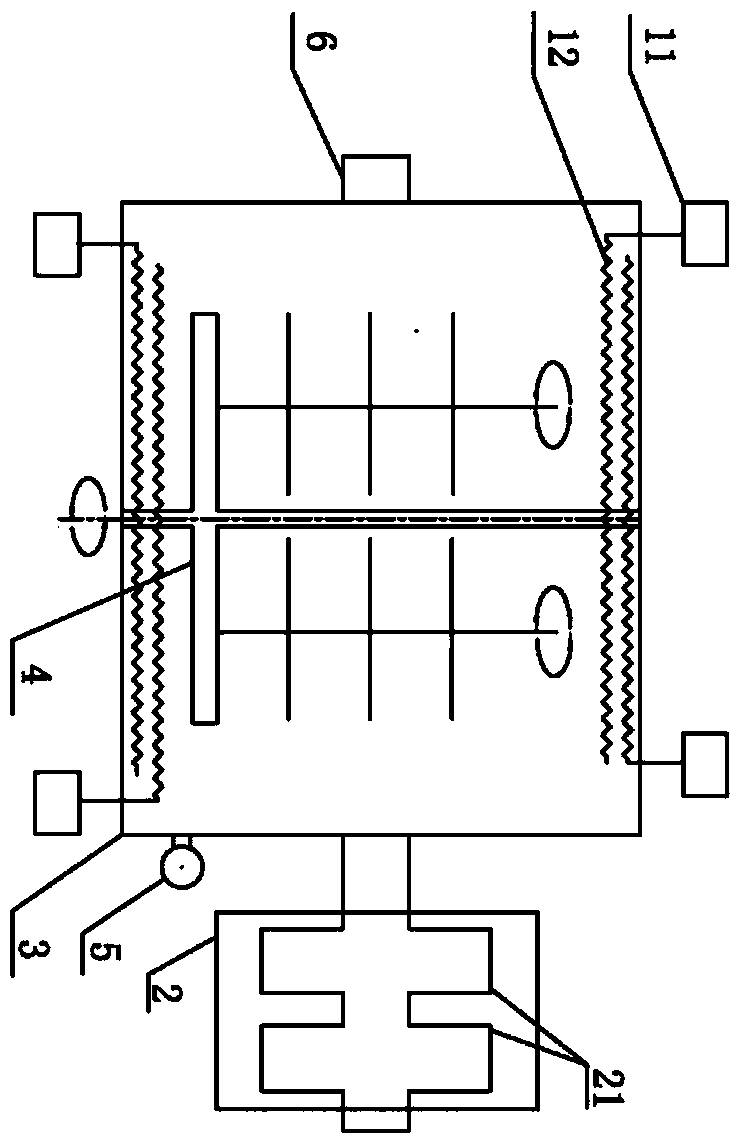

Plasma vacuum coating equipment with function of electrode and workpiece movement and using method

InactiveCN109183002AIncrease the sedimentation rateImprove coating production efficiencyChemical vapor deposition coatingSolventIntegrated circuit

The invention discloses plasma vacuum coating equipment with the function of electrode and workpiece movement and a using method. The equipment comprises moving electrodes, a vacuum air exhausting device, a plasma vacuum cavity, a workpiece driving moving device, a plasma discharge source and an air inlet channel; the plasma discharge source and the vacuum air exhausting device are arranged on theexterior of the plasma vacuum cavity; and the moving electrodes and the workpiece driving moving device are arranged in the plasma vacuum cavity. The using method of the equipment comprises the following steps that the plasma vacuum cavity is vacuumized, and coating is conducted on a to-be-coated workpiece. According to the plasma vacuum coating equipment with the function of electrode and workpiece movement and the using method, the coating sedimentation rate and the coating production efficiency are improved by adopting a plasma-enhanced chemical vapor deposition method, the coating uniformity and consistency are improved, the protection effects such as water prevention, sweat prevention, moisture prevention, corrosion resistance and solvent resistance of a coating are improved, and theplasma vacuum coating equipment can be applied to various coating occasions such as PCBs, PCBAs, electronic products, electric appliance parts, electronic semi-products, metals, electronic components, semiconductors, integrated circuit boards and plastic products.

