Preparation method of polyurethane hot-melt adhesive being sweat resistant

A polyurethane hot-melt adhesive and sweat-resistant technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve poor sweat corrosion resistance, low initial bonding strength, and sealant quality decline, etc. problems, to achieve the effect of excellent drop resistance, good sweat corrosion resistance, and increased salt spray corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

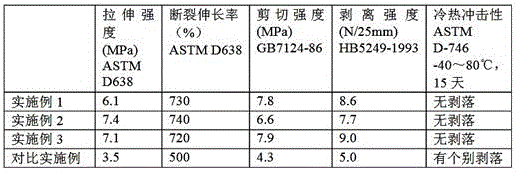

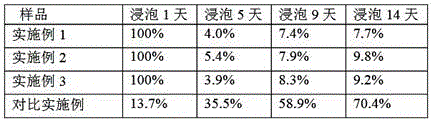

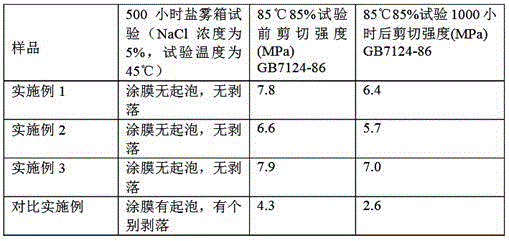

Examples

Embodiment 1

[0033] 1) Put 20 parts of hydroxyl-terminated liquid petroleum resin Novares LS500 and 40 parts of reactive elastomer POLVEST HT into the reaction kettle, dehydrate at 110°C and -0.095MPa for 2 hours, cool down to 70°C, add dibutyltin dilaurate 0.01 10 parts of German Bayer Desmodur N3300, stirred at 400 rpm, and reacted at 70°C for 3 hours. Then add 8 parts of silane modifier Y9669 and react at 70° C. for 5 hours to obtain a silane-terminated modified prepolymer.

[0034] 2) Dehydrate 10 parts of polyester polyol XCP-3000H, 70 parts of polyether polyol PPG220, and 35 parts of acrylic resin DB808 at 120°C and -0.095MPa for 2 hours. After dehydration, add 4,4' di 37 parts of phenylmethane diisocyanate MDI-100, stirred at 700 rpm, reacted at 120°C for 1 hour, then added 15 parts of silane-terminated modified prepolymer prepared in step a, antioxidant 1.0 parts of 264 doses, 0.1 parts of dimorpholino diethyl ether (DMDEE), heated up to 110 ° C, vacuumed to below -0.095 MPa, remo...

Embodiment 2

[0036] 1) Add 50 parts of hydroxyl-terminated liquid petroleum resin Novares LA300 and 10 parts of reactive elastomer POLVEST MA75 into the reactor, dehydrate at 110°C and -0.095MPa for 2 hours, cool down to 70°C, add 0.05 parts of stannous octoate, 40 parts of 2,4-toluene diisocyanate trimer were stirred at 700 rpm, and reacted at 80° C. for 1 hour. Then add 30 parts of silane modifier A189 and react at 80° C. for 2 hours to obtain a silane-terminated modified prepolymer.

[0037] 2) Dehydrate 30 parts of polyester polyol POL-356T, 40 parts of polyether polyol PPG204, and 15 parts of acrylic resin DB69 at 120°C and -0.095MPa for 2 hours. After dehydration, add 4,4' di 10 parts of phenylmethane diisocyanate MDI-100, 2 parts of toluene diisocyanate TDI-100, stirred at 400 rpm, reacted at 100°C for 3 hours, and then added the silane-capped modification prepared in step a. 50 parts of non-toxic prepolymer, 0.02 part of antioxidant 1010, 0.001 part of triethylenediamine, heating ...

Embodiment 3

[0039] 1) Add 35 parts of hydroxyl-terminated liquid petroleum resin Novares LA700 and 23 parts of reactive elastomer POLVEST HT into the reactor, dehydrate at 110°C and -0.095MPa for 2 hours, cool down to 70°C, add dibutyltin dilaurate 0.04 Parts, 26 parts of triphenylmethane triisocyanate (TTI), stirred at 550 rpm, reacted at 75°C for 2 hours. Then add 18 parts of silane modifier KH-550 and react at 75° C. for 3.5 hours to obtain a silane-terminated modified prepolymer.

[0040] 2) Dehydrate 20 parts of polyester polyol XCP-3000H, 32 parts of polyether polyol PPG210, 23 parts of polyether polyol PPG204, and 25 parts of acrylic resin DB29 at 120°C and -0.095MPa for 2 hours, dehydrate After completion, add 13 parts of 4,4' diphenylmethane diisocyanate MDI and 12 parts of toluene diisocyanate TDI100, stir at 550 rpm, react at 110°C for 3 hours, and then add this step a to prepare 32 parts of silane-terminated modified prepolymer, 0.05 part of antioxidant 1076, 0.04 part of dim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com