High-initial-bonding-strength light/moisture dual-curing polyurethane hot melt adhesive composition and preparation method thereof

A technology of polyurethane hot melt adhesive and initial bonding strength, which is applied in the direction of polyurea/polyurethane adhesive, adhesive type, adhesive, etc., can solve the problem of insufficient initial bonding strength, and achieve the improvement of initial bonding strength, Reduce volume shrinkage and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

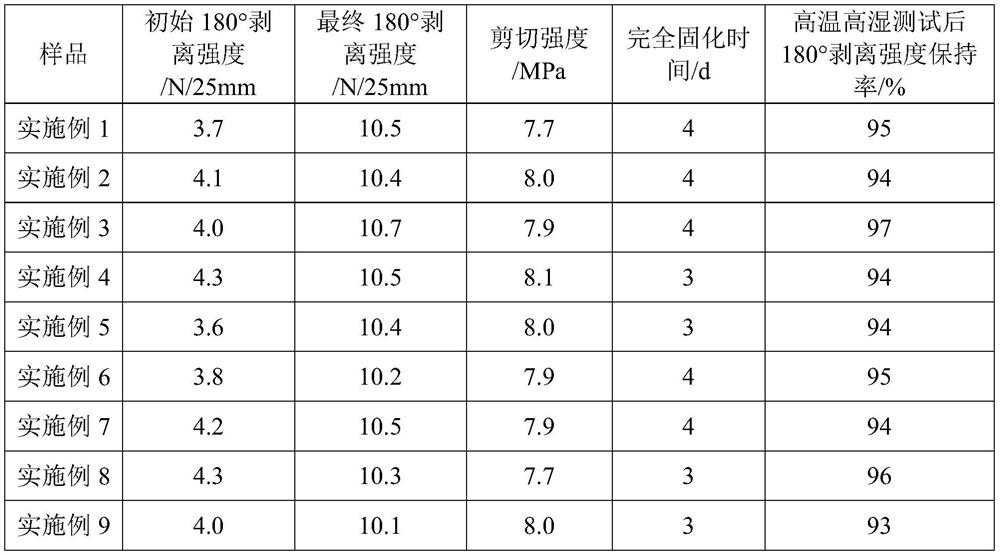

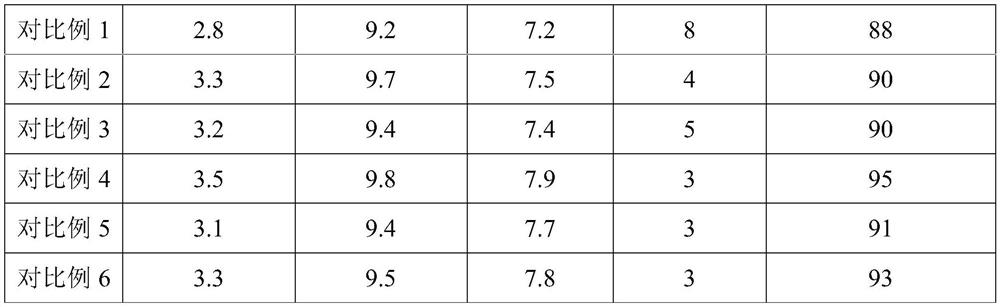

Examples

preparation example Construction

[0044] The present invention also proposes a method for preparing the polyurethane hot-melt adhesive composition according to any of the above embodiments, comprising the following steps:

[0045] S1, drying the raw material components that need to be dried; in the present invention, the raw materials that need to be dried include polymeric polyols and adamantane diols;

[0046] S2. Add the low-molecular-weight saturated diol and the adamantane diol into the container, heat up to 70-90° C., mix evenly, add the diisocyanate, stir and react for 2-5 hours, and then add the polymerization The substance-type polyol and the catalyst continue to react for 2-5 hours to obtain prepolymer A;

[0047] S3. Divide the prepolymer A obtained in step S1 into a first part of prepolymer and a second part of prepolymer, and the number of moles of isocyanate in the first part of prepolymer and the number of moles of hydroxyalkyl acrylate same;

[0048] S4, mixing the first part of the prepolyme...

Embodiment 1

[0054] By formula: 95 parts of PEO(10)-PPO(5) diol (where 10 and 5 represent the average degree of polymerization of PEO and PPO, respectively, and so on below), 4 parts of ethylene glycol, 0.5 part of 2,3-diol Hydroxypropyl acrylate, 15 parts 1,3-adamantanediol, 35 parts hexamethylene diisocyanate, 3 parts benzoin dimethyl ether, 2 parts hydroxypropyl acrylate, 0.5 parts stannous octoate and 1.5 parts KH-560 .

[0055] The PEO(10)-PPO(5) diol and adamantane diol were vacuum-dried at 60°C;

[0056] Add ethylene glycol and 1,3-adamantanediol into the container, heat up to 70-75°C, mix evenly, add hexamethylene diisocyanate, stir and react for 3 hours, then add PEO(10)-PPO(5 ) diol and stannous octoate, continued to react for 3 hours to obtain prepolymer A;

[0057] The above-mentioned prepolymer A is divided into the first part of the prepolymer and the second part of the prepolymer, and the number of moles of isocyanate in the first part of the prepolymer is identical with t...

Embodiment 2

[0062] The hydroxypropyl acrylate in Example 1 was adjusted to 1.5 parts, and the remaining steps remained unchanged to obtain a polyurethane hot-melt adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com