Owner:朱广智

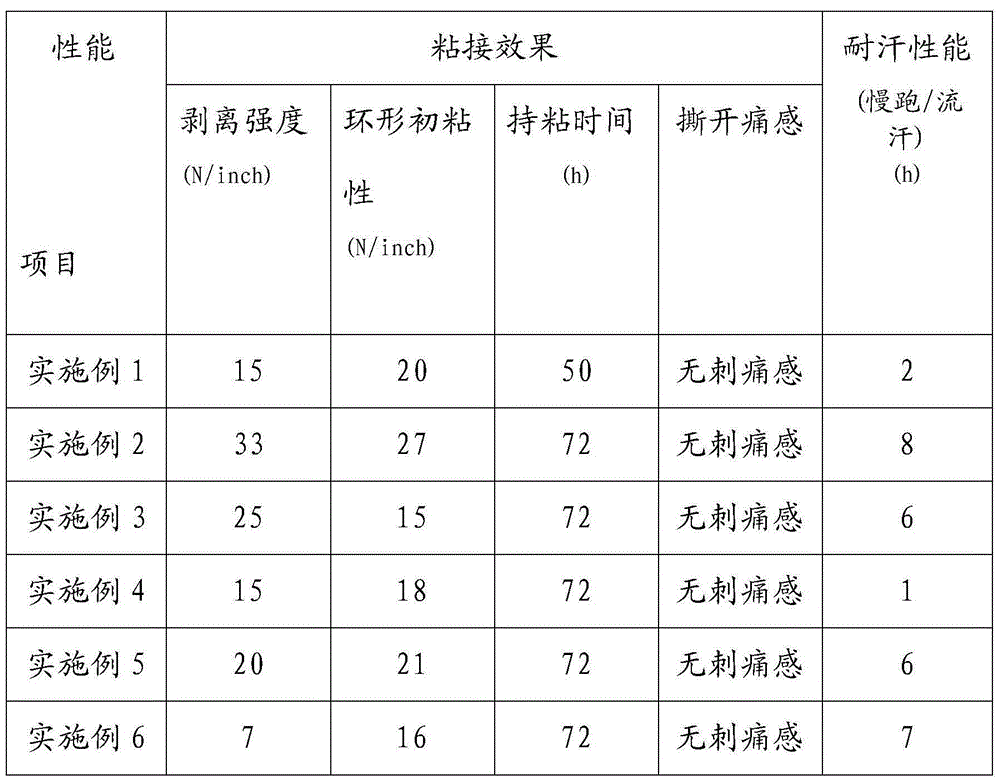

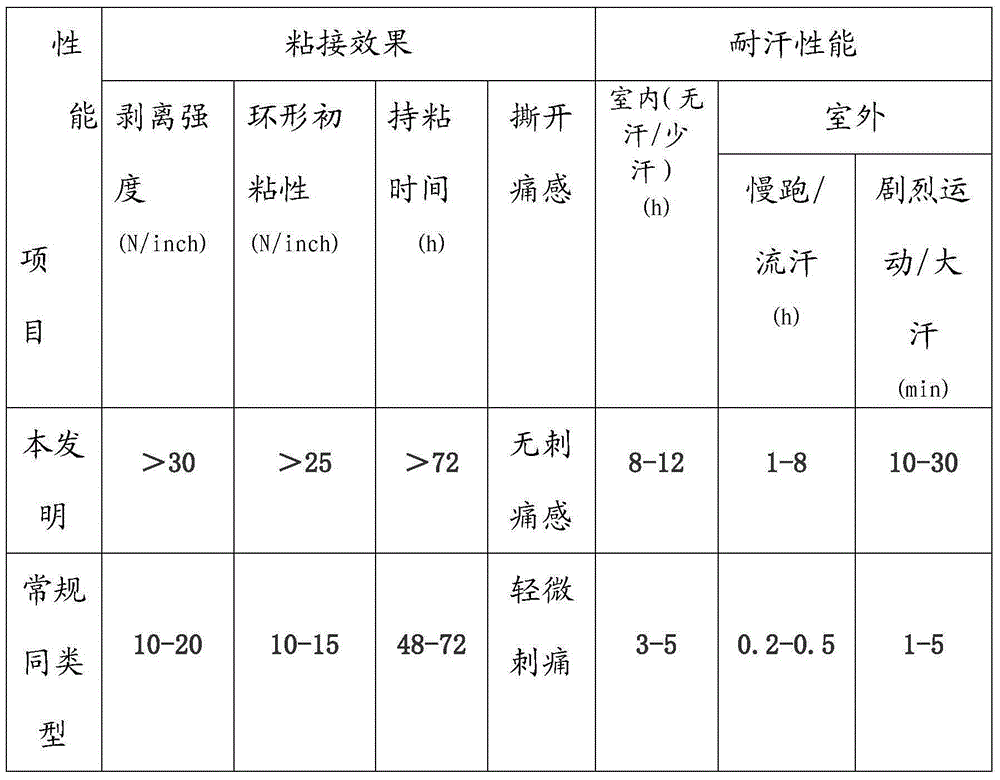

Medical hot melt adhesive and preparation method thereof

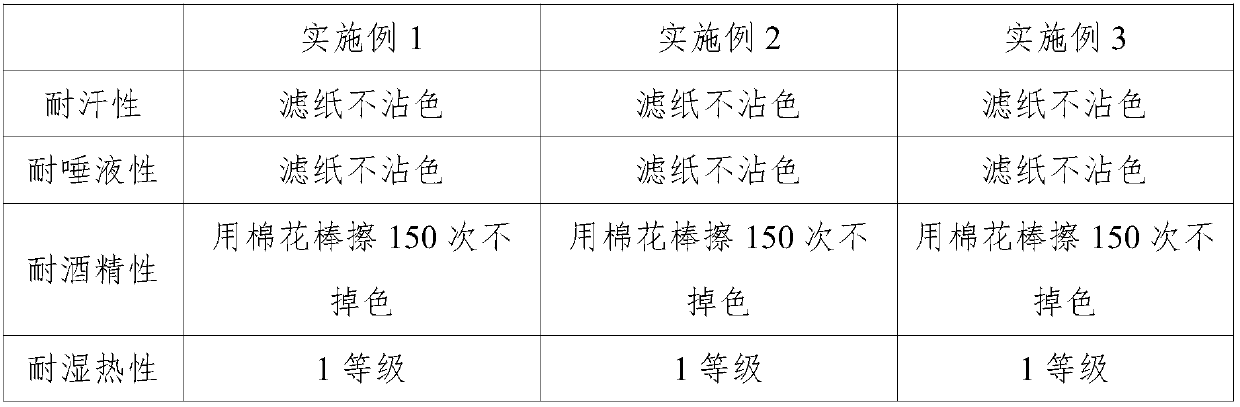

ActiveCN105086893AGood sweat resistanceStrong repeated stickinessMineral oil hydrocarbon copolymer adhesivesOil/fat/wax adhesivesElastomerPolymer science

The invention discloses a medical hot melt adhesive. The medical hot melt adhesion comprises the following raw materials in parts by weight: 30-70 parts of an SIS and PEG grafted product, 10-20 parts of naphthenic oil, 1-5 parts of an antioxidant, 30-60 parts of hydrogenated petroleum resin and 5-10 parts of SAP. The medical hot melt adhesive is prepared by blending an SIS elastomer and a PEG hydrophilic polymer and mixing a hydrophilic filler, a plasticizer and resin and is good in sweat resistance, strong in repeated adhesion and excellent in air permeability. The invention further discloses a preparation method of the medical hot melt adhesive, wherein the preparation method is low in energy consumption and short in reaction time.

Owner:佛山南宝高盛高新材料有限公司

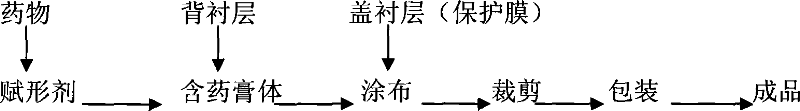

Compound panax notoginseng cataplasma

The invention relates to a compound external preparation of pseudo-ginseng, that is cataplasm, which is prepared by raw materials of extract (dry extract powder) of pseudo-ginseng, preserved Yunnan Kusnezoff monkshood, paris and psammosilene tunicoides with proper accessories. The compound cataplasm of the invention comprises a backing layer, a body containing ointment and a cover underlayer. The containing ointment body as a main part is formed by extract of pseudo-ginseng, preserved Yunnan Kusnezoff monkshood, paris and psammosilene tunicoides, with accessories such as adhesive, filer, penetration enhancers, humectant, etc., based on a predetermined ratio. The cataplasm has advantages of fast absorption, good moisture retention and ventilation property, and is comfortable for using. In addition, the product of the invention is convenient for using, has little acrimony to skin and has high compliance for patient.

Owner:KPC PHARM INC

Topical insect repellent composition and method of application

InactiveUS20070264295A1Improve sweatingImproved splash resistanceCosmetic preparationsBiocideSingle phaseOrganic solvent

Stable, single phase, low VOC, topical insect repellent compositions containing a film-forming polymer, insect repellent, water miscible organic solvent, and water.

Owner:3M INNOVATIVE PROPERTIES CO

Secondary recycling method of pigskin chrome-free combination tannage waste liquid

InactiveCN102312023AIncrease delayAvoid reduced absorptionHeat recovery systemsTanning treatmentPulp and paper industryWaste management

The invention discloses a secondary recycling method of pigskin chrome-free combination tannage waste liquid, comprising the following steps: using a vegetable tanning agent to carrying out penetration and tanning, after finishing the balance, discharging the solution; adding glutaraldehyde in tanning, collecting the waste solution, when the second batch of tanning begins, adding the first waste solution and supplementing the vegetable tanning agent, discarding after the tanning; and then adding aldehyde-containing waste liquid recycled by the first time and supplementing aldehyde for tanning, after the tanning, discharging the tanning solution. So, a circulation is finished, and a pollution discharge is reduced. According to the invention, the combination of the vegetable tanning agent and the aldehyde tanning agent are used for carrying out respective tanning on rawhide, each tanning agent is used for tanning according to certain proportion and order, and the two tanning agent form a cooperative effect, the shrinkage temperature can reach more than 90 DEG C, the produced leather presents light yellow without dying, is soft and full hand feel and very good elasticity, and has good aging resistance, sweat resistance, and flame retardation performance. The invention provides a new approach for present industrial production of chrome-free-tanned leather of tannery.

Owner:温州复亿实业有限公司

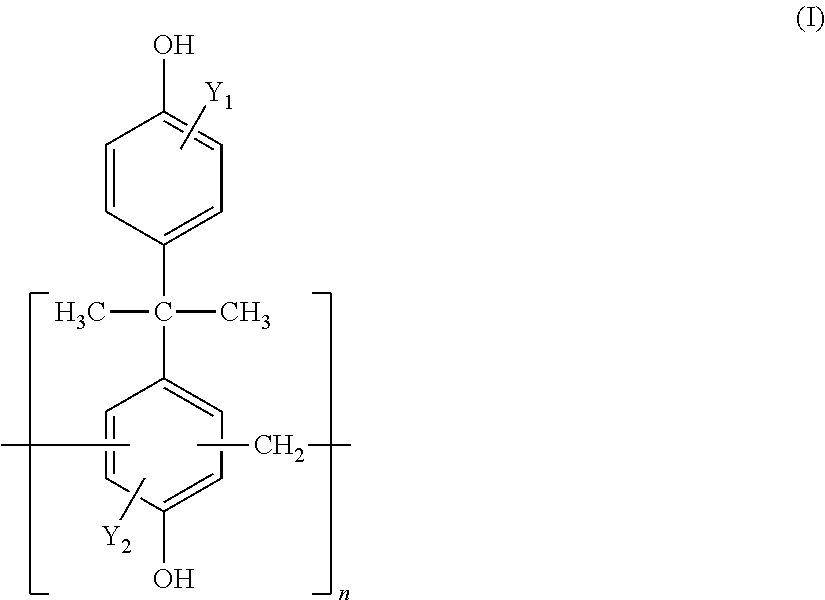

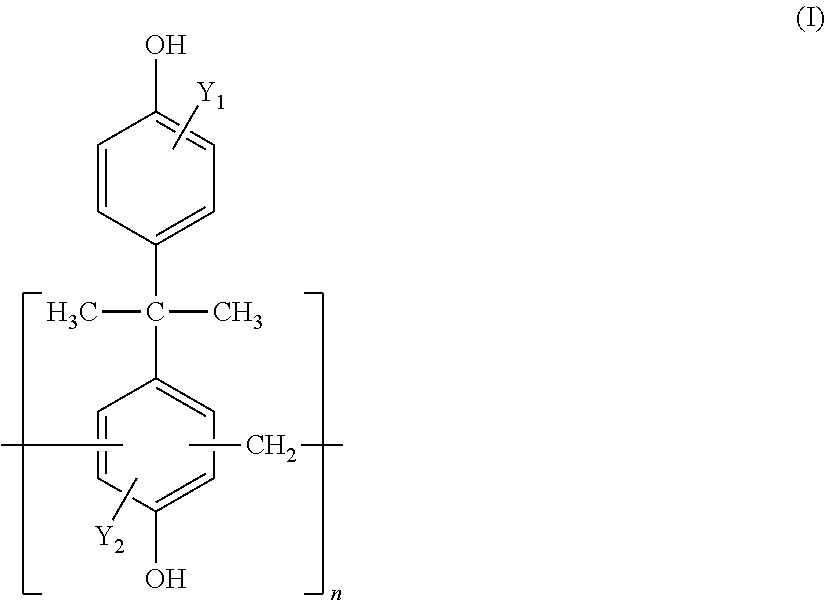

Surface treatment liquid for zinc or zinc alloy coated steel sheet, zinc or zinc alloy-coated steel sheet, and method for manufacturing the same

ActiveUS20130171468A1Improve corrosion resistanceGood sweat resistanceConductive materialPretreated surfacesChromium freeEmulsion

The present invention provides a chromium-free surface treatment liquid which enables forming, on a metal material surface, a film excellent in corrosion resistance at bent portions of a steel sheet, solvent resistance, coating properties after alkaline degreasing, and sweat resistance. The surface treatment liquid contains a resin compound having a specific bisphenol skeleton, a cationic urethane resin emulsion, a silane coupling agent, an organic titanium chelate compound, a quadrivalent vanadyl compound, a molybdate compound, a fluorine compound, and water at predetermined proportions. The pH of the surface treatment liquid is in the range of 4 to 5.

