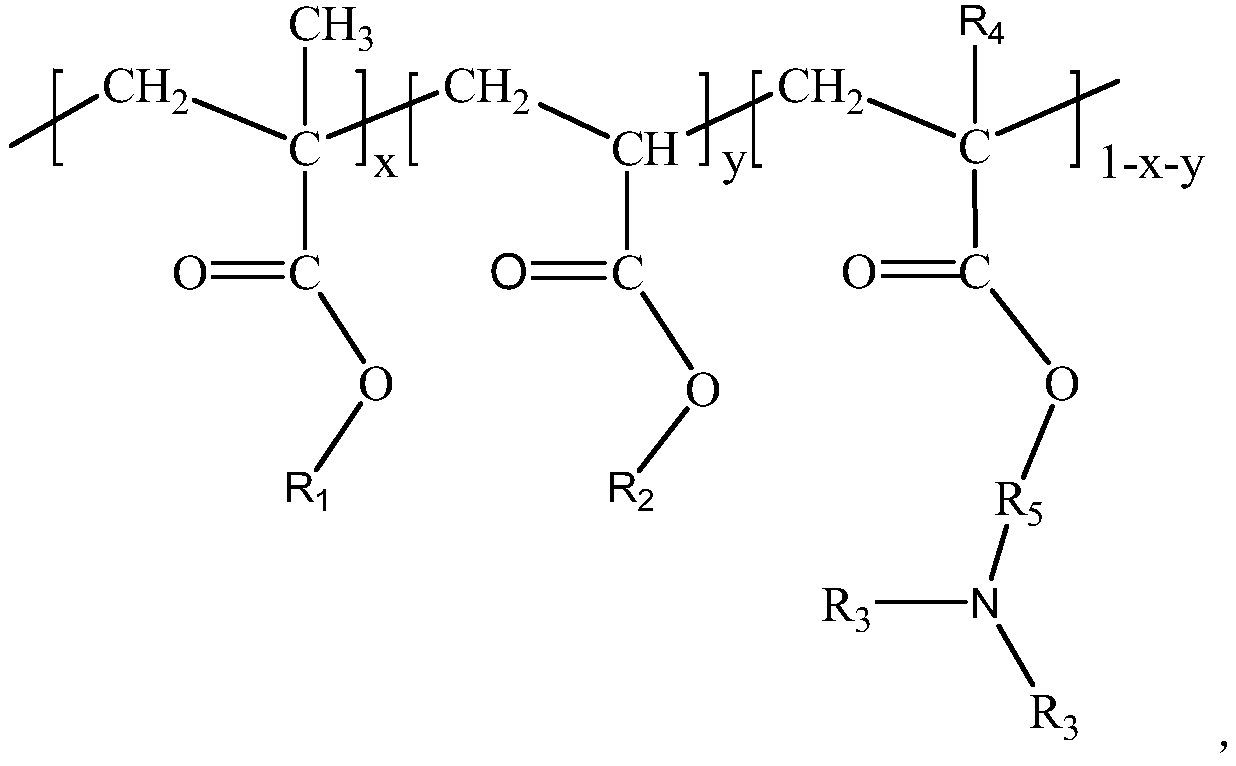

Tertiary-amine-group-containing polyacrylic acid resin modified reaction-type polyurethane hot melt glue and preparation thereof

A technology containing tertiary amine group polyacrylic acid and tertiary amine group polyacrylic acid, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problem of non-polar materials and metal substrate bonding requirements, the influence of the operation and use process of polyurethane hot-melt adhesive, the viscosity increase of reactive polyurethane hot-melt adhesive, etc., to achieve the effect of improving initial bonding strength, moderate viscosity and moderate opening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In a reactor equipped with a vacuum and nitrogen protection device, add 40 parts of polyester polyol, 40 parts of polyether polyol, and 5 parts of polyacrylic resin containing tertiary amino group according to weight. After vacuum dehydration for 2 hours, add 19.45 parts of polyisocyanate and 0.05 parts of catalyst by weight, react under nitrogen atmosphere for 2 hours, add 0.5 parts of silane coupling agent, stir evenly, and discharge under nitrogen protection.

Embodiment 2

[0035]In a reactor equipped with a vacuum and nitrogen protection device, add 40 parts of polyester polyol, 40 parts of polyether polyol and 10 parts of polyacrylic resin containing tertiary amino groups, and add them at 110-120 °C After vacuum dehydration for 1 hour, add 19.45 parts of polyisocyanate and 0.05 parts of catalyst by mass, react under nitrogen atmosphere for 3 hours, add 0.5 parts of silane coupling agent, stir evenly, and then discharge under nitrogen protection.

Embodiment 3

[0037] In a reactor equipped with a vacuum and nitrogen protection device, add 40 parts of polyester polyol, 40 parts of polyether polyol and 20 parts of polyacrylic resin containing tertiary amino groups, and add them at 110-120 °C After vacuum dehydration for 3 hours, add 19.45 parts of polyisocyanate and 0.05 parts of catalyst by mass, react under nitrogen atmosphere for 4 hours, add 0.5 parts of silane coupling agent, stir evenly, and discharge under nitrogen protection to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com