Owner:JFE STEEL CORP

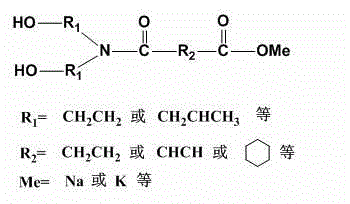

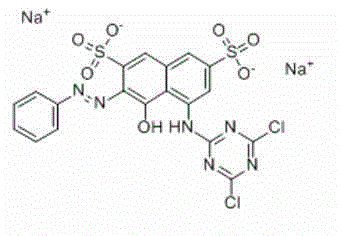

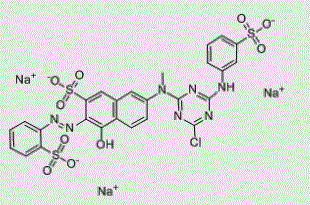

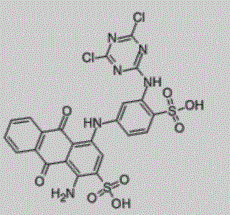

Reactive dye and preparation method thereof

ActiveCN104448930ASolve difficult-to-apply leather dyeing problemsHigh color fastnessOrganic dyesDyeing processCarboxylic saltSolvent

The invention discloses a reactive dye and a preparation method thereof. In order to achieve the above purpose, the reactive dye is prepared from a reactive dye and hydroxy amide carboxylate in a molar ratio N of 0.1: 1 to 2: 1, wherein the hydroxy amide carboxylate is prepared by neutralizing the pH value of a reaction product of hydramine and dicarboxylic anhydride in an equal molar ratio in a solvent to 8-10 by an alkaline solution. The method for preparing the reactive dye comprises the following steps: (1) taking the hydramine and the dicarboxylic anhydride in equal molar ratio to carry out amidation, neutralizing by using the alkaline solution until pH value is 8-10, and removing the solvent to obtain the hydroxy amide carboxylate; (2) reacting the hydroxy amide carboxylate with the reactive dye, and drying and grinding the product to obtain the reactive dye. The reactive dye and the preparation method of the reactive dye can be used for solving the problem that the existing reactive dye is hard to be applied in the leather dye; meanwhile, the color fastness of the leather is improved; the concentration of the residual dye of the dye waste solution is improved.

Owner:广州狮岭皮革皮具产业研究中心有限公司

Transfer film, resin laminate, method for producing the transfer film, and method for producing the resin laminate

ActiveCN102648091AImprove hydrophobicityGood oleophobic effectSynthetic resin layered productsThin material handlingPerspirationHigh surface

Disclosed is a transfer film which uses a film having high surface tension and is provided with an antifouling layer by a wet process, and on which a functional layer such as an antireflection layer can be laminated. The transfer film is capable of providing a laminate that has excellent water repellency, oil repellency, transparency, abrasion resistance and perspiration resistance. Also disclosed is a method for producing the transfer film. Specifically disclosed is a transfer film which is obtained by laminating an antifouling cured film on the surface of a transparent base film. The transfer film is characterized in that the water contact angle (1) of a surface of the antifouling cured film, said surface being not in contact with the transparent base film, is 100 DEG or less, the water contact angle (2) of a surface of the antifouling cured film, said surface being in contact with the transparent base film, is 90 DEG or more, and the contact angle (a) thereof with triolein is 55 DEG or more.

Owner:MITSUBISHI CHEM CORP

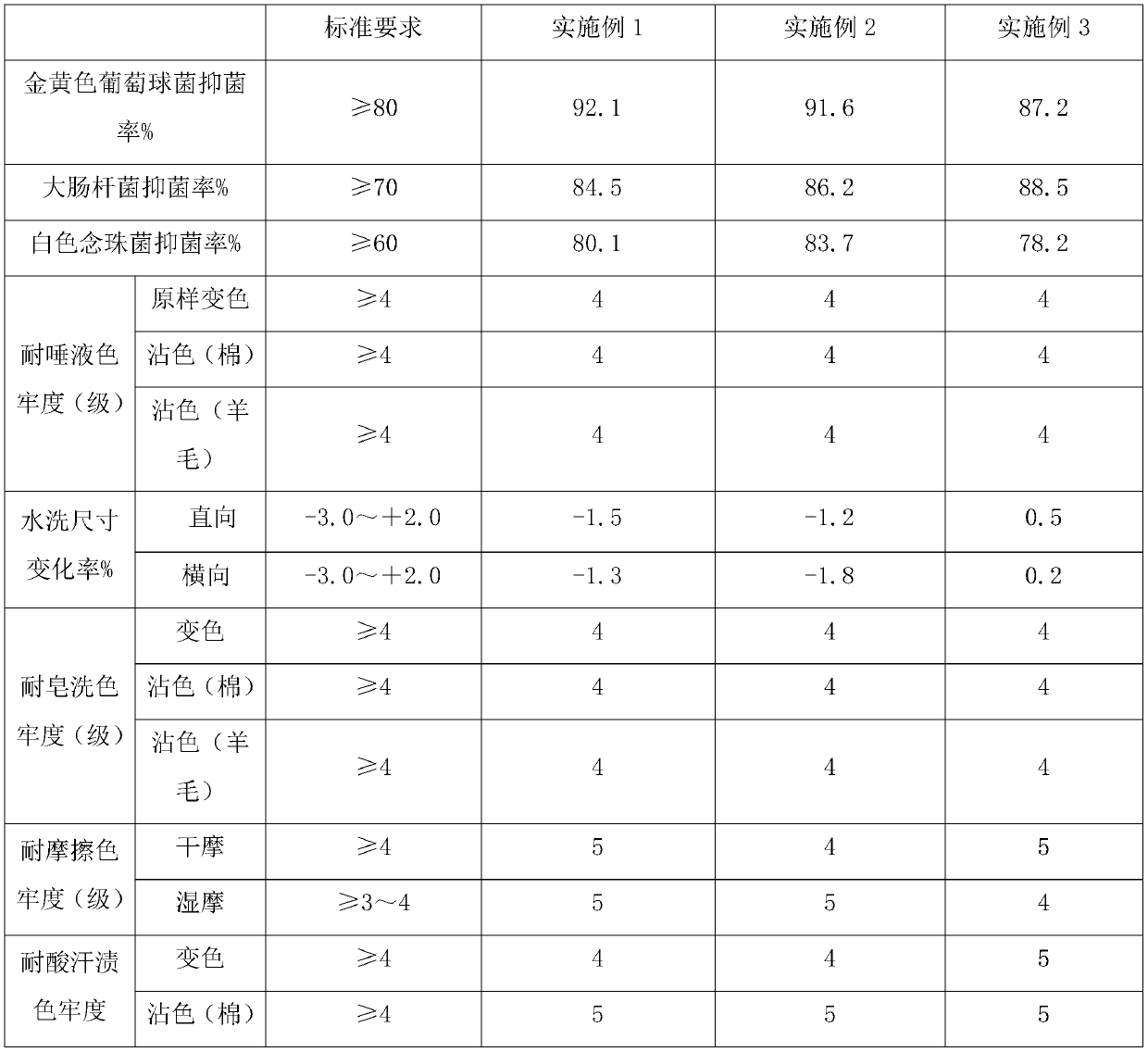

Taxus chinensis tencel cotton spandex double-sided functional fabric and preparation method thereof

InactiveCN111364235AImprove comfortImprove toughnessStain/soil resistant fibresWeft knittingCotton fibreTaxus mairei

The invention provides a taxus chinensis tencel cotton spandex double-sided functional fabric. The fabric is formed by blending taxus chinensis fibers, tencel, cotton fibers and spandex, the fabric comprises, by mass, 10%-15% of taxus chinensis fibers, 0%-50% of tencel, 45%-85% of cotton and 5%-10% of spandex. According to the taxus chinensis tencel cotton spandex double-sided functional fabric, the comfort, toughness and softness of the fabric are improved by adding tencel; the strength, the rubbing fastness and the hydrophilic performance of the fabric are improved by adding the cotton fibers; the acid and alkali resistance, the sweat resistance, the seawater resistance, the dry cleaning resistance and the wear resistance of the fabric are improved by adding the spandex; the fabric is finished through organic silicon, so that the dimensional stability, the wrinkle resistance, the water resistance, the air permeability and the friction resistance of the taxus chinensis fabric are improved; the water repellency, the oil resistance, the stain resistance, the washability, the heat resistance and the corrosion resistance of the fabric are improved through organic fluorine finishing; and the antibacterial performance of the fabric is improved through antibacterial finishing.

Owner:JIANGSU HONGDOU INDUSTRIAL CO LTD

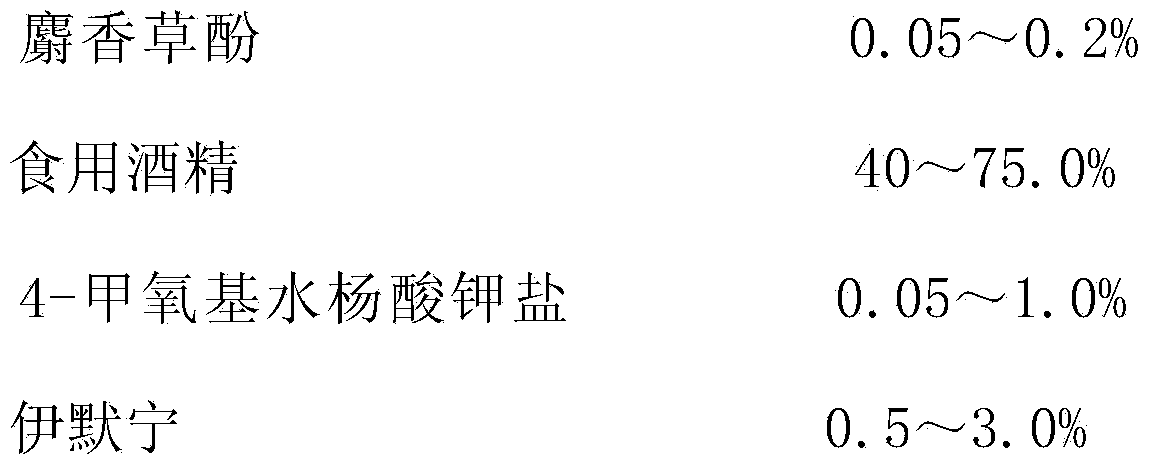

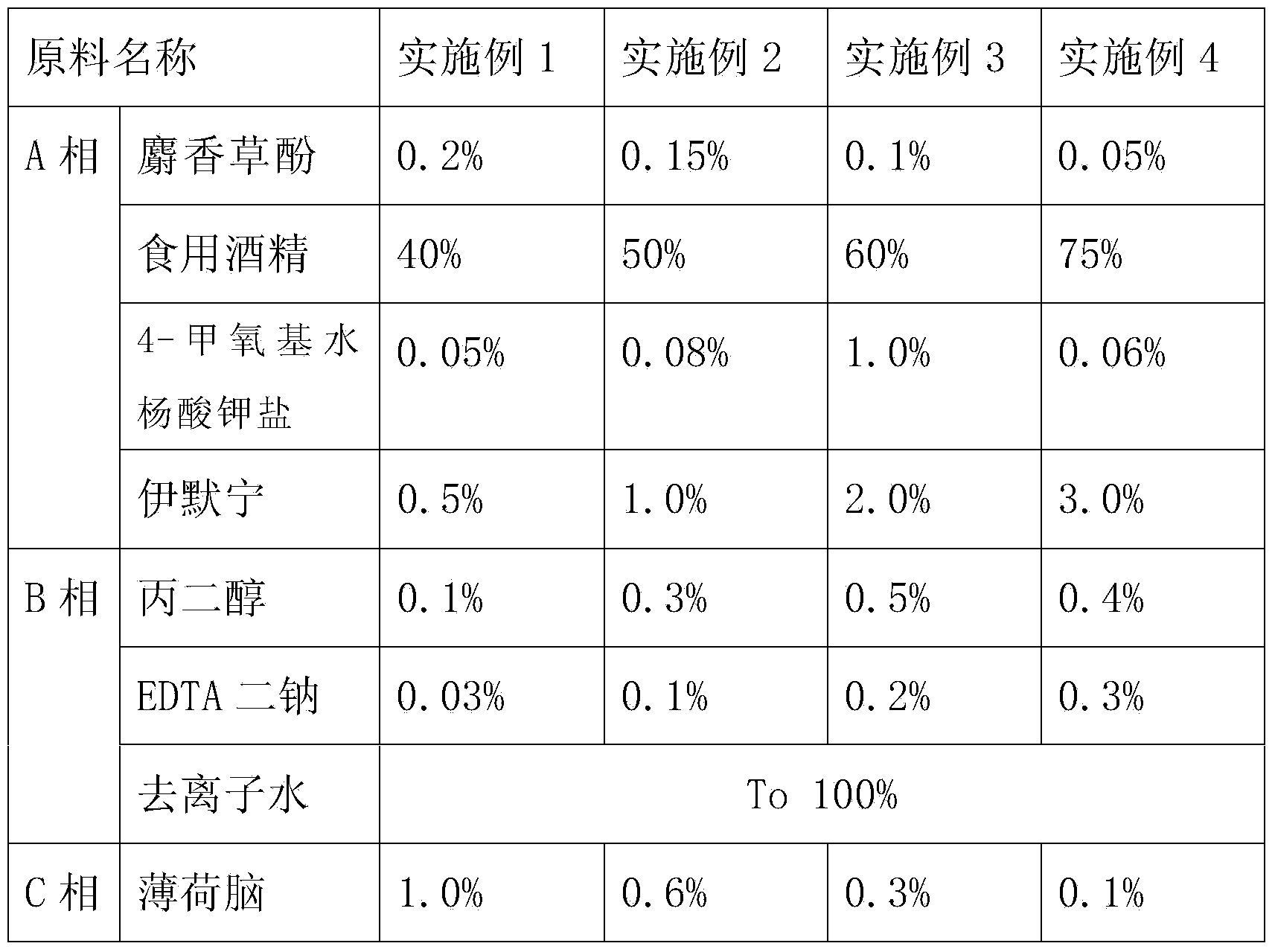

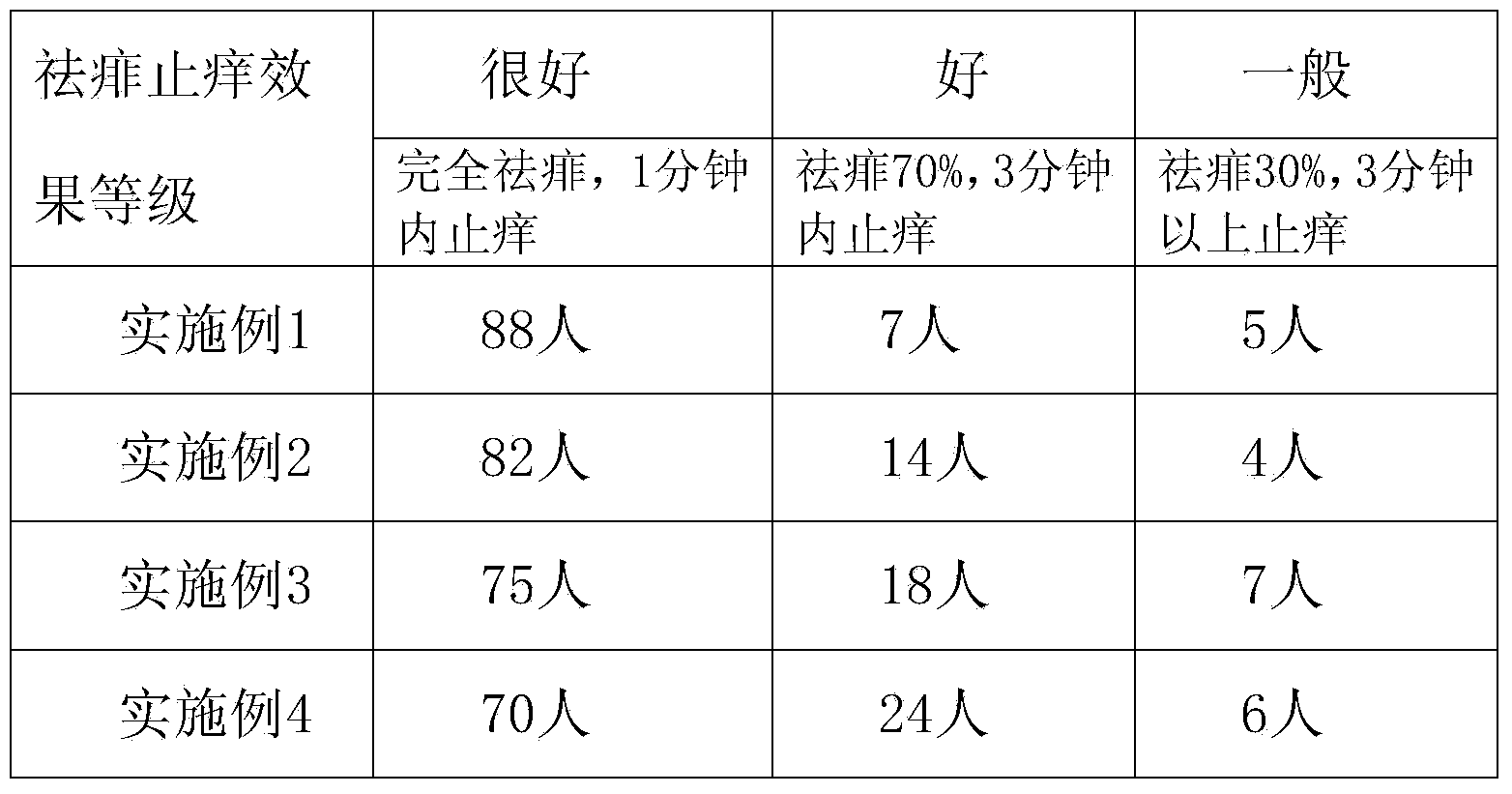

Repellent floral water for children for eliminating heat rash and relieving itching

ActiveCN103637920AGood repellent effectImprove thermal stabilityCosmetic preparationsToilet preparationsPotassiumConsciousness

The invention discloses repellent floral water for children for eliminating heat rash and relieving itching. The repellent floral water comprises thymol, edible alcohol, potassium 4-methoxy salicylate, IR3535, propylene glycol, ethylene diamine tetraacetic acid (EDTA) disodium, deionized water and menthol. A safe and effective anophelifuge is added; the effective mosquito-repellent action can be up to 7 hours; the repellent floral water has specific effects of eliminating heat rash and relieving itching, cooling and relaxing, refreshing restoring consciousness, and removing a peculiar smell, utilizes the most mild and safest anophelifuge to ensure the use safety in children products, and is an additive-free product. No essence or corrosion remover is added, so that the tenderness and the safety of the product are ensured to the maximal extent.

Owner:广州市澳莱化妆品有限公司

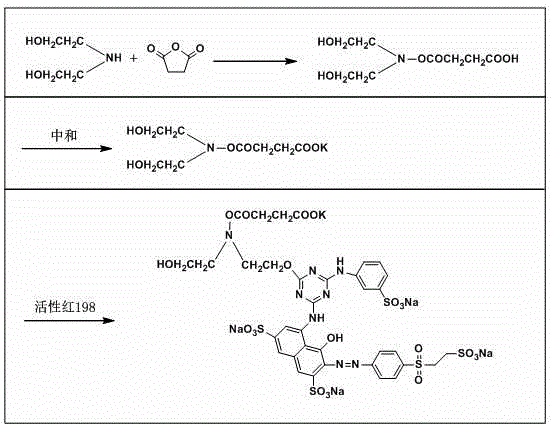

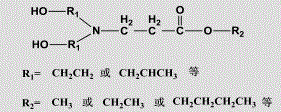

Preparation method for polymeric dye based on hyperbranched polyamine-ester

The invention relates to the technical field of special polymeric dyes for leather, fur and leather and fur products, in particular to a preparation method for a polymeric dye based on hyperbranched polyamine-ester. The preparation method comprises the following steps: by taking alcohol amine and acrylate as raw materials, reacting the alcohol amine and the acrylate, and removing a solvent after the reaction is ended to obtain an AB2 type monomer; reacting the AB2 type monomer, a catalyst and a micromolecular polyhydroxy compound to obtain hydroxyl-terminated hyperbranched polyamine-ester, and performing modification by using acid anhydride; reacting acid anhydride modified hyperbranched polyamine-ester with an active dye to obtain the polymeric dye. Compared with the prior art, the obtained polymeric dye can effectively improve the dyeing fastness, washing resistance, sweat resistance and other performance of the leather, the fur and the leather and fur products, the dye utilization rate is increased, and the content of dyes in waste liquor is reduced.

Owner:QILU UNIV OF TECH

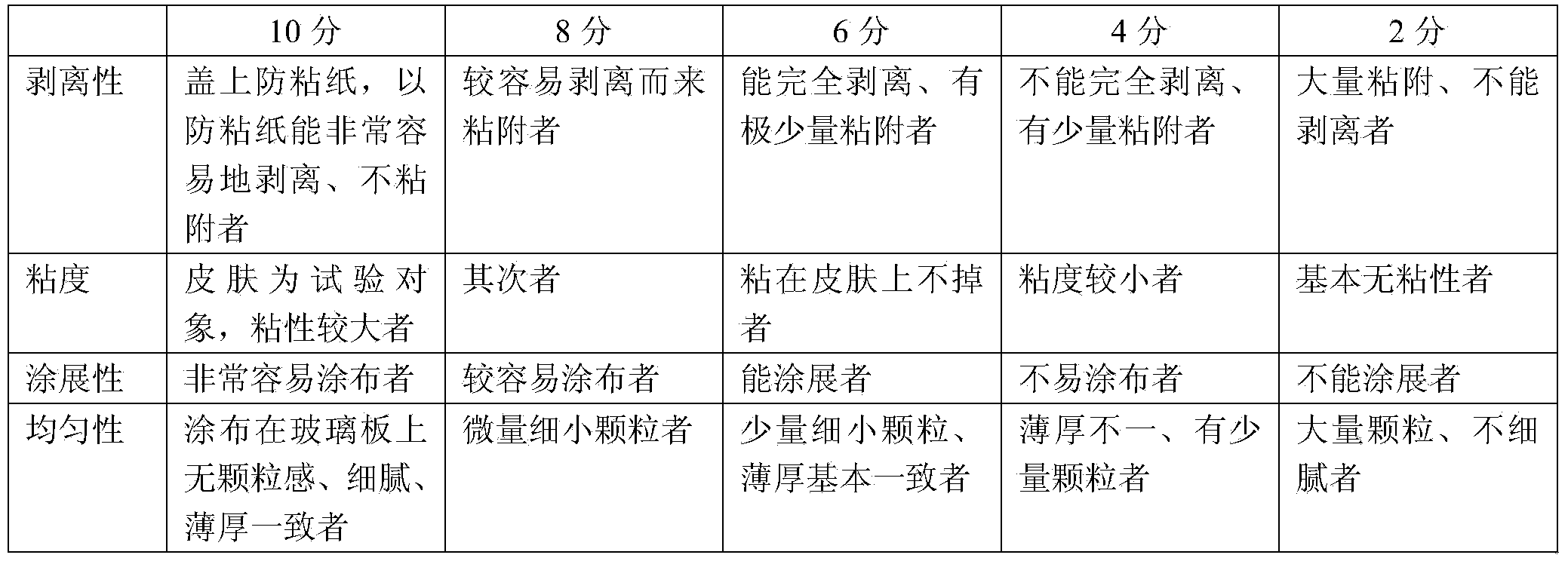

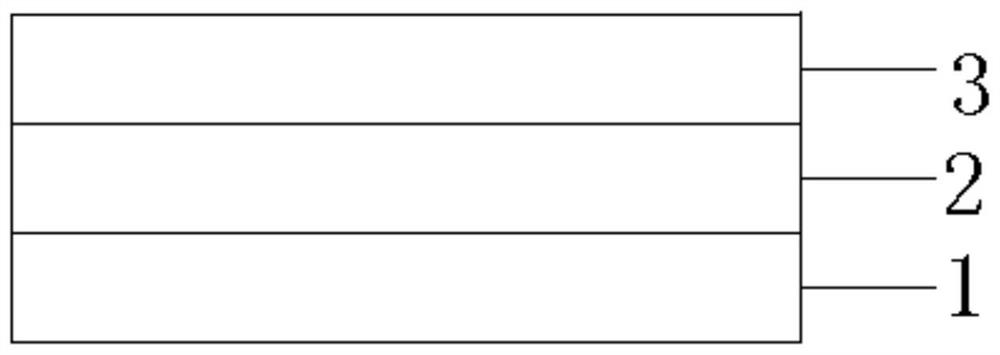

Traditional Chinese medicine cataplasm for acupoint application therapy of chronic fatigue syndrome and preparation method thereof

ActiveCN104162086ASignificant effectGood sweat resistanceHeavy metal active ingredientsAntinoxious agentsSodium polyacrylateCurative effect

The invention provides a traditional Chinese medicine cataplasm for acupoint application therapy of chronic fatigue syndrome and a preparation method thereof. The traditional Chinese medicine cataplasm comprises non-woven fabric, an anti-sticking film and drug-containing paste. The drug-containing paste comprises magnet, radix astragali, pilose asiabell root, toasted polygala root, poria with hostwood, fruit of Chinese magnoliavine, fructus amomi, albizia bark, sodium carboxymethylcellulose, sodium polyacrylate, carbomer, glycerin, gelatin, peach gum, polyvinylpyrrolidone, sodium hydroxide, borneol, menthol, purified water and ethanol. The preparation method comprises the following steps of respectively extracting extract I, volatile oil and extract II, preparing a matrix, adding borneol, menthol, the extract I, the volatile oil and the extract II into the matrix, carrying out stirring to obtain a uniform mixture, and carrying out coating, slicing and packaging to obtain the cataplasm. The traditional Chinese medicine cataplasm has substantial curative effects on chronic fatigue syndrome and does not cause allergy easily. The preparation method has simple processes and can be operated easily.

Owner:JIANGSU 707 NATURAL PHARMA

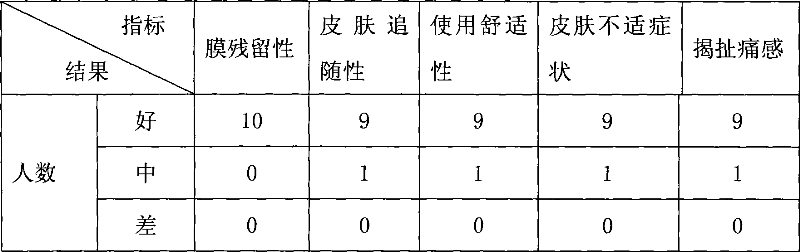

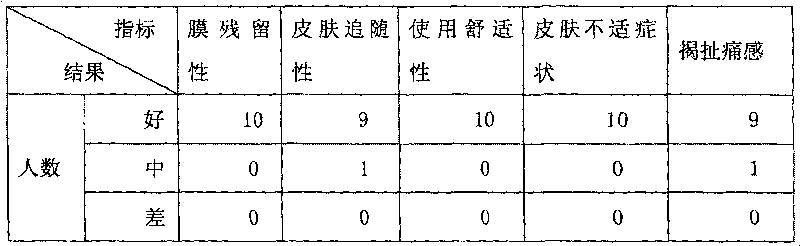

Saussurea involucrata extract and and producing method thereof

ActiveCN101209274BEasy to operateAntagonize painAntipyreticAnalgesicsChlorogenic acidBiocompatibility Testing

The invention relates to the technical field of medicine, and provides a snow lotus extract, a snow lotus cataplasm and a preparation method thereof. The snow lotus extract contains syringin, chlorogenic acid and rutin, the contents of which are respectively 6 times, 16 times and 200 times of the snow lotus injection. The snow lotus cataplasm forms snow lotus extract, adhesive, humectant, filler,thickening agent, cross linker and transdermal enhancer according to weight proportions of the raw materials. The results of the pharmacodynamic test of the invention indicate that the snow lotus cataplasm of the invention can obviously antagonize chemical pains, inhibit injury reaction and have anti-inflammatory effect; the invention has good performance on layer residue, skin tracing ability, using comfortableness, skin uncomfortable symptoms and tearing pain sense, can be torn and pasted repeatedly, has good biocompatibility, affinity, air permeability and perspiration resistance to the skin, and is not easy to cause allergy.

Owner:XINJIANG BIOCHEM PHARMA CO LTD

Wax-containing composition used for water resistance and viscidity increasing of table tennis bats

ActiveCN103773238AImprove water resistanceGood sweat resistanceWax coatingsRosin coatingsWaxMicrochiroptera

The invention discloses a wax-containing composition used for water resistance and viscidity increasing of table tennis bats. The wax-containing composition mainly comprises petroleum wax, oxidized polyethlene wax, amide wax, rosin, modified rosin or a derivative of rosin, a surfactant, and water. According to the wax-containing composition, petroleum wax is taken as a basic material so as to increase water resistance and sweat resistance of table tennis bats; oxidized polyethlene wax is used for increasing wear resistance; intersolubility of amide wax with other ingredients is excellent, system uniformity is increased, emulsifying efficiency is increased, and stability is improved. The wax-containing composition is used for rubber surface protection and maintenance of table tennis bats, is safe for using, is friendly to the environment, is convenient for coating, is excellent in water resistance and sweat resistance, long in use cycle, and stable in stability; and influence on the rubber surfaces is less.

Owner:CHINA PETROLEUM & CHEM CORP +1

Antiphlogistic analgesic Capparis spinosa L. catablasm and preparation method thereof

InactiveCN101474217AGood followabilitySymptoms improvedAntipyreticAnalgesicsPatient complianceIrritation

The invention discloses an anti-inflammation-analgesia capparis spinosa cataplasm and a preparation method thereof. The invention can be taken off and stuck on at any time, improving the adaptability of a patient. The drug is a capparis extract, the stroma is prepared, according to a certain mixture ratio, by water-soluble polymer skeletal materials, cementing compound, filling agent, cross-linking agent, pH regulator, humectant, preservative, transdermal enhancer, and the like, which have different mixture ratios. The invention has the advantages that the anti-inflammation-analgesia therapeutic effectiveness is obvious, the drug-loading rate of the stroma is large, the transdermal absorption effect is good, the use is convenient, the sticking is comfortable, the irritation to skin is small, and the compliance of patients is high.

Owner:石河子大学医学院第一附属医院

Method for making book-binding leather from rabbit skin and book-binding leather made according to method

InactiveCN105543422AEfficient use ofReduce wasteTanning treatmentPre-tanning chemical treatmentDepilationsFine grain

The invention provides a method for making book-binding leather from rabbit skin. According to the method, preservative-treated rabbit skin or fresh rabbit skin is soaked in water and subjected to meat removal to obtain a rabbit skin blank as a raw material. The method comprises the following steps: (1) liming and depilation, (2) deliming, (3) pickling, (4) tanning, and (5) retanning, finishing and coating. The method provided by the invention provides a new way of utilization of rabbit skin, provides a reasonable way of effective and reasonable utilization of rabbit skin, especially low-end and defective rabbit skin, and can reduce the waste of rabbit skin resources and avoid environmental pollution caused by abandonment of low-end and defective rabbit skin. The invention further provides book-binding leather made from rabbit skin according to the method, the book-binding leather made from rabbit skin has full dermatome and flat and fine grain, has no obvious location difference, and cannot suffer from the problem of loose grain easily during the making and using process.

Owner:SICHUAN UNIV

Preparation method of polyurethane hot-melt adhesive being sweat resistant

ActiveCN106634776AHigh initial bond strengthImprove toughnessPolyureas/polyurethane adhesivesElastomerPliability

The invention relates to a preparation method of a polyurethane hot-melt adhesive being sweat resistant. Terminal-hydroxyl liquid petroleum resin and terminal active liquid polybutadiene are used as a compound modifying agent, wherein the two components are both strong-hydrophobic monomers, so that a synergistic effect is achieved. Through a reaction with polyisocyanate and then molecular hybridization by a silane modifier, the compound modifying agent is significantly improved in anti-salt-spray-corrosion performance. The two components are flexible elastomers, so that the two components, as excellent flexibilizers, can effectively improve flexibility and anti-falling-impact performance. The polyurethane hot-melt adhesive is excellent in sweat corrosion resistance and has excellent comprehensive performance.

Owner:YANTAI DARBOND TECH

Fullerene-contained air cushion BB cream

InactiveCN108309868AGood repair blemishesStrong concealerCosmetic preparationsBody powdersDicaprylyl carbonateEngineering

The invention discloses fullerene-contained air cushion BB cream. The fullerene-contained air cushion BB cream is prepared from the following raw materials in parts by weight: 2-5 parts of PEG-10 polydimethylsiloxane, 0.3-0.8 part of dicaprylyl carbonate, 0.5-5 parts of fullerene, 0.5-2 parts of trimethylsiloxysilicate, 0.5-1 part of squalene, 0.1-2 parts of lecithin, 0.1-5 parts of polymethylsilsesquioxane, 0.5-5 parts of ethylhexylglycerin, 0.5-2 parts of tocopheryl acetate, 0.1-1 part of toner, 0.1-2 parts of thickener, 5-10 parts of glycerinum, 1-5 parts of sodium hyaluronate, 0.5-1.5 parts of EDTA disodium, 0.5-1 part of phenoxyethanol, 0.1-0.5 part of methylparaben, 0.01-0.1 part of essence, 0.5-2 parts of laurocapram, 0.5-2 parts of a herba rabdosiae extract, 0.6-4 parts of a fiveleaf carpetweet herb extract, 1-3 parts of a soulie barberry bark extract, 0.05-0.3 part of citric acid and 40-80 parts of water. The air cushion BB cream has the good effects of defect repair, sweat resistance and long-term lasting, has the remarkable anti-aging effect, and is capable of covering spots and nourishing skin, and enabling the skin to be moisturized and glossy after used for a long time.

Owner:广州雷诺生物科技有限公司

Waterborne UV (ultraviolet)-cure vacuum electroplating colorizing intermediate coat, and preparation method and electroplating method for same

InactiveCN108148496ASolve the problem of poor adhesionAffect performancePretreated surfacesPolyurea/polyurethane coatingsPolyurethane dispersionAlcohol

The invention provides waterborne UV (ultraviolet)-cure vacuum electroplating primer paint and a preparation method for the same, and belongs to the field of chemical coating. The waterborne UV-cure vacuum electroplating primer paint which is coating mainly comprises, by weight, 30-70 parts of waterborne polyurethane dispersion, 30-70 parts of waterborne UV dispersion, 2-15 parts of cosolvents, 0.2-1.5 parts of wetting agents, 1-6 parts of photoinitiators, 2-20 parts of water and an appropriate quantity of pigment. The waterborne UV-cure vacuum electroplating primer paint and the preparation method have the advantages that the difficult problem of poor adhesion between existing primer paint and existing finish paint can be solved by the aid of the waterborne UV-cure vacuum electroplating primer paint which is intermediate coat prepared by the aid of the preparation method; plating is colored and is ultimately protected by finish paint, and accordingly durable metal decoration effects can be realized; paint films formed by the aid of a method are excellent in adhesion, abrasion resistance, alcohol resistance, perspiration resistance and storage stability.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

Preparation method of waterborne acrylic resin with high heat resistance and product obtained by preparation method

The invention belongs to the field of chemical coatings and in particular relates to a preparation method of waterborne acrylic resin with high heat resistance. The preparation method of the waterborne acrylic resin with the high heat resistance, provided by the invention, comprises the following steps: carrying out chain extension reaction on dihydrazide carbonate by utilizing phenolic epoxy resin to obtain modified dihydrazide carbonate; then carrying out free radical polymerization to obtain waterborne acrylic resin with a main chain containing a maleic anhydride annular structure; adding the modified dihydrazide carbonate into the waterborne acrylic resin with the main chain containing the maleic anhydride annular structure and reacting to obtain the waterborne acrylic resin. The waterborne acrylic resin with the high heat resistance, which is prepared by the preparation method, has relatively high heat resistance; when the waterborne acrylic resin is applied to a coating, the rigidity, oil leakage resistance, pigment leakage resistance and yellow seepage resistance can be effectively improved; meanwhile, the waterborne acrylic resin also has the advantages of strong water resistance and corrosion resistance and is relatively ideal waterborne acrylic resin which is used for the coating and has high heat resistance.

Owner:广东立得新材料科技有限公司

Water-based UV curving vacuum electroplating finishing coating, preparation method and electroplating method thereof

InactiveCN108102536ASolve poor adhesionStrong adhesionPretreated surfacesPolyurea/polyurethane coatingsSolventPhotoinitiator

The invention provides a water-based UV curving vacuum electroplating finishing coating, a preparation method and an electroplating method thereof, and belongs to the field of the chemical coating. The coating is prepared from the following components in parts by mass: 10-60 parts of water-based polyurethane acrylate, 5-30 parts of water-based acrylate, 2.5-15 parts of trimethylolpropane triacrylate, 0.1-1.5 parts of flatting agent, 1-8 parts of photoinitiator, 8-20 parts of cosolvent, and 40-70 parts of water. The water-based finishing coating provided by the invention coats on the plastic aluminizing surface through vacuum electroplating, the paint film has good adhesive force, wear-resisting property, poach-resistance, and sweat resistance and the like. Furthermore, the finishing coating is the environment-friendly coating, and has the features of being convenient for operation, simple in construction and extensive in applicability and the like.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

Production method of compact slub yarn blending cotton and spandex

The invention discloses a production method of a compact slub yarn blending cotton and spandex. Technologies of compact spinning and slub yarn are applied to development of cotton and spandex blended yarn, so that the quality and the grade of the yarn can be excellently improved. The slub yarn has a unique style, and can excellently solve the problem that yarn levelness of a blended yarn of general cotton and other fibers is poorer, and the compact spinning can preferably reduce hairiness of a resultant yarn and improve the strength of the resultant yarn. Therefore, the yarn has good characteristics of the cotton and the spandex, is higher in strength and smaller in hairiness, and has the unique bamboo joint style; and meanwhile, elasticity, softness, aging resistance and sweat resistance of the product are improved greatly.

Owner:JIANGNAN UNIV

Composite material with holographic anti-counterfeiting effect and manufacturing method thereof

PendingCN113002212APrevent piracyHigh technology contentSpecial ornamental structuresInformation cardsUV curingNano structuring

The invention discloses a composite material with a holographic anti-counterfeiting effect and a manufacturing method thereof. The composite material comprises a holographic layer, a medium plating layer and a protective layer, wherein the holographic layer comprises a supporting layer and a holographic anti-counterfeiting micro-nano structure formed on the surface of the supporting layer; the transparent medium plating layer is formed on the holographic layer and covers the holographic anti-counterfeiting micro-nano structure; the protective layer is formed on the transparent medium plating layer; and the protective layer is formed by curing a UV curing coating layer and / or a thermosetting coating layer. In order to overcome the defects in the prior art and solve the problems in the prior art, the invention provides the composite material with higher physical strength and the holographic anti-counterfeiting effect and the manufacturing method thereof. The composite material is high in wear resistance and bending resistance, relatively high in anti-counterfeiting technical content level, significant in optical effect, easy to quickly identify the authenticity, and stable in product quality in long-term use. Meanwhile, the composite material with the holographic anti-counterfeiting effect is not prone to imitation, and not prone to information tampering.

Owner:SVG TECH GRP CO LTD

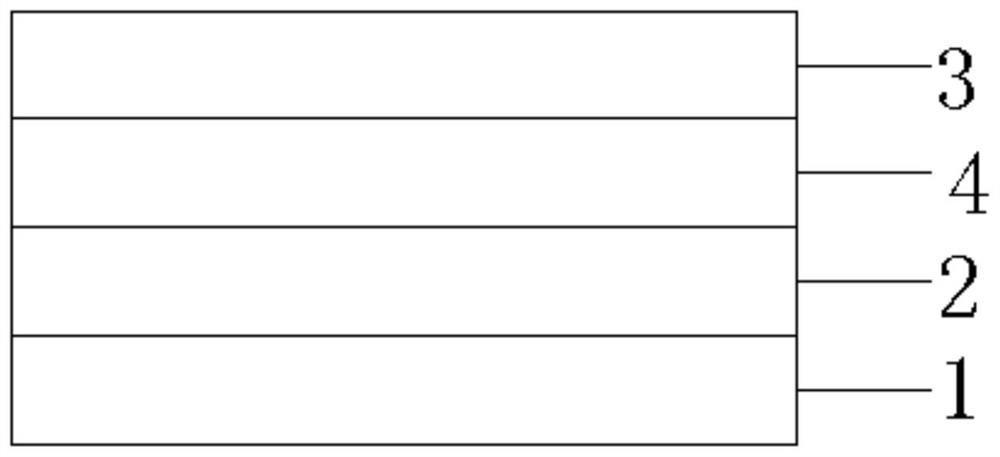

Artemether cataplasma and its application

InactiveCN101125135BGood biocompatibilityHigh affinityOrganic active ingredientsAntipyreticMedicineAdhesive

The present invention relates to an artemether cataplasma and the application. The cataplasma is prepared by artemether and proper excipients. The artemether cataplasma of the present invention is composed of three parts of a back lining layer, a paste body containing drug and a cover lining layer. The major part is the paste body containing drug which is prepared by artemether, adhesives, fillers, transdermal enhancers, moisturizing agents and other excipients according to a certain mixing ratio, each paste contain 20mg to 300mg of artemether. The cataplasma has the anti-fever effect and is characterized by fast acting, good moisture retention performance, good air permeability and comfortable usage, the product of the present invention has easy usage, small irritation on the skin and high compliance of the patients.

Owner:KPC PHARM INC

Cataplasm for curing acute injury of soft tissues and preparation method thereof

InactiveCN102579783AGood followabilitySymptoms improvedAntipyreticAnalgesicsPatient complianceIrritation

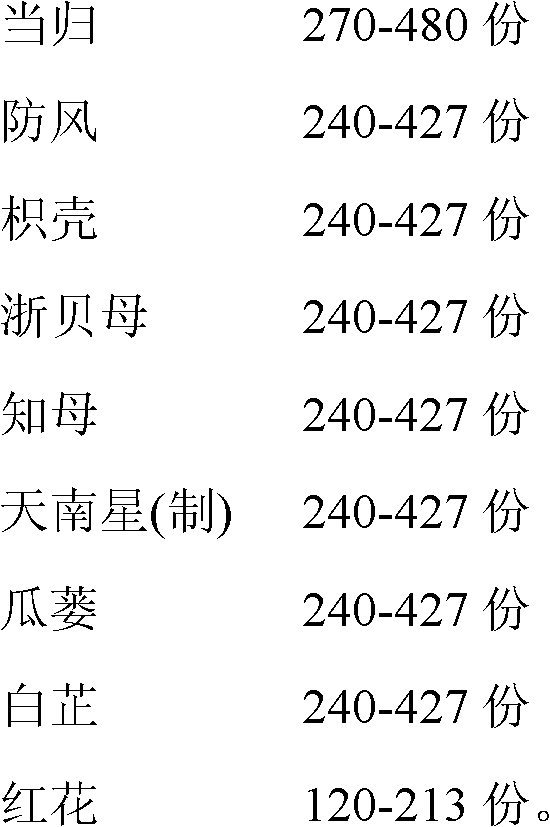

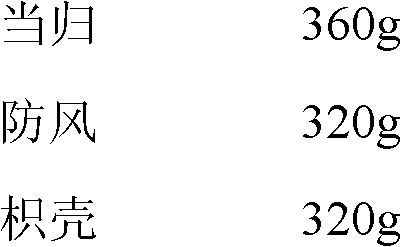

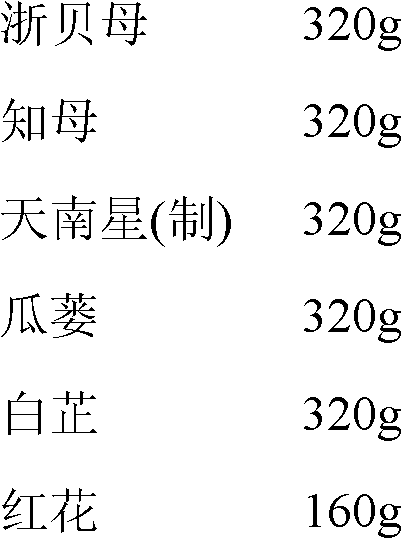

The invention relates to a cataplasm for curing acute injury of soft tissues and a preparation method thereof. The cataplasm is prepared by raw materials of angelica extract, saposhnikoviae radix extract, bitter orange extract, anemarrhena asphodeloides extract, rhizoma arisaematis (processed) extract, fructus trichosanthis extract, angelica dahurica extract, carthamus tinctorius extract, thunberg fritillary bulb extract and suitable accessories. The cataplasm consists of rear lining layers, ointments containing drugs, and cover lining layers. The cataplasm takes effect quickly, performances of moisture and air permeability are good, usage is comfortable and convenient, irritation on skins is small, and compliance of patients is high.

Owner:WUXI JIMIN KEXIN SHANHE PHARMA +1

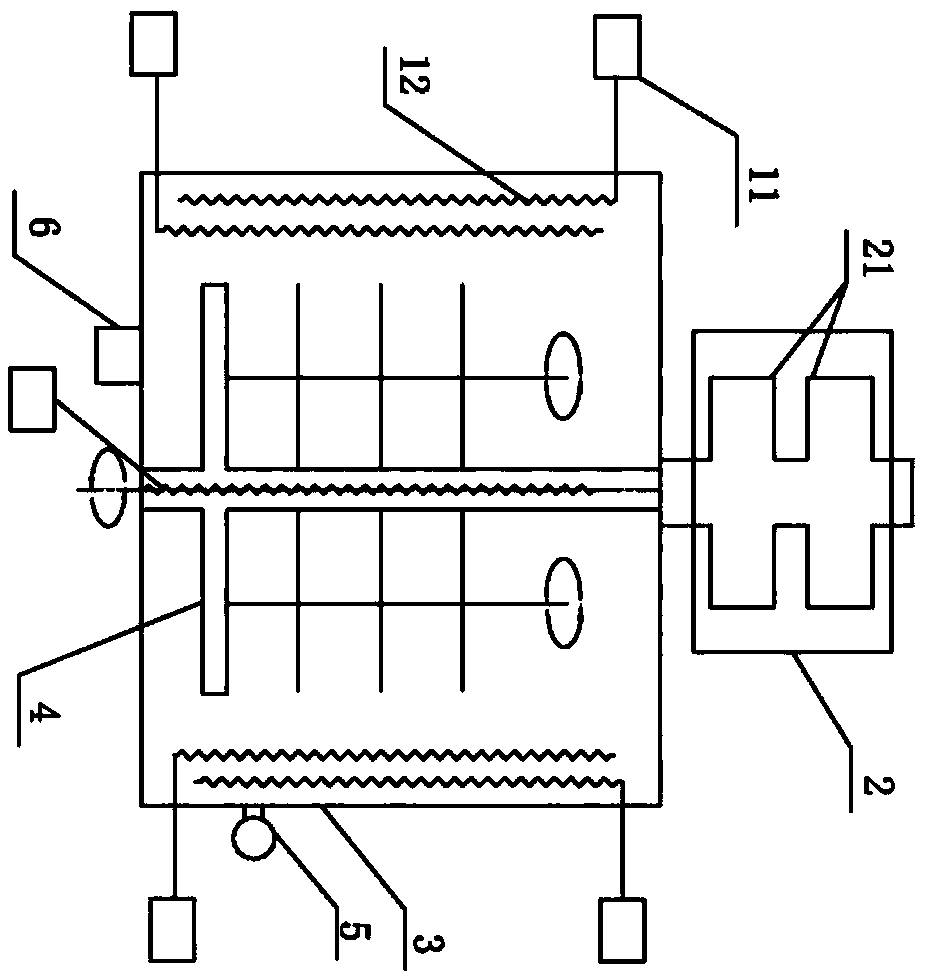

Microwave plasma vacuum film coating device and using method

InactiveCN109023307AIncrease the sedimentation rateImprove settlement efficiencyChemical vapor deposition coatingGas phaseSolvent

The invention discloses a microwave plasma vacuum film coating device and a using method. The device comprises a plasma generating system, a vacuum exhausting device, a plasma vacuum cavity and a movement device; the plasma generating system and the vacuum exhausting device are arranged outside the plasma vacuum cavity; and the movement device is arranged in the plasma vacuum cavity. The using method of the device comprises the following steps that the plasma vacuum cavity performs vacuumizing to perform pretreatment, film coating and the like on products to be subjected to film coating. According to the microwave plasma vacuum film coating device and the using method, a plasma chemical vapor deposition method is adopted for increasing the sedimentation rate of film coating substances andthe film coating production efficiency, and the film coating uniformity and consistency are improved; and meanwhile, the protective effects of waterproofness, sweat preventing, moisture preventing, corrosion resisting, solvent resisting and the like of a coating are improved at the same time, and application in occasions of various PCB, PCBA, electronic products, electric appliance parts, electronic half-finished products, metal, electronic parts and components, semiconductors, integrated circuit boards, plastic products and the like can be achieved.

Owner:朱广智

Microwave plasma vacuum coating equipment and use method

InactiveCN109554690AIncrease the sedimentation rateImprove settlement efficiencyChemical vapor deposition coatingGas phaseEngineering

The invention discloses microwave plasma vacuum coating equipment and a use method. The equipment comprises a microwave antenna, a microwave source, an air inflow device, an air exhaust device, a plasma vacuum cavity and a moving device. The vacuum air exhaust device is arranged outside the plastic vacuum cavity and connected with the cavity through a pipeline, the microwave antenna and the movingdevice are arranged in the plasma vacuum cavity, and the microwave source is arranged outside the cavity and connected with the microwave antenna in the cavity. The use method of the equipment includes the following steps that the plasma vacuum cavity is vacuumized, and a to-be-coated product is pre-treated, coated and the like. The sedimentation rate of coating matter is increased and the coating production efficiency of the coating matter is improved with a plasma chemical vapor deposition method, the uniformity and consistency of coating are improved, meanwhile, the waterproof, sweat-proof, damp-proof, corrosion-resistant and solvent-resistant performance and other protection effects of coatings are also improved, and the microwave plasma vacuum coating equipment can be used for the occasions of coating such as various PCBs, PCBAs, electronic products, electric appliance parts, electronic semi-finished products, metal, electronic components, semiconductors, integrated circuit boards and plastic products.

Owner:朱广智

Preparation method of fiber blended high-elastic fabric

InactiveCN112553905ABoth wear resistanceGood light fastnessAbrasion resistant fibresVegetal fibresFiberPolymer science

The invention discloses a preparation method of fiber blended high-elasticity fabric. The fiber blended high-elasticity fabric is composed of the following components: substrate cloth, elastic polyether ester fibers, polyurethane fibers, elastic polyolefin fibers, a compatilizer, an antioxidant, a defoamer and a crosslinking agent. The components are in following parts by weight: the polyurethanefibers are 20-39 parts; the elastic polyolefin fibers are 21-36 parts; and the compatilizer is 2-5 parts. The fiber blended high-elasticity fabric has the advantages of both the elastic polyether ester fibers, the polyurethane fibers and the elastic polyolefin fibers, has the mildew resistance, the aging resistance, the light resistance and the wear resistance of the elastic polyether ester fibers, and also has the advantages of the polyurethane fibers and the elastic polyolefin fibers; the problems that in a long-time use process of the existing fiber blended high-elastic fabric, the fabric needs to be cleaned, but the weather resistance of the existing fiber blended high-elastic fabric is poor, and the fabric can be damaged after being cleaned with a chemical agent for a long time are solved.

Owner:宿州市尔凯纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com